Adtech ADT-CNC4620 User manual

ADT-CNC4640

CNC46XX Series CNC System

Maintenance Manual

Adtech(Shenzhen)CNCTechnologyCo.,Ltd.

Add: 5/F, Bldg/27-29, Tianxia IC Industrial Park, Yiyuan Rd, Nanshan District, Shenzhen

Postal code: 518052

Tel: 0755-26722719 Fax: 0755-26722718

E-mail: export@machine-controller http://www.machine-controller.com

CNC4640 Maintenance Manual

1-- 2 -

Copyright

Adtech (Shenzhen) Technology Co., Ltd. (Adtech hereafter) is in possession of the

copyright of this manual. Without the permission of Adtech, the imitation, copy,

transcription and translation by any organization or individual are prohibited. This

manual doesn’t contain any assurance, stance or implication in any form. Adtech

and the employees are not responsible for any direct or indirect data disclosure,

profits loss or cause termination caused by this manual or any information about

mentioned products in this manual. In addition, the products and data in this

manual are subject to changes without prior notice.

All rights reserved.

Adtech (Shenzhen) Technology Co., Ltd.

CNC4640 Maintenance Manual

1-- 3 -

Version History

Item No. First uploaded on Version No. Pages Compiled by Typeset by

XT20100819 2011-3-01 A0101 119 Yang Jipeng Yang Jipeng

XT20100819 2011-9-22 A0201 102 Yang Jipeng Yang Jipeng

Revision

Date Version/Page Result Confirmed by

Remark:

We have collated and checked this Manual strictly, but we can’t ensure that there are no error and

omission in this Manual.

Due to constant improvement of product functions and service quality, any products and software

described in this manual and the content of the manual are subject to changes without prior notice.

Adtech CNC Technology Co., Ltd. Contents

I

Contents

1. Foreword............................................................................................................................- 3 -

2. System technical characteristics ......................................................................................- 3 -

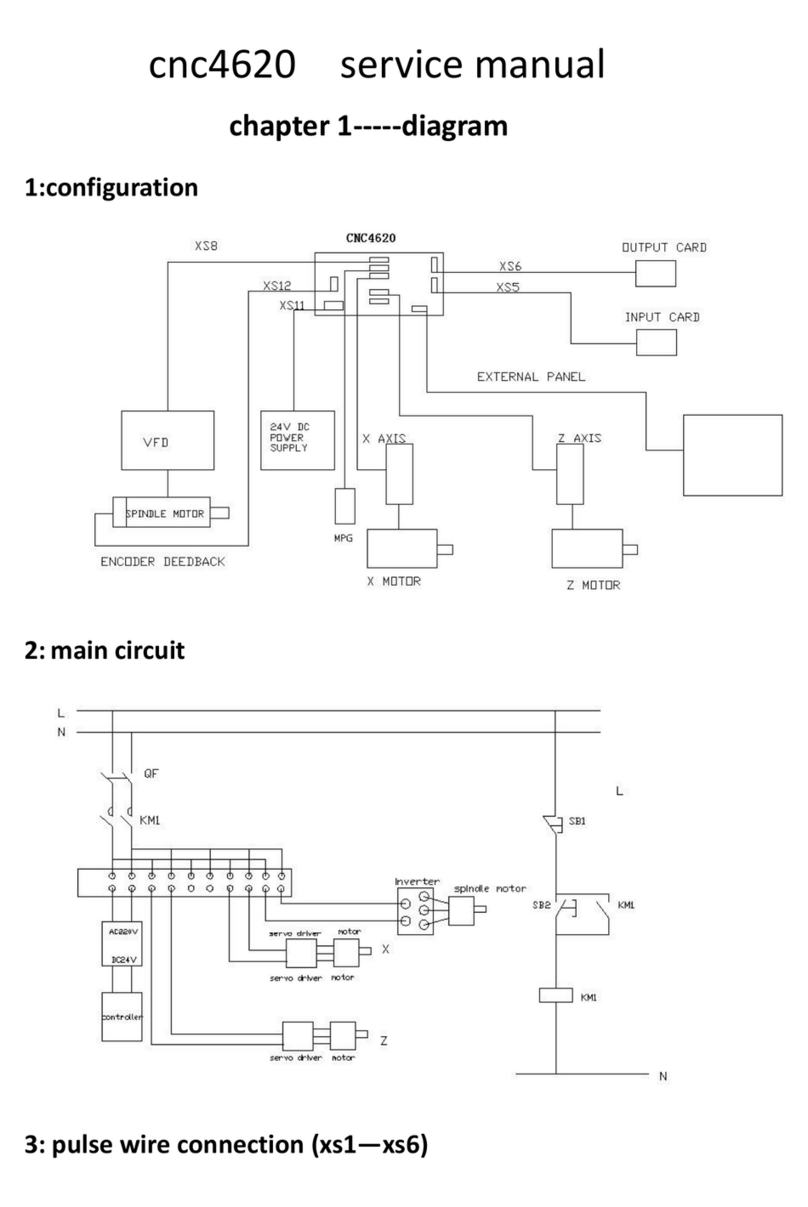

2.1 System structure .................................................................................................................................- 3 -

