Adtech Smart Touch TCT-327 User manual

1

(2/ 0) 190-A-000098 Rev. A

3750 Monroe Avenue

Pittsford, New York 14534-1302

(716) 383-8280

FAX (716) 383-

8386

TCT-327 Smart Touch3-Wire

Isolated Temperature Transmitter

Instruction Manual

1.0 INTRODUCTION

These instructions refer to the above model. Supplementary

sheetsareattachediftheunithasspecialoptionsorfeatures.

For detailed specifications, see page 4 or refer to the Data

Bulletin. All ADTECH instruments are factory calibrated and

supplied with a label detailing the calibration. Adjustments

are normally not necessary. A simple check must be

performed to verify calibration before installation to ensure

that it matches the field requirement.

2.0 GENERAL DESCRIPTION

The TCT-327 transmitter accepts any of the 11 standard

thermocouple input types and provides a linearized and

isolated output representing temperature. Calibration is

extremely easy with Adtech’s Smart Touch

technology.

Simply input your zero value, touch a button, input your full-

scale value and touch another button, and the unit is

calibrated.

The isolated output resolution is 12 bits and provides

standard voltage or current output signals (see table 1 page

3). Isolation is600 volts acor 1000 volts dc from the input to

theoutput/powersupply. Power requirementis15to42Vdc

at 40 ma maximum.

The primary features are:

Wide range - covers the full usable range of 11 NIST

standard thermocouple types.

Output setup is via plug in jumpers.

High accuracy, input resolution to 0.3

v.

Update rate of 20Hz, -3db response of 5.24 Hz (0.067

msec) standard. Consult factory for conversion rates to

500 Hz.

RFI resistant.

No interaction of ZERO and SPAN controls.

Adtech Smart Touch

calibration.

Small size

DIN mounting package (1"w x 3.1"h x

3.6"d).

Options for NEMA 4 and NEMA 7 housings, SNAP

TRAK and surface mounting.

3.0 INSTALLATION

Electrical Connections

Thewireusedtoconnecttheinstrumenttothe controlsystem

I/O should bea twisted pair(s) and sized according to normal

practice. Shielded cable is not normally necessary (if used,

the shield must be grounded at the input negative of the

ADTECH instrument and left floating at the sensor).

Six position compression terminalblocks are providedfor I/O

and power connection. A housing ground terminal is not

required due to non-metallic housing.

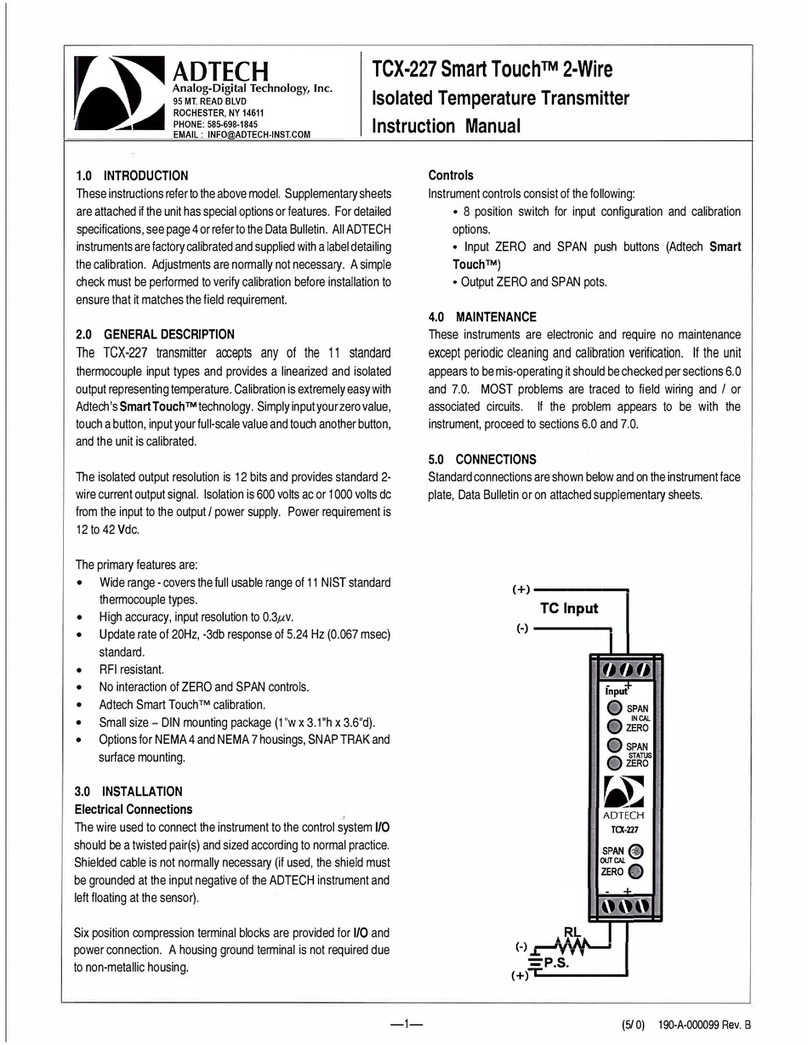

Controls

Instrument controls consist of the following:

8 position switch for input configuration and calibration

options.

