ADAST POPULAR LPG User manual

Adast Systems, a.s., 679 04 Adamov No. 496, Czech Republic

T+420 516 519 201, F+420 516 519 102, sales@adastsystems.cz

www.adastsystems.cz

OÚ/005/2005/A

XII/2016

USER´S MANUAL

Instructions for Operation, Maintenance

and Installation

LPG Dispenser for Dispensing of Liquiefied

Propane-butane

POPULAR LPG

MINOR LPG

V-line 899x.xxx/LPG

USER’S MANUAL V-line 899x.xxx/LPG

I

CONTENT

1. IMPORTANT NOTICE ................................................................................................... 1

2. USE 2

3. INSTRUCTIONS FOR THE SAFETY OF WORK ...................................................................... 2

3.1. Safety of the equipment design..............................................................................2

3.2. Operation safety ................................................................................................3

3.3. Ecological safety ................................................................................................3

3.4. Hygiene ...........................................................................................................3

3.5. Principles of the first aid......................................................................................3

4. DESCRIPTION ............................................................................................................ 4

4.1. Design of the dispensers.......................................................................................4

4.2. Skeleton ..........................................................................................................4

4.2.1. Case of the electronic counter ...............................................................................4

4.2.2. Case of the electronic counter –design 2017 (see fig.)..................................................4

4.3. Hydraulic system of the LPG fuel dispenser ...............................................................5

4.3.1. The hydraulic system of the fuel dispenser V-line 899x.xxx/LPG - piston volumetric flow meter

ADAST M 406.xxxx .......................................................................................................6

4.4. Electronics .......................................................................................................7

4.5. Communication to the control system ......................................................................8

4.6. Signalling of dispenser conditions (SO) .....................................................................8

4.7. Design with heating of the electronic case ................................................................8

5. TECHNICAL DATA....................................................................................................... 8

6. IDENTIFICATION ........................................................................................................ 9

6.1. Rating plate of the LPG fuel dispenser V-line 899x.xxx/LPG ..........................................9

7. FILLING OF LIQUEFIED GAS INTO MOTOR VEHICLES ...........................................................10

7.1. Dispensing with service ...................................................................................... 10

7.2. Self dispensing ................................................................................................ 11

7.3. Dispensing with preselection ............................................................................... 11

7.4. Description of the preselection function ................................................................. 12

8. FUNCTION OF KL-MANINF MANAGER KEYBOARD OR KL-SERINF ONE .....................................12

8.1. Manual setting of unit prices ............................................................................... 13

8.2. Setting of unit price values from the control system in AUTO mode ................................ 13

8.3. Displaying procedure of electronic totalizers for dispensers fitted with ADP1/T, ADP2/T,

ADP1/L electronic counter.................................................................................. 13

9. MAINTENANCE OF THE DISPENSER AND ITS INDIVIDUAL OPERATING UNITS..............................14

9.1. LPG piston flow meter ....................................................................................... 14

9.2. Differential valve ............................................................................................. 14

9.3. Separator....................................................................................................... 15

9.4. Electromagnetic two-stage valve .......................................................................... 15

9.5. Breakage coupling ............................................................................................ 15

9.6. Rupture coupling.............................................................................................. 15

9.7. LPG sight-glass ................................................................................................ 16

USER’S MANUAL V-line 899x.xxx/LPG

II

9.8. Dispensing hose ............................................................................................... 16

9.9. LPG dispensing nozzle ....................................................................................... 16

9.10. Dismantling of covers ........................................................................................ 16

9.11. Maintenance instructions for dispenser body parts..................................................... 17

9.12. Electronic counter............................................................................................ 18

10. DISASSEMBLY AND DISPOSAL ....................................................................................... 18

11. PRINCIPLES OF SERVICE INTERVENTIONS FOR LPG DISPENSER.............................................. 18

12. SUMMARY OF PRINCIPLES FOR INSPECTION OF LPG DISPENSER ............................................18

13. TRANSPORT ............................................................................................................19

14. DISPENSER INSTALLATION...........................................................................................19

14.1. Hydraulic section ............................................................................................. 19

14.2. Wiring........................................................................................................... 20

15. PUTTING OF THE DISPENSER INTO OPERATION.................................................................21

15.1. Putting of the dispenser and electronic counter into operation ..................................... 21

15.2. Shutdown of the dispenser and electronic counter..................................................... 21

15.3. Restart of the dispenser and electronic counter after power failure and voltage drop ......... 21

16. PACKING AND STORAGE .............................................................................................21

16.1. Packing ......................................................................................................... 21

1.1. Storage ......................................................................................................... 21

17. GUARANTEE AND RECLAMATION................................................................................... 21

18. SPARE PARTS CATALOGUE ..........................................................................................22

19. ACCESSORIES...........................................................................................................22

20. DOCUMENTATION DELIVERED ......................................................................................22

21. ENCLOSURES ........................................................................................................... 22

USER’S MANUAL V-line 899x.xxx/LPG

1

1. IMPORTANT NOTICE

This document is a guideline for the user how to proceed when installing, attending and maintaining the

dispenser. The information included in the present instructions are mandatory and the manufacturer does

not accept any responsibility for any damage due to their non-observance.

In the complex of the filling station, the dispenser is taken for a component of the dedicated gas

equipment subject to checks and revisions in the line of valid regulations anchored in the Filling station

operating regulation.

In the manufacturing plant, every dispenser is tested as to function, safety and metrology. User’s manual,

EC statement of a conformity and a service book with identification of the fuel dispenser components are

the parts of the dispenser delivery.

Dispensers are manufactured with high accuracy and care for the sake of their long term reliable and

safety operation. In time its operation it is necessary to keep primary safety codes, which first of all

protect the users before a possible accident and also the fuel dispenser before damage.

The dispenser has been designed for outdoor installation

Location/ Environmental class

Open/C

Machanical class

M 2 –with Beta Control ADPxxx electronic calculator

M 1 –with UNIDATAZ CDC electronic calculator

Elektromagnetická třída

E 2 - with Beta Control ADPxxx electronic calculator

E 1 –with UNIDATAZ CDC electronic calculator

Humidity

Condensing

ATTENTION!

The dispenser shall not be installed in an explosion danger zone 0, 1, 2 in compliance with

zones specified in the EN 60079-10-1!

