Adtech ADTECH9 Series Owner's manual

ADTECH9 Series

CNC Programming Manual

Basic Information

This Manual is written byAdtech (Shenzhen) Technology Co., Ltd.

This Manual is mainly written by Tang Xiaobing, Yao Lei and Xu Yuwen.

This manual was typeseted on July 21, 2018, and the project number is applicable for all the machine control

projects of CNC9 series.

Copyright

Adtech (Shenzhen) Technology Co., Ltd. (Adtech hereafter) is in possession of the copyright of this manual.

Without the permission of Adtech, the imitation, copy, transcription and translation by any organization or

individual are prohibited. This manual doesn’t contain any assurance, stance or implication in any form.

Adtech and the employees are not responsible for any direct or indirect data disclosure, profits loss or cause

termination caused by this manual or any information about mentioned products in this manual. In addition,

the products and data in this manual are subject to changes without prior notice.

All rights reserved.

Adtech (Shenzhen) Technology Co., Ltd.

Precautions and Notes

※Transport and storage

Do not exceed six layers for products packing cases piling

Forbid to climb, stand, or place heavy items on products packing cases

Do not use the cable connecting with the product to drag or move products

Non-collision, non-scratching on the panel and display screen

Prevent the moisture, exposure and rain affected packing cases

※Open Package Inspection

Confirm products after opening package

Check whether damages exist during the transportation

Confirm whether parts are complete or have damages by comparison with list

Contact us promptly if products models are inconsistent, parts are missed, or damages during shipping are

found etc.

※Wiring

Professional personnel with corresponding capability is must for participation in wiring and inspection

Reliable grounding is must for products, with less than 4Ω ground resistance, and neutral wire (neutral wire) is

not allowed to substitute grounding wire

Wiring should be correct and secure, to avoid the consequences of product failure or unexpected outcome

Surge absorption diode connecting with product should be linked upon the stipulated direction; otherwise the

product may be damaged

The power supply of the product should be cut before plug-in & plug-out or opening the cabinet.

※Overhauling

Power off prior to overhauling or replacement of components

Check defects when short circuit or overload occurs, and restart it after troubleshooting

Do not connect power frequently and at least 1 minute interval after power-off for re-connection of power.

※Miscellaneous

Do not open the cabinet without permission

Disconnect the power when long term stand-by

Avoid dust and iron powder from getting into controller

If non-solid-state relay is used as output relay, freewheel diode should be connected in parallel on the relay

coil.

Check whether connected power satisfies the requirement, in order to avoid burning the controller

The life span of controller is associated with environmental temperature; install cooling fan in the over-heat

processing field.

ADTECH9 Series CNC Programming Manual

The working temperature range is between 0℃~60℃

Avoid using it in the environments with high temperature, humidity, dust, or corrosive gas.

Provide rubber rails for buffering in the place with strong vibration.

※Maintenance

The following items can be conducted for daily and regular inspection, under the general usage conditions

(environmental conditions: daily average temperature: 30℃, load-carry duty: 80%, and operational rate: 12

hours per day)

Daily inspection

Daily

Confirm environmental temperature, humidity, dust and

foreign matter;

Check whether there are abnormal vibration and sounds

Check whether vents are blocked by yarns

Regular

inspection

One year

Check whether solid components are loose

Check whether terminal blocks are damaged

Contents

CONTENTS ........................................................................................................................................................... - 0-

1. OVERVIEW ............................................................................................................................................. - 0 -

1.1 SPECIFICATION............................................................................................................................................. - 0-

1.1.1 Basic functions.............................................................................................................................- 0 -

1.1.2 Auxiliary functions ......................................................................................................................- 1 -

1.1.3 Spindle functions .........................................................................................................................- 1 -

1.1.4 Tool functions ..............................................................................................................................- 2 -

1.2 GCODES LIST............................................................................................................................................... - 2-

1.3 PROGRAM STRUCTURE.................................................................................................................................. - 4-

1.3.1 Program composition ..................................................................................................................- 4 -

1.3.2 Main program and subroutine ....................................................................................................- 7 -

1.3.3 Modal and non-modal function...................................................................................................- 8 -

