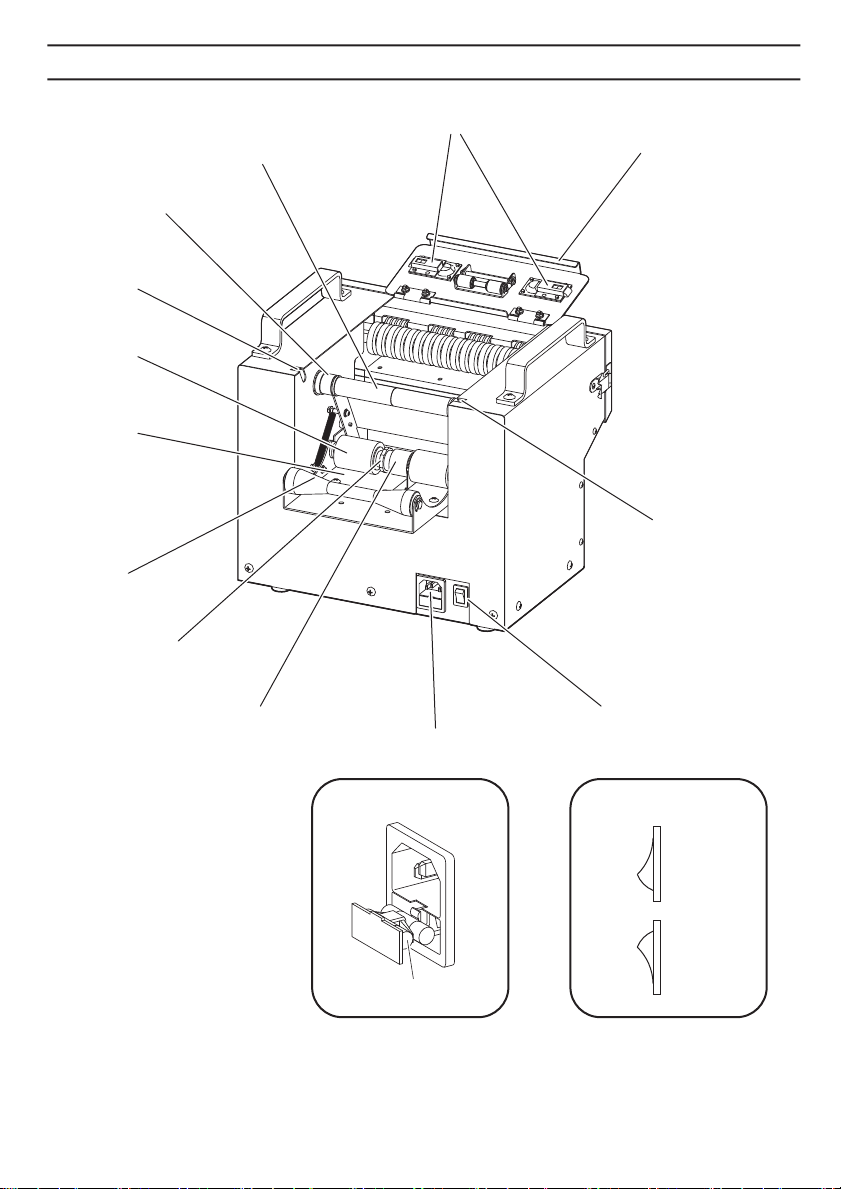

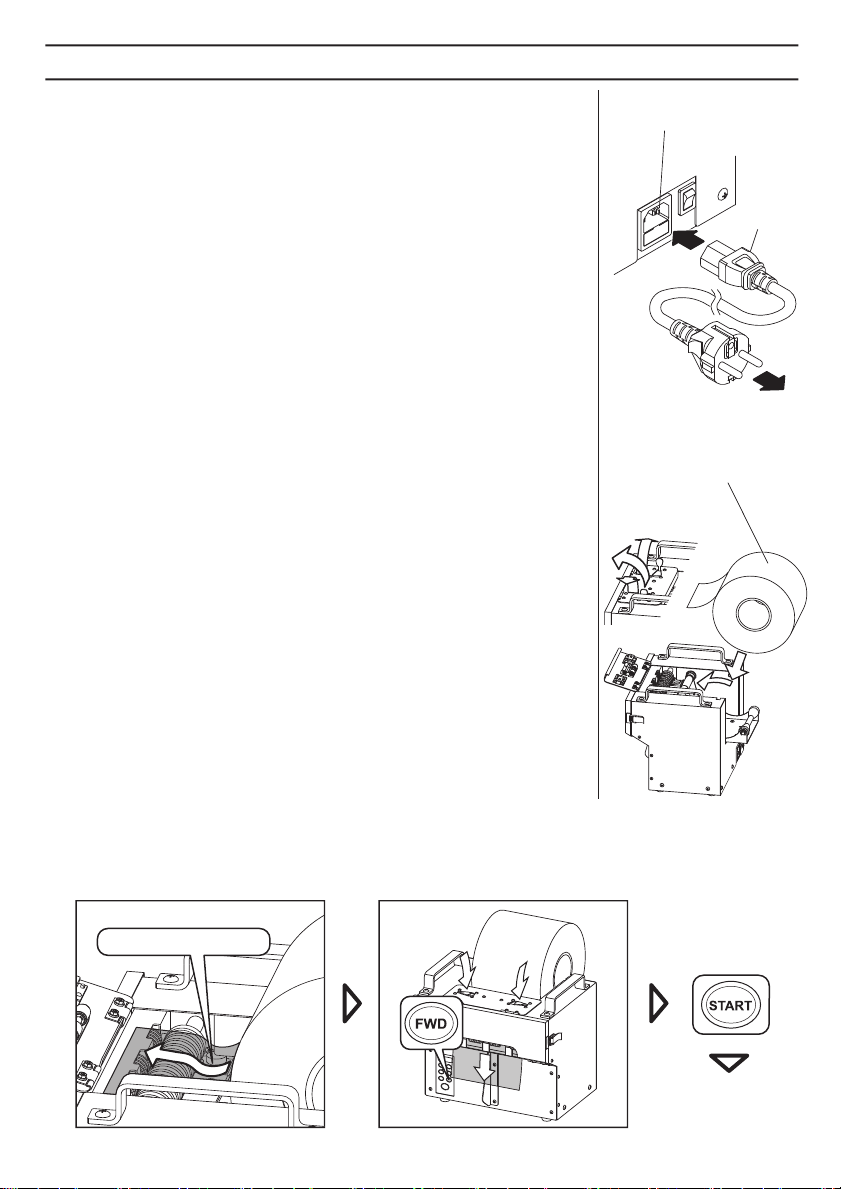

OUTLET

AC CORD INLET

AC CORD

Set a film on

FILM HOLDER

Open the

SAFETY COVER

8

Load the Film

■The SOCKET-OUTLET shall be installed near the equipment and shall be

easily accessible.

■Set the machine only in the upright position.

■Plug in AC CORD to the AC CORD INLET.

■Make sure the POWER SWITCH is off then plug into an appropriate

grounded AC outlet.

■Turn the POWER SWITCH on.

