®

Dual Technology Glassbreak Detector

Installation Instructions

Model FG-730

30’ range

The FG-730 is a dual technology glassbreak detector that uses

flex detection and audio discrimination to detect breaking glass.

The flex and audio technologies are sensitive to different

frequencies. The flex technology is sensitive to ultra low

frequencies, the type generated by a blow to a glass window. The

audio technology detects the frequency of breaking glass.

The audio technology remains off until the flex technology

detects a blow to the glass. For an alarm condition to occur, the

audio must detect the frequency of breaking glass within a

defined time-window after the flex detects a blow to the glass.

Because both technologies must detect and verify glass

breakage, false alarms are virtually eliminated.

•Dual flex/audio technology

Low 10 - 14 VDC operation

•Low 25 mA at 12 VDC

current draw

•No adjustment on audio

•Adjustment on flex

detection to fit

characteristics of each

location

•Alarm memory

•

Indicator LEDs

•Energized form C alarm

relay

•Circuit protection

•Cover tamper switch

•Noise burst rejection circuit

•RFI immunity

•UL listed

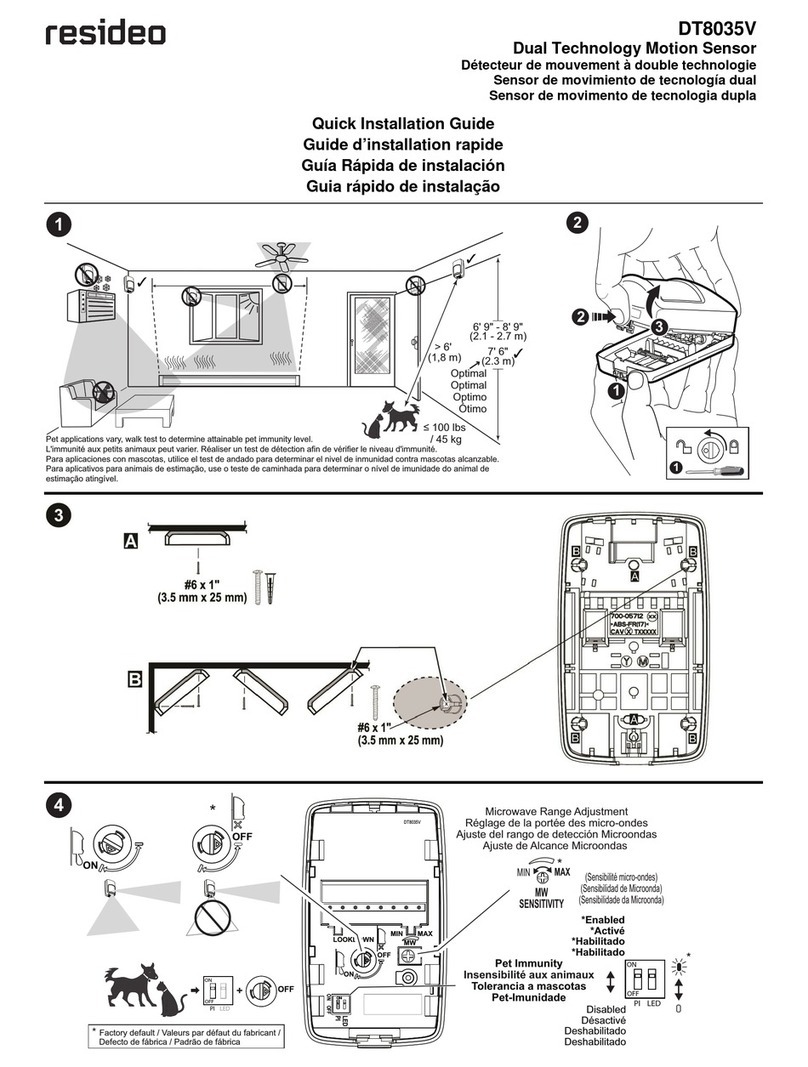

MOUNTING LOCATION

•The unit must have a direct line of sight to, and a clear view

of, the protected glass.

•Locate the FG-730 within 30' (9 m) of the glass to be

protected.

•Curtains, blinds, and other window coverings will absorb

energy from breaking glass. Heavy curtains, for example, will

effectively block the sound signal. In these cases, mount the unit

on the window frame behind the window covering, or above the

window. Make sure to test the unit thoroughly for proper

detection.

