SILADENT DA 2000 User manual

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

Dispenser unit

DA 2000

for 1:1 duplicating silicones

Working instruction

Date of information: 09/2013

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

Dear customer,

Thank you, for choosing that you bought a dispenser unit from SILADENT Dr.

Böhme & Schöps GmbH. With the DA 2000 we offer you the newest technique

and highest quality. For making sure that you are long term satisfied and can

receive the best results please read the following notes before connecting and

putting the unit into service. The operating service and the function of the unit

can only be guaranteed for, if the general safety and accident prevention

instructions of the legislation as well as the safety instructions of the working

instruction are observed.

The DA 2000 is designed for the use of SILADENT duplicating silicones. If you do

not use duplicating silicones from SILADENT we do not overtake a guarantee.

Duplicating silicones may vary in the viscosity and abrasion of both components.

There are many duplicating silicones which are not suitable for using with the DA

2000.

Description of the unit:

The DA 2000 1:1 is an automatic mixing and dosing unit for thin flowing addition

curing 1:1 duplication silicones. The condition for a homogenous mixing is that

both components have the same viscosity.

Advantages:

A new mixing head with separated outlets –a mixing of the A and B

component when fixing or removing the mixing tips is not possible.

When pressing a button the components are dosed and mixed 1:1

absolutely homogenous mixture without bubbles.

Mixture is effected by force through disposable cannulas mixing tips with

bayonet lock. The canisters can be put directly onto the implement by

means of fast locks.

Material and time saving filling of several flasks with one mixing tip

The quick-coupling allows the use of the 1 kg bottles, the 6 kg and 25 kg

canister (for the 25 kg canister you need a separate metal stand).

Caution:

This unit must only be used according to the present working instructions. We

cannot be held liable for damages which have been caused by improper

treatment respectively faulty manners of operation.

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

1. The indicated voltage on the type plate has to meet the voltage of the

power source.

2. Connect the unit only to a socket with protective conductor. Never touch

the plug with wet hands.

3. The unit has to be placed onto a stable and even surface.

4. Do not intrude any objects into the unit.

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

5. Only those appliances and spare parts may be used which are released by

the manufacturer. We are not responsible for damages caused by the use

of outside parts.

6. Do not lock the operation button of the unit.

7. The unit has to be examined before operation in view of proper condition

and general safety. If the unit is not in proper condition, it must not be

used and has to be marked accordingly.

8. Before cleaning and maintenance of the unit or the changing of parts the

plug has to be disconnected.

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

9. Plates and labels have to be maintained in a well legible condition and

must not be removed.

10.The opening of the unit and repairs are only to be carried out by

accordingly trained experts.

PUTTING INTO SERVICE

Ensure that the indicated voltage on the type plate meets the voltage of the

power source. Plug the power cable into the socket of the unit and create a

connection with the euro-plug.

OPERATION

PREPARATION OF THE SILICONE CONTAINERS

1 kg bottles, 6 kg or 25 kg canisters can be connected with the DA 2000.

BOTTLES: Open the bottles with the components A and B and apply bottle

adapter.

ATTENTION:

Coloured bottle / canister adapter onto the bottle filled with coloured

silicone mass –component B.

CANISTER: Unscrew the caps of the canister and fit colour-marked connect-ion

hoses.

ATTENTION: Keep the two silicone components always separated –do

not interchange connections! In case the two components have been

mixed the silicone cures in the unit which makes considerable repairs in

our plant necessary.

FILLING OF THE UNIT:

The SILADENT DISPENSER UNIT 1:1 is delivered ex-works with testing liquid in

the system. When putting the unit into service this liquid is produced by touching

the button until the duplication mass reaches the hoses. Remove the lock caps

from the coupling plugs (no. 19). Press the quick-coupling / bottle adapter of the

silicone containers onto the coupling plugs of the unit and let them snap

hearable.

ATTENTION! The components A and B have to be connected according to the

printing on the unit and the applied colour marking. Cut an opening of approx.

0.5 cm2into the bottoms of the canister in order to let air come in when

producing. Remove protection cap from mixing head (no. 4) and do not reuse.