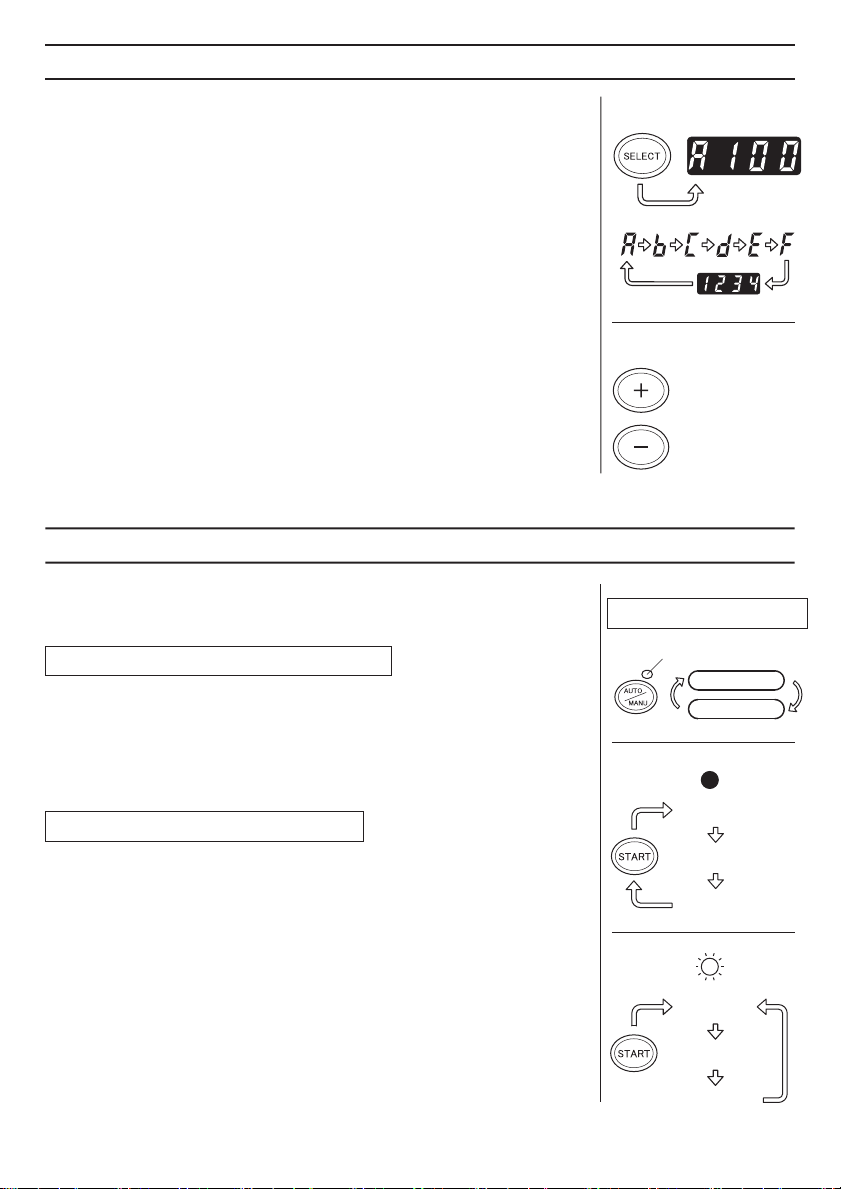

・When the POWER SWITCH is turned on, a letter, A, b, C, d, E, F and 3 or

4 digits will be displayed on CONTROL PANEL.

(Previous use cutting length will be displayed)

・When the POWER SWITCH is turned on, mode setting is set to previous use.

■Set a film on FILM HOLDER.

・Set film at center of FILM HOLDER, following to the drawing in right.

(As regards FD-200Ⅲand FD-300, set film roll into BOBBIN and place at the

BOBBIN SHAFT SOCKET. Refer to P-13.)

■Pull up SAFETY COVER HOOK and open the SAFETY COVER.

■Peel the film and put it on FILM GUIDE.

・To set the film properly, keep it a little loose as the drawing shows below.

■Close SAFETY COVER gently, and lock SAFETY COVER HOOK.

■Press the FWD BUTTON to feed out the film.

・Press the FWD BUTTON until the film comes out from the FILM OUTLET.

・If film comes out inclining, press the FWD BUTTON until film comes out

straight.

・FWD BUTTON Operates only while pressing the button.

■Make sure that the film is set properly.

■Press the START BUTTON.

・By pressing the START BUTTON after loading film by FWD BUTTON, the

cutting blade starts operation to cut the film.

・Remove first piece of film.

■When you pull out film, please follow the instruction below.

・Lift the SAFETY COVER HOOK and open the SAFETY COVER.

・Press REV BUTTON, and draw out the film from FEEDING ROLLER.

・After front edge of the film comes out between FEEDING ROLLER and

SUPPORTING ROLLER, stop pressing REV BUTTON.

Load the film

Keep the film a little loose

Confirm the setting

Cut the film

Remove the film