IM 01E20D01-01E

1. INTRODUCTION

(4) Maintenance

WARNING

•Maintenance of the magnetic flowmeter should

be performed by the trained personnel having

knowledge of safety standard. No operator

shall be permitted to perform any operations

relating to maintenance.

•When opening the cover, wait for more than 10

minutes after turning off the power.

• Do not open the cover in wet weather or humid

environment. When the cover is open, stated

enclosure protection is not applicable.

•Always conform to maintenance procedures

outlined in this manual. If necessary, contact

Yokogawa.

•Care should be taken to prevent the build up of

dirt, dust or other substances on the display

panel glass or data plate. If these surfaces do

get dirty, wipe them clean with a soft dry cloth.

(5) Explosion Protected Type Instrument

WARNING

•Magnetic flowmeters with the model name

AXFⵧⵧⵧC are products which have been

certified as explosion proof type instruments.

Strict limitations are applied to the structures,

installation locations, external wiring work,

maintenance and repairs, etc. of these instru-

ments. Sufficient care must be taken, as any

violation of the limitations may cause danger-

ous situations.

Be sure to read Chapter 8 “EXPLOSION

PROTECTED TYPE INSTRUMENT” before

handling the instruments. The description in

Chapter 8 is prior to the other description in this

user’s manual.

For TIIS flameproof type instruments, be sure

to read “INSTALLATION AND OPERATING

PRECAUTIONS FOR TIIS FLAMEPROOF

EQUIPMENT” at the end of this manual.

•Only trained persons use this instrument in the

industrial location.

•The protective grounding must be connected

to a suitable IS grounding system.

•Take care not to generate mechanical spark

when access to the instrument and peripheral

devices in hazardous locations.

(6) European Pressure Equipment Directive

(PED)

WARNING

•When using the instrument in compliance with

PED, be sure to read Chapter 7 before use.

1.2 Warranty

•The terms of this instrument that are guaranteed are

described in the quotation. We will make any repairs

that may become necessary during the guaranteed

term free of charge.

•Please contact our sales office if this instrument

requires repair.

•If the instrument is faulty, contact us with concrete

details about the problem and the length of time it

has been faulty, and state the model and serial

number. We would appreciate the inclusion of

drawings or additional information.

•The results of our examination will determine

whether the meter will be repaired free of charge or

on an at-cost basis.

䊏The guarantee will not apply in the following

cases:

•Damage due to negligence or insufficient mainte-

nance on the part of the customer.

•Problems or damage resulting from handling,

operation or storage that violates the intended use

and specifications.

•Problems that result from using or performing

maintenance on the instrument in a location that

does not comply with the installation location

specified by Yokogawa.

•Problems or damage resulting from repairs or

modifications not performed by Yokogawa or

someone authorized by Yokogawa.

•Problems or damage resulting from inappropriate

reinstallation after delivery.

•Problems or damage resulting from disasters such as

fires, earthquakes, storms, floods, or lightning strikes

and external causes.

䊏Trademarks:

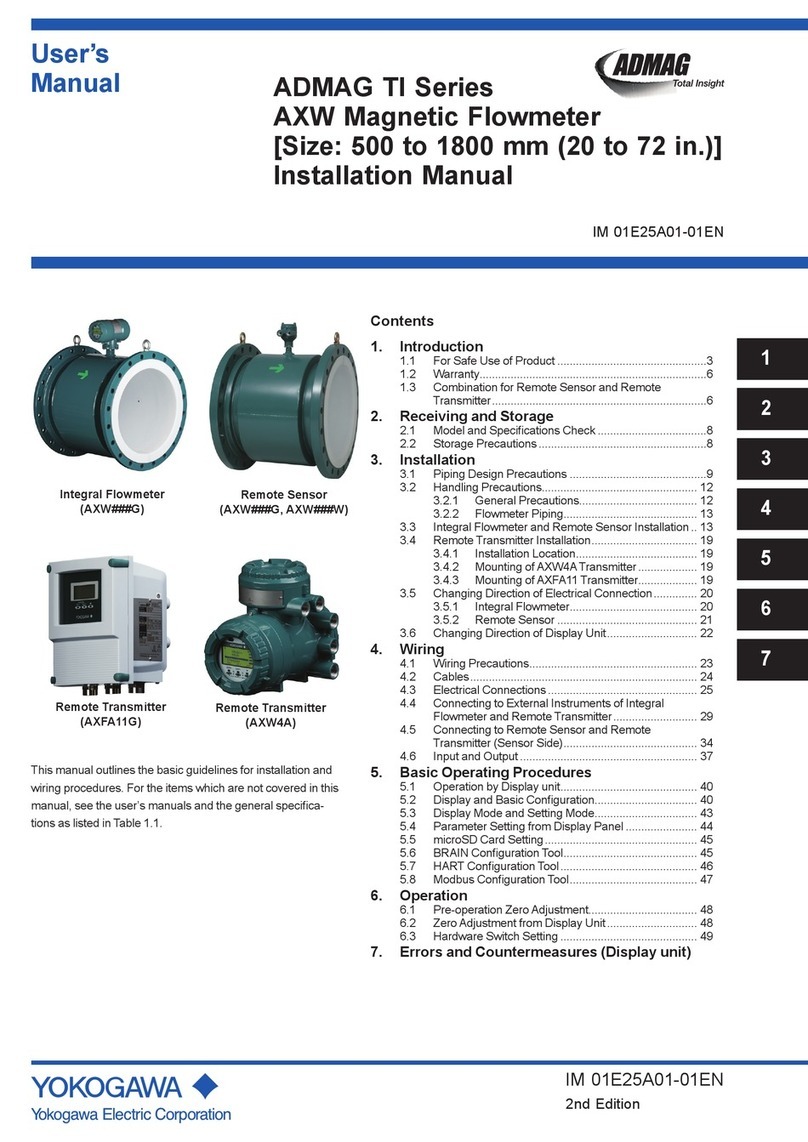

ADMAG, AXF and ADMAG AXF are registered

trademarks of Yokogawa Electric Corporation.

Company names and product names used in this

material are registered trademarks or trademarks of

their respective owners.

1-3