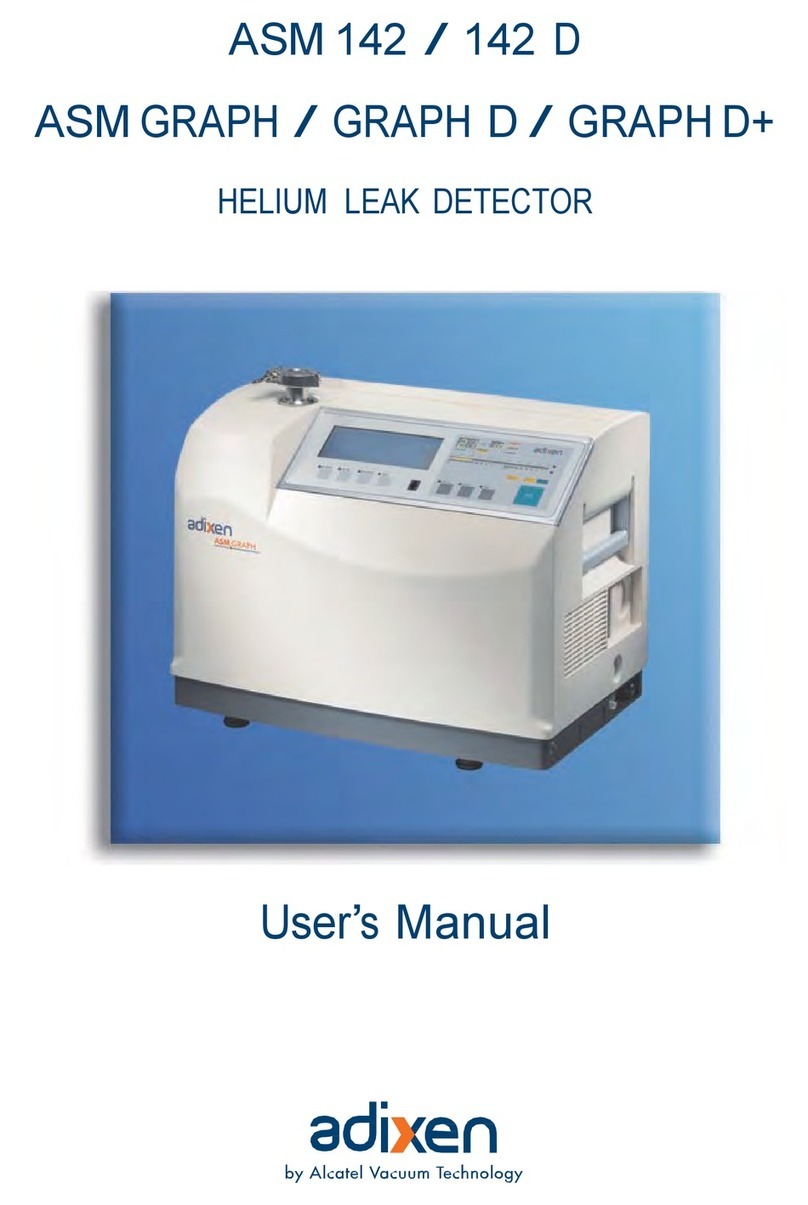

Adixen ASM 142 D User manual

1

CONDENSED MANUAL

• References refer to a specific chapter of the

User’s Manual.

• For further information, please refer to User’s

Manual supplied with your unit.

© AXESS

ASM 142/142 D/GRAPH/GRAPH D Detector connections................ 2

ASM 142/142 D Operator interface .... 3

ASM GRAPH/GRAPH D Operator interface 4

Start-up......................... 5

User interface level ................ 5

Test cycles ....................... 6

Helium signal analog display.......... 7

Audio alarm...................... 7

Zero function ..................... 8

Air inlet vent ..................... 9

Calibration....................... 10

Assistance to the test................ 11

P/N: 107768 Ed.03

Insert your

Condensed Manual

on the unit cover

2

DETECTOR CONNECTIONS

Main power

cord

Main power

switch “I”

Neutral gas purge (ASM 142 D and

ASM GRAPH D only)

Left side Right side

Printer interface

/headphone/

loudspeaker (option)

RS232 interface

(option)

I/O

interface

(option)