Input ZERO and SPAN push buttons (Adtech Smart

Touch

)

Jumper for zero based / elevated output.

Output ZERO and SPAN pots.

4.0 MAINTENANCE

Theseinstrumentsareelectronicandrequirenomaintenance

except periodic cleaning and calibration verification. If the

unit appears to be mis-operating it should be checked per

sections 6.0 and 7.0. MOST problems are traced to field

wiring and / or associated circuits. If the problem appears to

be with the instrument, proceed to sections 6.0 and 7.0.

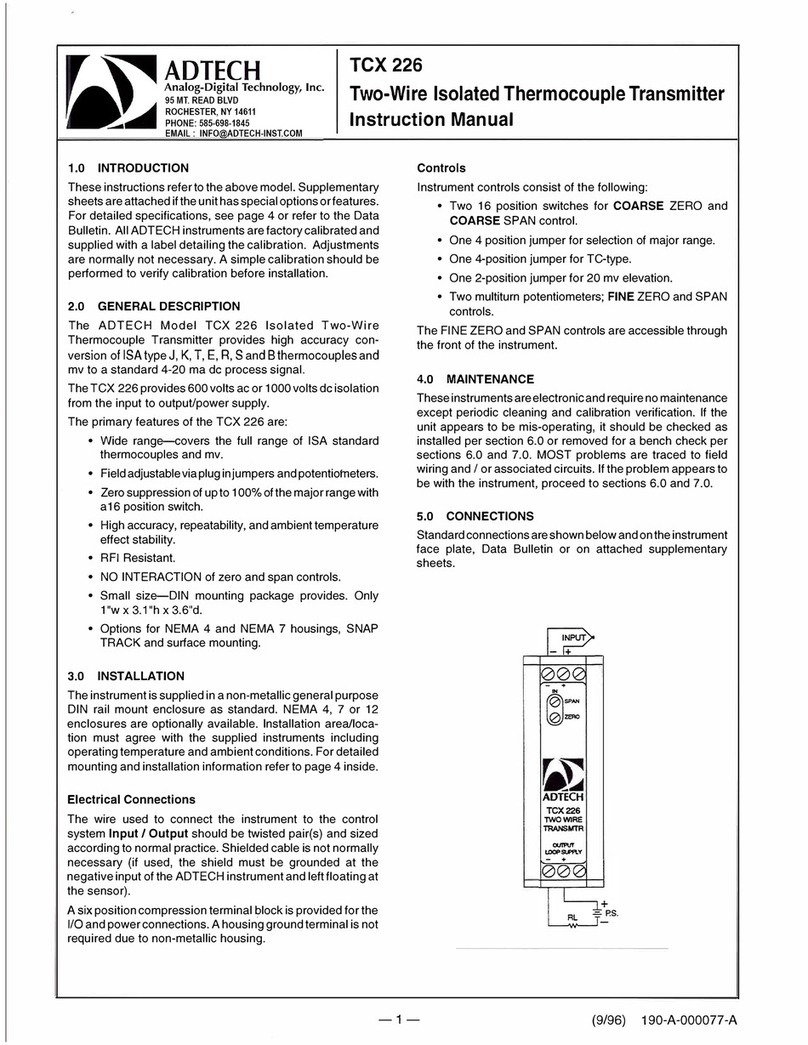

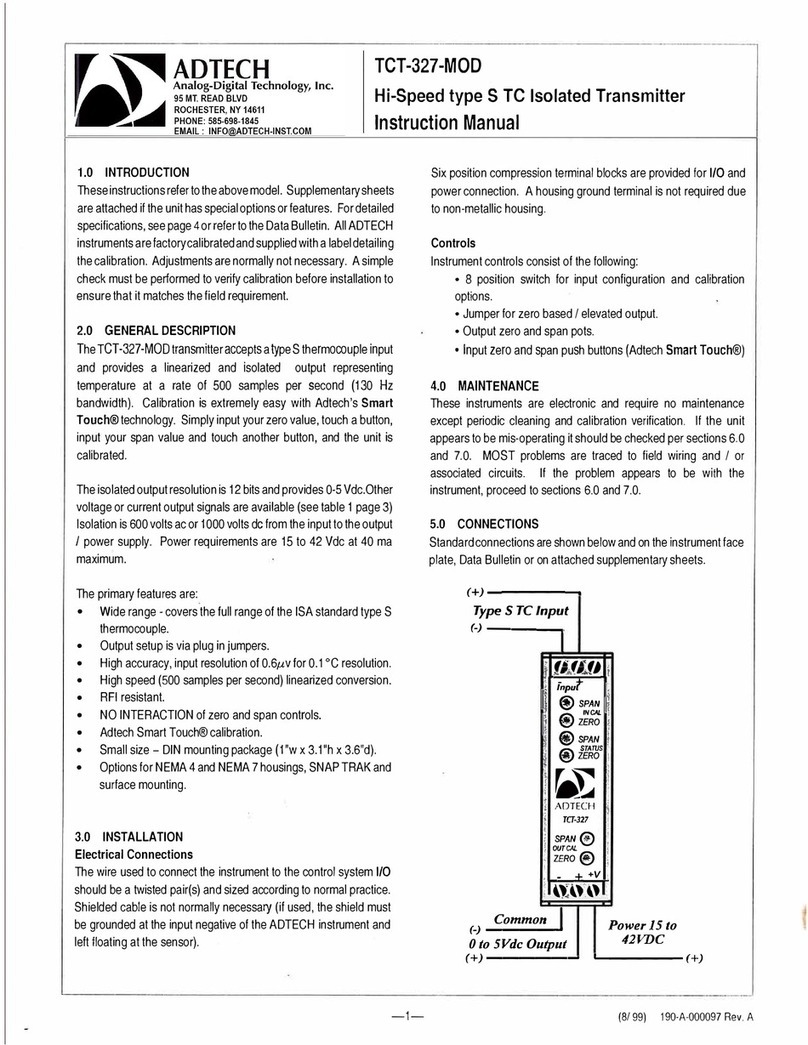

