Adtech HCB2001 User manual

Capacitive Torch Height

Controller

HCB2001

ADTECH (Shenzhen)Technology Co.,LTD

Read this manual fully before using the

HCB2001

HCB2001 Capacitive Torch Height

www.machine-controller.com 2

Ⅰ、Brief Introduction

Our design of Capacitive Torch Height Controller HCB2001 based on over 10

years practice and various requirements from domestic CNC cutting machine

manufacturers.

HCB2001 is a closed-loop control system, with 4 parts: Position Signal Detection,

Signal Process and Transform, Logic Control and Motor Drive, suitable for flame

cutter, above water cutting below 100A plasma cutter, and laser cutting machine.

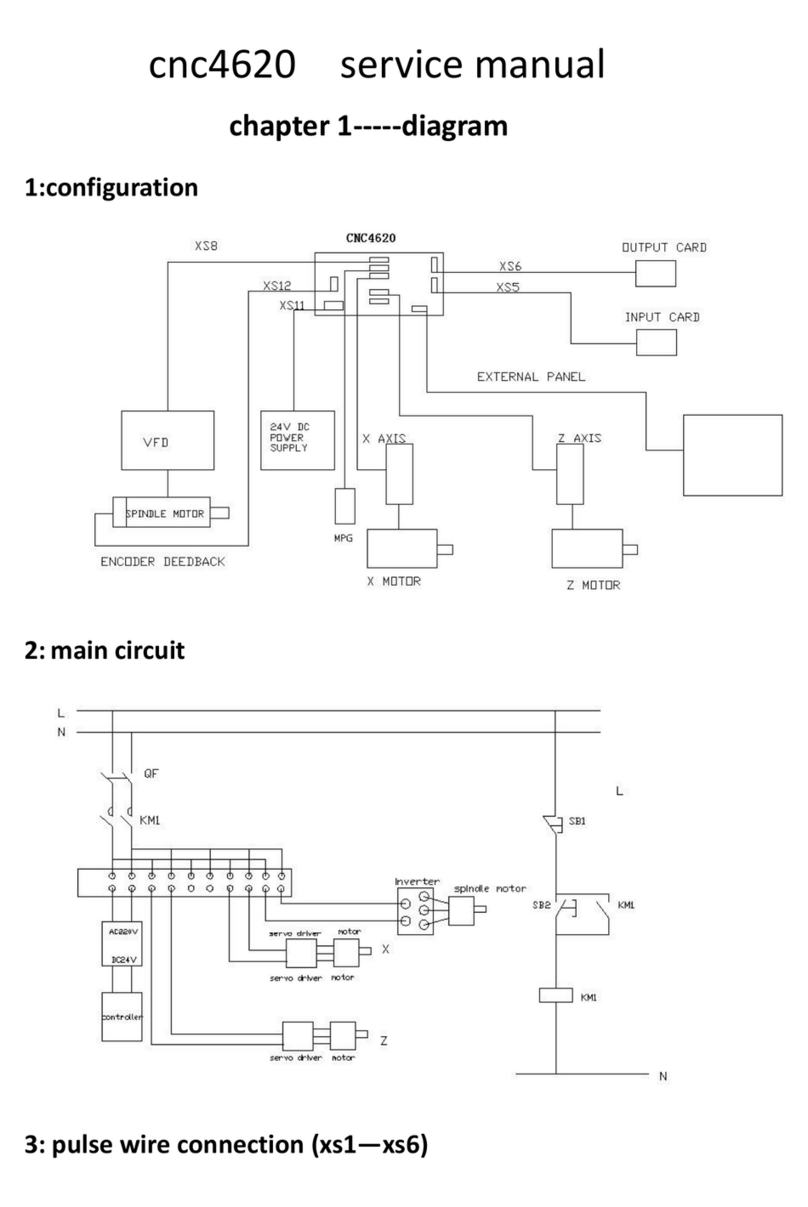

Figure 1 shows the working elements of HCB2001: The height signal detecting

device adopts capacitive sensing loop, the detecting loop has to be insulated from

cutting table and installed below cutting torch. Connect the detecting loop byside

of torch via co-axis cable, to sense the height between cutting torch and the

workpiece. HCB2001 sends out signal processed by circuit inside of it, to Logic

Control circuit, and then continues with control signal to Motor Drive circuit,

driving the lifter’s motor running accordingly to achieve the goal of adjusting

height between torch head and work piece. Motor-driving is PWM.