Turn on the unit at the operation button. Put a reception bowl under the mixing

head and press push-button pressed until the test silicone has been produced

completely and both components come out homogeneously at the mixing head.

Fix mixing tip at the missing head (no. 4) by means of turning it to the right by

90°.

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

The DA 2000 is now ready to operate. Put duplication flask under the opening of

the mixing tip and press push-button (no.2). As long as the material is not cured

in the mixing tip (depending to the product) several flasks can be filled in

succession.

After having finished the filling process do not remove the mixing tip. Do only

remove the mixing tip before the next duplication by means of a 90° turn to the

right.

ATTENTION: Never produce against a mixing tip with cured material!

CHANGE OF BOTTLES/CANISTERS:

Remove the quick-coupling / bottle adapter from the unit by means of tearing

upwards the lock-up. Screw quick-coupling / bottle adapter onto the new bottles

/ canisters and connect as described above. Observe the correct coordination of

the components according to the colour.

Observe the contents of the containers at any time! They must not be emptied

completely, as otherwise air gets into the system and the unit has to be bleeded

under great effort. A minimal filling of 2 –3 cm has to remain in the containers.

CARE AND MAINTENANCE

Disconnect the unit from mains supply before care and maintenance! Cleaning is

effected with a mild cleaning liquid.

Wipe always silicone remainders from the unit. Keep coupling plug and mixing

head clean. The cleaning liquid must not get into the unit.

GENERAL NOTES

Repairs on the DA 2000 may only be executed by experts. Disconnect the unit

from mains supply at any rate. SILADENT Dr. Böhme & Schöps GmbH is only

responsible for the safety, reliability and performance of the unit, if

- the unit is exclusively used for the corresponding field of application.

- operation is only carried out by accordingly trained personnel.

- the unit is operated in accordance with these working instructions.

- extensions, new adjustments, changes or repairs are executed by persons

authorised by the company.

As we are currently developing our products, we reserve the right for technical

changes.

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

TROUBLE SHOOTING LIST

PROBLEM

CAUSE

AID

Unit does not

produce.

Mixing head is

clogged.

Clean the mixing head carefully by means of

the enclosed cleaning spirals.

ATTENTION: Use a different spiral for each

drilling, as otherwise the two components

would mix and cure.

Unit does not

produce.

Cured material

in old mixing tip.

Assemble new mixing tip.

Unit does not

produce.

The components

A and B have

been inter-

changed, the

silicone has

cured in the

system of the

unit.

The unit has to be dismounted completely

and cleaned by an expert.

Unit does not

produce.

The filling of the

silicone

containers has

fallen below the

minimum filling,

the system has

sucked air.

Unscrew mixing head flange (no. 27) with a 4

mm hexagon spanner, take out mixing head

(no. 3) to the front. Loosen the union nuts

(no. 8a), spanner of 10 mm, from the hoses

and tear off hoses. Refill silicone material and

wait for approx. 20 minutes until the silicone

has flown into the pipe. Put reception bowl

under the opening of the hoses, switch unit

on and press button until both components

have come out of the hoses free of air

bubbles. Reassemble unit in reversed

succession.

Unit does not

produce.

The filling of the

silicone

containers has

fallen below the

minimum filling,

the system has

sucked air.

Unscrew mixing head flange (no. 27) with a 4

mm hexagon spanner, take out mixing head

(no. 3) to the front. Loosen the union nuts

(no. 8a), spanner of 10 mm, from the hoses

and tear off hoses. Refill silicone material and

wait for approx. 20 minutes until the silicone

has flown into the pipe. Put reception bowl

under the opening of the hoses, switch unit

on and press button until both components

have come out of the hoses free of air

bubbles. Reassemble unit in reversed

succession.

Unit does not

produce.

The filling of the

silicone

containers has

Unscrew mixing head flange (no. 27) with a 4

mm hexagon spanner, take out mixing head

(no. 3) to the front. Loosen the union nuts

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26 Tel.: +49 (0) 53 21 / 37 79 - 0 info@sbs-dental.de

DE-38644 Goslar Fax: +49 (0) 53 21 / 38 96 32 www.sbs-dental.de

fallen below the

minimum filling,

the system has

sucked air.