1.4 MOTION DIRECTION NAMING OF CONTROL AXES ............................................................................................... - 9-

2. SYSTEM PROGRAMMING ..................................................................................................................... - 12 -

2.1 PREPARATION FUNCTIONS (G FUNCTION) ........................................................................................................ - 12 -

2.1.1. G90 G91 absolute and relative programming ...........................................................................- 12 -

2.1.2. Rapid positioning (G00).............................................................................................................- 13 -

2.1.3. Linear interpolation (G01) .........................................................................................................- 14 -

2.1.4. Arc interpolation (G02, G03)......................................................................................................- 15 -

2.1.5. Pause instruction (G04) .............................................................................................................- 19 -

2.1.6. Plane selection (G17-G19) .........................................................................................................- 19 -

2.1.7. Machine tool coordinate system (G53)......................................................................................- 20 -

2.1.8. Programmable workpiece coordinate system (G92)..................................................................- 21 -

2.2 GFUNCTION RELATED TO REFERENCE POINT...................................................................................................... - 22 -

2.2.1. Auto return to reference point (G28).........................................................................................- 22 -

2.2.2. Auto return from reference point (G29).....................................................................................- 24 -

2.2.3. Reference point return checking (G27) ......................................................................................- 25 -

2.2.4. Local coordinate system (G52)...................................................................................................- 26 -

2.3 TOOL COMPENSATION GFUNCTION................................................................................................................ - 28 -

2.3.1. Tool length compensation (G43, G44,G49)................................................................................- 28 -

2.3.2. Tool radius compensation (G40, G41, G42) ...............................................................................- 31 -

ADTECH9 Series CNC Programming Manual

2.3.3. G41/G42instruction and I, J, K designation ...............................................................................- 45 -

2.3.4. Notes for tool radius compensation ..........................................................................................- 53 -

2.4 HOLE PROCESSING FUNCTION........................................................................................................................ - 57 -

2.4.1. High-speed deep-hole drilling cycle (G73) .................................................................................- 62 -

2.4.2. Left-hand Thread tapping cycle (G74) .......................................................................................- 63 -

2.4.3. Fine boring cycle (G76)..............................................................................................................- 64 -

2.4.4. Drilling cycle (G81) ....................................................................................................................- 66 -

2.4.5. Drilling cycle, rough boring cycle (G82) .....................................................................................- 66 -

2.4.6. Deep-hole drilling cycle (G83)....................................................................................................- 67 -

2.4.7. Tapping cycle (G84) ...................................................................................................................- 68 -

2.4.8. Boring cycle (G85)......................................................................................................................- 70 -

2.4.9. Boring cycle (G86)......................................................................................................................- 71 -

2.4.10. Back boring cycle(G87) ..............................................................................................................- 73 -

2.4.11. Boring cycle (G88)......................................................................................................................- 74 -

2.4.12. Boring cycle (G89)......................................................................................................................- 74 -

2.5 CONVERSION OF GCOMMAND...................................................................................................................... - 78 -

2.5.1. Program coordinates rotation G68 and G69..............................................................................- 78 -

2.5.2. G51.1and G50.1 mirroring.........................................................................................................- 80 -

2.6 PROBE GCOMMAND .................................................................................................................................. - 84 -

2.6.1. G31.1 .........................................................................................................................................- 84 -

2.6.2. G31.2 .........................................................................................................................................- 84 -

2.6.3. G31.3 .........................................................................................................................................- 84 -

2.7 MACHINE COORDINATE POSITIONING COMMANDS ............................................................................................ - 85 -

2.7.1. G53 ............................................................................................................................................- 85 -

2.7.2. G53.1 .........................................................................................................................................- 85 -

3. AUXILIARYFUNCTION........................................................................................................................... - 86 -

3.1 MCODE LIST ............................................................................................................................................. - 86 -

3.1.1. M00 program pause ..................................................................................................................- 89 -

3.1.2. M03 spindle moves clockwise (CW)...........................................................................................- 89 -

3.1.3. M04 spindle moves counterclockwise (CCW) ............................................................................- 89 -

3.1.4. M05 spindle stops......................................................................................................................- 89 -