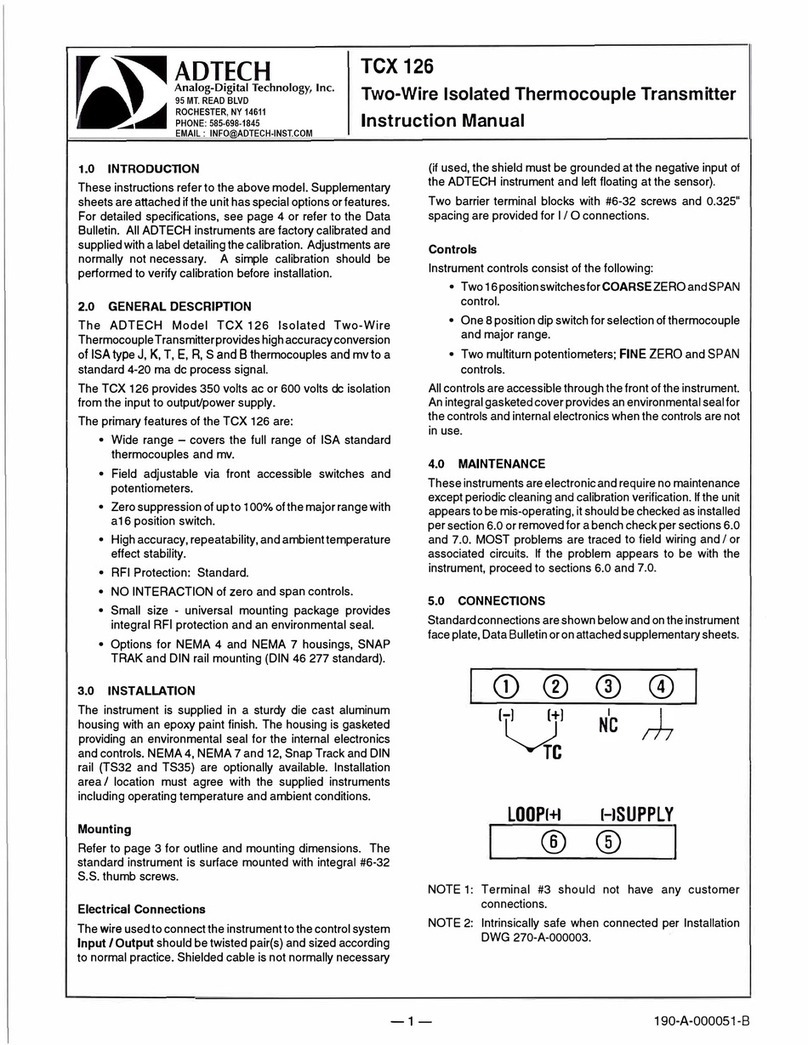

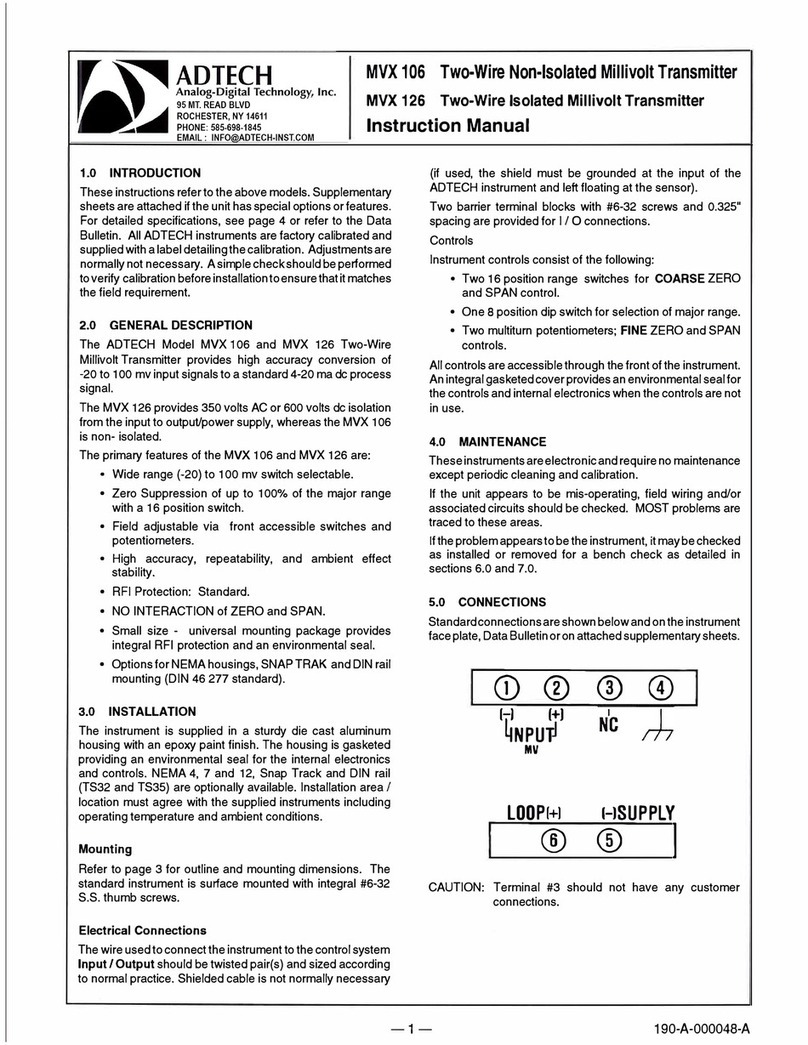

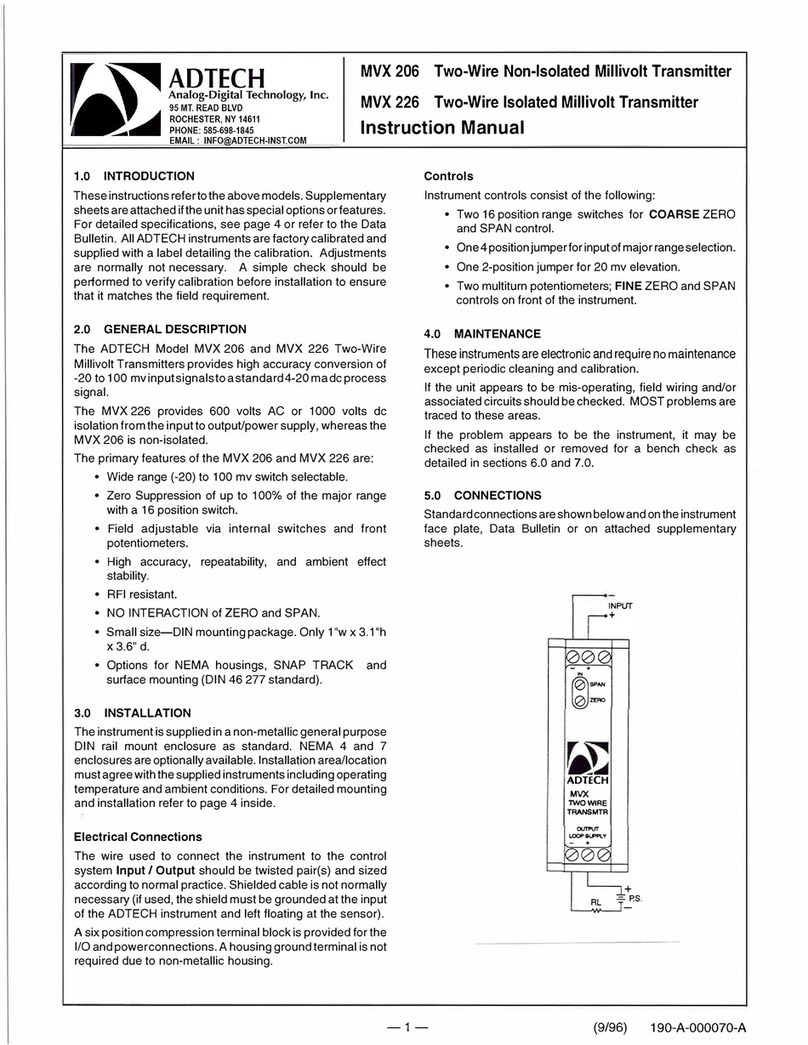

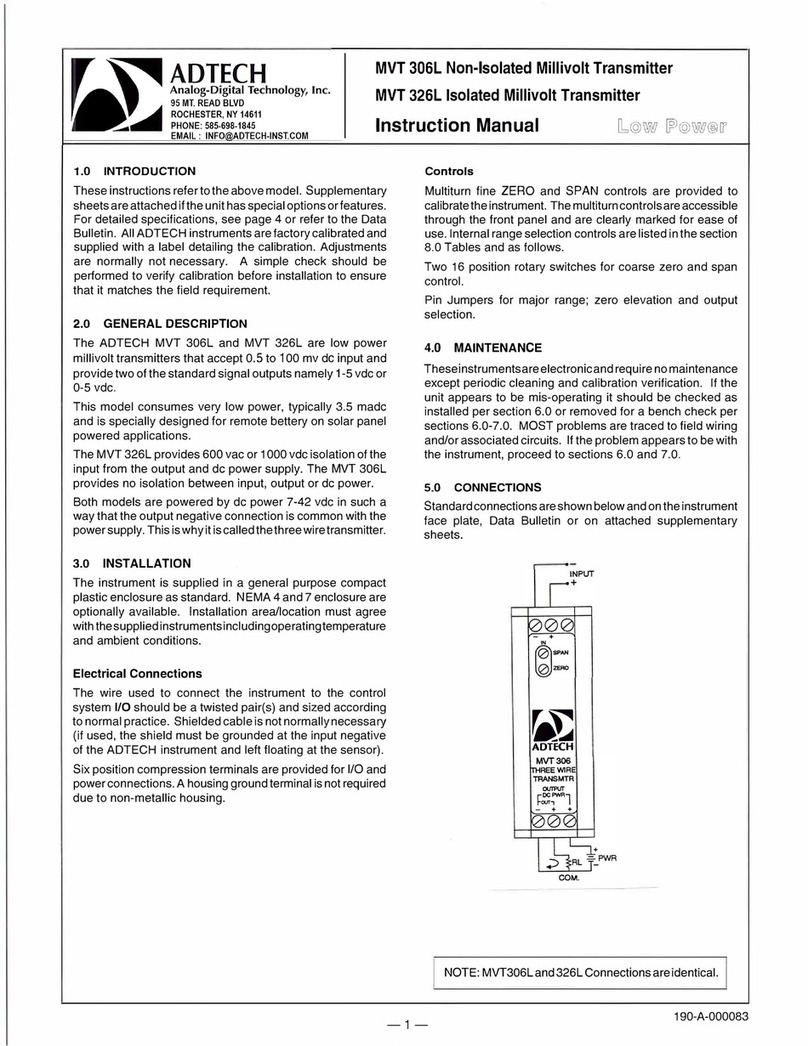

5.0 CONNECTIONS

Standard connections are shown below and on the

instrument face plate, Data Bulletin or on attached

supplementary sheets.