Quick connector

exhaust

Long distance sniffer

quick disconnect

3

OPERATOR INTERFACE ASM 142/142 D 1 Inlet port pressure analog display

2 Control and menu selection indicators (ON when activated)

3 Auto-calibration START/ABORT control key

4 Sniffing mode ON/OFF control key

5 Auto-zero ON/OFF control key

6 Cycle START/STOP control key

7 Control keys (4 keys)

8 Standby ON/OFF indicator

9 Evacuation ON/OFF indicator

10 Test ON/OFF indicator

11 Helium signal analogic display

12 Helium signal analogic scale ON/OFF indicator

13 Helium signal Zero scale ON/OFF indicator

14 Correction factor COR indicator (applied to digital display)

15 Units ON/OFF indicator

16 Helium signal digital display

17 Alphanumeric display (4 lines x 20 characters)

18 Parameter function keys (1 key per display line)

19 Modification access keys (4 keys)

20 NEXT : next display/parameter circular function

21/22 Plus or minus value adjustment, parameter selection, audio volume

adjustment keys

23 RESET of previously displayed values (cancels temporary inputs)

24 Menu selection access key (4 keys)

25 SET POINT menu selection key

26 SPECTRO calibration and analyzer cell configuration menu selection

key

27 MAINTENANCE menu selection key

28 OTHER menus selection key (test mode selection, inlet VENT

selection, date/time)

29 Remote control connection

AUTO CAL ZERO

NEXT

-

+

RESET

CYCLE

SNIFFER

SET POINTS SPECTRO

MAINTENANCE

OTHER

F1

F3

F2

F4

10

mbar

hPa

Torr

-3

10

-12

10

-11

10

-10

10

-9

10

-8

10

-7

10

-6

10

-5

10

-4

10

-3

10

-2

10

-2

10

-1

110

1

10

2

10

3

COR

mbar.l/s

STDBY

INLET PRESSURE

LEAK RATE

EVAC TEST

Pa.m

3

/s

Torr.l/s

13

12

1098

2

3

1

11

16

18 17

20 21 22 23

25

24

19

26 27 28

29

14

15

4 5

7

6

Setting and maintenance part Operation part

OPERATOR INTERFACE ASM GRAPH/GRAPH D 1 Inlet port pressure analog display

2 Control and menu selection indicators (ON when activated)

3 Auto-calibration START/ABORT control key

4 Sniffing mode ON/OFF control key

5 Auto-zero ON/OFF control key

6 Cycle START/STOP control key

7 Control keys (4 keys)

8 Standby ON/OFF indicator

9 Evacuation ON/OFF indicator

10 Test ON/OFF indicator

11 Helium signal analogic display

12 Helium signal analogic scale ON/OFF indicator

13 Helium signal Zero scale ON/OFF indicator

14 Correction factor COR indicator (applied to digital display)

15 Units of measurement selection

16 Helium signal digital display

17 Menu display (4 lines)

18 Spectro pressure analog display

19 Modification access keys (4 keys)

20 RESET: next display/parameter circular function

21/22 Plus or minus value adjustment, parameter selection, audio volume

adjustment keys

23 NEXT of previously displayed values (cancels temporary inputs)

24 Menu selection access key (4 keys)

25 SET POINT menu selection key

26 SPECTRO calibration and analyzer cell configuration menu selection

key

27 MAINTENANCE menu selection key

28 OTHER menus selection key (test mode selection, inlet VENT

selection, date/time)

29 Remote control connection: connect if before switching on

the detector

30 Graphic interface selection key

31 Color touch screen

4

AUTO CAL ZERO

CYCLE

SNIFFER

SET POINTS SPECTRO

MAINTENANCE

OTHER

10

-12

10

-11

10

-10

10

-9

10

-8

10

-7

10

-6

10

-5

10

-4

10

-3

10

-2

COR

mbar.l/s

STDBY

LEAK RATE

EVAC TEST

Pa.m

3

/s

Torr.l/s

13

12

1098

11

16

17

25 26 27

29

14

15

1

18

3 4 5

7

6

2

20

22 2321

19

24

28

30

31

Setting and maintenance part Operation part

The detector offers 4 user interface levels for this section to

accomodate any application requirements.

START-UP USER INTERFACE LEVEL

After unpacking the unit, please fill

up the roughing pump with oil, as

indicated in the User’s Manual

E 750

1 Connect the main cable from the detector to the

proper power outlet.

2Depress the main switch to position “I”. On the

control panel, the indicator lights flash.

3 The following screens are shown on the LCD.

4 When the detection pump

reaches its nominal speed,

the unit autocalibrates

itself.

5 When calibration is

completed, the unit is

ready to start a cycle.

STDBYSTDBY

F1

F3 F2

F4

PLEASE WAIT…

ALCATEL ASM...