2.2 System technical parameters ..............................................................................................................- 3 -

2.3 System function..................................................................................................................................- 5 -

2.3.1 Self-diagnosis....................................................................................................................................................- 5 -

2.3.2 Compensation ...................................................................................................................................................- 5 -

2.3.3 Abundant instruction system............................................................................................................................. - 5 -

2.3.4 Full Chinese menu operation & full screen edit................................................................................................ - 5 -

2.3.5 Abundant error-correction functions ................................................................................................................. - 5 -

2.3.6 Program exchange between CNC system and PC............................................................................................. - 5 -

2.4 System operating condition ................................................................................................................- 5 -

3. Operating panel.................................................................................................................- 6 -

3.1 LCD/keypad .......................................................................................................................................- 6 -

3.2 LCD brightness adjustment................................................................................................................- 7 -

3.3 System menus.....................................................................................................................................- 8 -

3.4 Operating keys..................................................................................................................................- 11 -

4. Manual operation............................................................................................................ - 12 -

4.1 Returning to reference point manually.............................................................................................- 12 -

4.2 Continuous feeding manually...........................................................................................................- 13 -

4.3 Single step feeding ...........................................................................................................................- 13 -

4.4 Handwheel feeding...........................................................................................................................- 13 -

4.5 Manual auxiliary function operation ................................................................................................- 14 -

4.6 Tool setting .......................................................................................................................................- 15 -

4.6.1 Centered (M series).........................................................................................................................................- 15 -

4.6.2 Tool regulator (M series)................................................................................................................................. - 16 -

4.6.3 Tool setting by test cutting (L series) .............................................................................................................. - 17 -

4.7 Data settings .....................................................................................................................................- 17 -

4.7.1 Tool compensation data setting .......................................................................................................................- 17 -

4.7.2 System parameter setting ................................................................................................................................ - 17 -

5. Automatic operation .......................................................................................................- 18 -

5.1 Memory operation ............................................................................................................................- 18 -

5.2 MDI operation ..................................................................................................................................- 18 -

5.3 USB disk DNC .................................................................................................................................- 18 -

5.4 Speed rate adjustment.......................................................................................................................- 18 -

5.5 Run idle ............................................................................................................................................- 19 -

5.6 SBK function....................................................................................................................................- 19 -

5.7 BDT function....................................................................................................................................- 19 -

5.8 Stopping automatic operating...........................................................................................................- 19 -

6. Safe operation..................................................................................................................- 20 -

6.1 Emergency stop ................................................................................................................................- 20 -

6.2 Hard limit over travel .......................................................................................................................- 20 -

6.3 Soft limit over travel ........................................................................................................................- 20 -

7. Alarm and self- diagnosis function................................................................................- 21 -

7.1 NC program execution alarm ...........................................................................................................- 21 -

7.2 System environment alarm...............................................................................................................- 22 -

7.3 Alarm processing..............................................................................................................................- 23 -

7.4 Self-diagnosis function.....................................................................................................................- 24 -

8. Program saving & editing...............................................................................................- 25 -

8.1 Saving the program in the memory ..................................................................................................- 25 -

8.1.1 Keypad input (new program) .......................................................................................................................... - 25 -

8.1.2 PC serial port input .........................................................................................................................................- 25 -

8.1.3 Copying processing files from USB disk........................................................................................................ - 25 -

8.2 Reading programs into work area ....................................................................................................- 25 -

8.2.1 Reading programs from controller into work area .......................................................................................... - 25 -

8.2.2 Reading programs from USB disk into work area .......................................................................................... - 25 -

8.3 Editing & modifying programs ........................................................................................................- 25 -

8.4 Deleting files ....................................................................................................................................- 26 -

8.4.1 Deleting files in memory................................................................................................................................. - 26 -

9. Main interfaces of the system.........................................................................................- 27 -

ADT-CNC46XX 系列维护手册

II

9.1 Position interface ............................................................................................................................. - 27 -

9.2 Edit interface.................................................................................................................................... - 29 -

9.3 MDI interface .................................................................................................................................. - 30 -

9.4 File management.............................................................................................................................. - 31 -

9.5 Graphic simulation........................................................................................................................... - 31 -

9.6 Parameter interface .......................................................................................................................... - 32 -

9.7 Compensation interface ................................................................................................................... - 35 -