•Do not mount the unit in front of air ducts or forced air fans, or

close to bells measuring 2" (5 cm) or larger in diameter.

MOUNTING PROCEDURE

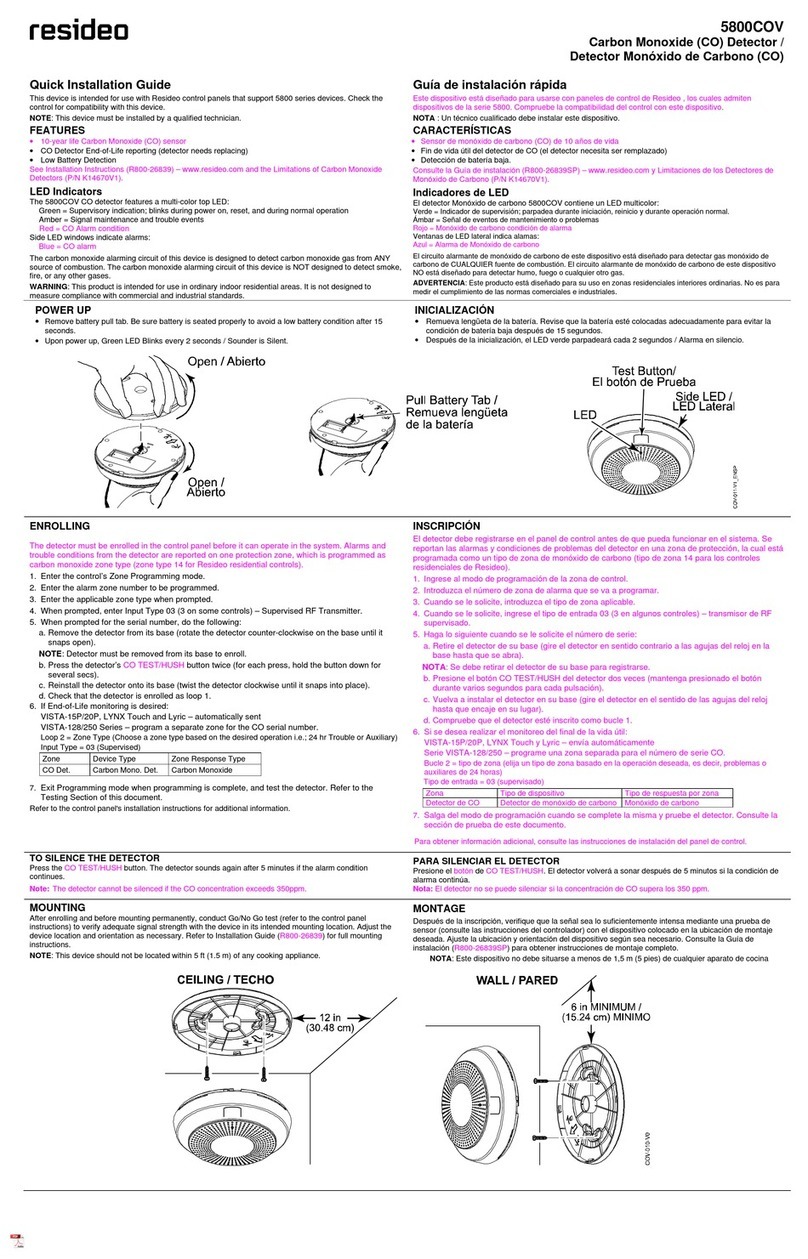

Orient the unit as shown in Figure 1. Remove the screw located

at its top. While depressing the latch near the top of the unit, swing

the front cover forward. Use the back cover as a template to mark

holes for the mounting screws and wiring, then drill the holes.

Note: If you plan to corner-mount the unit, remove the printed

circuit board before marking and drilling holes for the

mounting screws.

Pull the wiring into the unit through the back cover. Using the two

mounting screws, mount the rear housing at the desired

location.

