Adtech HCA1002 User manual

HCA1002

PLASMA HEIGHT TORCH CONTROLLER

2

1、Introduction

1.1、Product Name & Model:

HCA1002(upgrade)CNC Plasma Torch Height Controller

1.2、Basic Parameter

yWorking Voltage:AC24V+5%,50Hz/60Hz

yLifter motor- up/down:DC24V motor

yDriver mode: PWM

yOutput Current:1A-4A, Max.:6A, Load Capacity: 100W,

yWorking Temperature: -10 ∽60℃

yDivide-voltage ratio: 100:1

yControl Accuracy:±1V∽±3V

ySize:Length * Width * Height:320mm*260mm*90mm

yThe speed of lifting: 1000M/S ∽4000M/S(Contact the supplier if it exceeds the range of

speed)

1.3、Application:

HCA1002 supports mostly all plasma cutting machine on worldwide market like

Hypertherm, Thermal Dynamics etc. It includes HD Plasmas like HPR130, 260,

Ultra-cut series…. And it supports all CNC cutting controllers also. Like Hypertherm,

Burny, and industrial level controller or MACH3 such DIY controllers, because it can

start Auto Height Control with or without auto enable signal from CNC. But with Auto

enable/disable signal from CNC, THC would be work better.

1.4、Components

HCA1002 includes follow parts:

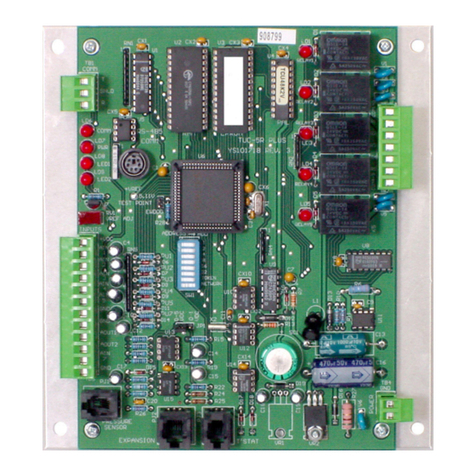

A. HCA1002 Control module;

B. Voltage Divider;

C. All related connectors.

3

1.5、Basic Functions:

A、Automatic Initial Height Sensing (IHS):

Torch Retaining Cap HIS and Proximity Switch HIS (NPN and PNP),

Proximity Switch HIS is backup for Torch Retaining Cap HIS for cutting dirty/rusty

workpiece, needing the Anti-Collision Fixture(breakaway kit).

B、Torch Anti-Collision Function:

We designed Touch-up circuit for Anti-collision function. No matter it is on Auto

Control Model or Manual Control Model, when torch head touches the workpiece,

THC would automatically lift torch up to HIS height, so with HCA1002, even in

Manual Control Model, user doesn’t need to worry about torch head crashing.

C、Freeze Auto Height Control on Corner Signal

It can recognize Corner Signal From CNC and Freeze Auto Control Model on

receiving this signal, and we have a unique design to backup this function. We set 30V

(adjustable) as Turning Point according to our years practice. When the Actual Arc

Voltage is higher than set Arc Voltage over 30V, THC Auto Control Mode freezes to

avoid torch head diving, until it goes back to 30V range. This Over Voltage protection

can avoid torch diving on voltage spikes (Corner Tuning, Kerf Crossing) Effectively.

D、Lifter Torch Up on HIS Disabled Status

On HIS disabled status, Jogging torch head down until it reaches workpiece,

when Arc Starts, Torch head would lift up automatically to the Set Height set via the button

SET-HIS.

E、Lifter Torch Up on TURN ON or ARC Off

When CNC is TURN ON or Plasma Arc Off, THC would lift torch up for 2

seconds, please notice this Function during commissioning, avoiding the possible

damage of limit switch or lift device.

F、Set Pierce Delay Time

SetButtonSet-PIERE(setPiercedelay time), to delay output this signal, it is a

4

switch signal, set to detect arc voltage lead in THC. Once THC detect arc lead in, it send

arc ok signal to CNC to start cut.

Dynamic Pierce works by receiving plasma’s Dynamic Pierce signal (Kjellbery plasma

has this signal) or plasma’s arc feedback signal. After HIS, THC controls plasma start

arc, and it lifts torch up when arc strikes. It is to protect the torch tip and electrode;

consumables can work longer in this way.

G、Manual Operation

Many functions can be Manually operated on Operation Panel of ADT-HC1002,

Such as, Set Auto/Manual Mode of THC, manually control torch Up and Down, HIS test,

Arc Start test etc.,

H、Arc Voltage Divide

Isolation Voltage Divide, the voltage divide ratio is 100:1 or 50:0. Once Isolation

voltage divide function damaged, user can also use Non-Isolation Voltage Divide on your

voltage divider.

