Adixen ASM 142 User manual

ASM 142

/

142

D

ASM

GRAPH

/

GRAPH

D

/

GRAPH D+

HELIUM LEAK DETECTOR

User

’

s

Manual

Gb 02834

-

Edition

04

-

Feb

08

Al

c

a

t

e

l

Vacuum Technology,

as

part of the Alcatel-

L

u

c

e

n

t

Group, has been

s

uppl

y

ing

vacuum pump

s

,

helium and hydrogen leak detection

s

y

s

t

e

m

s

,

plasma sensors, vacuum mea

s

ur

e

m

e

n

t

for

s

eve

r

a

l

y

ea

r

s

.

Thanks

to i

t

s

complete range of produ

c

t

s

, the

company

has

become an

e

ss

e

n

t

i

a

l player in

multiple

a

ppli

c

a

t

ion

s

: in

s

t

rum

e

n

t

a

t

ion,

Re

s

ea

r

c

h

&

D

eve

lop

e

m

e

n

t

, indu

s

t

r

y

and

s

e

mi

c

ondu

c

t

or

s

.

Alcatel Vacuum

Technology

has

launched

Adixen, i

t

s

new brand name, in recognition o

f

the

c

omp

a

n

y

’

s

international

s

t

a

nding in vacuum

po

s

i

t

ion.

With both

ISO

9001 and 14001

c

e

r

t

i

fi

c

a

t

ion

s

,

the

F

r

e

n

c

h company

is

an acknowlegded expert

in

service

and

s

uppor

t

, and

Adixen produ

c

t

s

have

the high

e

s

t

quality and

environmental

s

t

a

nd

a

r

ds

.

With 45

years

of

experience, AVT

today

has

a

w

orld

w

id

e

presence,

through i

t

s

international network that in

c

lud

e

s

a whole ho

s

t

of

experienced subsidiaries, di

s

t

ribu

t

or

s

and

a

g

e

n

t

s

.

The

fi

r

s

t

s

t

e

p

was

the founding of Alcatel Vacuum

P

rodu

c

t

s

(Hingham- MA)

in the United

S

t

a

t

e

s

,

t

hir

t

y

years

ago,

reinforced

today by 2 o

t

h

e

r

s

US subsidiaries

in

F

r

e

mon

t

(CA)

and

Tempe

(

A

Z

)

.

In

E

urop

e

, A

V

T

F

-

F

r

a

n

c

e

h

ea

dqu

a

r

t

e

r

s

and i

t

s

s

ub

s

idi

a

ri

e

s

,

Alcatel

Hochvakuumtechnik (Germany),

Alcatel Vacuum

Technology

UK

(

S

c

o

t

l

a

nd

)

, Alcatel Vacuum

T

e

c

hnolog

y

Benelux

(

N

e

t

h

e

rl

a

n

ds

)

, Alcatel Vacuum

S

y

s

t

e

m

s

(

I

t

a

l

y

)

and more recently Adixen

S

e

n

s

i

s

t

or

AB

in

S

w

e

d

e

n

(

in

2007)

form the foundation for the

E

urop

ea

n partner

n

e

t

w

ork.

In Asia,

our

presence

s

t

a

r

t

e

d in 1993 with Alcatel

Vacuum Technology

(

J

a

p

a

n

)

,

and has been

s

t

r

e

ng

t

h

e

n

e

d

with Al

c

a

t

e

l

Vacuum Technology Korea (in 1995),

Alcatel

Vacuum

Technology Taiwan (in 2001),

Alcatel Vacuum

Technology

S

ing

a

por

e

, Alcatel Vacuum

T

e

c

hnolog

y

S

h

a

ngh

a

i

(China) (in

2004).

This

organization

is

rounded off by more than 40

r

e

pr

e

s

e

n

s

a

t

i

v

e

s

based

in a

v

a

ri

e

t

y

of

c

on

t

in

e

n

t

s

.

Thus,

whatever the

c

ir

c

um

s

t

a

n

c

e

s

, the

users

of Adixen

produ

c

t

s

can

always

rely on quick

s

uppor

t

of our

s

p

e

c

i

a

li

s

t

s

in

Vacuum

T

e

c

hnolog

y

.

