Adixen ASM 310 User manual

Operating instructions

Operating instructions

Translated from original version

Translated from original version

Portable leak detector

EN

EN

ASM 310

GB 03328 - Edition 02 - September 12

1/2

Dear customer,

You have just bought an adixen detector.

We would like to thank you and we are proud to count you among

our customers.

This product is a result of the experience acquired since many years

in vacuum and leak detection technology.

The applications of helium leak testing are extremely diversified

ranging from high-tech installation maintenance to high-speed testing

of industrial products.

Each product of the adixen detector range is designed to meet the

specific needs of each application:

• portability,

• high sensitivity,

• pumping capacity,

• pumping type.

adixen Vacuum Products - ASM 310 Operating instructions

2/2

GB 03328 - Edition 02 - September 12

This product complies with the requirements of European Directives,

listed in the Declaration of Conformity contained in G100 of this

manual. These Directives are amended by Directive 93/68/E.E.C

(E.C. Marking).

Copyright/Intellectual property:

The use of adixen products are subject to copyright and intellectual

property rights in force in any jurisdiction.

All rights reserved, including copying this document in whole or

any part without prior written authorization from adixen Vacuum

Products.

Specifications and information are subject to change without notice

by from adixen Vacuum Products.

adixen Vacuum Products - ASM 310 Operating instructions

GB 03311 - Edition 04 - February 13

1/2

General contents

ASM 310 - Operating instructions

manuel reference: 114916 - GB

edition: 04 - February 2013

Softwares versions:

L0232 ≥ v3.3 r00

L0322 ≥ v3.3 r00

L0264 ≥ v3.2 r00

L0224 ≥ v2.0 r00

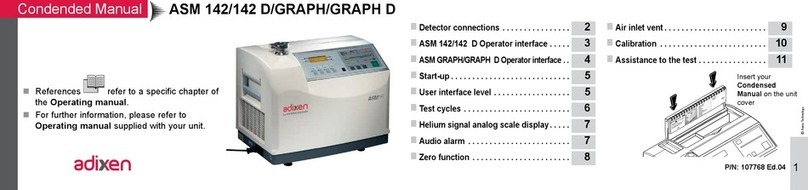

Preliminary remarks Throughout this operating manual, you could find this type of

message “"Setting" menus arborescence C 600”: it refers

to a specific chapter of the operating manual. Please read it for

further information.

Chapter A INTRODUCTION

A 100 - Introduction

A 200 - About leak detection

A 400 - Accessories

A 500 - Technical characteristics

A 600 - Dimensions

Chapter B INSTALLATION

B 100 - Safety instructions

B 110 - Unpacking - Storage - Transport

B 112 - Product labelling

B 200 - Neutral gas purge and inlet vent connection

B 300 - Controlling the detector)

B 301 - RS 232

B 302 - 15 pin Interface

B 400 - Start-up

Chapter C OPERATION

C 100 - Getting started with the leak detector

C 110 - Perform a test

C 200 - Control panel

C 300 - Graphic display

C 400 - Settings

C 401 - Set points Menu

C 402 - Test Menu

C 403 - Spectro Menu

C 404 - Maintenance Menu

C 405 - Configuration Menu

C 406 - Advanced Menu

C 500 - Factory configuration of the leak detector parameters

C 600 - "Setting" menus arborescence

C 700 - Remote control (accessory)

C 900 - Long distance sniffer probe and Helium spray gun (accessories)

Chapter D MAINTENANCE - TROUBLESHOOTING

D 100 - Indicator lights and default display

D 200 - General troubleshooting guide

D 200/D 300 - General troubleshooting guide/Symptoms description

D 300 - Symptoms description

adixen Vacuum Products - ASM 310 Operating instructions

2/2

General contents

ASM 310 - Operating instructions

GB 03311 - Edition 04 - February 13

manuel reference: 114916 - GB

edition: 04 - February 2013

Softwares versions:

L0232 ≥ v3.3 r00

L0322 ≥ v3.3 r00

L0264 ≥ v3.2 r00

L0224 ≥ v2.0 r00

Chapter E MAINTENANCE SHEETS

E 100 - Maintenance operation instructions

E 110 - Access to internal components

E 120 - Table of preventive maintenance intervals

E 141 - Leak detector tightness checking

E 142 - Leak detector depollution

E 231 - P0411 Supervisor board

E 262 - P0482 Bluetooth board

E 410 - Autocalibration of the leak detector

E 411 - Calibration of a leak detector connected to a pumping group

E 412 - Calibrated leaks

E 413 - Replacement of the internal calibrated leak

E 430 - Analyzer cell maintenance

E 530 - Valves installation and maintenance

E 550 - Replacement of a fan

E 555 - Replacement of the purge filter

E 600 - Remote control

E 610 - Long distance sniffer probe and Helium spray gun (accessories)