(no. 8a), spanner of 10 mm, from the hoses

and tear off hoses. Refill silicone material and

wait for approx. 20 minutes until the silicone

has flown into the pipe. Put reception bowl

under the opening of the hoses, switch unit

on and press button until both components

have come out of the hoses free of air

bubbles. Reassemble unit in reversed

succession.

Unit does not

produce, lamp

of the

operation

button does

not light up.

Miniature fuse is

defect.

Examine miniature fuse and exchange, if

necessary.

Unit does not

produce in a

mixing ratio

of 1:1.

The silicone

components do

not have the

same viscosity.

Use only material recommended by the

manufacturer (a deviation of about 5 % can

be tolerated).

Unit does not

produce in a

mixing ratio

of 1:1.

The tooth wheels

in the pump are

worn unequally.

The unit has to be overhauled by an expert.

Technical Data:

Description: Dispenser unit 1:1, „DA 2000“ – REF 111503

Dimensions: High: 310 mm, Width: 290 mm, Deep: 450 mm

Weight: 12.5 kg

Voltage: 240 V / 60 Hz (other voltages are possible)

Power consumption: 250 W

Paint colour: white / red

Accessories:

- Mixing tips pink, 100 pieces REF 111505

- Fast lock set with cover for 6 kg canister (A/B) REF 101513

- Metal stand for 25 kg canister REF 518601

Address of supplier:

SILADENT Dr. Böhme & Schöps GmbH

Im Klei 26

D-38644 Goslar

Tel.: +49(0)5321-3779-0

Fax: +49(0)5321-389632

info@sbs-dental.de

www.sbs-dental.de

Date of information: 09/2013

Table of contents

Popular Dispenser manuals by other brands

Taylor

Taylor R160 manual

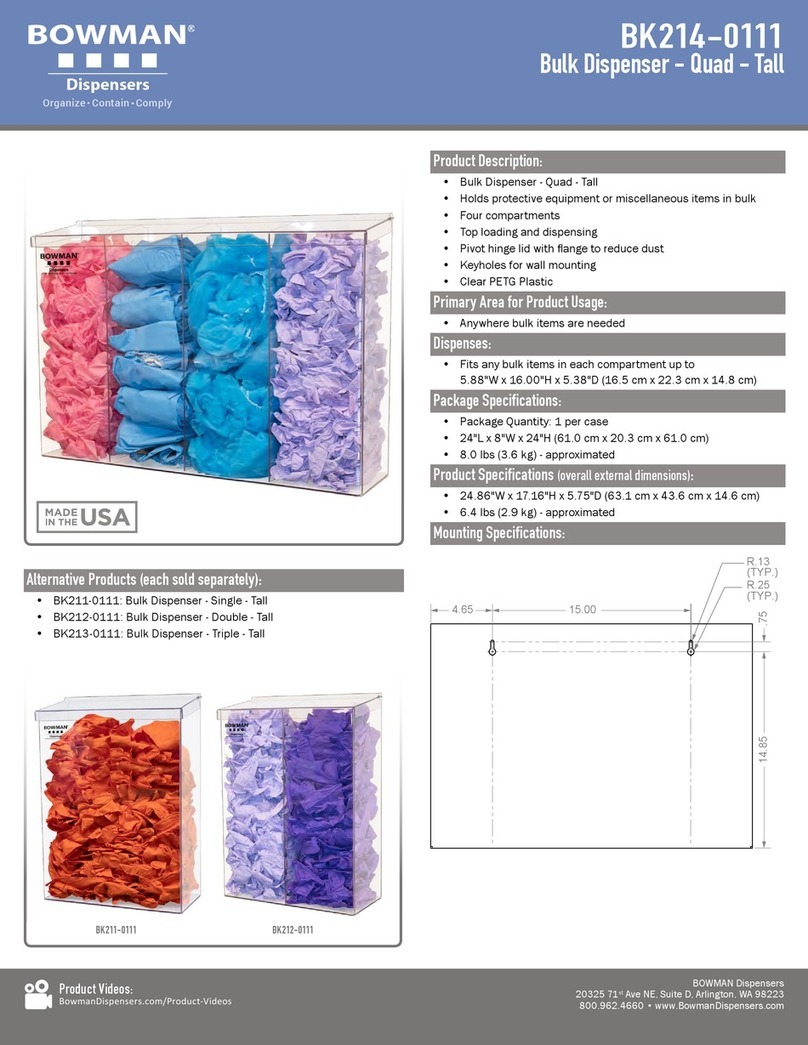

BOWMAN

BOWMAN BK214-0111 quick start guide

Emerson

Emerson STEAMIN' HOT H-SH10-SS owner's manual

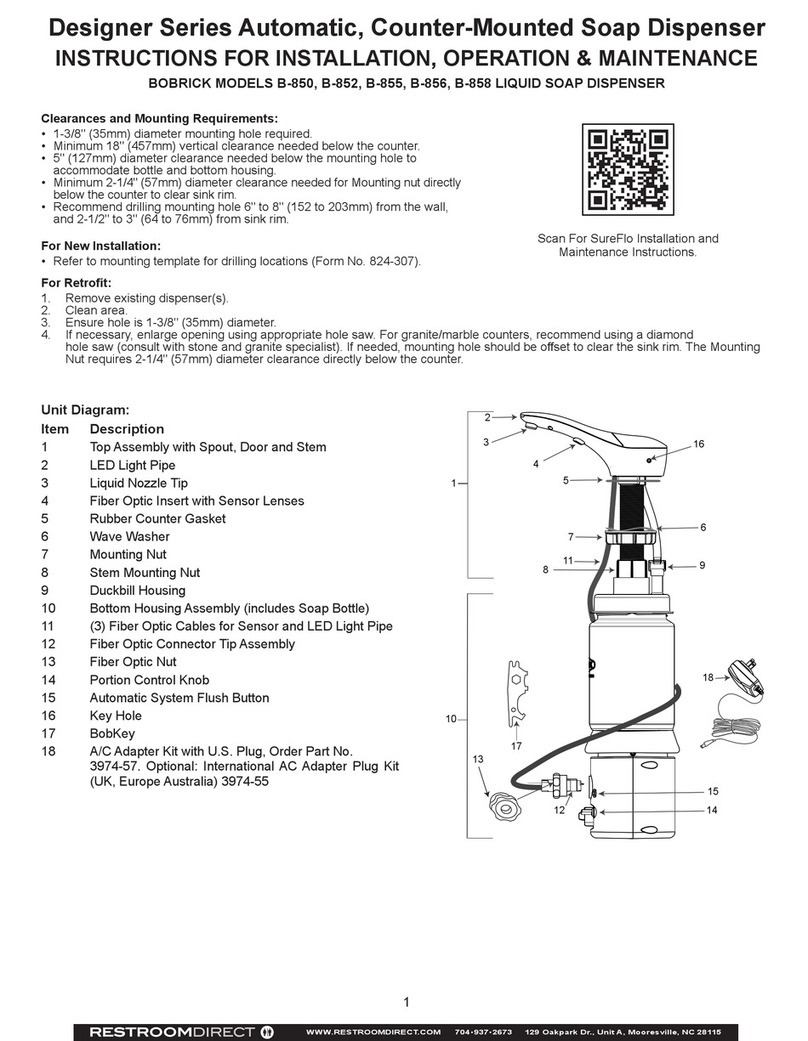

Restroomdirect

Restroomdirect Bobrick SureFlo B-850 Instructions for installation, operation, maintenance

Georgia Pacific

Georgia Pacific ActiveAire 56764 reference guide

Bobrick

Bobrick Classic Series installation instructions

BOWMAN

BOWMAN BD111-0012 manual

DS Produkte

DS Produkte 06115 instructions

Bobrick

Bobrick B-3942 Instructions for Replacing

lancer

lancer TD 1700 series Installation and service manual

Kimberly-Clark PROFESSIONAL

Kimberly-Clark PROFESSIONAL ICON user guide

Instanta

Instanta InstaTap Installation and user instructions