A very wide range of helium leak

GB00204 -

Edition

05 -

September

06

detectors

Dear customer,

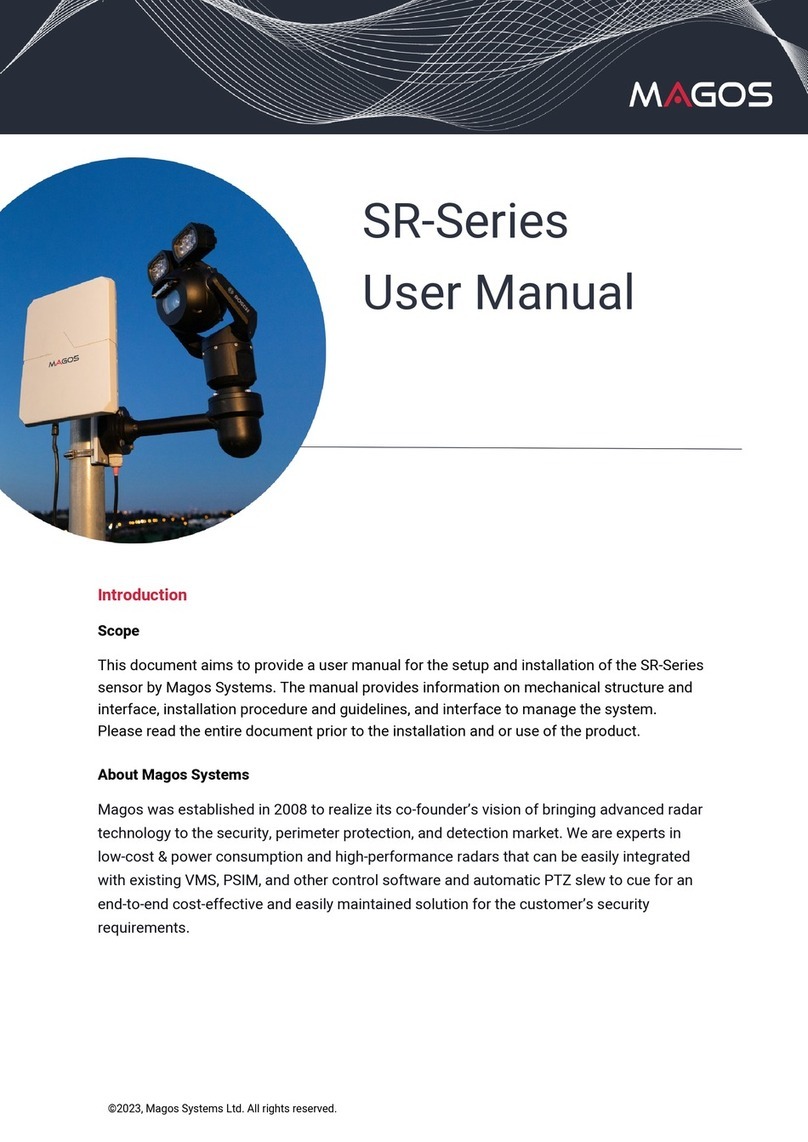

You have just bought an

Adixen leak detector.

We would like to thank you

and we are proud to count

you among our customers.

This

product is a result of

the experience acquired

over 35 years by Alcatel

Vacuum

Technology France

in vacuum and leak

detection technology.

The applications of helium

leak testing are extremely

diversified ranging from

high-tech

installation

maintenance to high-

speed testing of industrial

products.

Each product of the Adixen

detector range is designed

to meet the specific needs

of each application:

•

portability,

•

high sensitivity,

•

pumping capacity,

•

pumping type,

•

automation and

integration in an industrial

process.

1/2

A very wide range of helium leak

GB00204 -

Edition

05 -

September

06

detectors

This

product

complies

with the

requirements

of

European

Directives,

listed in the Declarationof Conformity containedin G100 of this

manual.

These Directives

are

amended

by

Directive

93/68/E.E.C

(E.C.

Marking).

The

Declarationof Conformity and

Safety Instructions

are available

in German,

Spanish,

Italian,

Portuguese, Dutch

and Danish

languagesat the end of this manual.

Copyright/Intellectual property:

The use

of Adixen

products

are

subject

to copyright and intellectual

property rights in force in any jurisdiction.

All rights

reserved,

including copying this

document

in whole or

any part without prior written authorization from Alcatel Vacuum

T

echnology

France.

Specifications

and information are

subject

to

change

without notice

by from Alcatel

Vacuum

T

echnology

France.