E 710 - Roughing pump maintenance (MD1)

Chapter F COMPONENTS

F 000 - Spares parts - Instructions of use

F 001 - Service

F 100 - Tools

F 200 - Monitoring and display

F 300 - Power and electrical supply

F 400 - Automatic control system and electronic circuits

F 500 - Measurement

F 600 - Pumping

F 700 - Valves

F 800 - Pipes - Connections - Seals

F 900 - Cover

F 1000 - Options and accessories

F 1100 - Pictures of components

Chapter G APPENDIX

G 100 - Declaration of conformity

G 200 - Wiring diagram

G 400 - Long distance sniffer probe user manual

G 500 - Helium spray gun user manual

G 600 - Service

G 700 - Units

G 800 - Tools

adixen Vacuum Products - ASM 310 Operating instructions

GB 03304 - Edition 02 - September 12

1/1

Introduction

ASM 310 Operating instructions

Detailed contents

A

Preliminary remarks Throughout this operating manual, you could find this type of

message “"Setting" menus arborescence C 600”: it refers

to a specific chapter of the operating manual. Please read it for

further information.

A 100 Introduction

A 200 About leak detection

- Overview

- Vacuum circuit of a leak detector

- Test method

- Analyzer cell operating principle

- About helium and hydrogen

A 400 Accessories

- Accessories Common to all leak detectors

- Specific accessories to one or several leak detectors

A 500 Technical characteristics

A 600 Dimensions

adixen Vacuum Products - ASM 310 Operating instructions

GB 03322 - Edition 03 - February 13

1/1

A 100

Introduction

Congratulations, you have just acquired a unique dry helium leak

detector truly portable: the ASM 310.

The ASM 310 is the lightest unit of its category (less than 48 lbs)

that offers the following features:

1 cfm (1.7 m3/h) dry and clean roughing capacity,

1.1 l/s helium pumping speed at the inlet of the unit,

New analyzer cell design that delivers 3 years of full operation

without any maintenance required,

Operator interface display 100 % customized to meet all

customers needs,

Data acquisition downloadable to a SD memory card for easy

storage and convenience (graphs as well as text),

Import capabilities such as pictures (bmp format).

Ideally suited for any leak testing applications where portability is a

Must, this unit will deliver more than you would expect. This is more

than a helium leak detector, it is now yours to discover and enjoy.

adixen Vacuum Products - ASM 310 Operating instructions

GB 03302 - Edition 03 - July 12

1/11

A 200

About leak detection

Overview Leak detection is used to detect micro-openings, porosities, permeation

through materials etc. The means of detection is a tracer gas: Helium.

This gas is so light that it can penetrate microscopic cracks very fast.

The analyzer cell measures helium partial pressure created by helium

molecules that come from the leaking parts. These molecules are

pumped in by the vacuum pumps of the helium leak detector and end

up inside the analyzer cell. This partial helium pressure is converted

into a flow rate. The analyzer cell is tuned to detect three gas species,

hydrogen (M2), helium isotope (M3) and helium (M4). For more

information on the operating principle, please go to the end of this

chapter.

The ASM 310 helium leak detector has a wide measuring range

capability. It can detect a leak as large as 10-2 mbar l/s down to a

leak as small as 3x10-11 mbar l/s.

A leak of 10-2 mbar l/s is equivalent to a bubble of 1 cc escaping a

part every 100 seconds.

A leak of 3x10-11 mbar l/s corresponds to a bubble of 1 cc escaping

a part every 1,050 years.

As for reference, please see below for more leak rate correlations.

For the same size crack, a part will leak out helium at different rates

based on the internal helium pressure. The greater the internal helium

pressure, the higher the leak rate.

Leak testing large leaks versus leak testing tiny leaks will require

different settings, for more information, please go to chapter C.

Leak

Rate

3x10-11

mbar l/s

1x10-10

mbar l/s

1x10-09

mbar l/s

1x10-08

mbar l/s

1x10-07

mbar l/s

1x10-06

mbar l/s

1x10-5

mbar l/s

1x10-04

mbar l/s

1x10-03

mbar l/s

1 cc

Bubble

over time

frame

1,050

years 317

years 31.7

years 3.17

years 116

days 11.6

days 1.2

day 2.7

hours 17

minutes

adixen Vacuum Products - ASM 310 Operating instructions

2/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

The general vacuum diagram of the leak detector is shown below.