2

(2/ 0) 190-A-000098 Rev. A

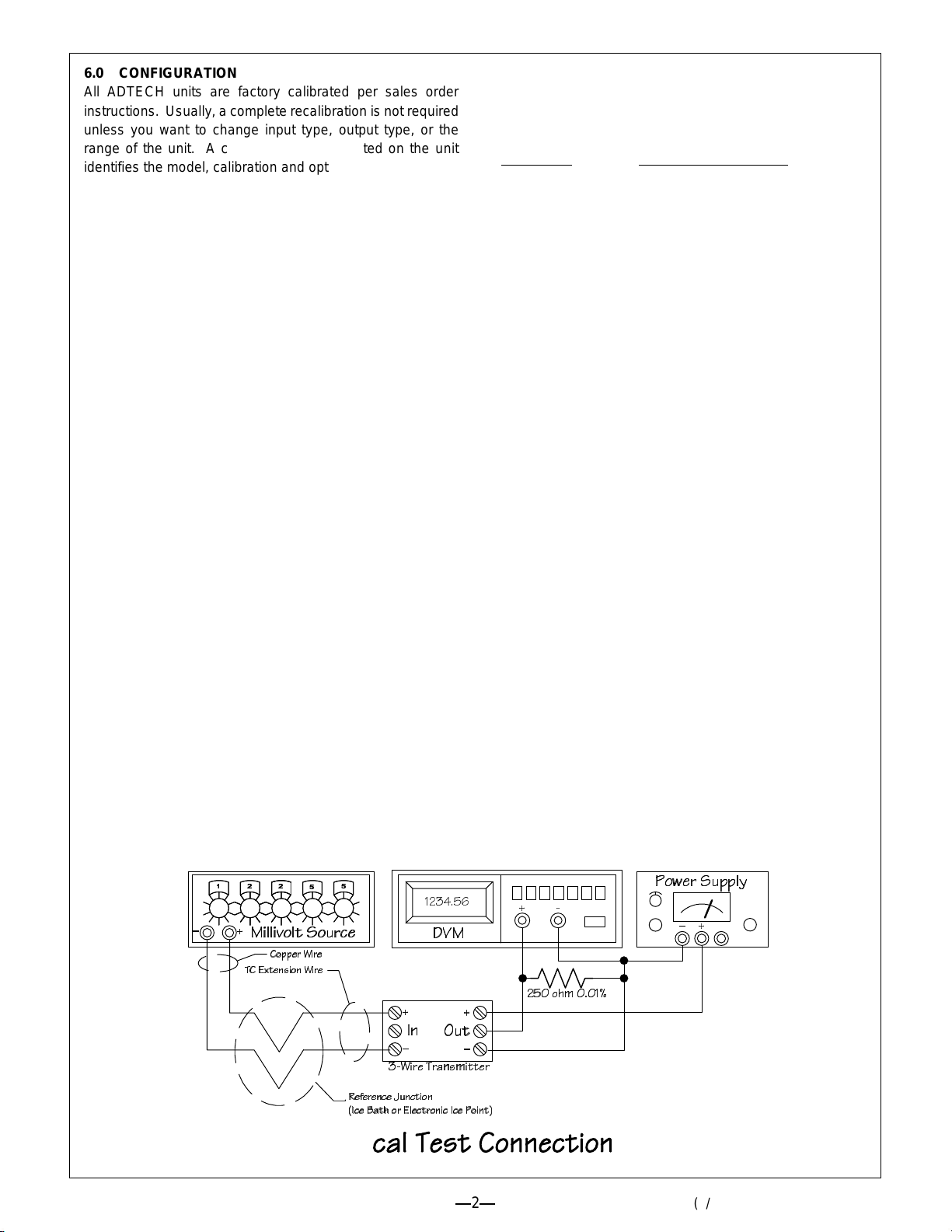

6.0 CONFIGURATION

All ADTECH units are factory calibrated per sales order

instructions. Usually, a complete recalibration is not required

unless you want to change input type, output type, or the

range of the unit. A calibration sticker located on the unit

identifies the model, calibration and options present.

NOTE: For recalibration to the existing range proceed to

section 6.1; for new input or output range proceedas follows.

A. Remove power from the unit. Remove the right cover to

expose the 8 position switch and Jumper J1 on the input

PCB (just above the potentiometers).

B. Set output configuration jumpers per table 1 in section

8.0.

C. Set switch 3 position 1 forupscale or downscaleburnout.

Setswitch3position2toLinearizedornon-linearizedper

table 2, section 8.0. Re-apply power to the unit.

D. Set switch 3 position 3 to the on position and adjust the

output ZERO potentiometer for the proper output.

E. Set switch 3 position 3 to off and position 4 to on. Adjust

the output SPAN potentiometer for full scale output.

Repeat steps D and E until you reach the desired

accuracy. (Note: you can check the midscale value by

depressing switch 3 positions 3 and 4 simultaneously.)

F. Return switch 3 positions 3 and 4 to the off position, and

proceed with section 6.1 below to finish the calibration.

6.1 CALIBRATION

A. Apply the zero input value at the input terminals of the

unit. Depress and hold the ZERO input calibration push

button switch until the ZERO status led flashes. You

have just set the input zero, and the output should be at

your zero value after a short time delay.

B. Apply the full scale input value at the input terminals.

Depressandholdthe SPAN inputcalibration pushbutton

switch until the SPAN status led flashes. You have just

set the full scale value and the output should be at full