HCB2001 Capacitive Torch Height

www.machine-controller.com 3

I、Key features

1. Analog circuit instead of SMD Tech on our THC, PWM driving mode,

ensuring high reliability of THC.

2. Circuit-broken protection. On Auto Mode torch lift up automatically in the

situation of HF disconnected, open circuit, short circuit, avoid crashing the torch.

3. Full-closed design, waterproof, dustproof, shockproof.

4. It adopts a method of modularization design, which is convenient for

installation, commissioning and maintenance.

5. Professional circuit-protection design greatly strengthens ability of

anti-jamming. Resister and Capacitor Absorb Circuit is adopted on power

supply, preventing the interference of Surge Voltage and Harmonic Wave to THC

effectively. Pressure Sensitive Circuit protection is adopted, avoiding the damage

of over-voltage, and mis-connecting of power supply. Time-varying circuit is

adopted, avoiding the damage of over-high voltage brought by workpiece under

sensing (protection voltage>91v). Self-recovery circuit is adopted on

signal-collecting part, at this part, the detecting circuit would break off if the

current is over 1.3Ah.

6. Outside height setting, besides the HEIGHT button on operation panel, there’s

a R39⊕at the back of control box, adjusting the height when the set height is

not right.

Ⅱ、Specification

Power Supply :AC24V+10%,50Hz/60H z

lifting motor:DC24V, DC motor

output current:1A-4A

HCB2001 Capacitive Torch Height

www.machine-controller.com 4

Working temperature:

HCB2001 -10∽60℃,

High frequency coaxial-cable:-10∽200℃,

Detective component/groupware:-10∽350℃,

Accuracy:±0.2mm

Adjustment range within accuracy:from the surface of work piece: 1mm —

20mm

Max output power:150W

Length of HF-cable:200mm∽1500m

Size :Length*Width*Height:200mm*104mm*50mm

Protection range of cutting-wire:There is no protection function when the length

of HF-cable exceeds 1200mm.

Ⅲ:Appearance and Installation

1、Shape of HCB2001:

Figure 2:front panel view,

Figure 3:back sight View,

Figure 4:bottom view :installation size,

Figure 5: Back view

Figure 2 shows the shape of HCB2001.

HCB2001 Capacitive Torch Height

www.machine-controller.com 5

Figure 4 shows the installation size, the hole’s size is 5x10mm, with 4mm screw

to install. THC should be installed above and left side of cutting torch.

HCB2001 Capacitive Torch Height

www.machine-controller.com 6

2、Installation of detecting loop: According to our years practice, detecting loop

should be installed lower about 1∽2mm than torch head to avoid the edge

effect during cutting edge of workpiece, and it anti-bump more effectively, as

HCB2001 Capacitive Torch Height

www.machine-controller.com 7

showed in Figure 6. While on plasma cutting, the detecting loop shall be installed little higher

than the torch head, to avoid the effect of plasma arc voltage.

HCB2001 Capacitive Torch Height

www.machine-controller.com 8

Ⅳ:Components

As the Figure 7 shows the CHC consists of three parts: HCB2001, detecting loop

and loop groupware.

Figure 7: HCB2001 Assembly

HCB2001 Capacitive Torch Height

www.machine-controller.com 9

Ⅴ:Instruction of Operation Panel Function

1、The operation panel of HCB2001 as Figure 8 shows:

Power indication:

Auto Button:

Press the AUTO button, the HCB2001 is always on Auto Mode, no matter there

is a auto signal from outside or not. Then the demanded height can be set via

Height button, (keep pressing AUTO during this process). It greatly simplify the

setting of Auto Height Position.

During cutting, THC needs to work on Auto Mode and it should be controlled by

CNC, having nothing to do with this Auto button

Up/Down Button:

It is active on any mode. Priority is always given to Manual mode.

For UP and Down, priority’s given to UP. In case HF gets problem, it’s always

on UP mode, so the Down doesn’t work.

HCB2001 Capacitive Torch Height

www.machine-controller.com 10

Height:

It is used to adjust cutting torch’s height during Auto Mode. Height increases

when it is turned clockwise. At the first commissioning, turn clockwise maximum

to reach the highest height.

Sensitiveness:

On Auto Mode, the Sensitiveness increases when it is turned clockwise.

Detecting loop connects the socket: One end of HF Cable link with the socket, the

other end link with the probe through loop groupware.