UNIT : mbar.l/s

SOFT : Lxx Vx.x rxx

F1

F3 F2

F4

PLEASE WAIT…

DETECTION PUMP: 75%

F1

F3 F2

F4

AUTOCAL IN PROGRESS

ELECTR. ZERO ADJUST.

80

F1

F3 F2

F4

READY FOR CYCLE

INLET VENT : off

To know your user interface level and to change it C 120

Setting and maintenance part User part

LEVEL

11

This level has very limited information on the alphanumeric display (LCD). This level is generally selected for production

types of applications.

No access to control keys (Cycle key

included).

LEVEL

22

This level allows the operator to visualize some parameters without the possibility of making any

changes.

Same as Level

11

, this level is usually selected for production types of applications.

Access to all the control keys.

LEVEL

33

Same as level

22

but with possibility to set some parameters. This level is generally selected for

maintenance applications.

LEVEL

44

This level allows access to all the parameters and is generally used for settings all the parameters.

Note: When switching from level

44

to any other level, the switch can be performed without using the

password. This level is generally selected for R&D applications.

ASM 142/GRAPH

5

6

TEST CYCLES

HARD VACUUM TEST MODE

Leak detector in stand-by mode; connect the part or assembly

to be tested to the detector.

SNIFFING TEST MODE

Leak detector in stand-by mode; connect the long distance sniffer

probe to the quick connector.

STDBYSTDBY

F1

F3 F2

F4

READY FOR CYCLE

INLET VENT : off

STDBYSTDBY

F1

F3 F2

F4

READY FOR CYCLE

INLET VENT : off

CYCLE

STDBYSTDBY

EVACEVAC

EVACEVAC

TESTTEST

SNIFFER

SNIFFER

SNIFFER

SNIFFER

CYCLE

TESTTEST

STDBYSTDBY

Starting a cycle

Ending a cycle

Starting Sniffing test mode

Ending Sniffing test mode

(1) As soon as the inlet pressure reaches 10 mbar (7.5 torr),

the unit goes in gross leak test mode, or when the pressure

has reached 5.10-1 mbar (0.37 torr), the unit goes in fine

leak test mode.

F1

F3 F2

F4

READY FOR CYCLE

INLET VENT : off

F1

F3 F2

F4

SNIFFING MODE

PLEASE WAIT…

F1

F3 F2

F4

SNIFFING MODE

Selecting a test mode C 210

(1) Read leak

value

7

He SIGNAL ANALOG SCALE DISPLAY AUDIO ALARM

Leak detector in hard vacuum or sniffing

test mode and zero function not activated.

How to read the He signal analog scale?

reject point is visualized by a blinking led.

if the leak value exceeds the reject point, the leds will turned red (the blinking led will turn orange).

if the leak value remains under the reject point, the leds will remain green.

Example : Reject point = 1 x 10-7 mbar.l/s

The audio alarm offers 2 modes of operation. They are both linked to the zero function.

zero function not activated: the audio alarm starts when the He signal exceeds a fixed set point:

this set point is programmable.

zero function activated: the audio alarm is modulated with respect to the position of the helium

background.

To active/deactive audio alarm C 520

Blinking led = reject point

AUTO CAL ZERO

NEXT

-

+

RESET

CYCLE

SNIFFER

SET POINTS SPECTRO

MAINTENANCE

OTHER

F1

F3

F2

F4

10

mbar

hPa

Torr

-3

10

-12

10

-11

10

-10

10

-9

10

-8

10

-6

10

-5

10

-4

10

-3

10

-2

10

-2

10

-1

110

1

10

2

10

3

COR

mbar.l/s

STDBY

INLET PRESSURE

LEAK RATE

EVAC TEST

Pa.m

3

/s

Torr.l/s

10

-7

Purpose: the zero function offers the operator the possibility to detect small leaks that are smaller than the

helium background.

Activation of zero function: connect the part or installation to be tested.

Deactivation of zero function:

the digital display shows the standard He signal.

Use Helium signal analog scale.

Analog display:

• When zero function is activated, use the Helium signal zero scale.

• The He signal zero scale displays 2 leds signal centered around the zero value.

Example:

Operator could find an example in the User’s Manual C 540 8

ZERO FUNCTION

CYCLE

on the digital display, the detector He background displays.

ZERO

the digital display becomes 0.0E-00. On and after this time, it will display only Helium variation.