3.2 MCOMMAND FOR INPUT SIGNAL DETECTION OUTPUT ....................................................................................... - 89 -

3.2.1. M88 input port signal detection................................................................................................- 89 -

ADTECH9 Series CNC Programming Manual

3.2.2. M89 specifies output port control .............................................................................................- 89 -

3.3 SPINDLE SPEED FUNCTION S ......................................................................................................................... - 90 -

3.4 TOOL FUNCTION......................................................................................................................................... - 90 -

4. CATEGORY B MACRO FUNCTION .......................................................................................................... - 91 -

4.1 VARIABLE INSTRUCTION ............................................................................................................................... - 91 -

4.2 MACRO PROGRAM CALL .............................................................................................................................. - 93 -

4.3 MACRO PROGRAM CALLING COMMAND .......................................................................................................... - 93 -

4.4 VARIABLE.................................................................................................................................................. - 97 -

4.5 TYPES OF VARIABLES.................................................................................................................................... - 99 -

4.6 CALCULUS INSTRUCTION ............................................................................................................................ - 101 -

4.7 CONTROL INSTRUCTION ............................................................................................................................. - 105 -

4.8 NOTES OF USING MACRO ........................................................................................................................... - 109 -

4.9 MACRO VARIABLE USER PARAMETERS SYSTEM CONFIGURATION.......................................................................... - 109 -

4.10 EXTENDED SPECIAL MACRO FUNCTIONS......................................................................................................... - 111 -

4.10.1. RCOOR read workpiece coordinates ........................................................................................- 111 -

4.10.2. RMACPOS read machine tool coordinates...............................................................................- 111 -

4.10.3. WMACPOS write machine tool coordinates ............................................................................- 111 -

4.10.4. SPEEDS set interpolation speed ...............................................................................................- 111 -

4.10.5. SPEEDA set positioning speed..................................................................................................- 112 -

4.10.6. MOVEABS single axis moves to the machine’s position...........................................................- 112 -

4.10.7. MOVEREL relative moved position of single axis .....................................................................- 112 -

4.10.8. MOVEASA two axes move to the machine’s position (positioning or interpolation) ...............- 112 -

4.10.9. MOVERSA relative moved position of two axes (positioning or interpolation)........................- 113 -

4.10.10. MOVEASB three axes move to the machine’s position (positioning or interpolation) .............- 113 -

4.10.11. MOVERSB Relative Position of Motion of Three axes ..............................................................- 113 -

4.10.12. MOVEASC absolute position of motion of multiple axes (positioning or interpolation) ..........- 114 -

4.10.13. MOVERSC relative position of motion of multiple axes (positioning or interpolation) ............- 114 -

4.10.14. WRITEOUT Write Physical Output ...........................................................................................- 115 -

4.10.15. WRITELED Write Physical LED..................................................................................................- 115 -

4.10.16. READOUT Read Physical Output..............................................................................................- 115 -

4.10.17. READIN Read Physical Input ....................................................................................................- 115 -

4.10.18. READLED Read Physical LED ....................................................................................................- 115 -

4.10.19. MOVEWAITIN Search and Wait for the Input Signals in Motion..............................................- 116 -

ADTECH9 Series CNC Programming Manual

4.10.20. WAITMOVE Wait for the End of the Motion of All Axes...........................................................- 116 -

4.10.21. WAITMOVED Wait for the End of Motion of All Axes ..............................................................- 116 -

4.10.22. WRITEPLC Write Physical or Auxiliary Output Point ................................................................- 117 -

4.10.23. READPLC Read Physical or Auxiliary Output Point ...................................................................- 117 -

4.10.24. WAITPLC Timeout Waiting for Read of Physical or Auxiliary Input Point ................................- 117 -

4.11 SPECIAL MCODE ..................................................................................................................................... - 117 -

4.11.1. Cancel the synchronization of all axis or switch function (M10002)........................................- 118 -

4.11.2. Process after switching Axis X to Axis A (M10003) ..................................................................- 118 -

4.11.3. Process Axis X and Axis A synchronously (M10004) ................................................................- 118 -

4.11.4. Process after switching Axis Y to Axis A (M10005) ..................................................................- 118 -