9.8 M series workpiece coordinate system setting interface.................................................................. - 36 -

9.9 Controller diagnosis interface (diagnosis) ....................................................................................... - 39 -

9.10 Macro variable view interface (macro variable)............................................................................ - 39 -

9.11 Current mode instruction info........................................................................................................ - 40 -

10. System maintenance........................................................................................................ - 41 -

10.1 Restart............................................................................................................................................ - 41 -

10.2 System upgrade.............................................................................................................................. - 41 -

10.3 Reset .............................................................................................................................................. - 41 -

10.4 Parameter backup and restore........................................................................................................ - 41 -

10.5 Entering BIOS ............................................................................................................................... - 41 -

11. System parameters.......................................................................................................... - 42 -

11.1 Parameter index list ....................................................................................................................... - 42 -

11.2 Comprehensive parameters (P1.) ................................................................................................... - 52 -

11.3 Axis parameter configuration (P2.)................................................................................................ - 62 -

11.4 Management parameters (P3.) ....................................................................................................... - 69 -

11.5 Tool magazine parameters (P4.)..................................................................................................... - 72 -

11.6 Principal axis parameters (P5.) ...................................................................................................... - 73 -

11.7 Port configuration (P6.) ................................................................................................................. - 74 -

12. Hardware interface definition and connection instructions ....................................... - 76 -

12.1 Installation layout .......................................................................................................................... - 76 -

12.1.1 External interface diagram ............................................................................................................................- 76 -

12.1.2 Mounting dimensions....................................................................................................................................- 77 -

12.1.3 Installation precautions .................................................................................................................................- 78 -

12.2 Interface definition......................................................................................................................... - 80 -

12.2.1 Motor drive control interface (XS1..XS4).....................................................................................................- 80 -

12.2.2 Digital input interface (XS5).........................................................................................................................- 83 -

12.2.3 Digital output interface (XS6).......................................................................................................................- 86 -

12.2.4 Handheld box interface (XS7).......................................................................................................................- 89 -

12.2.5 Analog output interface (XS8) ......................................................................................................................- 90 -

12.2.6 Principal axis encoder interface (XS12)........................................................................................................- 91 -

12.2.7 RS232 transmission interface (XS9) .............................................................................................................- 93 -

12.2.8 USB memory connection interface (XS10)...................................................................................................- 93 -

12.2.9 PC USB communication interface (XS11) ....................................................................................................- 93 -

12.3 Electrical connection diagram ....................................................................................................... - 94 -

12.3.1 Symbol schematic diagram ...........................................................................................................................- 94 -

12.3.2 Power connection diagram ............................................................................................................................- 95 -

12.3.3 Servo drive connection diagram....................................................................................................................- 96 -

12.3.4 Step connection diagram ...............................................................................................................................- 97 -

12.3.5 IO electrical connection diagram...................................................................................................................- 98 -

Adtech CNC Technology Co., Ltd. 1. Program saving & editing

- 3 -

1. Foreword

CNC4640/4620 numerical control system is economic embedded system developed by Adtech (Shenzhen)

CNC Technology Co., Ltd. for milling machines and machining centers, where CNC4640 is four axes motion

controller and CNC4620 is two axes motion controller.

Instructions and reading convention of the Manual

Before using this CNC system, please read this Manual carefully to operate properly.

Terminology note and reading convention in this Manual:

CNC4640 and CNC4620 are control systems with different axes and same hardware functions. The programs

developed on this platform contain M series software for milling machines and L series software for lathes.

Different software has different functions and masks.

M series are system for milling machine motion. The ‘M’ or “M series” mark indicates specific interface or

function for milling machine software system.

L series are system for lathe motion. The ‘L’ or “L series” mark indicates specific interface or function for lathe

software system.

“CNC system”, “NC controller” and “CNC46XX” mentioned in this Manual all refer to CNC4640/4620;

The articles marked with “Caution” prompt users to pay special attention for operation or setting, or else this

operation may fail or certain action can’t be performed.

2. System technical characteristics

2.1 System structure

¾CPU: ARM industrial mainboard;

¾Communication: USB interface;

¾Capacity: 64MB RAM, 60M Flash ROM;

¾Feedback: AB phase pulse feedback;

¾Control: FPGA motion controller;

¾Hand pulse: Incremental hand encoder;

¾Display: 800×480 pixels 7” LCD;

¾I/O full optical coupling isolation;

¾Touch/film type operation panel;

¾Highly anti-interference switching power supply;

¾RS232 interface

2.2 System technical parameters

Function Name Specification

Control axes 4 axes (CNC4640 series)

2 axes (CNC4620 series)

Control axis

Simultaneous control axes

4 axes linear interpolation (CNC4640

series)

2 axes linear interpolation (CNC4620

series)