A dynamic version of the vacuum diagram is available on the leak

detector display panel. Green valves indicate opened valves. Red

valves indicate closed valves.

Vacuum circuit of a

leak detector

Test Procedure:

nConnect the part to be tested at the inlet of the leak detector 1,

then press the [START/Stand by] key.

When the unit is not in test mode (stand-by or roughing mode), the

helium displayed corresponds to the internal helium background of the

unit.

nRoughing Mode: Valve 3opens and the primary pump evacuates

the inlet of the unit as well as the part connected to it.

nWhen the inlet pressure 2reaches the test cross over, the roughing

valve 3closes, the exhaust valve 6opens, the test valve 4opens.

The high vacuum is then connected to the inlet of the leak detector

taking care of the gas load. The analyzer cell 8will measure any

helium present. The value of the leak will be measured and displayed

on the control panel.

analyzer

cell

tested

part

8

6

secondary

pumping

exhaut

valve

7

primary

pumping

5

3

4

1

2

roughing

valve

test

valve

inlet pressure

gauge

inlet

C 200

General vacuum circuit

of a leak detector

Vacuum circuit of

the ASM 310

adixen Vacuum Products - ASM 310 Operating instructions

GB 03302 - Edition 03 - July 12

3/11

A 200

About leak detection

Test method

Choice Several test methods are possible.

The testing method is selected according to the test part and the

measurement range required:

Hard Vacuum test

Hard Vacuum test Sniffing test

C 402

The part can

be connected to

an evacuation line The part is sealed

BOMBING method

The sensitivity is limited by the

internal dead volume of the part as

well as on the bombing time and the

pressurization value.

Global test without possible location

of the leak.

SPRAY method

leak rate measurement from 5 · 10-12

to 10-1 mbar l/s and possibility of

locating the leak.

SNIFFING method

Minimum detectable leak of

10-7 mbar l/s and possibility of

locating the leak.

Its characteristics

allow it to be

evacuated

Its characteristics

allow it to be

pressurized with helium

or a mixture containing

helium

Its characteristics

allow it to be placed

in a vacuum

vessel

yes

yes yes yes

no

no

adixen Vacuum Products - ASM 310 Operating instructions

4/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

He

He

START

STAND-BY

START

STAND-BY

Spray method

Response time

When spraying starts, the leak signal is not displayed instantaneously

on the analyzer cell:

there is a response time which depends on the volume V being tested

and the helium pumping speed S of the system at the opening of the

part, according to the following relation:

T = V/S (T in second, V in litre, S in l/s)

T is the time required for the signal to reach 63 % of the final value.

This involves removing air from the part tested, connecting it to the

analyzer cell and then spraying helium over the outer surface.

The part is placed under a

cover, into which helium is

injected.

The leak cannot be located.

Potential leaking areas are

sprayed with helium.

The leak can be located.

Global test

part

spray probe

detector

Spray test

The detector measures the flow of helium penetrating the part.

Connection rules: refer to B 300

or part

detector

adixen Vacuum Products - ASM 310 Operating instructions

GB 03302 - Edition 03 - July 12

5/11

A 200

About leak detection

He

START

STAND-BY

He

START

STAND-BY

or

The sniffer probe is moved over

areas likely to contain leaks.

The leak can be located.

The signal supplied by the

analyzer is not a exact

measurement of the leak.

The sniffer probe only samples

part of the helium escaping

from the part. The sample

depends on the distance

separating the leak from the tip

of the probe.

The part is placed under a

cover containing a sniffer

probe.

The leak cannot be located.

The helium from the leak

accumulates over time inside the

cover. The detector measures

the concentration of helium.

Global test Local sniffing test

Sniffing method The test part is pressurized with helium. The detector, via a sniffer

probe samples the helium escaping from the part.

Global test is generally kept for gross leaks (> 10-3 mbar l/s). In 90 %

of uses, the sniffing method is used in local.

part

Sniffer probe

detector part detector

Sniffer probe

adixen Vacuum Products - ASM 310 Operating instructions

6/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

He

He

START

STAND-BY

The part is placed in a chamber containing pressurized helium.

The helium penetrates the part if it has a leak.

The part is then removed from the chamber and placed in another

vacuum chamber which is connected to the detector. The helium

escapes from the part through the leak and produces a signal.