Important instructions for installation and operation:

a) Prior to proceed to the dispenser handling, study these Operating User’s manual and other

manufacturer’s documents belonging to the dispenser accessories carefully.

b) Check the dispenser delivery for completeness and in the case of any discrepancy or damage, inform

supplier or the manufacturer without delay.

c) Ensure the proper storage of the dispenser in a dry and protected room for the pre-installing period.

d) Prior to installation, check the dispenser for the completeness of the filling station technology against

the valid project, and revise the connecting dimensions of the base frame including the outlet of the

piping system.

e) Rinse the technological equipment (piping systems) through the filtering device and continue rinsing

until the filtering device remains free of impurities.

f) With respect to operating safety it is necessary at dispenser installation situate with connection of

dispensing hose in the direction of exit from the filling station.

g) The dispenser requires the connection to the return piping of a DN 16 (1/2“) inner diameter.

h) Connect the dispenser electrical equipment and revise it.

i) Carry out the pressure test of the dispenser including its piping systems with a 2,5 MPa pressure and

revise it.

j) For putting the dispenser into operation, proceed in accordance with the point 16.

k) Carry out the test for proper function and entrust the metrological verification to a metrological

authority representative.

l) On meeting all of these requirements and after the approval by the representatives of the

metrological authority, the standard operation may start.

m) The servicing interventions should be entrusted to the properly trained personnel of the service firm

only.

SAVE FOR FUTHER USING!

USER’S MANUAL V-line 899x.xxx/LPG

2

2. USE

The liquid fuel dispensers of the V-line 899x.xxx/LPG series with an electronic counter ADP1/L, ADP1/T,

ADP2/T L of volume and price, alternatively mechanical counter of volume (for non-public dispensing)

described in the present manual have been designed for the dispensing of liquefied propane-butane (LPG).

The dispensing is made only by operating staff of the filling station (service mode).

They have been designed for the installation at road filling stations and a fleet of vehicles, etc. By means

of a communication line the dispensers are prepared for connecting to the control system and it is

possible operate this dispensers of self-service operation or serviced operation.

A gas leakage detector connected to the monitoring unit in the filling station booth can be installed in the

LPG dispenser for safe and ecological operation of the filling station.

This User´s manual serves the user to gain information on the design, correct attendance, maintenance

and safe installation.

3. INSTRUCTIONS FOR THE SAFETY OF WORK

The dispenser shows a clear indication to stop the engine and a maximum 80 % filling. The vehicle must be

ensured against a spontaneous move.

3.1. Safety of the equipment design

The manufacturer guarantees safety of the equipment design.

The dispenser design complies with the EN 14678-1 requirements and it is homologated for the

operation in environment specified by II2G IIAT3 symbols shown on the dispenser plate.

Considering operation safety in environs with explosion danger the dispensers have been EC –type

examination (certification) according to the annex III of the Directive 2014/34/EU –ATEX by an

authorised body FTZÚ, Pikartská 7, 716 07 Ostrava –Radvanice –Notified body no. 1026.

EC - Type Examination Certificate: No. FTZÚ 05 ATEX 0222

Regular inspection of production quality assurance according to supplement no. 4 to SO no. 23/2003

executes FTZÚ, s.p., Ostrava –Radvanice, NO no. 1026.

Notification of quality assurance: No. FTZÚ 02 ATEX Q 020.

Considering legal metrology the dispensers have been EC –type examination (certification) according

to the annex B of the Directive 2004/22/EC –MID by an authorised body Český metrologický institut,

Okružní 31, 638 00 Brno – Notified body no. 1383.

EC - Type Examination Certificate: No. TCM 141/07 - 4506

The producer performed a conformity examination for the fuel dispenser with the type described in

EC –Type Examination Certificate No. TCM 141/07 –4506 and technical requirements according to the

Directive of European Parliament and the Council 2004/22/EU.

The producer is competent for “The Declaration of Conformity” with the type based on production

quality assurance of measuring units according to the Directive Supplement D of European Parliament

and the Council 2004/22/EC.

Certificate of the Quality Management System for production, check-out and testing:

No. 0119-SJ-C007-07.

Regular inspection of production quality assurance, check-out and testing according to the Directive

Supplement D of European Parliament and the Council 2004/22/EC executes authorised body Český

metrologický institut, Okružní 31, 638 00 Brno – Notified body no. 1383.

ATTENTION!

Any handling open flame is prohibited during LPG filling and smoking is prohibited even in

vehicles interior. Also filling vehicle tanks with running motor and any other activities

possibly initiating explosion are prohibited!

USER’S MANUAL V-line 899x.xxx/LPG

3

3.2. Operation safety

Responsible for the filling station operation is the keeper who is bound to charge with the station

operation the properly trained and authorised personnel only with corresponding qualification. Duty of the

operators consists in filling the vehicle LPG pressure tanks in qualified way while respecting all safety

regulations, and in checking - in regular intervals - the dispenser and tank for proper conditions, the

mechanical equipment for proper run, gas pressure for proper level, and in keeping the prescribed

operational records.

Operator’s obligation:

–Keep the operated equipment in safety and proper conditions.

–Follow the filling station operating regulations and gas equipment operating instructions.

–Without delay report any defect, failure or irregularity arisen in the course of the gas equipment

operation to the keeper and, in case of a danger in delay, put the equipment out of operation

immediately.

–Keep the gas equipment clean and in order permanently and take care with avoiding the presence of

strangers close to the equipment.

–Without delay report the circumstances that make him more difficult the equipment operation

(sudden indisposition, for instance)

–Record the data on the beginning and the end of the work shift and the results of revisions made by

the operators and the extent of maintenance, repairs, checks and revisions performed.

–The dispenser and storage tank operators are not supposed to make any repairs of mechanical section,

and to alter the setting of any safety fittings.

3.3. Ecological safety

The dispenser space, where is the pumping mechanism, may be provided with gas leakage detectors (they

do not belong to the dispenser standard outfit) connected to the evaluating unit. In case some leak has

been detected (low concentration), the respective unit signals the leakage automatically and –in the case

of any danger - (higher concentration) puts the whole system out of operation immediately.

In the case of a small leak of gas, the filling station operators check the whole system and if they do not

detect any failure, ventilate the gas leaked (small leakage when connecting and disconnecting the

dispensing hose, effect of exhaust gases) and put the system into the operation again. In the case of a

higher concentration of leaked gas, the evaluating unit puts the electrical system out of operation. The

filling station operators shall put the station out of operation and report the defect to a specialised firm

that takes care of the repair.

3.4. Hygiene

From the point of view of hygiene, the dispensers are unobjectionable for the operators and the keeper.