2 axes arc interpolation

Minimum setting unit 0.001mm

Minimum moving unit 0.001mm

Input instruction

Maximum instruction value ±9999.999mm

Adtech CNC Technology Co., Ltd. 2. Program saving & editing

- 4 -

Function Name Specification

Fast feeding speed X axis, Y axis, Z axis, A axis: 9999

mm/min (maximum)

Per minute 1~9999mm/min

Feeding speed range Per rotation 1~500rpm

Automatic acceleration/deceleration Yes

Feeding

Feeding speed rate 10~150%

Continuously manual feeding, Yes

Returning to reference point manually

All control axes return to reference point

simultaneously

(allow setting order of priority)

Manual

Single step/handwheel function Yes

Interpolation Positioning, linear interpolation, arc

interpolation

G00, G01, G02/G03

Operating mode MDI, auto, manual, single step, edit Yes

Testing function Test run, single program section, Handwheel Yes

Pause (sec/ms) G04 X/P_

Coordinate system setting G92 (M series)

G50 (L series)

Coordinate system and

pause

Automatic coordinate system setting Yes

Soft & hard limit check Yes

Safe functions Emergency stop Yes

Program storage Program storage capacity, storage quantity

Capacity: 60MB

100 work areas

No limit on processing file quantity

Program edit

Insert, modify, delete, cancel

Program No., sequence No., address,

character retrieval

Yes

Program edit

Decimal point programming Yes

800×480 pixels 7” LCD

Display Position screen, program edit

Tool compensation setting, alarm display

Handwheel test, diagnosis screen

Parameter setting, graphic simulation

Yes

Auxiliary function M code

Principal axis function

S0-S15 (gear position control)

S15-S99999 (analog)

M, S, T function

Tool function T code

Tool compensation memory

30 tools length, radius compensation

Compensation function

Reverse clearance compensation Yes

Measurement centered

Automatic tool regulator Yes

Specify arc radius R/center position Yes

Other functions

Electronic gear ratio Yes

Adtech CNC Technology Co., Ltd. 2. Program saving & editing

- 5 -

2.3 System function

2.3.1 Self-diagnosis

Diagnose CPU, memory, LCD, I/O interface, parameter state, coordinates and processing program

comprehensively every time the system is started or reset; diagnose power supply, principal axis, limit and I/O

ports in real-time during operating.

2.3.2 Compensation

Automatic reverse clearance compensation

Automatic tool length compensation

Automatic tool radius compensation

Automatic tool radius biasing and automatic tool tip transition

2.3.3 Abundant instruction system

Scaling instruction

Mirror processing instruction

Tool biasing instructions

Program cycle, program skip, program shift, program transfer, different end processing modes, macro

definition and program management instructions

Fixed-point instructions: starting point, setting point, etc.

Linear, arc and spiral interpolation instructions

Six workpiece coordinate systems, nine extension coordinate systems and one reference point

2.3.4 Full Chinese menu operation & full screen edit

4640/4620 CNC system uses cascading menu structure and full Chinese operation to ensure simple

operation and visibility.

2.3.5 Abundant error-correction functions

Point out the nature and correct the errors in operation.

2.3.6 Program exchange between CNC system and PC

Perform CAD/CAM/CAPP auxiliary programming with abundant software in PC, and then transmit CNC

program to the system through communication interface (USB disk, RS232 interface), or transmit the

programs from the system to PC.

2.4 System operating condition

Operating voltage 24V DC (with filter)

Operating temperature 0℃— 45℃

Optimum operating temperature 5℃— 40℃

Operating humidity 10%——90% (no condensing)

Optimum operating humidity 20%——85%

Storage temperature 0℃—50℃

Storage humidity 10%——90%

Operating environment No excessive dust, acid, alkali, corrosive and explosive gases, no strong

electromagnetic interference

Adtech CNC Technology Co., Ltd. 3. Program saving & editing

- 6 -

3. Operating panel

3.1 LCD/keypad

Keypad

Fig. 3.1 CNC4640 Operating Panel Diagram

Note:

Press the submenu buttons to perform the operations of submenus.

Manual axis moving and edit & input are composite. It has different definitions according to the modes.

System working mode switch section is used to switch working modes, which can improve the security

and system performance. Handwheel and single step mode are switched with Repeat button.

Adtech CNC Technology Co., Ltd. 3. Operating panel

- 7 -

LCD unit

Fig. 3.2 CNC4640 LCD Screen Diagram

Note:

Screen info shows the information of current window

Working mode info shows currently selected working mode

System main screen shows current main screen.

The submenu options are used to switch submenus with left triangle, F1~F6 and right triangle. The right

arrow is used to turn pages, and the left arrow is used to close the submenus in next level and previous menu.