This signal is not a direct measurement of the leak as the helium

pressure inside the part is difficult to determine. Several parts play an

important part such as: the pressurization time, the helium bombing

pressure, the internal volume, the aeration time, the size of the leak.

Please consult us for details about this method.

Bombing method This method is used for sealed objects that cannot be connected

directly to the detector (semiconductors, waterproof watches, etc.).

The "MIL-STD-883- Method 1014" standard allows to comprehend

parameters of this test. Before this test, it is necessary to do a gross

leak test to remove parts with a very gross leak.

part part

Chamber 1 Chamber 2

detector

adixen Vacuum Products - ASM 310 Operating instructions

GB 03302 - Edition 03 - July 12

7/11

A 200

About leak detection

Analyzer cell

operating principle

The analyzer cell works on the principle of mass spectrometry and is

set by default to the mass of helium (m/e = 4). Other gasses can be

used (helium 3 or hydrogene).

m/e = atomic mass of the particle/number of electrons lost on

ionization.

The principle of magnetic deflexion spectrometry is as follows.

The molecules of the gas being analyzed pass into an ionization

chamber 4where they are bombarded by an electron beam

generated by a heated iridium filament 5. A large number of the

molecules are transformed into ions.

6

He

2.5V

3 A

He

He

He

He

Stabilized power supply

Amplifier

He Leak Signal

4

5

1

"Heavy" ions

Electrons beam

"Light" ions

Helium ions

2

3

TARGET

+ 140 V adjustable

1 Triode electrode

2 Diaphragm

3 Braking electrode

4 Ionization chamber

5 Iridium filament

6 Spare filament

Magnetic field

Description

adixen Vacuum Products - ASM 310 Operating instructions

8/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

The iridium filament allows a good performance at high pressures and

a small overheating.

These ionized particles are accelerated by an electrical field.

They arrive in a zone subjected to a magnetic field which has the

property of deflecting the trajectories of the ions along different curves

according to the masses of those ions (to be more precised, according

to their m/e ratios). Thus the ions beam, which contained ions with

different masses, is divided into several beams, each containing only

ions with the same m/e ratio. For example, the helium ions (m/e = 4)

are separated from the lighter (H2+ or H1+, smaller beams) or heavier

ions (N2+ or O2+, bigger beam).

The triode electrode 1collects the ions which the mass is higher than

the tracer gas mass. The electronic current measured in this way

allows to calculate the total pressure in the analyzer cell.

Because there is a constant magnetic field (permanent magnet), the

accelerator electrical field is adjusted so that the tracer gas ions follow

a pre-determined trajectory (passing through diaphragm 2) and arrive

on the target at the input to a direct current amplifier.

In order to separate the helium ions from "noise" caused by other

ions, an electrode located in front of the target eliminates them. This

electrode 3 is called the "braking electrode".

The current of ions of the tracer gas is proportional to the partial

pressure this one in the installation and by measuring it we can find

the flow rate of the leak that has been detected.

It is essential that the total pressure in the analyzer cell is less than

10-3 mbar, so that the trajectories of the electrons and the ions are not

disturbed by residual molecules.

There is a spare iridium filament 6in the analyzer cell.

adixen Vacuum Products - ASM 310 Operating instructions

GB 03302 - Edition 03 - July 12

9/11

A 200

About leak detection

Design Great care has been taken with the design of the 3rd generation cell

in order to repeatedly obtain the same characteristics and to achieve

excellent stability:

- the metal parts are made of stainless steel,

- the filament holder is made of machined aluminium and filament

iridium,

- there is an integrated amplifier.

The cell assembly is composed of:

nThe vacuum chamber:

The analyzer cell vacuum chamber is made of light alloy (aluminium).

nThe main cover function is to contain and position the following 3

modules:

-ionisation module: "ions" generation,

- braking module: ions sorting and dispersed ions suppression,

- equipped plate module: recepted ions amplification.

nThe preamplifier and its associated electronics:

-Power supply board: delivers power to all the components

-Measure board: Treat and convert the signal into a digital signal

(semi-log form).

-Preamp board: preamplification and mechanical interface.

adixen Vacuum Products - ASM 310 Operating instructions

10/11

A 200

About leak detection

GB 03302 - Edition 03 - July 12

Helium is the second most common element in the universe,

representing about 23 % of the total matter. 76 % is Hydrogen. All

other elements represent an insignificantly small fraction of the total.

Helium is a 100 % green gas and has absolutely no environmental

impact on the atmosphere.