1.1、Basic Functions:

1.6.1 Work with HIS

When CNC send out Arc Start Signal(HIS enabled), THC starts with HIS, then send

Arc Start signal to plasma, after plasma start, THC delay lead in arc voltage from plasma (Set

pierce delay time), THC send arc feedback (Arc ok) Signal to CNC to Start Cut after arc

voltage lead in. If THC is on auto model, and CNC auto Control enabled, the cutting is under

THC Auto control.

We don’t recommend work without IHS

5

2、Commission & Set

2.1、Operation Panel Introduction

Arc Voltage

Before Arc Start it shows the Set Arc voltage, after it shows the Actual Arc Voltage.

Arc-Voltage Setting

Based on the thickness of steel plate being cut and cutting speed, it shall be set according to

the parameter offered by plasma, and it will be showed on operation panel. Set arc voltage

decides the torch height during cut; the higher the arc is the higher the torch height will be.

On auto mode, adjust the set voltage means adjusting the torch height.

Pierce HEIGHT

Increase on clock –wise turn, decrease on anto-clockwise. Pierce height means torch lift up

height after receiving dynamic pierce signal from plasma or arc feedback signal from plasma.

It is used on cutting thick material. If the dynamic pierce signal is disconnected, this function

is disabled.

6

HIS HEIGHT

Set Initial Height, Turn clockwise, the height increase

PIERCING DELAY

Set the Delay Time from plasma start to CNC start cut (delay lead in arc voltage into THC),

the arc feedback (Arc ok) signal would be sent to CNC only after arc voltage is detected by

THC.

HIS –Test

Press one time, it would check HIS on time, which is used to check whether it is a workable

HIS or not.

AUTO

Set THC Auto or Manual mode. Meanwhile enables the Auto Signal between connectors of

CNC and THC, (for EDGE system, the Auto signal shall be connected as Normally Closed).

ARCON TEST

Press and hold, to test the Plasma Start, during test, Torch lifts up and HIS height.

Up and Down

Manual operation button of Up and Down, It is effective on any mode.

Indicators

Down Indicator: Turn on when torch lift down.

Collision Indicator: Turn on when torch touch workpiece or proximity switch effective.

TRANS Indicator: Turn when THC receives arc feedback signal, and sent out Arc OK

signal to CNC.

AUTO Indicator: On means THC is on Auto Mode, Four Conditions have to be completed:

1. CNC Auto Height Control (THC) enables;

7

2. THC is on Auto Model;

3. Arc voltage has been lead in THC;

4. Actual Arc Voltage not higher than Set Arc Voltage over 30V.

Note:

A. When THC on Auto Mode, the 5 indicators all should be ON, if anyone is OFF, that

means Auto Mode failed, please check the reason according to indicators.

B. There are 6 indicators on Operation panel, demo THC from Torch down - Touch

workpierce - arc start-arc feedback - Auto on, please check the failure reason from

the one by one step.

2.2、Voltage divider

Our Voltage Divider offers tow modes of Voltage Divide; None Isolation Voltage

Divide is backup for Isolation Voltage Divide.

2.2.1 None Isolation Voltage Divide

Note: Plasma Output positive pole is GND, negative pole connected with electrode in

torch. DO NOT mis-connected, or THC will be Un-effective.

As none isolation voltage divide is directly connected with plasma power supply, to

enable THC escape from interference caused by the HF during Plasma Arc Start, the Divide

Arc Voltage guided into THC is Time-Delayed.

It just needs to prolong the time of lead Arc Voltage into THC, the interference can be

avoid effectively.

As shoed in figure 2-2

8

2.2.1 None Isolation Voltage Divide

Plasma Arc Voltage is divided by Voltage Divider (offered with THC) on 100:1 none

isolate voltage divide, lead into THC after processed by Isolation Circuit. Arc Voltage has

little effect on THC after Isolation Circuit. This voltage divider can be connected as Isolation

Voltage Divider or Non Isolation Voltage Divide mode.

As showed in figure 2-3

9

Note: Non Isolation Voltage Divide is backup for Isolation Voltage Divide. On

Non Isolation Voltage Divide, AC220V power can be unconnected; but it must be

connected on isolation voltage divide.

2.3 HIS

2.3.1 None Isolation Voltage Divide

10

The Torch Retaining Cap should be metal, so the metal can be electric conducted with

steel plate. It has a piece of Isolated HIS plate that can be fixed in the THC directly, the

connection showed as Figure 2-4 below:

Torch Retaining Cap HIS

THC receives arc start signal from CNC, lift torch down, when torch retaining cap

torches steel, THC lift torch up to set HIS height, After HIS, THC control plasma to start

arc.