3.2 LCD brightness adjustment

CNC46XX doesn’t support brightness adjustment.

Adtech CNC Technology Co., Ltd. 3. Program saving & editing

- 8 -

3.3 System menus

CNC46XX system uses cascading menu structure. You can press the following keys to operate the menus.

Press a key to show the corresponding content in the bottom of the LCD.

Key in the left: Return to previous menu

Key in the right: Turn pages to show other menus of same level

The main menus of the system include [Monitor], [Edit], [Parameter], [Coordinate] and [Diagnosis]. Each

main menu contains several submenus, which are shown below:

[Edit]

[Program Edit]

[File]

[Monitor]

[Position]

[Track]

[MDI]

[Absolute Position]

[Relative Position]

[Comprehensive

P iti ]

[Preview]

[Select Plane]

Adtech CNC Technology Co., Ltd. 3. Operating panel

- 9 -

L Series [Coordinates]

[Compensation]

[Tool Setting for Test

Cutting]

M Series [Coordinates]

[Coordinate Setting]

[Compensation]

[Coordinate Parameter]

[Centered Measurement]

[Tool Regulator]

[Measurement]

[Parameter]

[Comprehensive

Parameter]

[Axis Configuration]

[Management]

[Tool Magazine]

[Principal Axis]

[Port]

Adtech CNC Technology Co., Ltd. 3. Program saving & editing

- 10 -

[Diagnosis]

[Alarm Info]

[Input Diagnosis]

[Output Diagnosis]

[DA Diagnosis]

Adtech CNC Technology Co., Ltd. 3. Operating panel

- 11 -

3.4 Operating keys

The keys of CNC46XX system are defined below:

Key Purpose

[RESET] Cancel alarm, reset CNC

Address/number keys Enter letters, numbers, etc.

[EOB], [CAN] Confirm or cancel operation

[EOB], [CAN], [DEL] Program edit (insert, delete, modify)

Mode switch key Select operating mode

Cursor moving key Four keys are available: Up/Down: adjust ration, move

cursor between subsections; Left/Right: move cursor to

left/right

Page key Up/Down: Turn pages

Menu keys Select the menus

Principal axis positive rotation Press it to rotate the principal axis positively, and press it

again to stop rotating

Principal axis reverse rotation Press it to rotate the principal axis reversely, and press it

again to stop rotating

Coolant Coolant on/off

Lubricant Lubricant on/off

[BDT] Block delete on/off

[SBK] Single block function on/off

[PAUSE] Pause automatic running

[START] Start automatic running

Adtech CNC Technology Co., Ltd. 4. Manual operation

- 12 -

4. Manual operation

4.1 Returning to reference point manually

CNC machine tool has specific mechanical position, which is called as reference point and for tool

exchange and coordinates setting. Generally, when the power supply is connected, the tool should be moved to

the reference point. This operation is also called as home operation, which will make the CNC system confirm

the origin of machine tool.

The home operation includes program and mechanical mode:

For program home, the action completes when the coordinates of machine tool are 0, and won’t check

whether origin switch is in position;

For mechanical home, the external home sensor switch is used to locate the origin of the machine tool;

two checking modes are available:

With the external sensor switch, the home operation completes when the sensing is successfully

repeatedly.

The external sensor switch is used as deceleration switch, the servo home is enabled as home signal after

sensing and then the sensing stops.

You can set the “Home mode” in [Parameter][Comprehensive Parameter], in which 0 (default) indicates

program and 1 indicates mechanical. You can also press [SBK] key in home mode to switch among

“Mechanical – Program – Mechanical…” quickly. This method doesn’t conflict with parameter setting. You

can select accordingly. To use servo home as the home signal, you need to set “Axis phase Z home enable” to

“1” in [Parameter][Axis Configuration] in mechanical home mode, and the setting will take effect in next

home checking.

Several methods are available for tool returning to reference point and the steps follow:

⑴Each axis returns to reference point separately

¾Press the mode switch key [Home] to select home operation;

¾Press the composite key [X-], [Y-], [Z-], [A-] in the numbers section to return the corresponding axis to reference point.

⑵The axes return to reference point simultaneously

¾Press the mode switch key [Home] to select home operation;

¾Press the [Start] key to return Z axis to reference point, and other axes return to reference point simultaneously. The

automatic home sequence can be configured in the parameters.

⑶Reset machine tool position

¾Press the mode switch key [Home] to select home operation;

¾In [Absolute Position] and [Coordinate System] screen, press [X], [Y], [Z], [A] respectively to show the value of

corresponding axis position, and then press the [Cancel] key to reset the machine tool position of current axis, i.e.

current point is used as machine tool origin. After this operation, the system considers it as a home action. Therefore,

when the program is running, the alarm of not home won’t occur. If you press by mistake, it will switch the screen and

cancel selection automatically.