4.11.5. Process Axis Y and Axis A synchronously (M10006).................................................................- 118 -

4.11.6. Process after switching Axis Z to Axis A (M10000) ..................................................................- 118 -

4.11.7. Process Axis Z and Axis A synchronously (M10001).................................................................- 118 -

4.11.8. Process after switching Axis X to Axis B (M10007) ..................................................................- 118 -

4.11.9. M10008 Process Axis X and Axis B synchronously (M10008) ..................................................- 118 -

4.11.10. Process after switching Axis X to Axis C (M10009) ..................................................................- 118 -

4.11.11. Process Axis X and Axis C synchronously (M10010).................................................................- 118 -

4.11.12. Process after switching Axis Y to Axis B (M10011) ..................................................................- 118 -

4.11.13. Process Axis Y and Axis B synchronously (M10012).................................................................- 118 -

4.11.14. Process after switching Axis Y to Axis C (M10013) ..................................................................- 118 -

4.11.15. M10014 Process Axis Y and Axis C synchronously (M10014) ..................................................- 118 -

4.11.16. Process after switching Axis Z to Axis B (M10015) ..................................................................- 119 -

4.11.17. Process Axis Z and Axis B synchronously (M10016).................................................................- 119 -

4.11.18. Process Axis A, Axis B and Axis C synchronously (M10017) .....................................................- 119 -

4.12 SPECIAL PROGRAM SEGMENT ..................................................................................................................... - 119 -

4.12.1. M2000 .....................................................................................................................................- 119 -

4.12.2. M2203 .....................................................................................................................................- 119 -

4.12.3. M2201 .....................................................................................................................................- 119 -

4.12.4. M2202 .....................................................................................................................................- 119 -

4.12.5. M2200 .....................................................................................................................................- 119 -

4.12.6. M2205 .....................................................................................................................................- 119 -

4.12.7. M2206 .....................................................................................................................................- 119 -

4.12.8. M2207 .....................................................................................................................................- 120 -

4.12.9. M2208 .....................................................................................................................................- 120 -

ADTECH9 Series CNC Programming Manual

4.12.10. M2209 .....................................................................................................................................- 120 -

4.12.11. M2212 .....................................................................................................................................- 120 -

4.12.12. M2213 .....................................................................................................................................- 120 -

4.12.13. M2214 .....................................................................................................................................- 120 -

4.12.14. M2216 .....................................................................................................................................- 120 -

4.12.15. M2217 .....................................................................................................................................- 120 -

4.12.16. M2218 .....................................................................................................................................- 120 -

4.12.17. M2219 .....................................................................................................................................- 120 -

4.12.18. M2220 .....................................................................................................................................- 120 -

4.12.19. M2221 .....................................................................................................................................- 120 -

4.12.20. M2222 .....................................................................................................................................- 120 -

4.13 MCODE SEGMENT ACTIVATED BY EXTERNAL INPUT POINT............................................................................... - 121 -

4.14 AUXILIARY CHANNEL GRUN 4, 5, 6AND 7 ................................................................................................... - 121 -

5. INSTRUCTION ON CUSTOM CAM.........................................................................................................- 122 -

5.1 OVERVIEW .............................................................................................................................................. - 122 -

5.2 INTRODUCTION OF CAM INSTRUCTION INTERFACE.......................................................................................... - 122 -

5.3 CAM INSTRUCTION MENU FUNCTIONS ......................................................................................................... - 123 -

5.4 CAM INSTRUCTION CONFIGURATION FILE..................................................................................................... - 124 -

5.5 SCHEMATIC DIAGRAM OF CAM INSTRUCTION................................................................................................ - 131 -

5.6 GENERATION OF PROCESSING PROGRAMS ..................................................................................................... - 135 -

6. CAD DXF CONVERSION........................................................................................................................- 139 -

6.1 FUNCTION .............................................................................................................................................. - 139 -

6.2 KEYWORDS DESCRIPTION ........................................................................................................................... - 140 -

6.3 EXAMPLE................................................................................................................................................ - 141 -

6.4 DXF FILE MANUAL PATH PROCESSING............................................................................................................ - 144 -

7. AUTOMATIC TOOL CHANGE (ATC) .......................................................................................................- 147 -

SPINDLE........................................................................................................................................................... - 147 -

SPINDLE CABINET ............................................................................................................................................ - 147 -

1. Overview

1.1Specification

Pulse equivalent: (electronic gear ratio: 1:1) 0.001MM

Linkage/control axis: CNC9640 4-axis, CNC9650 6-axis, CNC9960 6-axis, CNC9810 6-axis, CNC9810E

6-axis/supporting two channels.