For carrying out the routine maintenance and dispensing the liquefied propane-butane (LPG), it suits to

protect the hands with gloves.

3.5. Principles of the first aid

In the course of pumping avoid breathing in the propane-butane vapour because of the danger of

asphyxiation

Take the injured individual off the dangerous room to the fresh air. Take care with your own safety.

Be also aware of the danger of fire and explosion. Lay the injured individual comfortably, release his

cloths and leave it in absolute rest (he is not supposed to speak or walk). Call a doctor or take the

injured individual to a hospital. In the case of his dyspnoea or lack of breathing give him oxygen, or

apply artificial respiration.

In case the propane-butane contaminates the eyes, pour a bit of water on them, open the eye-lids

with care and rinse the eyes with plenty of running water (for about 15 min) and then look for

a medical care –injury of the cornea is imminent.

In case the skin gets in contact with the propane-butane, rinse the skin with plenty of water, take

off the cloths and shoes that have been contaminated with propane-butane (taking care with the risk

of fire and explosion) and rinse the attacked skin with running water (for about 15 min).

Do not chafe the chilblained skin, instead cover it with a sterile bandage!

In the case of a burn, it suits the cold the injury with cold water from water supply system

immediately (for about 15 min). Do not grease the injury with anything and visit a doctor. In case of

USER’S MANUAL V-line 899x.xxx/LPG

4

emergency apply sterile bandage exclusively or, in the case of large burns, wrap up the injured

individual into a clean bed sheet –do not take off the cloths! In case the cloths start burning, do not

run (because the flames would be fomented), extinguish with water, stifle the flames with a blanket –

jacket, by rolling on the ground. In case of being in the middle of fire, lie down immediately,

because the flame and gas getting the face, may origin lethal burning of breathing organs.

4. DESCRIPTION

4.1. Design of the dispensers

The dispensers ADAST POPULAR LPG is produced in two model lines:

V-line 899х.ххх/LPG - with a measuring unit ADAST LPG - piston positive displacement flow meter ADAST

M 406.xxхх

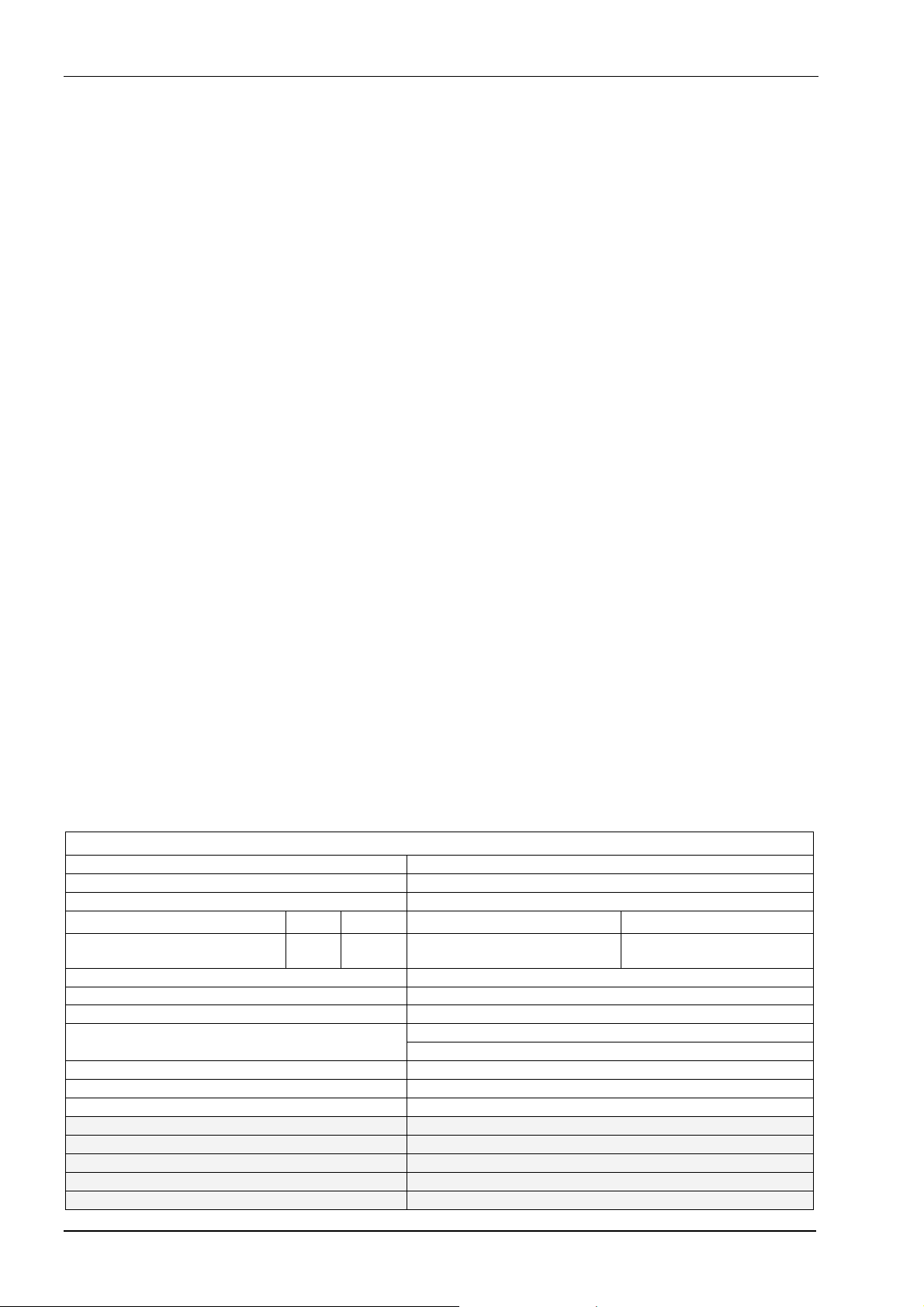

Type V - line

Number of hydraulics

Number of dispensing

places

Marking

8991.xxx/LPG

1

1

„MONO―

8992.xxx/LPG

2

4

„QUATTRO―

8993.xxx/LPG

1

2

„DUO―

8994.xxx/LPG

2

2

„DUPLEX―

8995.xxx/LPG

1

2

„DUO―

4.2. Skeleton

Skeleton –a self-supporting structure consisting of parts with high anticorrosive resistance. The base of

the dispenser is made of steel sheet, zinc-coated and varnished. Internal parts of the skeleton are made of

galvanised sheet. Parts of the body with the exception of the door of the hydraulic module and the

electronic counter case are made of stainless brushed sheet as a standard.