scale after a short delay.

C. Calibration is complete. Check the calibration with

various input values and verify the output values.

7.0 FIELD TROUBLE SHOOTING GUIDE

This sectionoffers a simple, first level trouble-shooting aid for

an apparent instrument malfunction.

SYMPTOM CORRECTIVE ACTION

No Output 1. Check the input and output

connections carefully.

2. Check that the power supply

polarity is correct and that the

output loop power is present on

the indicated terminals.

3. Check that the input source(s) is

correct and that it changes

magnitude between zero and full

scale values when so adjusted.

4. Make sure the output loop is

complete and that the correct

meter range is selected.

All external checks are complete.

Problem seems to be internal.

The instrument is made of small components.

Troubleshooting beyond the above may be difficult with out

special equipment. We do not recommend attempting repair

of the unit in the field. ADTECH offers a very responsive

repair policy. Contact theADTECH factory for information on

repair and return at 716-383-8280 or 716-383-8386(FAX).

3

(2/ 0) 190-A-000098 Rev. A

Input PCB Output PCB

TC Type 5 6 7 8

B Off Off Off Off

C On Off Off Off

D Off On Off Off

E On On Off Off

G Off Off On Off

J On Off On Off

K Off On On Off

N OnOnOnOff

R Off Off Off On

S On Off Off On

T Off On Off On

Table 3

8.0 TABLES

Output Configuration Jumpers

Output

Output PCB

(Small Board) Input PCB

(Large Board)

J1 J2 J1

4-20mA A A B

0-20mA A A A

0-10mA A B A

0-1mA A C A

1-5V B A B

0-5V B A A

0-10V C A A

Table 1

Configuration Switch SW3

Switch

Position Function

1Off Downscale burnout

On Upscale burnout

2Off No Linearization

On Linearized

3Off Normal Operation

On Output the zero Value

4Off Normal Operation

On Output the span Value

5,6,7,8 See Table 3

Table 2

Configuration Switch SW3 - TC Type T/C Range and Error

Table 4

!