Program capacity: The electronic disk capacity is 4GB, and is divided into 2 zones: 2G each for Disk D and C.

RAM: 512M

Display: CNC9640, CNC9650 7” LCD 800 * 480 pixels; CNC9810, CNC9810E 8” LCD 800 * 600 pixels

CNC9960 10.4” LCD 800*600 pixels

1.1.1 Basic functions

Name

Specification

Data input method

(1) NC keyboard input

(2) U disk import

(3) Network and serial port download and upload

Edit

(1) New program

(2) Teach program

(3) Save file

(4) Programmed search

(5)Search, search row, copy row, paste row, delete row, copy segment,

delete segment

(7) Replace

File management

(1) Browse

(2)Copy

(3)Paste

(4)Cut

(5)Delete

Authority

management

(1) Superuser

(2) Operator

(3) Guest

System data

management

(1) Parameter backup

(2) Parameter recovery

ADTECH9 Series CNC Programming Manual

Name

Specification

(3) Factory reset of parameters

Auxiliary function

control

(1)M_FUNC.NC M code control macro program

(2)T_FUNC.NC T code control macro program

User configurable

items

(1) Axis (number of axis, characteristic linear rotation, return-to-zero

sequence)

(2) IO port configuration

(3) Variable name customize "SYSTABLE.csv" import

Language

(1) Simplified Chinese

(2) Traditional Chinese

(3) English: users can translate it into other languages through the

"ZIDIAN.ZD" file.

Diagnosis

(1) Input point status

(2) Output point status, and manual control

(3)Alarm information

(4) Auxiliary channel operation information

(5)System information

1.1.2 Auxiliary functions

Name

Specification

Common functions

(1) M03,M04,M05

(2) M08and M09 coolant switches

(3)M10and M11 chuck control

(4)M06 tool change command

Special auxiliary

function

(1)GRUN4, GRUN5, GRUN6, GUR7

(2)M2000, M2201 ……

(3)M10003 ……Axis dynamic switching and synchronization

(4) Input point triggered segments M2001 IN1 M2002 IN2

1.1.3 Spindle functions

Name

Specification

M03

(1) Spindle forward

ADTECH9 Series CNC Programming Manual

Name

Specification

M04

(2) Spindle reversal

M05

(3)Spindle stop

S

(1) Spindle rotating speed

1.1.4 Tool functions

Name

Specification

M06

(1)M06 Txx, two-digit tool number

1.2G codes list

G code

Group

Function

*G00

01

Positioning (rapid traverse)

G01

Linear interpolation (cutting feeding)

G02

Arc interpolation CW (clockwise)

G03

Arc interpolation CCW(counterclockwise)