High resistance acrylurethane enamel is applied on the hydraulic module door and the electronic counter

case. The colour shade of the door including the logo can be optional.

Both doors are lockable; being unlocked, swing out and with earth wire disconnected they can be removed

and thus the hydraulic part is accessible. Connect the earth wires when the door is fitted back. A junction

box is built-in into the supporting column and is accessible after dismounting the side cover of the column.

4.2.1. Case of the electronic counter

A case of the electronic counter or ADAMAT electronics is bolted to the column. The counter case space is

closed with lockable covers. The covers are provided with transparent glass. Indicators with integrated

large-area display of dispensed volume, total price, price for one unit and unresetable electromechanical

total counters (totalizers) are connected from the case interior to the covers. The set of these elements

represents all necessary information for the customer.

The covers of the case are hung up on hinges enabling tilting upwards after unlocking and thereby easy

access in the case interior. The user’s local

preselection keyboard (if required) is located on the

case cover as well - an independent keyboard for

each dispensing point.

4.2.2. Case of the electronic counter –design

2017 (see fig.)

A case (1) of the electronic counter or ADAMAT

electronics is bolted to the hose module column.

The counter case space is closed with lockable

covers (2). The covers are provided with transparent

glass.

On the inside cover of the case is mounted under

glass large-area display (3) issued volume and total

price, which displays all necessary information for

the customer.

USER’S MANUAL V-line 899x.xxx/LPG

5

Above the display is placed IR sensor (5) for controlling and adjusting the dispenser calculator manager or

servicing keyboard.

On the outer side of the case cover is placed (optional) keyboard local user preferences (4) - an

independent keyboard for each dispensing point.

On request they can be built in a case unresetable electromechanical total counters –totalizers (6), which

are accessed by opening the cover.

ATTENTION!

Before opening the covers, it is always necessary to disconnect power to the dispenser and

perform a reliable hedge against its re-connection.

The dispensing nozzles are seated in covers in the „V― form pressed shape of the column. When the

dispenser is out of operation the dispensing nozzles in covers can be locked.

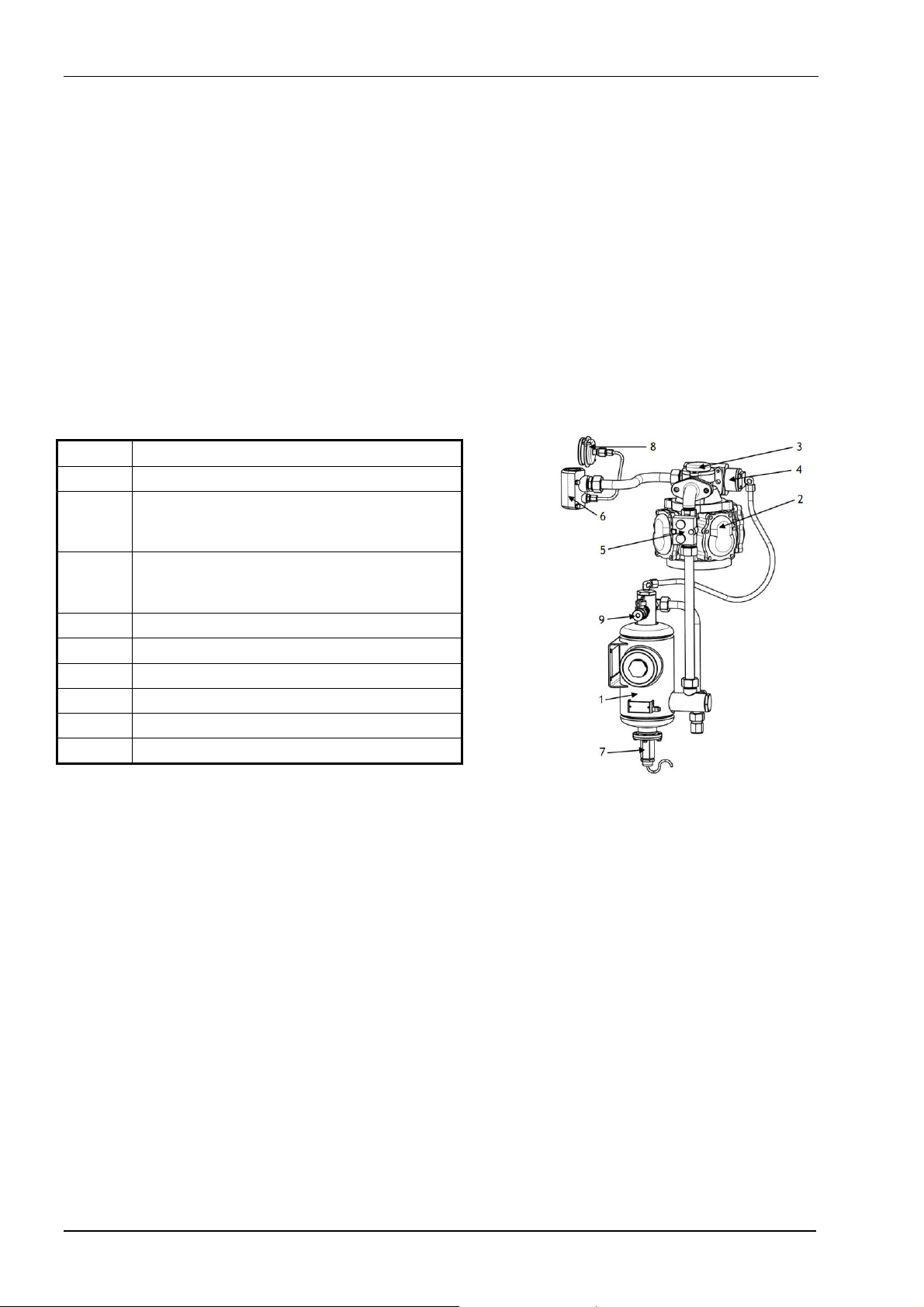

4.3. Hydraulic system of the LPG fuel dispenser

Poition

Hydraulics components LPG

1

Ball valve –supply pipe

2

Filter

3

Return valve liquid phase

4

Pressure release valve of the gas phase

5

Safety valve of gaseous phase

6

Hole in the safety valve

Supply piping

Return piping

Separator

USER’S MANUAL V-line 899x.xxx/LPG

6

7

LPG measurement unit

8

Differential valve

9

Electromagnetic valve

10

Manometer

11

Sight glass (optional)