2

/

2

M

anual reference

: 107817

e

dition

:

07 - March 2009

Software version:

ASM

142

/

A

S

M

G

R

A

P

H

:

L

0088

v3.1 r

.02

ASM

142

D

/

A

S

M

G

R

A

P

H

D

/

ASM

G

R

A

P

H

D+:

L

0114

v3.1 r

.02

General

contents

ASM

142 -

ASM

142 D

ASM GRAPH

-

ASM GRAPH

D

ASM GRAPH

D+

User

’

s

Manual

GB00205 -

Edition

07 - March 09

Preliminary

remarks

Throughout

this

User’s

Manual, you could find this type of message

“Summary of screen

C

140”: it

refers

to a specific chapter of the

User’s

Manual.

Please

read it for further information.

Chapter

A

INTRODUCTION

A 100

-

Introduction

to the ASM 142 series

A 200

-

ASM 142

-

Detector

operating principle

A 201

-

ASM 142 D

-

Detector

operating principle

A 202

-

ASM 142 Graph D+

-

Detector

operating principle

A 300

-

Analyzer cell operating principle

A 400

-

Testing

methods

A 401

-

About Helium and Hydrogen

A 500

-

Operator interface: control panel

A 600

-

Options

A 700

-

Accessories

A 800

-

ASM 142

-

T

echnical

characteristics

A 801

-

ASM 142 D

-

ASM Graph D+

-

T

echnical

characteristics

A 900

-

Dimensions

A 901

-

Dimensions

ASM Graph D+

Chapter B

INSTALLA

TION

B

100

-

Safety instructions

B

110

-

Unpacking

-

Storage

-

T

ransportation

B

200

-

Neutral gas purge and inlet vent connection

B

201

-

Neutral gas purge installation (accessory)

B

210

-

Connecting the

detector

to the installation

B

211

-

Connecting the

detector

to the installation: ASM graph D+

B

300

-

Controlling the

detector

with the I/O interface

B

310

-

Controlling the

detector

with a

PC computer

through the

RS

232 interface

B

320

-

Connecting the

detector

directly to a printer or another device

B

400

-

Before

starting up the leak detector

Chapter C

OPERA

TION

C

100

-

Factory

configuration of the leak

detector

parameters

C

110

-

Operating principle of the control panel

C

120

-

Setting

and

maintenance

part

presentation

of the control panel

C

130

-

Access

to level 4

-

Password

C

140

-

Summary

of screens

C

200

-

Starting up

/

Switching off the leak detector

C

210

-

How to

use

the leak detector: 2 methods

C

211

-

Operation of the leak detector

C

300

-

Calibration of the leak detector

C

301

-

Basic

internal calibration of the leak detector

C

302

-

Advanced internal calibration of the leak detector

C

303

-

External

calibration of the leak detector

C

304

-

Correction factor

C

305

-

Calibrated leak

values

programming

C

306

-

Adaptor for calibrated leak in sniffing mode

C

400

-

Remote

control

C

410

-

Headphone and loudspeaker

C

430

-

3

masses

option

C

440

-

Control panel with graphic interface

C

450

-

Long

distance sniffer probe and Helium spray gun

Alcatel Vacuum

T

echnology

France

-

User’s

Manual ASM

142/142

D - ASM

GRAPH/GRAPH D/GRAPH

D+

1/3

M

anual reference

: 107817

e

dition

:

07 - March 2009

Software version:

ASM

142

/

A

S

M

G

R

A

P

H

:

L

0088

v3.1 r

.02

ASM

142

D

/

A

S

M

G

R

A

P

H

D

/

ASM

G

R

A

P

H

D+:

L

0114

v3.1 r

.02

General

contents

ASM

142 -

ASM

142 D

ASM GRAPH

-

ASM GRAPH

D

ASM GRAPH

D+

User

’

s

Manual

GB00205 -

Edition

07 - March 09

C

500

-

Inlet vent

C

510

-

Bargraph zoom

C

520

-

Audio alarm/Digital voice

C

530

-

Cycle end

C

540

-

Zero function

C

550

-

Memo function

C

560

-

Helium pollution prevention

C

570

-

Date

-

Time

-

Language

-

Unit

C

580

-

Fault

/

information indicator and display

Chapter

D

MAINTENANCE

-

TROUBLESHOOTING

D 100

-

T

able of

preventive maintenance

intervals

D 200

-

Maintenance message

D 300

-

General

troubleshooting

guide

D 300/D 400

-

General

troubleshooting

guide/Symptoms description

D 400

-

Symptoms

description

Chapter E

MAINTENANCE

SHEETS

E

100

-

Maintenance operations introduction

E

110

-

ASM 142

/

ASM 142

S -

Access

to internal components

E

111

-

ASM 142 D

-

ASM Graph D+

-

Access

to the internal components

E

120

-

Sending the leak detection for reparation to a

service

center

E

400

-

Basic maintenance

of the analyzer cell

E

530

-

Valves

installation and maintenance

E

560

-

Replacement

of the internal calibrated leak

E

600

-

Remote

control

E

610

-

Long

distance sniffer probe and Helium spray gun

E

710

-

Primary

pump

maintenance (AMD

1

)