Note:

A. The cable from SHIELD (marked as shield on THC) to torch retaining cap.

11

B. The GND must be well grounded WORK must connected with ground, and

the grounding cable must be > 4mm2

C. The cable connected to retaining cap must be Height Voltage cable.

2.3.2 Proximity Switch HIS

HCA1002 supports torch retaining cap HIS and proximity switch HIS both. We

recommend proximity switch HIS, which can be HIS and anti-collision function job both,

especially cutting rusty/painted steel,

Proximity switches HIS uses 3-pin connector, named on THC “Switch HIS”, Pin

definition as follow:

It uses 2 Proximity switch connected as above drawing, any one of then effective, THC

can receive this signal, as figure 2-6 shows:

Note: In side THC, a 250mA Recoverable Fuse is installed at the power supply of

proximity switch, to avoid damage of power when proximity switch failed.

Work Process: Once THC received Arc Start signal from CNC, torch moves down, when

it reaches workpiece, Proximity Switch leaves proximity position, THC receives the

signal, lifts torch to the set height,( proximity Switch recovers during lifting). After HIS,

THC drives plasma Start Arc.

Proximity Switch HIS is suitable for all plasma

HIS

12

3、Wiring Introduction:

Introduction HCA1002 Connector’s wiring details,

13

3.1、Power

HCA1002 works under AC24V

Socket as right picture Power

3.2 Motor Port

HCA1002 use DC24V motor as drive output,

14

Socket shows as right picture TO TORCH

3.2.1 TO TORCH

3.2.2 Drive Current & Set

The relationship between adjusting the SP2 current and the ON/OFF of Switch

15

3.3 To CNC

HCA1002 connect to CNC via a 10-pin socket

Shows as right picture To CNC

16

3.4 To plasma

HCA1002 Connects to Plasma via 4-pin socket,

Marked as TO PLASMA

17

3.5 Proximity Switch HIS Port

HCA1002 Proximity switch HIS port is 3-pin socket,

Marked as SWITCH HIS,

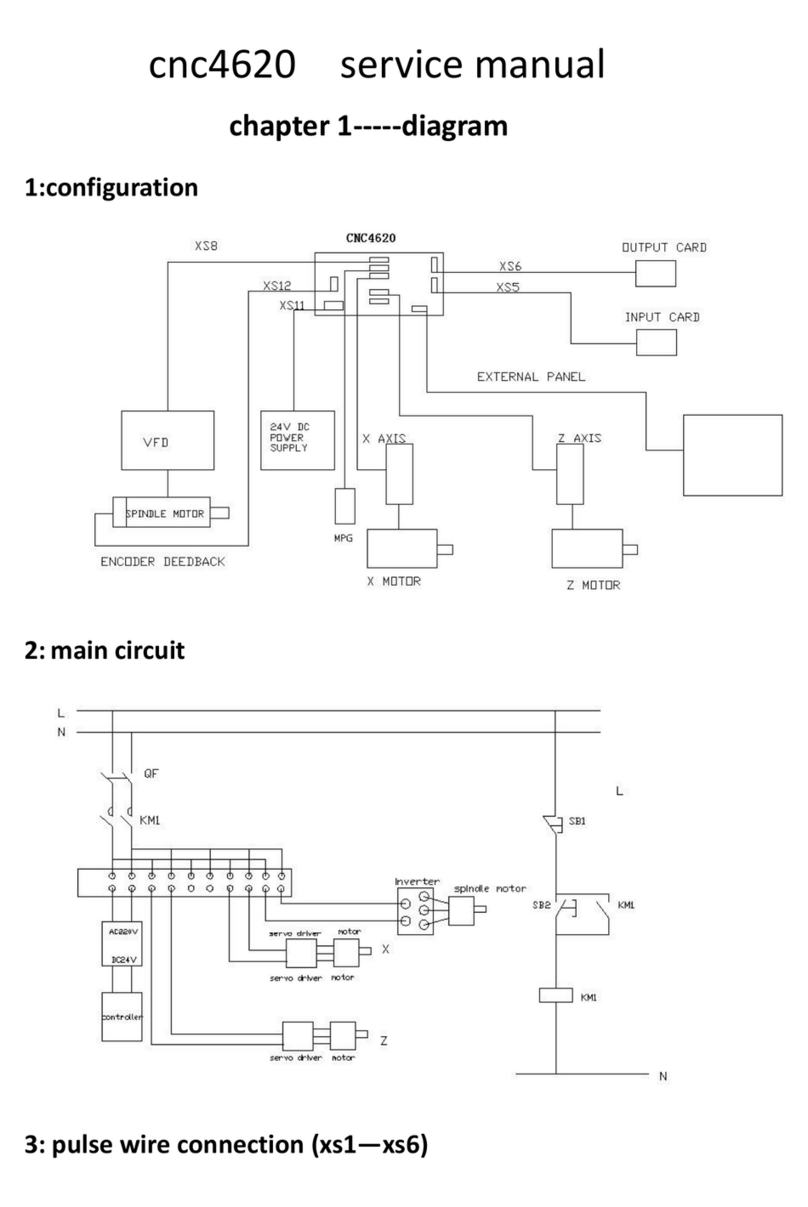

4、THC wiring diagram

18

HCA1002 Wiring Diagram

19

5、Maintenance

20

Table of contents

Other Adtech Controllers manuals