⑷Reset relative position manually

¾Press the mode switch key [Manual] to select manual operation;

¾In [Relative Position] and [Coordinate System] screen, press [X], [Y], [Z], [A] respectively to show the value of

corresponding axis, and then press the [Cancel] key to reset the relative position of current axis.

)Note

The tool also can return to reference point according to program instruction, i.e. returning to reference point automatically.

0Caution:

Generally, the system will perform home operation after connecting the power supply. If the power fails while the machine

tool is moving, the system also will return to reference point when the power supply is connected again. Return to Z axis to

prevent tool and workpiece from colliding, and damaging tool, workpiece and clamp.

Adtech CNC Technology Co., Ltd. 4. Manual operation

- 13 -

4.2 Continuous feeding manually

Press the keys on the operation panel or handwheel to move the tool along every axis.

The operation follows:

⑴Press the mode switch key [Manual] to select manual operation;

⑵Press composite keys [X+], [X-]; [Y+], [Y-]; [Z+], [Z-]; [A+], [A-] in numbers area to move the tool

along selected axis. The keypad follows:

In manual mode, 5# key can be used to switch the manual speed and rapid traverse speed. The rapid

traverse speed of every axis depends on comprehensive parameter 009-012 (rapid traverse speed setting). After

switching to rapid traverse speed, the manual speed of the position interface will be highlighted, while the

actual speed of the position interface is sampled from the moving speed of current axis. This value can truly

reflect the moving speed of current axis (unit: mm/min);

)Note

Only single axis motion is available in manual mode.

4.3 Single step feeding

Single step mode is similar to manual mode, the operations are same, but only moves a specified pulse

increment every time press the key.

The specific operation follows:

⑴Press the mode switch key [Handwheel/Single step] (this key is composite, and you can press it

repeatedly to switch the modes) to select the single step operation;

⑵Press composite keys [X+], [X-]; [Y+], [Y-]; [Z+], [Z-]; [A+], [A-] in numbers area to move the tool

for a fixed distance along the selected axis. This distance is controlled by four rates (1.000, 0.100, 0.010, 0.001)

(unit: mm). To select pulse increment, press Up (+) and Down (-) key in the [Position] interface.

4.4 Handwheel feeding

In handwheel mode, rotate the handwheel to make the machine perform single step or continuous motion.

Determine the feed by testing the handwheel signal of the handheld box. In handwheel mode, the feeding axis

and feeding unit are determined by the axis selection signal of the handheld box.

The handwheel feeding step follows:

⑴Press the mode switch key [Handwheel/Single step] to select handwheel operation;

⑵Rotate the dip switch on the handwheel to select handhweel axis (X, Y, Z, A);

⑶Rotate the increment dip switch on the handwheel to select the moving amount (0.1, 0.01, 0.001);

⑷Rotate the handwheel to move the machine tool. The tool moves certain distance every time you rotate

the handwheel for a scale. (For example, if you select X axis in step ⑵and select 0.01 in step ⑶, the tool

moves 0.01mm every scale). Rotate the handle continuously to move the machine tool on this axis

continuously.

)Note

The handwheel feeding mode controls only one coordinate axis every time; the faster the handwheel rotates, the faster the

machine tool moves.

Adtech CNC Technology Co., Ltd. 4. Manual operation

- 14 -

4.5 Manual auxiliary function operation

Coolant on/off

In handwheel/single step/manual mode, press this key to switch on/off the coolant.

Key indicator: No matter in what mode, the key indicator is on if only the coolant is on, or else the

indicator is off.

Lubricant on/off

In handwheel/single step/manual mode, press this key to switch on/off the lubricant.

Key indicator: No matter in what mode, the key indicator is on if only the lubricant is on, or else the

indicator is off.

Principal axis positive rotation/stop

In handwheel/single step/manual mode, press this key to rotate the principal axis positively and

press it again to stop the axis.

Key indicator: No matter in what mode, the key indicator is on if only the principal axis is positive

rotating, or else the indicator is off.

Principal axis reverse rotation/stop

In handwheel/single step/manual mode, press this key to rotate the principal axis reversely and

press it again to stop the axis.

Key indicator: No matter in what mode, the key indicator is on if only the principal axis is reverse

rotating, or else the indicator is off.

General instructions for manual operation keys

Cooling, lubricant, principal axis positive/reverse rotation are available in handwheel, single step and

manual mode;

When the principal axis is rotating, press the reverse rotation key, the principal axis will stop first, and

rotate in reverse direction after pressing it again.