"# $%&

'

8.1 PCB LAYOUT

4

(2/ 0) 190-A-000098 Rev. A

R

(

ohm

)

(

V

supply

5

)

1000

I

ou

t

max.

mA

9.0 SPECIFICATIONS

INPUT/OUTPUT

INPUT SIGNAL

a. Standard NIST Thermocouple (see Table 3) (Z in

greater than 22 megohm).

b. Conversion to 0.3

V input resolution linearized to 0.1

C conformance - (rms measured noise at 20 Hz

conversion rate is 5

V maximum). Conversion is

filtered to 5.24 Hz bandwidth.

OUTPUT SIGNALS

4-20 mA DC, 0-20 mA DC, 0-10 mA DC, 0-1 mA DC,

0-5 V DC, 1-5 V DC, 0-10 V DC

OUTPUT LOOP DRIVE CAPABILITY

I out 0-20 mA or 4-20 mA (22 mA maximum)

V

supply 15 24 36 42

R (ohm) 500 950 1550 1850

PERFORMANCE

a. Calibrated Accuracy: ± 0.1% of mv input

b. Independent Linearity: ± 0.05% maximum; ± 0.02%

typical

c. Repeatability: ± 0.01% maximum; ± 0.004% typical

d. Zero TC: ±0.15

V /

C

e. Span TC: ± 30 ppm of span max/

C

f. Load Effect: ± 0.005% zero to full load

g. Output Ripple: 10 mV (p-p) maximum

h. Response Time: 67 milliseconds (10 to 90% step

response)

i. Bandwidth (-3 db): 5.24 Hz

j. Temperature Range: -25

to 185

F (-31

to 85

C)

operating; -40

to 200

F (-40

to 93

C) storage

k. Power Supply Effect: ± 0.005% over operating range

l. Isolation: Input/output/case: 600 VAC, 1000 VDC

m. Cold Junction Sensor Error: 0.5

Cmax (-31

to

85

C)

n. Burnout current: 0.1

a - nominal

Note: All accuracies are given as a percentage of span

POWER

a. 15 to 42 VDC - standard, 28 mA typical, 33 mA max

MECHANICAL

a. Electrical Classification: general purpose

b. Connection: Screw, compression type, accepts up to

14 AWG

c. Controls: 8 position switch, input ZERO and SPAN

push button switch and status led’s, output SPAN and

ZERO pots

d. Mounting: DIN Surface, Snap-Track, or NEMA 4,7

e. Weight: Net Unit: 4 oz (115 grams)

Shipping: 7 oz (200 grams)

OPTIONS

Option

Number Description

H 15D Explosion proof: Class 1, Group B, C &

D

H 23 Two (2) inch pipe mounting plate and

clamps

H 25 Snap track mounting ( specify)

H 26 Surface mounting (specify)

H 27 NEMA 4 enclosure (up to 3 units)