G04

00

Pause, accurate stop

*G17

02

XY plane selection

G18

ZX plane selection

G19

YZ plane selection

G20

06

Imperial data entry

*G21

Metric data entry

G27

00

Return to and check reference point

G28

Return to reference point

G29

Return from reference point

*G40

07

Tool radius compensation cancel

G41

Left tool radius compensation

G42

Right tool radius compensation

G43

08

Positive tool length offset

G44

Negative tool length offset

*G49

Tool length offset cancel

G52

00

Local coordinate system setting

G53

Select machine tool coordinate system

*G54

05

Workpiece coordinate system 1

G55

Workpiece coordinate system 2

ADTECH9 Series CNC Programming Manual

G code

Group

Function

G56

Workpiece coordinate system 3

G57

Workpiece coordinate system 4

G58

Workpiece coordinate system 5

G59

Workpiece coordinate system 6

G591

Extended workpiece coordinate system 7

G592

Extended workpiece coordinate system 8

G593

Extended workpiece coordinate system 9

G594

Extended workpiece coordinate system 10

G595

Extended workpiece coordinate system 11

G596

Extended workpiece coordinate system 12

G597

Extended workpiece coordinate system 13

G598

Extended workpiece coordinate system 14

G599

Extended workpiece coordinate system 15

G65

00

Macro program command

G73

09

Deep hole drilling fixed cycle

G74

Reverse threading fixed cycle

G76

Boring fixed cycle

*G80

Cancel fixed cycle

G81

Drilling fixed cycle

G82

Drilling fixed cycle

G83

Deep hole drilling fixed cycle

G84

Taping fixed cycle

G85

Boring fixed cycle

G86

Boring fixed cycle

G87

Reverse boring fixed cycle

G88

Boring fixed cycle

G89

Boring fixed cycle

*G90

03

Absolute value programming

G91

Increment value programming

G92

01

Programmable workpiece coordinate system setting

*G98

10

Return to initial plane in fixed cycle

G99

Return to point R plane in fixed cycle

ADTECH9 Series CNC Programming Manual

Notice:

The items marked with * are the default modal values of G codes of the system;

1.3Program structure

1.3.1 Program composition

CNC processing program consists of the following parts:

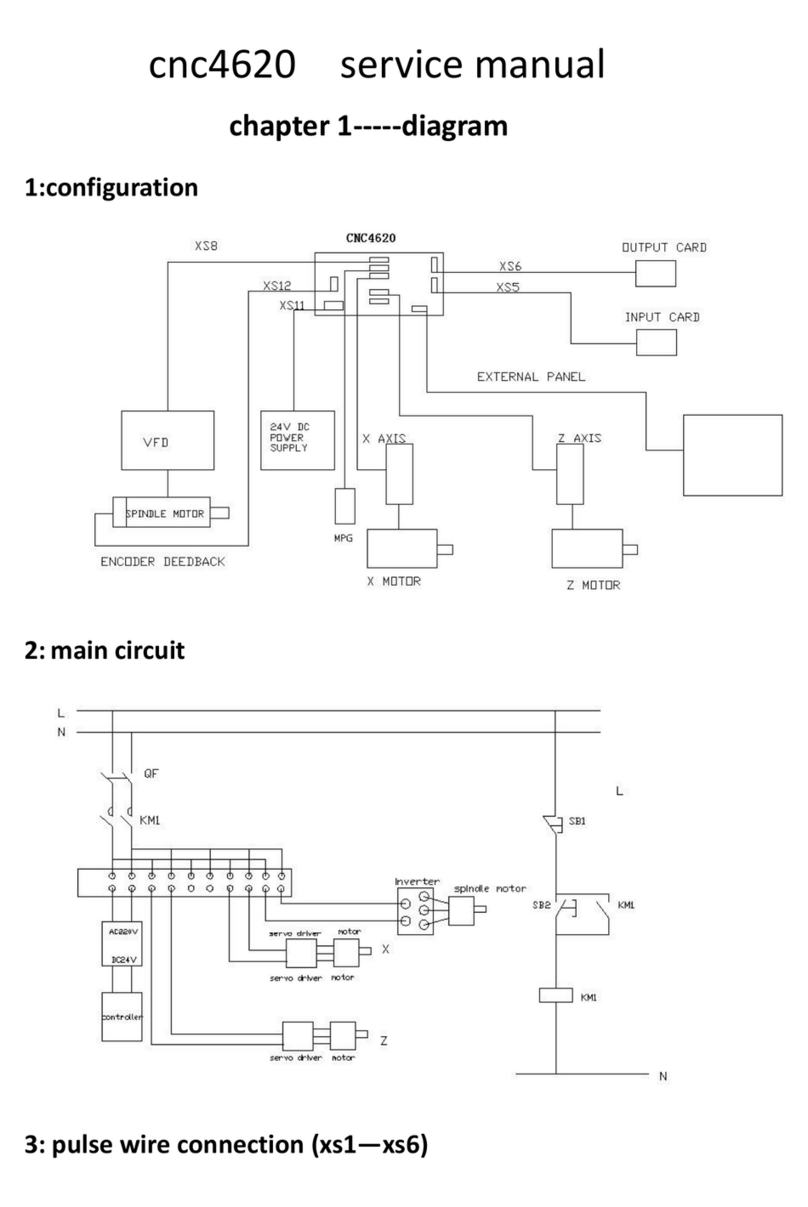

Fig. 1.3.1 CNC Program Structure Diagram

Program name:

Used to mark different programs, and consists of O and four digits.