When auxiliary output is on, if the system is switched to other modes, the output is unchanged; you need

to press “Reset” key to switch it off, execute the corresponding M code in automatic mode or execute the

corresponding M code in MDI interface to turn off the output;

When the principal axis is positive/reverse rotating and execute M04/M03 directly, the system first stops

positive/reverse rotating and then execute M04/M03 instruction;

Positive/reverse rotating of principal is stopped while emergency stop, and other outputs can be set

according to system parameters.

Adtech CNC Technology Co., Ltd. 4. Manual operation

- 15 -

4.6 Tool setting

Tool setting is the main operation and important skill during CNC processing. Under certain conditions,

tool setting precision can determine the processing precision of parts, and the tool setting efficiency also

affects the CNC processing efficiency directly. CNC46XX has M series tool setting mode and L series tool

setting mode, while M series has two tool setting methods, i.e. centered and tool regulator, and L series uses

test cutting.

4.6.1 Centered (M series)

The centered function is that the system calculates the center position of the workpiece automatically

while tool setting to realize segment centered, rectangle centered and circle center location.

)Note

In the tool setting operation below, if the auxiliary parameters of the coordinate system doesn’t need setting, the first three

steps can be omitted. Please refer to chapter 9.5 for auxiliary parameters of the coordinate system.

⑴Single axis centered

¾Select the edit mode;

¾Press [Coordinates], [Coordinates Parameter] to enter the auxiliary parameters setting interface of the coordinate

system;

¾Move the cursor to desired position, enter new parameters and press [EOB];

¾Select handwheel or manual mode;

¾Press [Coordinates] to enter coordinate system setting interface;

¾Press the left/right arrow to move the cursor to select coordinate system;

¾Press [Centered Measurement] to enter centered interface;

¾Move the tool to make its side blade touch side A surface of the workpiece, and press [EOB] to record boundary point

1;

¾Move the tool to make its side blade touch side B surface of the workpiece, and press [EOB] to record boundary point

2;

¾Press [EOB] to calculate the coordinates of center point;

¾If there is no question, press [EOB] again to return the result to specified coordinate system.

⑵Square centered

¾Select the edit mode;

¾Press [Coordinates], [Coordinates Parameter] to enter the auxiliary parameters setting interface of the coordinate

system;

¾Move the cursor to desired position, enter new parameters and press [EOB];

¾Select handwheel or manual mode;

¾Press [Coordinates] to enter coordinate system setting interface;

¾Press the left/right arrow to move the cursor to select coordinate system;

¾Press [Centered Measurement] to enter centered interface;

¾Move the tool to make its side blade touch side A surface of the workpiece, and press [EOB] to record boundary point

1;

¾Move the tool to make its side blade touch side B surface of the workpiece, and press [EOB] to record boundary point

2;

¾Record boundary point 3.4 in the same method;

¾Press [EOB] after recording all boundary points to calculate the coordinates of center point;

¾If there is no question, press [EOB] again to return the result to specified coordinate system.

⑶Plane circle (XY plane) centered

Adtech CNC Technology Co., Ltd. 4. Manual operation

- 16 -

Circle centered has two modes, which are three points and two points with specified radius; If the user

only types two coordinates in the option of workpiece boundary point and specifies one value for R, the system

will determine the circle center with two points and radius automatically; if the user types coordinates of three

points in the option of workpiece boundary point, the system will determine the circle center with three points

and shield R.

The centered step of three points arc follows:

¾Select the edit mode;

¾Press [Coordinates], [Coordinates Parameter] to enter the auxiliary parameters setting interface of the coordinate

system;

¾Move the cursor to desired position, enter new parameters and press [EOB];

¾Select handwheel or manual mode;

¾Press [Coordinates] to enter coordinate system setting interface;

¾Press the left/right arrow to move the cursor to select coordinate system;

¾Press [Centered Measurement] to enter centered interface;

¾Move the tool to make its side blade touch the surface of round workpiece, and press [EOB] to record boundary point

1;

¾Move the tool to make its side blade touch another point in the surface of the workpiece, and press [EOB] to record

boundary point 2;

¾Move the tool to make its side blade touch another point in the surface of the workpiece, and press [EOB] to record

boundary point 3;

¾Press [EOB] after recording all boundary points to calculate the coordinates of circle center and display in the result

section;

¾If there is no question, press [EOB] again to return the result to specified coordinate system.

Arc centered validation

In the main menu, press [Monitor], [MDI] to enter the MDI interface, select edit mode, enter program

block G55G0X0Y0 (if coordinate system G55 is selected while tool setting), press [Start], [EOB], and the tool

moves to workpiece center automatically, indicating that three points arc centered properly.

The validation steps for other tool setting methods are same.

4.6.2 Tool regulator (M series)

Tool regulator principle:

The tool regulator uses external sensor switch to set the reference point for axis Z, which is similar to

home. After changing tool during processing or changing tool manually, transfer this function to automatically

check the Z value of current workpiece’s home.