12

Coupling safety (breaking or rupture coupling)

13

LPG Dispensing Hose

14

LPG dispensing nozzle

15

Ball valve metrological branch

16

Metrological branch

17

Electronic counter LPG

4.3.1. The hydraulic system of the fuel dispenser V-line 899x.xxx/LPG - piston volumetric

flow meter ADAST M 406.xxxx

Position

Hydraulics components LPG dispenser

1

Separator ADAST N 821.20/1, 821.20/1/ATC

2

LPG piston meter and an integrated

magnetic pulse transmitter M 406.xxP, M

406.xxP/1, M 406.xxЕP, M 406.xxЕP/1

3

Magnetic pulse transmitter ELTOMATIC

ME 01-05 or ME 01-05-05 or METRA MTX 075

or ADAST40

4

Differential valve ADAST V 860.20/LPG

5

Electromagnetic valve

6

Sight glass LPG –ADAST (optionally)

7

Snímač teploty LPG Pt 100 - ZPA

8

Manometer 0/25 bar

9

Ball valve G 1/2― metrological branch

In normal operation LPG is always in the liquid phase in the hydraulic system of the LPG dispenser.

A spherical cock (in the LPG piping) and a separator with a filter which forms one assembly unit with a

check valve of the liquid phase and pressure release valve and safety valve of gaseous phase are located

at the bottom of the fuel dispenser. A medium temperature resistance transmitter is connected to the

separator from the bottom for the dispensers designed with automatic temperature compensation of

dispensed volume in relation to its momentary temperature (ATC).

A metrological branch with a spherical cock G 1/2" for metrological verification and service purposes is

a part of the separator return piping.

A piston meter fitted with a sensor of impulses transmitted to the counter is connected to the separator

output through a pipe connection. The meter is fitted with pressure control valve keeping the medium in

the meter in liquid phase. The output from a differential valve is connected through an electromagnetic

valve to a sight-glass to which the dispensing hose with the dispensing nozzle is connected.

The dispensing hose is connected through safety breaking or rupture coupling.

The LPG being dispensed is supplied by a pump built-in in the storage tank area. At first the LPG flows

through the spherical cock and the filter into the separator. In case the liquid contains gaseous

components they should be separated and returned through the nozzle in the separator upper part and the

return piping which has to be open (if the dispenser is in operation) to the section of the storage tank that

contains the gaseous phase. The return piping internal diameter should be DN 16 mm (1/2") at least.

The gaseous phase space of the differential valve is connected to the return piping.

If required, the LPG dispenser can be fitted with a two-stage electromagnetic valve closing the LPG flow

during dispensing by means of preselection.

USER’S MANUAL V-line 899x.xxx/LPG

7

Meters LPG are supplied with optional integrated magnetic pulse transmitter Eltomatic ME 01-05

or ME 01-05-05 - type designation M 406.25P, M 403.32EP or with a magnetic pulse transmitter

METRA MTX 075 or ADAST 40 - type designation M 406.25P/1, M 406.25EP/1.

Meters with the designation of EP in electronic calibration, indicating P mechanical calibration

In the hydraulic system of the LPG dispenser during normal operation occurs always LPG in the liquid

phase.

4.4. Electronics

The dispenser control shall meet the exacting requirements of simplicity and convenience and depends on

the button pressing, alternativelly on the switch closure of LPG pump motor.

ADP1/T, ADP2/T, ADP1/L electronic counter of an up-to-date design with central processor board

equipped with a high efficient microprocessor. The configuration of the counter and its modes of

operation are adjusted by more than seventy parameters. The counter is provided with a self-diagnostic

system. The counter outlets control the motors, valves and signalling circuits. The electronic counter

processes the impulses coming from the impulse sensor and transmits them to the display, which displays

the dispensed volume, its price and a price per a volume unit. In case of power failure or voltage drop the

data displayed remain for 30 minutes at least.

Counters ADP1/T, ADP2/T, ADP1/L are standardly equipped for electronic meter calibration

(Electronic Calibration of Meters –EC) and per request by ATC –(Automatic Temperature

Compensation)

Electronic Calibration of Meters (EC) enable to correct measured volume by designed declination in

operation range -5,00 % to +5,00 % of recognised meter non accurancy by step of 0,05 %.

Automatic Temperature Compensation (ATC) is designed to compensate temperature expandity of

dispensed medium based on measured temperature during dispensing. For temperature measuring is used

approved certified temperature sensor –resistance temperature sensor PT 100, in the fuel dispensers V-

line 899x.xxx/LPG build in the separator N 821.20/ATC.

Calibration tablets for ATC on designed medium (type of fuel) can be integrated into SW of electronic

counter by customer request. Setting of calibration EC or ATC is provided by using of service keyboard KL-

SERINF and setting of proper calibrating switches DIP on body of electronics counter as per instructions

described in manual of electronic counters ADP1/T, ADP2/T, ADP1/L.

Providing of calibration is allowed to authorised person, only. The DIP calibration switches must be

fixed by plomb after calibration finish.

Displays: LCD type with BACK LIGHT illumination

LCD displays with BACK LIGHT (BLD) illumination are used especially for their good readability. The

duration of data holding on the display after supply voltage failure is 30 minutes at least. Decimal point on

BLD display devices is represented automatically in accordance with the setting of parameters.

Lighting

LED diodes are used for the illumination of displays at dispensers.

ON / OFF switching of the illumination is automatically carried out with the activation of electronics.

Totalizer: non-resettable electronic counter of dispensed volume and its price –11 digits –or non-

resettable electromechanical counter of dispensed volume –7 digits.

Electronic counter of ADP1/T, ADP2/T, ADP1/L series operates with a 2-channel impulse generator

producing 2x 100 impulses per 1 dm3. The HW and SW counters of the ADP1/T, ADP2/T, ADP1/L series

enable high metering accuracy and the application of the electronic calibration using the 2-channel

impulse generator.

The local electronic preselection system in IP67 design is integrated into the counter case. The

preselection enables the Customer’s preselection of the exact volume or the price of the product to be

dispensed. The two-stage electromagnetic valves ensure the closing of flow and exact dispensing of the

preselected volume / price and smooth initiation of dispensing.

The fuel dispensers can be equipped with ADAMAT paymant terminal (filling automatic equipment). This

equipment enables dispensing and payment of the product by means of contactless, magnetic and chip

cards including receipt printing. This equipment undertakes simultaneously all functions of the dispenser

electronic counter for non-public and public dispensing. The electronics of the filling automatic

USER’S MANUAL V-line 899x.xxx/LPG

8

equipment can be complemented by the ADP1/T, ADP2/T, ADP1/L electronic counter for public

dispensing.