WIRING

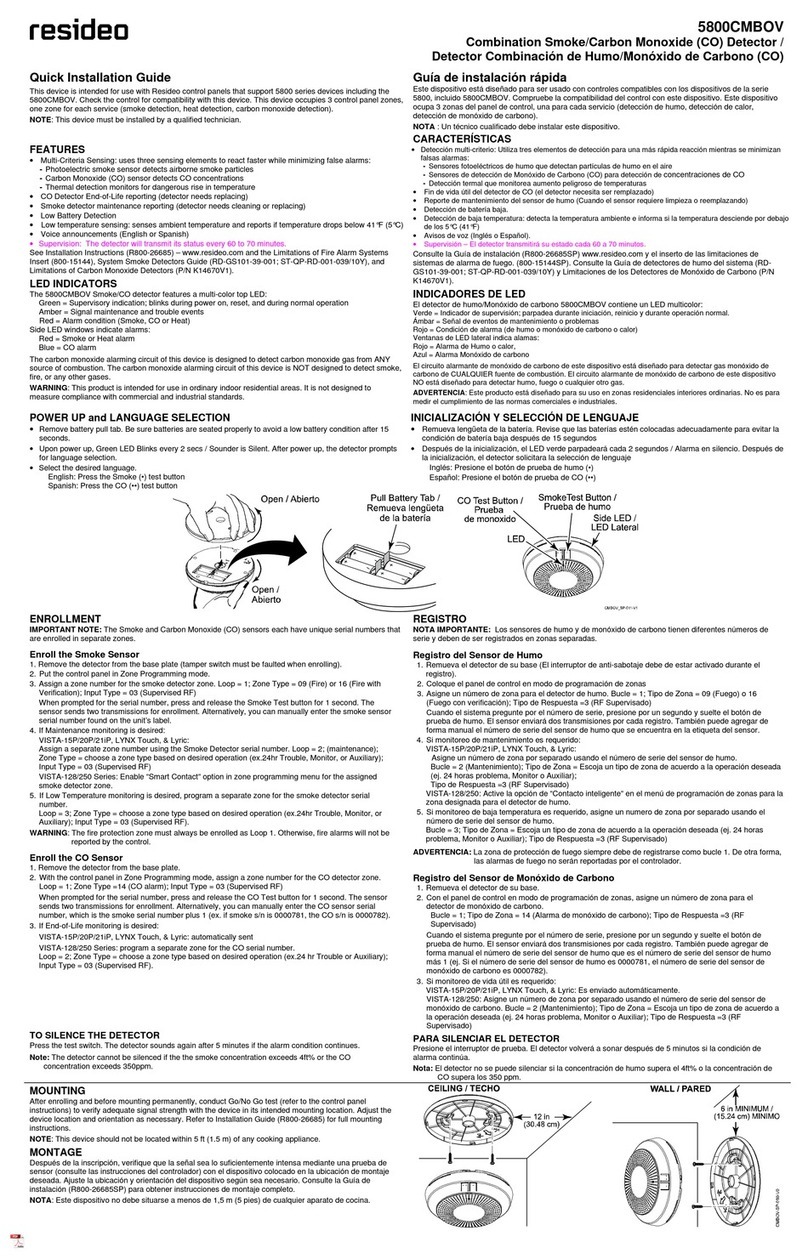

Observing the proper polarity, wire the unit as shown in Figure 2

(use 22 to 14 AWG). Reverse-polarity connections will not

damage the unit.

FLEX ADJUSTMENT

To adjust the flex technology: Use a screwdriver to set the flex

sensitivity control (R5) at MAXIMUM by turning it all the way

clockwise. Refer to Figure 3 on the back side of this page.

Turn on any heating/air conditioning system in the vicinity and

observe the yellow flex LED (DS2) for approximately one minute.

Excessive subsonic (inaudible) noise typically produced by air

handling systems may cause the flex LED to flash randomly.

If it flashes randomly, turn the R5 control counterclockwise just

until the flashing stops.

TESTING THE FG-730

Use the FG-701 Glassbreak Simulator to test the FG-730

detector. The FG- 700 may also be used.

Activate the simulator in MANual mode at the farthest point of

the glassto be protected (30' maximum). If the green LED (DS1)

on the detector flashes, the audio technology will detect

breaking glass at that distance.

Test the flex technology by carefully striking the glass with a

cushioned tool. If the yellow LED on the detector flashes, the flex

technology will be sensitive enough to detect a blow to the glass

at that distance.

FG-730-002-V0

REAR HOUSING

Knockouts

For corner mounting

(score and pull flap open)

For surface mounting

After removing screw at top of

unit, depress this latch to open

housing

FRONT HOUSING

FG-730-003-V0

NC

NO

NC

C

C

V+

V -

Form A (NC)

50 mA, 30 VDC

Tamper

10 - 14 VDC

25 mA, 12 VDC

Power

Form C

500 mA max, 30 VDC max,

30 VA max

Alarm