Advanced Energy LumaSense Technologies E2T QUASAR Series User manual

OPERATION MANUAL

E2T QUASAR Flare Monitors

M8100PM-EXP • M8100FM-EXP • M8100SM-EXP

E2T QUASAR Flare Monitors Operation Manual General •ii

Confidential Information

The material contained herein consists of information that is the property of LumaSense

Technologies, an Advanced Energy Company, and intended solely for use by the purchaser of

the equipment described in this manual.

All specifications are subject to change without notice. Changes are made periodically to the

information in this publication, and these changes will be incorporated in new editions.

LumaSense Technologies prohibits the duplication of any portion of this manual or the use

thereof for any purpose other than the operation or maintenance of the equipment described

in this manual, without the express written permission of LumaSense Technologies or Advanced

Energy Industries, Inc.

Any unauthorized use of this manual or its contents is strictly prohibited.

Copyright

© 2018 LumaSense Technologies, Inc. All Rights Reserved. LumaSense Technologies, Inc., a

subsidiary of Advanced Energy Industries, Inc.

Trademarks

E2T is a trademark of LumaSense Technologies.

All other trademarks are trademarks, registered trademarks, and/or service marks of their

respective holders.

Service Centers

LumaSense Technologies, Inc.

North America

Sales & Service

Santa Clara, CA, 95054

Ph: +1 800 631 0176

Ph: +1 408 727 1600

Fax: +1 408 727 1677

LumaSense Sensor GmbH

Other Than North America

Sales & Support

Frankfurt, Germany

Ph: +49 (0) 69 97373 0

Fax: +49 (0) 69 97373 167

Global and Regional Centers

Our Headquarters

LumaSense Technologies, Inc.

Santa Clara, CA, USA

Ph: +1 800 631 0176

Fax: +1 408 727 1677

Americas, Australia, & Other Asia

LumaSense Technologies, Inc.

Santa Clara, CA, USA

Ph: +1 800 631 0176

Fax: +1 408 727 1677

Europe, Middle East, Africa

LumaSense Technologies GmbH

Frankfurt, Germany

Ph: +49 (0) 69 97373 0

Fax: +49 (0) 69 97373 167

France

LumaSense Technologies Sarl

Erstein, France

Ph: +33 3 8898 9801

Fax: +33 3 8898 9732

India

LumaSense Technologies, India

Mumbai, India

Ph: + 91 22 67419203

Fax: + 91 22 67419201

China

LumaSense Technologies, China

Shanghai, China

Ph: +86 133 1182 7766

Ph: +86 21 5899 7915

E-mail

Website

http://www.lumasenseinc.com

Part No 11180-75-EN

Rev. G

February 2019

E2T QUASAR Flare Monitors Operation Manual General •iii

Contents

1General............................................................................................................................. 7

1.1 Information about the user manual...................................................................... 7

1.1.1 Legend......................................................................................................................7

1.2 Safety ....................................................................................................................... 7

1.2.1 Explosion Proof Housing .........................................................................................8

1.3 Limit of Liability and Warranty.............................................................................. 8

1.4 Unpacking and Inspection ...................................................................................... 8

1.5 Service Request, Repair, or Support...................................................................... 9

1.6 Shipments to LumaSense for Repair ................................................................... 10

1.7 Disposal / Decommissioning ................................................................................ 10

2Introduction................................................................................................................... 11

2.1 System Overview .................................................................................................. 11

2.2 System Features .................................................................................................... 12

2.3 Principle of Operation .......................................................................................... 13

2.3.1 Alarm Set Point ......................................................................................................13

2.3.2 Relay Contacts........................................................................................................13

2.4 Signal Path............................................................................................................. 13

2.4.1 SM: Smoke Monitor’s Dual Wavelength (2 color) ...............................................13

2.4.2 PM: Pilot Monitor’s Flame Sensitive Wavelength................................................14

2.4.3 FM: Flare Monitor’s Flame Sensitive Wavelength ...............................................14

2.5 Quick Installation Procedure................................................................................ 14

3Mechanical Installation................................................................................................. 17

3.1 Getting Started ..................................................................................................... 17

3.2 Sight Assessment .................................................................................................. 17