Tool regulator usage

Before using the tool regulator, you need to set the parameters. In [Coordinate] menu, press [Coordinate

Parameter] to show tool setting parameters. After that, press [Tool Regulator] in the setting interface to execute

the tool regulator program according to specified parameters.

The action sequence of tool regulator follows

¾Return Z axis to mechanical home first, and then locate principal axis to X, Y coordinates of the tool regulator;

¾Tool regulator blows to start;

¾Z axis moves down, and retracts when touches tool regulator sensor switch, moves down at lower speed when the

sensor switch leaves, records the machine tool coordinates of current Z axis when touches the switch and assigns to the

Z coordinates of current selected coordinate system;

¾Tool regulator blows to turn off;

¾Z axis returns to home position.

This manual suits for next models

1

Table of contents

Other Adtech Controllers manuals

Popular Controllers manuals by other brands

Zennio

Zennio ZCL-FC010F Technical documentation

EuroLite

EuroLite TP-330 user manual

WAREMA

WAREMA Omnexo 2M230 REG installation instructions

Metso

Metso Jamesbury Series Installation maintenance and operating instructions

THERMODYNE

THERMODYNE Smart Controller user manual

Epson

Epson S1D13506 Technical manual

Danfoss

Danfoss PVE 4 Series technical information

Neptronic

Neptronic BM000N Specification & installation instructions

Dantel

Dantel B18-05776 Series Installation & operation manual

Morningstar

Morningstar Sunlight SL-10 Operator's manual

Samson

Samson 45-6 Mounting and operating instructions

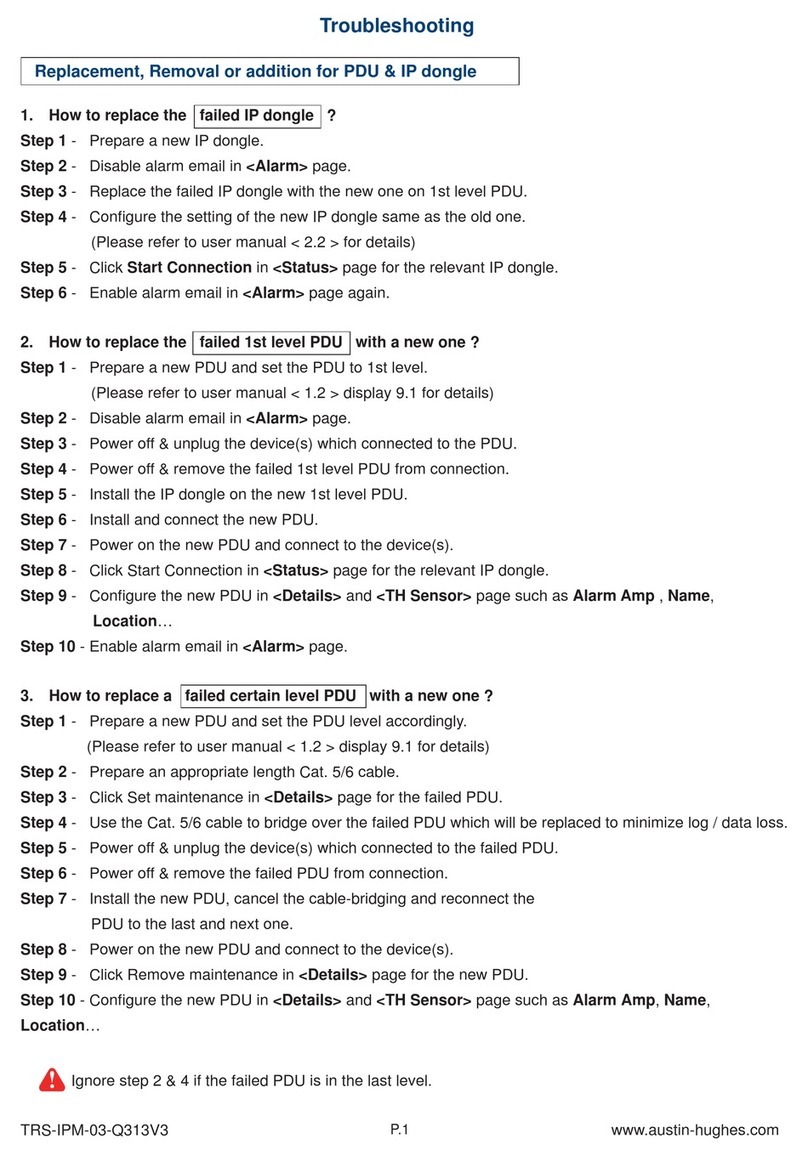

Austin Hughes

Austin Hughes InfraPower Manager IPM-03 Troubleshooting