2、Back of HCB2001:

Figure 9: Back of HCB2001

3、Spec of detecting loop: Figure 10

HCB2001 Capacitive Torch Height

www.machine-controller.com 11

HF Cable: The length of the cable can be chosen from 500mm∽1500mm requested by

clients as Figure 11 shows:

Figure 11:HF cable

HCB2001 Capacitive Torch Height

www.machine-controller.com 12

Figure 12: Installation Handle

Figure 13:Elastic Connector

Ⅵ、Interface Circuit

1、Control circuit of HCB2001

The HCB2001 consists of 2 pieces PCB, the control circuit as Figure 14

shows:

HCB2001 Capacitive Torch Height

www.machine-controller.com 13

THC consists of following connecting ports:

Connect with CNC (4Pins JP3 socket):

HCB2001 Capacitive Torch Height

www.machine-controller.com 14

HCB2001 Capacitive Torch Height

www.machine-controller.com 15

MOTOR Drive: S13 and S12 is the output of Motor Drive.

The voltage of MOTOR is DC24V.

Motor driving elements as Figure 19 shows:

Figure 19:MOTOR drive

It adopts PWM mode, the frequency of PWM ranges from 18khz and 36 khz, the

HCB2001 Capacitive Torch Height

www.machine-controller.com 16

switch operation is made by SP2-1 on the control panel. As Figure 20 shows:

Ⅶ:Connection Instruction

1、Figure 21 shows the connection of control PCB’s aviation socket.

HCB2001 Capacitive Torch Height

www.machine-controller.com 17

2、Connection Of CNC and THC (X1-CNC )

3、Connection of Down/Up limit and motor(X2-TORCH)

HCB2001 Capacitive Torch Height

www.machine-controller.com 18

5Pin Socket (plug)

Figure 23: Connection of Down/Up limited and motor

Ⅷ、Commissioning.

1. Up/Down connects with GND, motor moves up and down at maximum speed.

Auto/Manual connects with GND, THC is on Auto Mode. When it is open, the

manual mode is active. In this situation, if the detecting loop is not connected

with THC and THC is under circuit-broken protection function, cutting torch

would keep lifting up. If loop is connected with THC, the cutting torch shall stop

at a height via adjusting the Height button.

On Auto Mode, the height of cutting torch is under control of Height button. At

first commission, always turn clockwise maximum to get the highest height, then

turn anti-clockwise, the height decreases. In case over adjusted, cutting torch

touches the workpiece; motor will be on a shocking-state.

The system always drives motor to make detecting loop close to the balance

position (it stops when loop is around the balance position, 0.2m lower or higher).

The closer, the more slowly the motor runs.

Auto sensitivity meets the request of system when loop is 5—20mm away from

workpiece.

2. As the difference of cutting torch, it might be hard to find the balance position

in all range of Height adjusting. In this situation, DO NOT open the control box,

just debug the⊕of R39 +⊕at the back of HCB2001,

HCB2001 Capacitive Torch Height

www.machine-controller.com 19

As follow,

2.1. Ensure the Auto Height Control is Enabled, or press the AUTO button and

hold on.

2.2 Turn the Height button clockwise maximum, then the motor will drive loop

move, and turn Height button left and right, the balance position should be found.

Still negative, please try follow ways,

A.lift cutting torch to at least 50mm height, then put it on manual mode.

B. if previous Auto Height too low, then turn the R39 clockwise, the height will

increase. If previous Auto Height too high then turns anti-clockwise, the height

will decrease. DO NOT open control box, and DO NOT damage the R39 during

debug, every time just turn 1/4 round, and record the direction.

C. Press AUTO button and hold on, or turn on the Auto Mode of CNC, adjust the

HEIGHT button of THC, cutting torch shall stop at a position. And the adjusting

arrange changed much.

3. On Auto Mode, turn the HEIGHT button clockwise, the probe shall lift up,

anti-clockwise, it lifts down.

Note: Our THC’s already passed well commissioning. Do not change the

setting unnecessarily, especially the adjustable resistance inside like R39.

Follow are the info of the adjustable resistances.

R39---1K----Auto height setting

R47---20K----Setting the position under circuit-broken protection(HF part) .

Free Offer……………………………

To make users’ job much easier, we designed a Fixture fixing torch and detecting

loop, made of Aluminum Alloy. From May 10th, we offer it with HCB2001 on

Free Base.

HCB2001 Capacitive Torch Height

www.machine-controller.com 20

Other Adtech Controllers manuals