H 29 T 35 DIN "T" rail two (2) feet long

H 30 T 32 DIN "G" rail two (2) feet long

10.0 OUTLINE MOUNTING

Other Adtech Transmitter manuals

Popular Transmitter manuals by other brands

Beyerdynamic

Beyerdynamic Unite TH quick start guide

BBC Bircher

BBC Bircher XRF-TI Original operating instructions

Continental Automotive

Continental Automotive 5WK50079 user manual

Emerson

Emerson Rosemount 3051G quick start guide

NBB

NBB Nano-L SMJ operating instructions

Hyundai

Hyundai FMT 419 BTCHARGE instruction manual

dji

dji Transmission High-Bright Monitor Combo manual

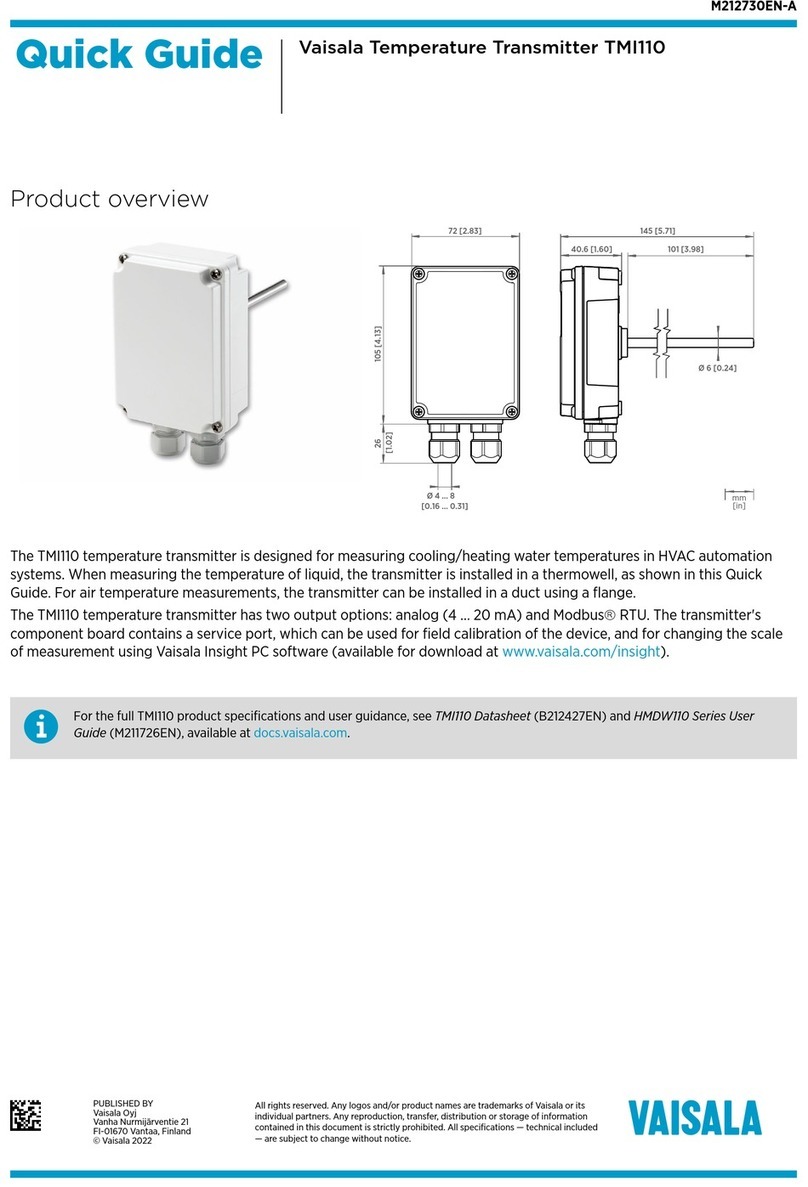

Vaisala

Vaisala TMI110 quick guide

Endress+Hauser

Endress+Hauser iTEMP TMT187 operating instructions

CYP

CYP CH-1103TX Operation manual

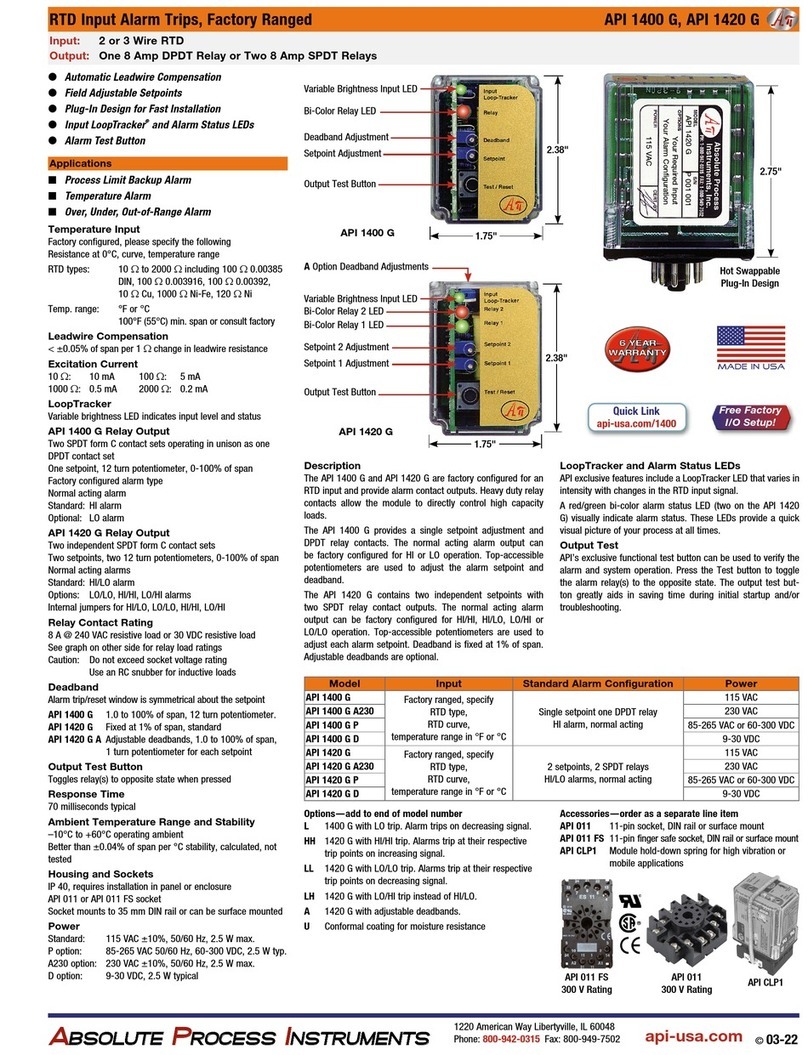

Absolute Process Instruments

Absolute Process Instruments AP11400 G quick start guide

blukii

blukii Smart Beacon Wear 1000 manual