3.2.1 Pilot Monitor (PM) Sighting..................................................................................17

3.2.2 Flare Monitor (FM) Sighting..................................................................................18

3.2.3 Smoke Monitor (SM) Sighting...............................................................................18

3.2.4 Mounting Options .................................................................................................18

3.3 Ambient Temperature Limits ............................................................................... 19

3.4 Cooling Requirements .......................................................................................... 19

3.4.1 Water Cooling........................................................................................................19

3.4.2 Vortex Air Cooling .................................................................................................20

3.5 Viewport Air Purge Requirements....................................................................... 20

3.6 Target Size and Focusing Range .......................................................................... 20

3.7 Focusing on the Target (Adjust Lens).................................................................. 20

4Electrical Installation .................................................................................................... 23

4.1 Electrical Installation Guidelines ......................................................................... 23

4.1.1 Conduit/Connections .............................................................................................23

4.1.2 Over-Current Protection/Service Switch ...............................................................23

E2T QUASAR Flare Monitors Operation Manual General •iv

4.2 Power Connections ............................................................................................... 23

4.2.1 Service Markings ....................................................................................................23

4.2.2 Protective Ground Connection .............................................................................24

4.2.3 Cover Attachment..................................................................................................24

4.2.4 Powering with 115 Volts AC∽...............................................................................25

4.2.5 Powering with 220/230 Volts AC∽........................................................................25

4.2.6 Powering with 24 Volts DC ..........................................................................25

4.3 Fusing..................................................................................................................... 26

4.3.1 Mains ......................................................................................................................26

4.3.2 Heater.....................................................................................................................26

4.4 Connection for mA Output................................................................................... 26

4.5 Connecting the Set Point Relay ........................................................................... 27

5Operating the M8100PM-EXP ....................................................................................... 29

5.1 Start-Up Operation Checklist, Pilot Monitor (PM) .............................................. 31

5.1.1 Getting Started ......................................................................................................31

5.1.2 Initial Control Settings...........................................................................................32

5.1.3 Delay Setting..........................................................................................................32

5.1.4 System Gain/Climate Compensation.....................................................................32

5.1.5 Oscillation on the Analog Meter ..........................................................................32

5.1.6 Noise Amplification ...............................................................................................33

5.1.7 Relay Contacts........................................................................................................33

5.1.8 Delay Adjust ...........................................................................................................34

5.1.9 Milliamp Output (+mA / -mA)...............................................................................34

6Operating the M8100FM-EXP........................................................................................ 35

6.1 Start-Up Operation Checklist, Flare Monitor (FM).............................................. 36

6.1.1 Getting Started ......................................................................................................36

6.1.2 Initial Control Settings...........................................................................................37

6.1.3 Delay Setting..........................................................................................................37

6.1.4 System Gain/Climate Compensation.....................................................................37

6.1.5 Oscillation on the Analog Meter ..........................................................................37

6.1.6 Flare Monitor (FM).................................................................................................37

6.1.7 Noise Amplification ...............................................................................................38

6.1.8 Relay Contacts........................................................................................................39

6.1.9 Delay Adjust ...........................................................................................................39

6.1.10 Milliamp Output (+mA / -mA)...............................................................................39

6.2 Considerations for the Flare Monitor (FM)......................................................... 39

7Operating the M8100SM-EXP ....................................................................................... 41

7.1 Start-Up Operation Checklist, Smoke Monitor (SM) .......................................... 43

7.1.1 Getting Started ......................................................................................................43

7.1.2 Initial Control Settings...........................................................................................44

7.1.3 System Gain/Climate Compensation.....................................................................44

7.1.4 Set-point.................................................................................................................44

7.1.5 Relay Contacts........................................................................................................44

7.1.6 Delay Adjust ...........................................................................................................45

7.1.7 Milliamp Output (+mA / -mA)...............................................................................45

7.1.8 Final Steps...............................................................................................................45

7.2 Considerations for the Smoke Monitor .............................................................. 45

E2T QUASAR Flare Monitors Operation Manual General •v

8Troubleshooting ............................................................................................................ 47

8.1 Problem Isolation Checkout Procedure............................................................... 47

8.1.1 Sight Path and Optical Alignment........................................................................47

8.1.2 Power Input............................................................................................................47

8.1.3 Power Fuse .............................................................................................................47

8.1.4 Instrument Loops ...................................................................................................47