ZERO

2 leds flash

1x10-7 1x10-8 1.1x10-7 9x10-8 2x10-7

AUTO CAL ZERO

NEXT

-

+

RESET

CYCLE

SNIFFER

SET POINTS SPECTRO

MAINTENANCE

OTHER

F1

F3

F2

F4

10

mbar

hPa

Torr

-3

10

-12

10

-11

10

-10

10

-9

10

-8

10

-6

10

-5

10

-4

10

-3

10

-2

10

-2

10

-1

110

1

10

2

10

3

COR

mbar.l/s

STDBY

INLET PRESSURE

LEAK RATE

EVAC TEST

Pa.m

3

/s

Torr.l/s

10

-7

9

AIR INLET VENT

Purpose: the air inlet valve vents the inlet of the detector back to atmosphere at the end of the test.

• The indicator “inlet valve = off” indicates that the venting valve is not activated (= closed)

at the end of cycle.

• The setting by default is «off» (= valve closed).

F1

F3 F2

F4

READY FOR CYCLE

INLET VENT : off

F3F3

(opening) /

(closing)

F3F3

Opening / closing air inlet valve

(user level

22

,

33

or

44

)

To open/close air inlet valve with user level

11

C 500

10

CALIBRATION

Internal: The internal autocalibration is automatically activated during

the start-up process. It doesn’t require any operator action.

Thanks to the initial autocalibration, the leak detector can be

immediately operational.

Internal autocalibration on request: it can be started by the operator

whenever needed (the unit has to be off-cycle).

The result of the autocalibration process is displayed.

External: The external autocalibration allows direct readout in cases of

operation with an auxiliary pumping system.

F1

F3 F2

F4

READY FOR CYCLE

INLET VENT : off

F1

F3 F2

F4

READY FOR CYCLE

INLET VENT : off

F1

F3 F2

F4

AUTOCAL IN PROGRESS

ELECTR. ZERO ADJUST.

80

To perform an external calibration C 303

AUTOCAL

11

ASSISTANCE TO THE TEST The leak detector offers to the user 4 interesting functions in

order to improve test.

MEMO FUNCTION. . . . . . Memorization of the latest He signal measured after depressing the CYCLE key at

the end of the cycle.

CYCLE END . . . . . . . . . . . . Automatic control of the roughing and measure timers.

BARGRAPH ZOOM . . . . Display a greater resolution of the He signal around the reject point.

ON THE REJECT POINT

HELIUM POLLUTION . . . Device that prevents the unit from getting polluted with Helium.