➢If the start of the program doesn’t have program name, the program segment No. of the program start

will be considered as the program name by default;

➢If the program segment No. contains five digits, the latter four digits will be used as the program

name;

➢If the latter four digits are 0, add 1 automatically to use as the program name;

➢N0 can’t be used as program name;

➢When saving the program, if both program name and program segment No. don’t exist, it is necessary

to make a program name through MDI panel.

Note:

The content in the parentheses, in which the user can specify notes, guide, etc.:

ADTECH9 Series CNC Programming Manual

➢The note doesn’t have limit on length; if the program has a long note, the axis motion will pause for a

while; therefore, if a long note is required, please put it at the place that motion pauses or without

motion;

➢If there is only one “)” without “(”, “)” will be ignored;

➢The note may have multiple lines and are separated with space;

➢During processing, the note can’t be executed.

Instruction address:

One English letter in the text of the processing program (“Address” hereinafter)

Instruction word:

Adding a number after the instruction address will constitute an instruction word.

Program segment No.:

Consist of letter N and number (≤5 digits), and can be randomly arranged.

➢The sequence of executing program segments only related to the storage position rather than program

segment No.;

➢If program segment N20 appears before program segment N10, N20 shall be executed first.

Program segment:

A program segment consists of one or several instruction word and ends with “;”;

N_ G_ X_Z_ F_ S_ T_

M_ ;

Program segment No. Preparation Size definition Feeding speed Spindle rotation Tool

change Auxiliary function

Skip symbol:

If the first character of a program segment is “/”, this program segment is conditional, i.e. skip switch. In upper

position, this program segment isn’t executed; when the skip switch is in lower position, this program segment

is executed.

Program end:

Generally, the following codes are used when program ends:

Code

Action

M30

End main program

M99

End subroutine

ADTECH9 Series CNC Programming Manual

Note:

After M30 is executed, CNC stops executing and returns to program start;

After M99 is executed, CNC returns to the program that calls this subroutine and continues executing.

File end:

If the program end doesn’t have %, CNC is reset.

Instruction word is the basic unit of program segment. Every address has unique meaning, and the following

values also have different formats and ranges, as in the Table below:

Table 4.1 Instruction Address and Range of Command Value

Function

Address

Range

Meaning

Program name

O

1~9999

Program No.

Program

segment No.

N

1~9999

Sequence No.

Preparation

function

G

00~99

Specify motion mode (linear,

arc…)

Size definition

X, Y, Z

±99999.999 mm

Coordinate position value

R

±99999.999 mm

Arc radius, corner radius

I, J, K

±9999.9999 mm

Arc center coordinate position

value

Feeding rate

F

1~100,000 mm/min

Feeding rate

Spindle rotation

S

1~4000 rpm

Spindle rotation

Select tool

T

0~99

Tool No.

Auxiliary

function

M

0~99

Auxiliary function M code No.

Tool offset No.

H, D

1~200

Specify tool offset No.

Pause time

P, X

0~65 sec

Pause time (ms)

Specify

subroutine No.

P

1~9999

To call subroutine

Repeat times

P, L

1~999

To call subroutine

Parameter

P, Q, R

P is 0~99999.999

Q is ±99999.999 mm

R is ±99999.999

Fixed cycle parameters

ADTECH9 Series CNC Programming Manual

1.3.2 Main program and subroutine

The processing programs include main programs and subroutines. Generally, NC executes the instructions of

main program; however, NC will turn to execute subroutine when executes a subroutine calling instruction,

and will return to the main program when executes the return instruction in subroutine.

When the processing program needs to run same track for several times, edit this track into the subroutine and

save in the program memory of the machine tool, and this subroutine can be called when this track should be

executed in the program.

When the main program calls a subroutine, this subroutine can call another subroutine, which is called double

nesting. Generally, the machine tool allows up to quadruple subroutine nesting. In calling subroutine

instruction, the subroutine can be repeated for 999 times.