Helium was discovered by spectroscopy in a solar eclipse on August

18, 1868. The discovery in the sun’s chronosphere gave the new

element its name: “helios” in Greek means “sun”. While Helium is

very common in the universe most of it is in the stars: on earth it is

actually not abundant. Since it is so light all the Helium present during

the formation of earth escaped to space.

Helium is created deep in the earth from the radioactive decay of

uranium and thorium which also gives the earth its internal heat. On

earth Helium was discovered in 1881 by spectroscopy of Mount

Vesuvio in Italy – the volcanic gases emanated by the mountain

showed the same lines in the spectrum as already known from the sun.

Helium concentration in the atmosphere is 5 times bigger than the

one of Krypton and 60 times higher than Xenon. The heavier noble

gases are isolated from air rectification. In contrary, Helium is “mined”

from natural gas and oil wells and stored. The annual world wide

production is ca. 3x107m3or 4,500 tons.

Helium is constantly seeping up from the ground all around us, but it

is so light that almost all of it escapes into space fairly rapidly. On the

other hand there is a constant flow of Helium from space and the sun

to earth. This gives a dynamic equilibrium and is the reason for the

world wide constant concentration of 5 ppm Helium in air.

Helium is a very light colorless element and it is one of the six noble

gases which means it doesn’t react with anything for all practical

intents and purposes. It’s the most difficult gas to liquefy.

It’s used as an inert shield gas to protect things from oxidation – and

of course as leak detection tracer gas.

About helium and

hydrogen

Helium

adixen Vacuum Products - ASM 310 Operating instructions

GB 03302 - Edition 03 - July 12

11/11

A 200

About leak detection

Helium and leak detection:

which purity?

Helium is commercialized in many different purity levels, the highest

level of purity is requested from some laboratories for fundamental

researches or very accurate analyses.

The use of the Helium as a tracer gas into a mass spectrometer

doesn’t require such attention. A purity in the range of 97 % to 99 %

is enough.

There is absolutely no risk of accuracy lost or contamination for the

analyzer cell by using standard purity level of Helium gas.

Hydrogenated nitrogen If Hydrogen (H2) and Oxygen (O2) are mixed and heated, they react

and create water vapor (H2O). During this process more heat is

generated which may (if the concentration is high enough) ignite the

surrounding gas. If this process propagates, the gas explodes.

At low concentration of Hydrogen (< 4 % in air) the generated heat is

not enough to ignite the surrounding gas.

At concentrations in the range 4 to 12 % the combustion may

spread only if actions are taken to prevent the generated heat from

dissipating. It is a common misconception that hydrogen will explode

as soon as the concentration exceeds 4 %. It may explode only if

conditions are favorable for spontaneous propagation of combustion.

Never use pure hydrogen or a mixture with a hydrogen concentration

higher than 10 % to realize a "hydrogen" test as tracer gas.

If you use the recommended tracer gas of 5 % H2/ 95 % N2and mix

it with air there will either be too little hydrogen or too little oxygen

to constitute a combustible gas mixture. Hence this gas mixture is

classified as non flammable. The actual limit is 5.7 %.

The mixture 10 % H2/ 90 % N2is commonly used in the industry

because it is flammable only under certain conditions. This mixture is

however classified according to ISO 10156 as Flammable Gas and

should only be used after due safety considerations and approvals.

adixen Vacuum Products - ASM 310 Operating instructions

1/16

A 400

Accessories

GB 03329 - Edition 06 - February 12

Accessories Common

to all leak detectors

Calibrated leaks C1

Calibration accessory in sniffing C2

Remote control C3

Sniffer probe C4

Liquid sniffer probe C5

Helium spray gun C6

Locking clamp C7

Bombing chambers C8

Inlet filters C9

Specific accessories

to one or several leak

detectors

ASM 310 ASM 380 ASI 30

Transport case S1 •

Transport cart S2 •

Bottle support S3 •

Bluetooth (*) S4 • •

37 pin Input/Output board (*)

S5

37 pin Input/Output board with Wi-Fi (*) • •

37 pin Input/Output board with Ethernet (*)

Profibus board (*) S6 •

Industrial control panel (*) S7 •

Sniffing kit (*) S8 •

2005 IS primary pump S9 •

Interface extension kit S10 •

Power supply cords S11 • •

Measurement gauge S12 •

(*) also available in option

You can find via our Web Site free softwares designed to help you in

your applications. Refer to G 800.

adixen Vacuum Products - ASM 310 Operating instructions

Table of contents

Other Adixen Security Sensor manuals