The fuel dispenser is connected through a communication line to the control system, which controls the

operation of the whole filling station (releasing of dispensers, volume preselection, unit price variation,

self-diagnosis, etc.). The dispensers can be operated even at the filling stations without any control

system –i.e. in serviced operation.

Circuit diagrams for the connection of individual dispenser types to the switchboard of the filling station

are in enclosures.

4.5. Communication to the control system

The dispensers are equipped with ADP1/T, ADP2/T, ADP1/L electronic counters, which are able to

communicate to POS Win control systems. A communication serial interface RS 485 or a communication

standard IFSF LON are used for the communication of electronic counters to the superior control system.

Communication to different control systems shall be consulted with the manufacturer of the dispensers in

advance.

The fuel dispensers connected to the control system can be operated in the mode of volume preselection

or the financial sum preselection from the control system (the dispensers have to be equipped with two-

stage or proportional electromagnetic valves).

The POSWIN control system (POS Win EURO) enables the process control and the sale of goods according

to stock cards (999 999 items in 99 groups) including storage facilities. The control systems communicate

with the dispenser on the principle of the bus interface RS 485. They combine the basic functions of the

filling station, i.e. sale of fuels, sale of dry goods and their filing. The POS system is also able to operate

even as a multi-cash one, i.e. its individual parts can be interconnected in the communication SW

network, two backoffices and three tills, if more than five backoffices or tills are connected, a server has

to be included.

4.6. Signalling of dispenser conditions (SO)

On Client’s special requirement the fuel dispenser can be equipped with a red signal light, which gives

information to the customer and the operator about the present dispenser condition –the dispenser is

blocked or ready for fuel filling.

4.7. Design with heating of the electronic case

On the special customer´s requirement the fuel dispenser can be delivered with heating of electronic case

by heater 250 VA. For feeding of the heating is used an individual cable - see the enclosure no.14.

5. TECHNICAL DATA

5.1. Basic parameters

Dispensed liquid

Liquefied propane butane (LPG)

Electronic counter

ADP1/T, ADP2/T, ADP1/L

Display

illuminated LCD - BACK LIGHT DISPLAY (BLD)

Power supply of electronics

Unap

Pnap

1/N/PE AC 230 V ± 15 %, 50 Hz

input 85 VA

Power supply of electronic case

heating

Unap

Pnap

1/N/PE AC 230 V ± 15 %, 50 Hz

input 250 VA

Volume displayed

6 digits with the setting of digit position

Price displayed

6 digits with the setting of digit position

Unit price displayed

4 digits with the setting of digit position

Total volume counter

electromechanical - 7 digits

electronically - 11 digits

Number of impulses per 1 dm3

100

Basic sensed unit

0,01 dm3

Permissible deviation of sensed volume

+/-1 impulse, i.e. 0,01 dm3

Max. flow rate Qmax

40 dm3.min-1

Min. flow rate Qmin

8 dm3.min-1

Min. measured quantity (MMQ)

5 dm3

Accuracy of measurement

±0,5 %

Max. operating pressure pmax

1,8 MPa

USER’S MANUAL V-line 899x.xxx/LPG

9

Min. operating pressure pmin

0,7 MPa

Ambient operating temperature

standard -20 °C to +50 °C;

special -40 °C to +55 °C / -40 °C to +60 °C

Liquid temperature

-20 °C to + 50 °C

Filtering property

10 µm

Reach of dispensing hose

4 to 7 m

Max. level of noise

<60 dB

Required inner diameter of feeding piping

DN 19 –inner thread G 3/4― ISO 228 – G ¾―

Required inner diameter of return piping

DN 16 –inner thread G 1/2― ISO 228 – G ½―

Communication interface

RS 485; IFSF –LON, TCP/IP (Ethernet)

Average operating period of a repair

too = 25 min

Average service life

tz= 5 years

5.2. Technical parameters of the fuel dispenser LPG MONO

V-line 8991.6x2/LPG; M

V-line 8991.6x3/LPG; M

V-line 8991.614/LPG

Max. flow rate Qmax

40 dm3.min-1

Min. flow rate Qmin

8 dm3.min-1

Operating flow rate by dispensing from one nozzle Q

40 dm3.min-1

Min. measured quantity (MMQ)

5 dm3

5.3. Technical parameters of the fuel dispenser LPG DUO and QUATTRO

V-line 8992.6x2/LPG; M

V-line 8993.6x2/LPG; M

V-line 8995.6x2/LPG; M

Max. flow rate Qmax

40 dm3.min-1

Min. flow rate Qmin

8 dm3.min-1

Max. flow rate Q dispensed from one nozzle

40 dm3.min-1

Operating flow rate by dispensing from both nozzles - DUO Q

2 x 30 dm3.min-1

Operating flow rate by dispensing from four nozzles - QATTRO Q

4 x 30 dm3.min-1

Min. measured quantity (MMQ)

5 dm3

5.4. Technical parameters of the fuel dispenser LPG

DUPLEX

V-line 8994.6x2/LPG

Max. flow rate Qmax

40 dm3.min-1

Min. flow rate Qmin

8 dm3.min-1

Operating flow rate by dispensing from both nozzles Q

2 x 40 dm3.min-1

Min. measured quantity (MMQ)

5 dm3

6. IDENTIFICATION

6.1. Rating plate of the LPG fuel dispenser V-line 899x.xxx/LPG

1.

Measuring device manufacturer and address

Adast Systems, a.s., CZ –679 04 Adamov 496

2.

Name of measuring device

LPG dispenser

3.

CE marking with the number of the Notified body

coopreated in the conformity Assessment and

supplementary metrology marking M(xx –year of

verification of the dispenser)

4.

Type

See enclosure 22 and 23

5.

Number of EC –type examination certificate - M

TCM 141/07 –4506

6.

Accuracy class

1,0

7.

Serial number and year of manufacture

xxxx/xx - according to dispensers

manufacturer files

8.

Ambient temperature range –TAmb [°C]

Ambient operating temperature –according to

version of the fuel dispenser

USER’S MANUAL V-line 899x.xxx/LPG

10

9.

Liquid temperature range –TLiq [°C]

–20 to +50 [°C]

10.

Mechanical class

M 2

11.

Electromagnetic class

E 2

12.

Liquid

LPG

13.

Maximum flowrate

Qmax [L/min]

14.