E

730

-

Starting of the

molecular

and

turbomolecular

pumps

E

740

-

Greasing

molecular

and

turbomolecular

pumps

E

750

-

Primary

pump maintenance

Chapitre

F

COMPONENTS

F

000

-

Spare

parts instructions

of use

F

001

-

AVTF Customer Service

Offer

F

100

-

T

ools

F

200

-

Monitoring and display

F

300

-

Power and electrical supply

F

400

-

Automatic control

system

and

electronic

circuits

F

500

-

Measurement

F

600

-

ASM 142

-

Pumping

F

600

-

ASM 142 D

-

Pumping

F

700

-

Valves

F

800

-

ASM 142

-

Pipes

-

Connections

-

Seals

F

800

-

ASM 142 D

-

Pipes

-

Connections

-

Seals

F

900

-

Cover

F

1000

-

Options

-

Accessories

F

1100

-

Pictures

of components

2

/3

Alcatel Vacuum

T

echnology

France

-

User’s

Manual ASM

142/142

D - ASM

GRAPH/GRAPH D/GRAPH

D+

M

anual reference

: 107817

e

dition

:

07 - March 2009

Software version:

ASM

142

/

A

S

M

G

R

A

P

H

:

L

0088

v3.1 r

.02

ASM

142

D

/

A

S

M

G

R

A

P

H

D

/

ASM

G

R

A

P

H

D+:

L

0114

v3.1 r

.02

General

contents

ASM

142 -

ASM

142 D

ASM GRAPH

-

ASM GRAPH

D

ASM GRAPH

D+

User

’

s

Manual

GB00205 -

Edition

07 - March 09

Chapter

G APPENDIX

G 100

-

Declaration of

confor

mity

G 200

-

ASM 142

-

Wiring

diagrams

G 201

-

ASM 142 D

-

Wiring

diagrams

G 300

-

Analog

output

G 400

-

Long

distance sniffer probe

user

manual

G 500

-

Helium spray gun

user manual

G 600

-

Safety

questionnaire

G 800

-

T

ools

Indicates

a potentially hazardous situation which, if not avoided,

could resultin property damage.

CAUTION

Indicates

a potentially hazardous situation which, if not avoided,

could resultimmoderate or minor injury. It may also be

used

to alert

against unsafepractices.

CAUTION

Indicates

a potentially hazardous situation which, if not avoided,

could resultin death or

severe

injury.

W

ARNING

Indicated an imminently hazardous situation that, if not avoided,

will resultin death or

severe

injury

(extreme

situations).

Alcatel Vacuum

T

echnology

France

-

User’s

Manual ASM

142/142

D - ASM

GRAPH/GRAPH D/GRAPH

D+

3

/3

Introduction

A

ASM

GRAPH

- ASM

GRAPH

D

GB00206 -

Edition

03 -

June

08

ASM 142 - ASM 142 D

Preliminary

remarks

ASM

GRAPH

D+

User

’

s

Manual

Detailed contents

Throughout

this

User’s

Manual, you could find this type of message

“Summary of screen

C

140”: it

refers

to a specific chapter of the

User’s

Manual.

Please

read it for further information.

A 100

Introduction

to the ASM142 series

-

A new generation of Adixen helium leak detector

A 200 ASM142 -

Detector

operating principle

-

Vacuum

circuit

-

Stand-by

mode

-

Roughing

mode

-

Gross leak

test

mode

-

Normal

test

mode

-

Sniffing

test

mode

A 201 ASM142 D -

Detector

operating principle

-

Vacuum

circuit

-

Stand-by

mode

-

Roughing

mode

-

Gross leak

test

mode

-

Normal

test

mode

-

Sniffing

test

mode

A 202 ASM142 Graph D+ -

Detector

operating principle

-

Vacuum

circuit

-

Stand-by

mode

-

Roughing

mode

-

Gross leak

test

mode

-

Normal

test

mode

-

Sniffing

test

mode

A

300

Analyzer

cell

operating

principle

-

Description

-

Design and manufacture

A

400

T

esting

methods

-

Overview

-

Helium

concentration

and signal displayed

-

Spray method (inboard testing)

-

Sniffer method (outboard testing)

-

Bombing method

A 401 About Heliumand hydrogen

-

Helium

-

Helium and leak detection: which purity?