PREVENTION

Memo function

Cycle end

Bargraph zoom on the reject point

Helium pollution prevention

To active/deactive this function and adjust display time of the leak value

C 550

To active/deactive this function and adjust roughing and measure times C 530

To active/deactive this function C 510

To active/deactive this function C 560

This manual suits for next models

3

Table of contents

Other Adixen Security Sensor manuals

Popular Security Sensor manuals by other brands

Banner

Banner LTF Series instruction manual

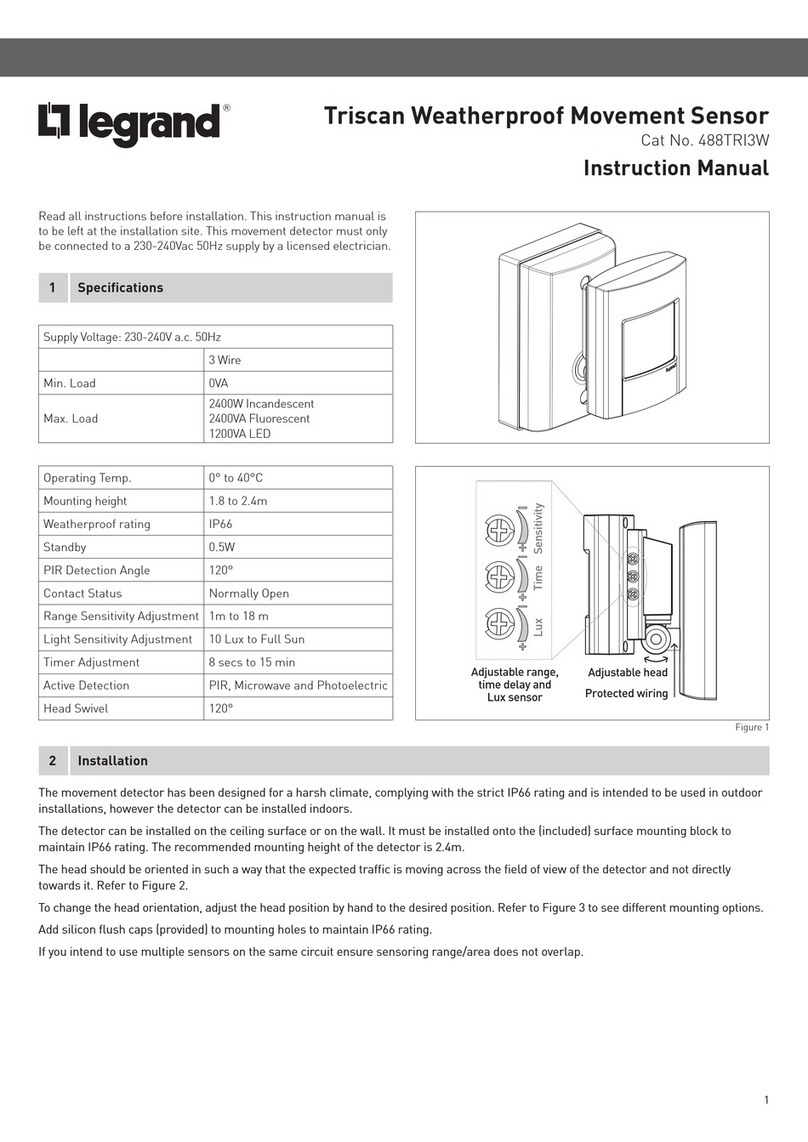

LEGRAND

LEGRAND Triscan 488TRI3W instruction manual

PCB Piezotronics

PCB Piezotronics 117B37 Installation and operating manual

Esser

Esser IQ8Quad Ex (i) technical information

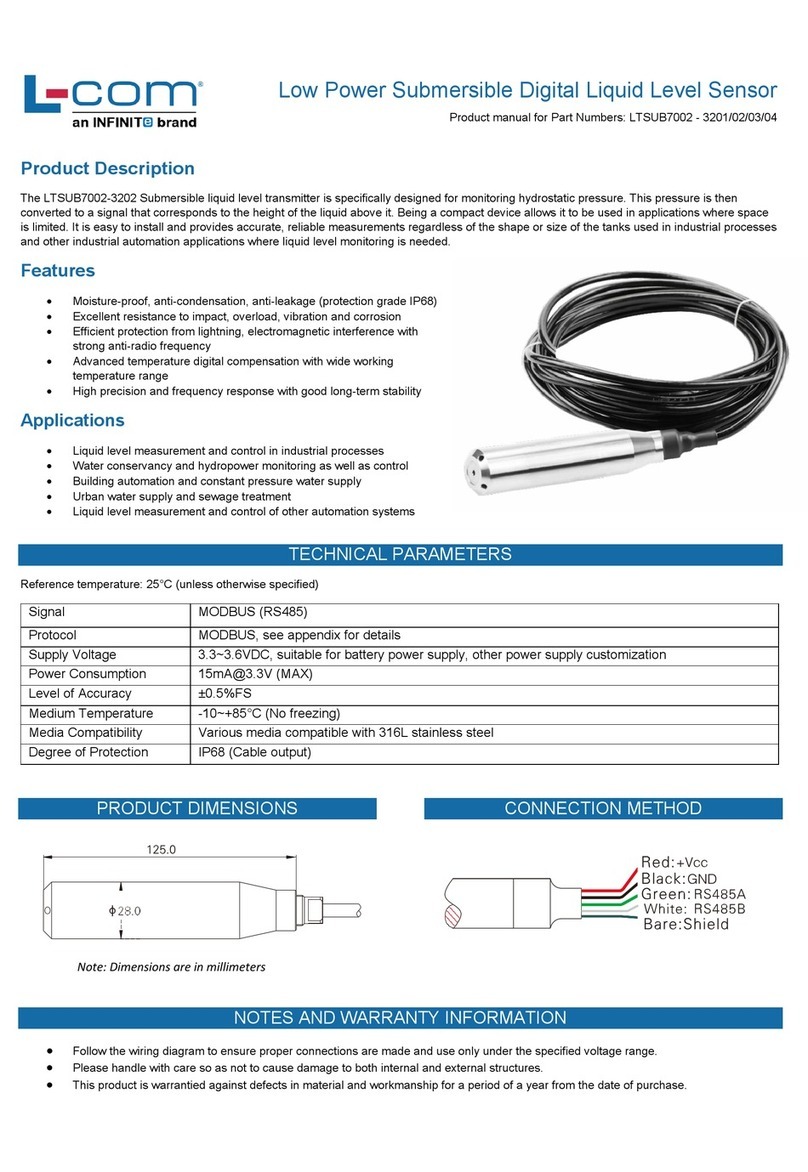

Infinite

Infinite L-com LTSUB7002-3202 product manual

Lightcloud

Lightcloud LCLCSENSE/M/EG/A manual