Minimum flowrate

Qmin [L/min]

15.

Minimum measured quantity

MMQ [L]

16.

Maximum pressure

pmax [bar]

17.

Minimum pressure

pmin [bar]

18.

Number of EC –type examination certificate - Ex

FTZÚ 06 ATEX 0222

19.

CE marking with the number of the Notified body

coopreated in the conformity assessment

20.

Specific marking for the explosion protection

including the symbol of the group and category of

the device, explosion and temperature categories

of dispensed fuels

II2G IIAT3

21.

Standard for fuel dispensers

EN 14678-1

22.

Electrical parameters

Values of electronics, heating and el. motors

feeding

7. FILLING OF LIQUEFIED GAS INTO MOTOR VEHICLES

The construction of dispenser meets the high requirements of simplicity and comfort commissioning by

pressing a button or turning on the switch of the pump motor.

Controlling of the dispenser V-line 899x.xxx/LPG

1

STOP switch

2

Switch

3

Control Button –„SAFETY KEY DEAD MAN―

7.1. Dispensing with service

1. The operator controls the movement of vehicles within the liquefied gas filling area so that the

dispensing hose reaches the fuel tank filler of the vehicle.

1

2

3

USER’S MANUAL V-line 899x.xxx/LPG

11

2. Then he checks the connection to the filler of the storage tank which is led to the vehicle surface,

the type of the vehicle fuel tank filler and decides either for direct connection of the dispensing

nozzle to the filler of for the use of an adapter for different types of vehicle fillers. The operator

checks visually the condition and the wear of the filler which could result in gas leakage from the

vehicle. He performs smell test to identify prospective gas leakage from the vehicle. In case he

identifies any serious deficiencies, he has to refuse to fill the vehicle and recommends the

customer to visit an authorised service shop which can remedy the defects detected.

3. After connecting the dispensing nozzle to the vehicle filler the operator shall check the

connection and then pressing the button (3) or switch (2) on the dispenser to "ON" position resets

the counter automatically. After resetting the pump motor is started. The filling can be stopped

at any time by releasing the button (3) or switching to "OFF" position.

4. After filling and releasing the push-button or switch to "OFF" position, the dispensing nozzle is

disconnected from the vehicle tank and hung up.

ATTENTION!

In case of gas leakage or any danger the operator stops the filling!

IMPORTANT WARNING:

In case the tank is filled to be full (most frequent case) the automatic safety level

regulation controlling the filling of the tank to 80 % max. shuts off the supply by means of

a mechanical limiter without respect to manual push-button control.

7.2. Self dispensing

ATTENTION!

Dispenser for self-service must be within the meaning of Article. no. 4.5.8 EN 14678-1

provided with a means ensuring an that the filling process can start and maintain only

PRESS OF BUTTON A DEAD MAN! By releasing this button must flow LPG immediately

conclude!

1. Attach the dispensing nozzle to the filling end of the vehicle tank and check the connection.

2. After connecting the dispensing nozzle to the vehicle filler the operator shall check the

connection and then pressing the button (3) resets the counter automatically. After resetting the

pump motor is started. The filling can be stopped at any time by releasing the button (3).

3. After filling and releasing the push-button, the dispensing nozzle is disconnected from the vehicle

tank and hung up.

ATTENTION!

In the event of a gas leak or danger immediately stop pumping!

IMPORTANT WARNING:

In case the tank is filled to be full (most frequent case) the automatic safety level

regulation controlling the filling of the tank to 80 % max. shuts off the supply by means of

a mechanical limiter without respect to manual push-button control.

7.3. Dispensing with preselection

Such filling is only possible with dispensers equipped with

local preselection.

USER’S MANUAL V-line 899x.xxx/LPG

12

7.4. Description of the preselection function

The selection of the required value of fuel to be dispensed is carried out with the switch for pump

motor start in the position OFF (0)!

1. Connect the dispensing nozzle to the fuelling ending of the vehicle tank.

2.a) Preselect the required quantity to be dispensed according to the price by keys identified 5 and 10

in arbitrary sequence up to the amount of money level. The preselected quantity to be dispensed is

displayed on the price display. In case of invalid option deselect it by the "RESET"key.

2.b) Preselect the required quantity to be dispensed according the volume by keys identified 5 litres and

10 litres in arbitrary sequence up to the required volume level. The preselected volume to be

dispensed is displayed on the volume display. In case of invalid option deselect it by the "RESET"

key.

3. The display is reset by pressing down or switching the control switch to the position ON (I), the

dispenser is started and filling can be carried out up to the preselected price or volume when

dispensing is automatically stopped.

4. After stopping the LPG filling by means of the push-button, release or switching over the switch

to "OFF" (0) position, disconnect the dispensing nozzle from the vehicle filler and hang it up into

the cover.

ATTENTION!

In the event of a gas leak or danger immediately stop pumping!

IMPORTANT WARNING:

When filling the tank to 80% capacity cut off the mechanical limiter, and regardless of the

manual control button or switch.

In case the tank is filled to be full (most frequent case) the automatic safety level

regulation controlling the filling of the tank to 80 % max. shuts off the supply by means of

a mechanical limiter without respect to manual push-button control.

Non-dispensed preselected volume is reset after 20 seconds approximately.

8. FUNCTION OF KL-MANINF MANAGER KEYBOARD

OR KL-SERINF ONE

The KL-MANINF manager keyboard and the KL-SERINF service keyboard are delivered as a design with

infrared wireless transmission IR.

IR KL-MANINF manager keyboard

The keyboard enables the setting of unit prices and the situation display of electronic totalizers.

The manager keyboard is equipped with four keys marked „0―, „+― and „-― (the „R― is not used). The

„0― key is used for the transition to the "setting of unit prices for MAN" and for the termination of any

function executed on the manager keyboard.

The „+― and „-― keys are used for proper setting of the unit price values or for the transition to the mode

of "situation display of electronic totalizers".

IR KL-SERINF service keyboard

The keyboard enables the counter setting and the keying of values for electronic calibration of meters and

ATC, the situation display of electronic totalizers, setting of unit prices and setting the vapour exhaust

recovery.

The service keyboard is fitted with four keys, „0―, „+―„-― as a standard and the "S" key as an extra key.

The "S" key is used for the transition to the mode of "the data setting / calibration".

If the "S" key is not used, the service keyboard can be used for all functions controlled by the manager

keyboard and the keying is identical with that of the manager keyboard.