-

Hydrogen

A 500 Operator interface: control panel

1/2

Introduction

A

ASM

GRAPH

- ASM

GRAPH

D

GB00206 -

Edition

03 -

June

08

ASM 142 - ASM 142

D

ASM

GRAPH

D+

User

’

s

Manual

Detailed

contents

A 600 Options

-

Which options for which model?

-

Metal

seals

-

Inlet port

-

Units

-

Languages

-

3 masses

-

Automatic

test

chambers

-

Roughing system

-

Interface

board

-

Remote

control cable length

- Test

of gas

line

-

Stainless steel

cover

(UCT)

-

Control panel with graphic interface

-

Control panel racks

-

Sniffing

-

Cables

lengths

A 700

Accessories

-

Which

accessories

for which model?

-

Remote

control

-

Long Distance

Sniffer probe

-

10 m/30 feet

LDS

extension

-

Headphone

connector

-

T

ranspor

t

car

t

-

Foot pedal for cycle

command

(1.5 m/5 feet)

-

Calibrated Helium leaks

-

Calibration

accessor

y

-

Spray probe

-

Inlet adaptor

-

Printer

-

Inlet filters

-

Short

distance sniffer probe (to be

connected

to the inlet part of a leak detector)

-

Bombing chamber

- Test

chambers

-

Neutral gas vent line kit

-

4 swiveling

wheels

kit (Ø125 mm)

-

Covered sniffer probe and

remote

control kit

-

Bottle

handle for cart

-

Built-in

mini-printer

-

2005 IS

Pump

-

Pressure measurement

kit

-

Ventilation

Kit

-

Bottle

handle for cart

A 800 ASM142 -

T

echnical

characteristics

A 801 ASM 142 D - ASMGraph D+ -

T

echnical

characteristics

A 900

Dimensions

A 901

Dimensions

- ASMGraph D+

2

/2

A

100

ASM

142

ASM

Graph

ASM

142 D

ASM

Graph

D

ASM

142

S

ASM

Graph

D+

high

performances, such

as,

a roughing capacity of 7 CFM

(60 l/mn) with a usable helium

sensitivity

in the

10

-

11

atm.cc/

sec range.

x

x

x

high

performances, such

as,

a dry roughing capacity of 0.9

CFM

(1.5 m3/h) with a usable

helium sensitivity

in the 10-11

atm.cc/sec

range.

x

x

x

a

usable helium

sensitivity

in the

10-7

atm.cc/sec

range (with

auto-zero

function).

x

comprehensive

control

panel

with two

distinct

areas (one

for the operation of the unit,

the

other

for

entering

the

test

parameters).

x

x

x

x

x

x

evolved features

to assist

the

operator in his daily

operation

(auto-calibration,

auto-zero,

helium

signal direct readout,

...).

x

x

x

x

x

x

very rugged

design, based on

field-proven components,

which

makes

it ideal for any industrial

environment.

x

x

x

x

x

x

various accessories

to

reinforce

the

versatility

of the

product (remote control,

sniffer

probe).

x

x

x

x

x

x

totally dry leak detector.

x

x

x

specific to sniffing

test

mode

applications.

x

graphic interface.

x

x

GB 00207

-

Edition 04

- June

08

Introduction to the ASM 142 series

A new generation

of

Adixen helium

leak

detector

The

ASM

142/142 D/142

S/ASM Graph/ASM Graph

D/

ASM

Graph D+ are

universal helium

leak

detectors

which

set

new

performance standards

for

multi-purpose

unit.

These detectors

are the

end-result

of an

innovative engineering

approach

utilizing the

latest electronics technologies

and

vacuum concepts,

which

make them

a truly

universal

unit:

Model photographed:

ASM

142

We

suggest

that you read this manual before you start to use

your

detector

to obtain optimum

levels

of

performance

and

complete

satisfaction.