8.1.5 Stopped Chopper Wheel.......................................................................................48

8.1.6 Broken Wire Harness .............................................................................................48

8.1.7 Component Failure ................................................................................................49

9Maintenance .................................................................................................................. 51

9.1 General Maintenance............................................................................................ 51

9.1.1 Chopper Motor Repair ..........................................................................................51

9.2 Cleaning the Optics............................................................................................... 52

10 Safety Assurances and Precautions ............................................................................. 53

10.1 Hazardous Environment Safety ........................................................................... 53

10.2 Electrical Service Protection................................................................................. 53

10.2.1 Over-Current Protection / Service Switch .............................................................53

10.2.2 Over-Voltage Protection .......................................................................................53

10.2.3 Transient Protection ..............................................................................................54

10.2.4 Wiring.....................................................................................................................54

10.2.5 Protective Ground Connection .............................................................................54

Appendix A: Specifications and Parameter Settings........................................................ 55

Appendix B: Area Classification/Protection Concepts...................................................... 57

Label Markings .............................................................................................................. 57

Protection Concepts, Article 500.................................................................................. 58

Appendix C: Declaration of Conformity/ Certificate ........................................................ 61

Appendix D: Statement of Limited Warranty, New Instruments.................................... 63

Appendix E: Engineering Drawings ................................................................................... 65

Index..................................................................................................................................... 71

E2T QUASAR Flare Monitors Operation Manual General •vi

To ensure consistent document formatting, this page was intentionally left blank.

E2T QUASAR Flare Monitors Operation Manual General •7

1General

1.1 Information about the user manual

This manual provides important information that can be used as a work of reference for

installing, operating, maintaining, aligning, and/or troubleshooting your LumaSense

Instrument. It is important that you carefully read the information contained in this manual and

follow all safety procedures before you install or operate the system. To avoid handling errors,

keep this manual in a location where it will be readily accessible.

1.1.1 Legend

Note: Indicates tips and useful information in this manual. All notes should be read

to effectively operate the instrument.

Caution: Denotes information critical to avoiding instrument damage or a severe

impact to processing. When this symbol is found on the instrument it

indicates a potential hazard. Consult the documentation before

proceeding with any actions.

Warning: Denotes information critical to avoiding personal injury, such as when an

electrical hazard is present. When this symbol is found on the instrument it

indicates a potential hazard. Consult the documentation before

proceeding with any actions).

Protective Earth Ground connection.

Caution Must be Followed: reference supplied documents.

Electric Shock Hazard: disconnect service before opening.

∽

Voltage Alternating current (VAC).

Voltage Direct Current (VDC).

1.2 Safety

This manual provides important information on safely installing and operating your LumaSense

Instrument. Several sections of this manual provide safety warnings to avert danger. These

safety warnings are specified with a warning symbol. You must read and understand the

contents of this manual before operating the instrument even if you have used similar

instruments or have already been trained by the manufacturer.

It is also important to continually pay attention to all labels and markings on the instrument and

to keep the labels and markings in a permanent readable condition.

See Chapter 10 Safety Assurances and Precautions,for more information.

E2T QUASAR Flare Monitors Operation Manual General •8

1.2.1 Explosion Proof Housing

The housing is designed to meet the explosion-proof requirements of the National Fire

Protection Association (NFPA) Article 500 for hazardous locations. This Instrument holds both

CSA International and European (ATEX) certifications.

To ensure safe operating conditions, it is recommended that you review the certification and

area classifications that pertain to this system:

Reference

•Appendix B, Area Classification/Protection Concepts

•Appendix C, Declaration of Conformity/Certificate

Warning: Service personnel shall be qualified to install and service electrical

equipment designed for areas classified as hazardous. At no time should the cover be

removed unless power is switched off first. When it is necessary to service the

instrument with the power applied, ensure proper safe environmental conditions exist

and that such maintenance is authorized and pursuant to safe conditions. See

Chapter 10, Safety Assurances and Precautions, for more information.

1.3 Limit of Liability and Warranty

All general information and notes for handling, maintenance and cleaning of this instrument

are offered according to the best of our knowledge and experience.

LumaSense Technologies is not liable for any damages that arise from the use of any examples

or processes mentioned in this manual or in case the content of this document should be

incomplete or incorrect. LumaSense Technologies reserves the right to revise this document and

to make changes from time to time in the content hereof without obligation to notify any

person or persons of such revisions or changes.