N. B.

If the nozzle has been lifted at least once since the last activation of the counter, the transition to the

setting of unit prices is not executed in the MAN mode. The transition to the setting is also not executed

USER’S MANUAL V-line 899x.xxx/LPG

13

even in case the nozzle has been either hung up again without fuel dispensing or previous transaction has

not been deactivated by means of RLS entry.

8.1. Manual setting of unit prices

Necessary conditions for the transition to the setting of unit prices

–MAN mode of operation

–the nozzle has not been lifted since the last activation of the counter

–transaction executed shall be acknowledged (deactivation by means of RLS entries).

In the MAN mode the unit prices of fuel product are set by means of the KL-MANINF manager keyboard or

the KL-SERINF service keyboard.

1. The user can enter the setting mode of unit prices by depressing the „0― key.

2. In the setting mode of unit prices

- the number of side for which the unit price is being set ("1" ... A side, "2" ... B side) is displayed

on the first line of displays (i.e. on the line of total price)

- the number of nozzle for which the unit price is being set is displayed on the second line of

displays (i.e. the line of total volume)

- on the third line of displays the digit, the value of which is being set by the user, is flashing (e.g.

on the line of unit price)

3. The user

- raises the numerical value of the digit actually set by the "+" key(i.e. the flashing one), (digit 9

passes into 0), by depressing the "+" key we can list through 0-9 values - i.e. the autorepeat

function

- shifts the digit setting to higher digit positions by means of the "-" key

- shifts the setting from the highest position of the product unit price to the lowest digit position

of the product unit price of the next nozzle by means of the "-" key

4. In this way the user can set successively the price values for all nozzles on the A side, then B side (if

it exists and the products on this side differ in price).

5. Whenever the user can terminate the setting of the unit price values by depressing the „0― key.

6. Now the unit price values have been written in non-volatile storage in this way and the counter sets

the MAN mode.

8.2. Setting of unit price values from the control system in AUTO mode

In AUTO mode the unit price values are set from the control system for all transactions independently on

unit price values set for the MAN mode.

The unit price values for the AUTO mode are set for all dispensing points by dynamic statement

(command) "permission to dispense" transmitted from the filling station console or by the "price setting"

statement. All these statements are a part of the specification of the EASYCALL communication protocol.

8.3. Displaying procedure of electronic totalizers for dispensers fitted with

ADP1/T, ADP2/T, ADP1/L electronic counter

The ADP1/T, ADP2/T, ADP1/L counter is fitted with non-resettle electronic totalizers of volume and price

for individual dispensing nozzles.

The totalizers can be displayed on the displays of the side by means of the KL-MANINF manager keyboard.

The display of the totalizer can be switched by lifting the relevant nozzle or by switching the LPG switch.

The sum of the volume (or the sum of the price) is displayed on the displays of the side on the coupled

lines of the total price and total volume. Both displays of the side display an identical sum, as the first

from the left "U" character is displayed on the total price line for the display of the volume sum and

"A" character for the display of the price sum.

The second character from the left displays the highest digit position of the relevant sum, the sixth

character from the left displays the lowest digit position of the relevant sum.

The side number and the nozzle number of the totalizer displayed at this moment are displayed on the

unit price line:

e.g..: 1 - 1...A side - nozzle No. 1;

2 - 1...B side - nozzle No. 1.

Display procedure:

USER’S MANUAL V-line 899x.xxx/LPG

14

1. Both dispensing points shall be free (transitions are not running at any of the both points and

terminated transactions shall be acknowledged).

2. Depress the "+" key to display the volume sum. Depress the "-" key to display the price sum.

3. All segments light up and light out on the displays of the sides after depressing the "+" key (or the "-"

key) (similarly with the transaction starting to checking if all segments display correctly) and total

number of feeding voltage drop-outs is shortly displaced.

4. Then "U" and the volume sum of the relevant nozzle (or "A" and the price sum of the relevant nozzle)

are displayed on the displays of sides.

5. It is possible to carry out the transition to the volume totalizer displays of the next dispensing nozzles

by repeated depressing the "+" key or by lifting the relevant nozzle (as well as the transition to the

price totalizer displays of the next dispensing nozzles by repeated depressing the "-" key or by lifting

the relevant nozzle).

6. Terminate the scanning of electronic totalizers by depressing the "0" key and in case the thermal and

electronic calibration are activated, transition in the display mode of their setting occurs.

7. The setting of thermal calibration for relevant nozzle is activated by the ATC text. The setting of

electronic calibration of the relevant nozzle counter is activated by the EC text.

8. Terminate the scanning by depressing the "0" key and return to the standard mode.

9. MAINTENANCE OF THE DISPENSER AND ITS INDIVIDUAL

OPERATING UNITS

The user of the dispenser is obliged to operate the device safely, reliably and in economic way. First of all

he is obliged to:

–appoint a worker responsible for the operation and technical conditions of the dispenser and its

individual components

–ensure inspection, testing, repairs and maintenance by qualified methods

–carry out records and file documents

ATTENTION!

All repairs of operating units can only be carried out by a service repair shop and their

serviceman with relevant authorisation.

Repairs, changes and dismantlings of undermentioned dispenser units depends of the

perfect propane butane displacement with nitrogen from all space of dispenser hydraulic

system.

Since even after the education of nitrogen from the dispenser its residues with minimum

pressure stay in the hydraulic system, it is necessary to come on very carefully at the

service interventions.

Marking of space endangered with pressure expansion of residual nitrogen - see the

enclosure no. 8.

9.1. LPG piston flow meter

The LPG meter unit consists of proper meter and integrated impulse detector. It is adjusted by the

producer. Only authorised specialist can handle the metering unit because the meter is officially sealed. If

the seals are damaged, it is necessary to carry out an official inspection and new official sealing.

A trained worker should follow the meter continuously to carry out necessary repairs immediately in case

of any defect. Constant accuracy of the adjusted meter is one million dm3at least for measured liquid

without mechanical impurities. It is recommended to check the accuracy of the meter after dispensing

such liquid gas quantity. The meter should be periodically inspected (calibrated) by a metrological office

according to relevant legal regulations - once per year at least.

The impulse sensor is not being repaired - the meter should only be replaced. New official authorisation

(sealing) must be carried out after its replacement.

9.2. Differential valve

The valve is designed to keep the substance in liquid condition in the meter. It also damps pressure

shocks. Only uncompressible liquefied substance of pressure higher (appxm. by 0,1 MPa) than the

This manual suits for next models

1

Table of contents

Other ADAST Dispenser manuals