1/

1

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

Vacuum

circuit

1

2

V

T3

3

VA1

7

18

VC

V

T2

5

8

V

S

4 VR1 VR2

VT1

Bacosol

valve

Minisol valves

15

Reference correspondence between

v

a

l

v

e

/

v

a

c

uum

block marks

E

530

1 Preamplifier

2 Analyzer cell

3

Detector

inlet port

4 Internal calibrated leak

5 Inlet

pressure

gauge

7 Vent connector

8

Long

distance sniffer connector

15

Roughing

primary pump

(RVP

20 0)

18

Detection molecular

pump (AMP

007I)

VA1 Inlet vent valve (6 points)

VR1

Roughing

valve ( point)

VR2

Roughing

valve (2 points)

VT1

Exhaust

valve (3 points)

VT2

Detection

valve (4 points)

VT3

Detection

valve (5 points)

V

S

Sniffing valve (9 points)

V

C

Calibration valve (7 points)

/4

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

Stand-by mode

3

1

2 VA1

7

18

V

T1

15

Roughing

mode

(Patm

to 10 mbar inlet

3

pressure)

5

V

R1

VR2

15

2

/4

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

Gross

leak

test

mode

(10 mbar to

5x10-1 mbar

inlet

pressure)

1

2

18

VT1

3

VR1

5

VR2

15

1

3

2

V

T3

Normal

test

mode

(lower than

5x10-1 mbar

inlet

pressure)

18

VT1

VT2

5

15

3

/4

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

Sniffing

test

mode

1

3

2

VA1

7

18

8

V

S

VT1

15

4

/4

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

Vacuum

circuit

1

2

V

T3

3

VA1

7

18

VC

V

T2

8

V

S

4

VT1

VR1

5

VR2

10 12 16

15

Bacosol

valve

Minisol valves

Reference correspondence between

v

a

l

v

e

/

v

a

c

uum

block marks

E

530

1

Preamplifier

V

A1

Inlet vent valve (6 points)

2

Analyzer cell

V

R1

Roughing

valve (1 point)

3

Detector

inlet port

V

R2

Roughing

valve (2 points)

4

Internal calibrated leak

V

T1

Exhaust

valve (3 points)

5

Inlet

pressure

gauge

V

T2

Detection

valve (4 points)

7

Vent connector

V

T3

Detection

valve (5 points)

8

Long

distance sniffer connector

V

S

Sniffing valve (9 points)

10

Outlet pump connector

V

C

Calibration valve (7 points)

12

Purge

filter

15

Roughing

pump (AMD

1

)

16

Roughing molecular

pump

(MDP

5006 HDS)

18

Detection molecular pump (AMP

007I)

1/4

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

Stand-by mode

1

2

18

3

VA1

7

V

T1

16

15

Roughing

mode

3

(Patm

to 10 mbar inlet

pressure)

5

V

R1

VR2

16

15

2

/4

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

Gross

leak

test

mode

1

3

(10 mbar to

2

5x10-1 mbar

18

inlet pressure)

5

V

T1

VR1 VR2

16

15

1

3

2

V

T2

Normal

test

mode

(lower than

5x10-1 mbar

inlet

pressure)

18

V

T1

16

VT3

5

15

3

/4

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

Sniffing

test

mode

1

2

3

VA1

7

18

V

S

8

V

T1

16

15

4

/4

A

202

ASM 142 Graph D+ detector operating

principle

GB 03710

-

Edition 01

- June

08

Vacuum

circuit

1

2

V

T3

3

VA1

7

18

VC

V

T2

8

V

S

4

VT1

VR1

5

VR2

10 12 16

15

Bacosol

valve

Minisol valves

Reference correspondence between

v

a

l

v

e

/

v

a

c

uum

block marks

E

530

1

Preamplifier

V

A1

Inlet vent valve (6 points)

2

Analyzer cell

V

R1

Roughing

valve (1 point)

3

Detector

inlet port

V

R2

Roughing

valve (2 points)

4

Internal calibrated leak

V

T1

Exhaust

valve (3 points)

5

Inlet

pressure

gauge

V

T2

Detection

valve (4 points)

7

Vent connector

V

T3

Detection

valve (5 points)

8

Long

distance sniffer connector

V

S

Sniffing valve (9 points)

10

Outlet pump connector

V

C

Calibration valve (7 points)

12

Purge

filter

15

Roughing

primary pump

(ACP

1

5)

16

Roughing molecular

pump

(MDP

5006 HDS)

18

Detection molecular pump (AMP

007I)

1/4

A

202

ASM 142 Graph D+ detector operating

principle

GB 03710

-

Edition 01

- June

08

Stand-by mode

1

2

18

3

VA1

7

V

T1

16

15

Roughing

mode

3

(Inlet pressure:

Patm

to 10 mbar)

5

V

R1

VR2

16

15

2

/4

Other manuals for ASM 142

1

This manual suits for next models

3

Table of contents

Other Adixen Security Sensor manuals