Fig. 1.3.2 Main Program and Subroutine

Subroutine format:

OXXXX ; Subroutine name

………… ;

………… ; Subroutine content

………… ;

M99 ; Subroutine ends, and returns to previous program

Example: X100.0 Y100.0 M99;

Note:

ADTECH9 Series CNC Programming Manual

Program start should have a subroutine name specified by address O

M99 doesn’t need to appear in a program segment separately.

Subroutine call format:

M98P XXX XXXX

Note:

In the number following address P, the latter four digits are used to specify the program No. of called

subroutine, and the former three digits are used to specify the repeat times of calling.

Example:

M98 P41005; call subroutine 1005, repeat four times

G90 G00 X-75. Y50. Z53. M98 P40035; this program segment specifies the X, Y, Z axis to fast locate the

instruction position, and then call subroutine 0035 for four times.

Note:

➢If the calling time isn’t specified, the subroutine will be called only once;

➢M98 doesn’t need to appear in a program segment separately;

➢Different from other M codes, M98 and M99 won’t send signal to the machine tool when executing;

➢NC gives an alarm if can’t find the program No. specified by address P;

➢Subroutine call instruction M98 can’t be executed in MDI mode; to execute a subroutine separately,

please edit the following program in the editing mode, and execute in automatic running mode.

O×××;

M98 P××××;

M30;

1.3.3 Modal and non-modal function

G code determines the function of the command and can be classified into two types:

Non-modal G code:

G code is only valid in defined program segment

Modal G code:

G code is always valid, until next G code of same group appears.

Example: G01 and G00 are modal G codes

ADTECH9 Series CNC Programming Manual

G01X_;

Y_; G01 is valid in this range

Z_;

G00X_;

1.4Motion direction naming of control axes

This system can control the rapid traverse, feeding and interpolation of four axes. The axis direction is defined

in Cartesian coordinate system, as shown below (facing to the machine tool):

Z axis: The up and down movement of the tool relative to the workpiece is Z axis motion, with the upward

movement the positive motion and the downward movement the negative motion.

X axis: The left and right movement of the tool relative to the workpiece is X axis motion, with the rightward

movement the positive motion and the leftward movement the negative motion.

Y axis: The forward and backward movement of the tool relative to the workpiece is Y axis motion, with the

forward movement the positive motion and the backward movement the negative motion.

Spindle:

Look down to the workpiece, the clockwise rotation is spindle positive rotation and the counterclockwise

rotation is negative rotation.

A, B, C axes:

ADTECH9 Series CNC Programming Manual

The positive directions of rotation axes correspond to the positive directions of X, Y, Z axis, which are

determined according to the forward direction of right hand screw.

Notice:

The X, Y, Z, A, B, C axis motion described in this manual is the tool’s motion relative to the workpiece, i.e. it

is assumed that the workpiece coordinate system has been set.

Coordinate systems of machine tool and workpiece

Machine tool coordinate system:

The coordinate system fixed on the machine tool is created through returning to reference point after NC is

electrified every time. To select machine tool coordinate system, use G53 instruction.

Workpiece coordinate system:

When start programming, the programmer doesn’t know the position of the workpiece on the machine tool,

and usually uses a point on the workpiece as the reference point to write processing program. The coordinate

system created with this reference point is the workpiece coordinate system. When the workpiece is fixed on

the worktable of the machine tool, move the tool to specified workpiece reference point and set the coordinate

value of this point as the origin of workpiece coordinate system, and the tool will use this workpiece

coordinate system as the reference system and process according to program instruction when the system

executes the machining program. Therefore, the origin offset function of coordinate system is very important

to CNC machine tool.

This system can preset six workpiece coordinate systems (nine extended coordinate systems G591-G599 are

added in new version). Set the offset of every workpiece coordinate system origin relative to machine tool

coordinate system origin, and then use G5X (5X is the specific workpiece coordinate system number, the same

below) instruction to select. G5X are nodal instructions, corresponding to 1#~6# preset workpiece coordinate

system respectively.

This manual suits for next models

6

Table of contents

Other Adtech Controllers manuals