All instruments from LumaSense Technologies have a regionally effective warranty period. This

warranty covers manufacturing defects and faults which arise during operation, only if they are

the result of defects caused by LumaSense Technologies.

See Appendix D: Statement of Limited Warranty, New Instruments, for more

information.

1.4 Unpacking and Inspection

Before unpacking the instrument, locate the packing invoice on the outside of the carton. The

invoice lists every item that was included in your shipment. Each LumaSense E2T QUASAR

M8100-EXP instrument is configured to customer specifications. It is recommended that you

confirm that the instrument’s configuration meets expectation by carefully reviewing the

packing slip details.

E2T QUASAR Flare Monitors Operation Manual General •9

When unpacking and inspecting your system, you need to do the following:

•Check all materials in the container against the enclosed packing list.

•LumaSense Technologies cannot be responsible for shortages against the packing

list unless a claim is immediately filed with the carrier. Final claim and negotiations

with the carrier must be completed by the customer.

•Carefully unpack and inspect all components for visible damage.

•Save all packing materials, including the carrier’s identification codes, until you

have inspected all components and find that there is no obvious or hidden damage.

•Before shipment, each instrument is assembled, calibrated, and tested at the

LumaSense Factory. If you note any damage or suspect damage, immediately

contact the carrier and LumaSense Technologies, Inc.

Once you have determined the unit you received is the unit you ordered and it is in acceptable

condition, it is recommended that you spend a few minutes acquainting yourself with the

design and functions of the QUASAR M8100-EXP.

Be sure to reference Chapter 10, Safety Assurances and Precautions, before you begin

installation.

1.5 Service Request, Repair, or Support

Contact LumaSense Technologies Technical Support in case of a malfunction or service request.

Provide clearly stated details of the problem as well as the instrument model number and serial

number. Upon receipt of this information, Technical Support will attempt to locate the fault

and, if possible, solve the problem over the telephone.

If Technical Support concludes that the instrument must be returned to LumaSense Technologies

for repair, they will issue a Return Material Authorization (RMA) number.

Return the instrument upon receipt of the RMA number, transportation prepaid. Clearly

indicate the assigned RMA number on the shipping package exterior. Refer to Section 1.6,

Shipments to LumaSense for Repair, for shipping instructions.

Technical Support can be contacted by telephone or email:

Santa Clara, California (U.S., Mexico, and Canada)

•Telephone (408) 727-1600 or 1-800-631-0176

•Email support@lumasenseinc.com

Frankfurt, Germany

•Telephone: +49 (0) 69 97373 0

•Email: [email protected]

For customers requiring language assistance, please contact your local office or representative to

facilitate support and repair.

E2T QUASAR Flare Monitors Operation Manual General •10

1.6 Shipments to LumaSense for Repair

All RMA shipments of LumaSense Technologies instruments are to be prepaid and insured by

way of preferred carrier. For overseas customers, ship units air-freight, priority one.

The instrument must be shipped in the original packing container or its equivalent. LumaSense

Technologies is not responsible for freight damage to instruments that are improperly packed.

Clearly indicate the assigned RMA number on the shipping package exterior. If no RMA is

indicated, shipment will not be accepted.

Send RMA Shipments to your nearest technical service center:

Customers in North America

should send RMA Shipments to:

Santa Clara, California

All other customers should

send RMA Shipments to:

Frankfurt, Germany

LumaSense Technologies, Inc.

3301 Leonard Court

Santa Clara, CA 95054 USA

Telephone: +1 408 727 1600

+1 800 631 0176

Email: support@lumasenseinc.com

LumaSense Technologies GmbH

Kleyerstr. 90

60326 Frankfurt

Germany

Telephone: +49 (0)69-97373 0

Email: [email protected]

1.7 Disposal / Decommissioning

Inoperable QUASAR M8100-EXP instruments must be disposed of in compliance with local

regulations for electro or electronic material.

E2T QUASAR Flare Monitors Operation Manual Introduction •11

2Introduction

2.1 System Overview

The Quasar 8100-EXP Pilot Monitor (PM), Flare Monitor (FM), and Smoke Monitor (SM) are

unique monitoring and detection instruments designed for continuous duty monitoring of Pilot

Flame, Flaring and Smoke on Flares.

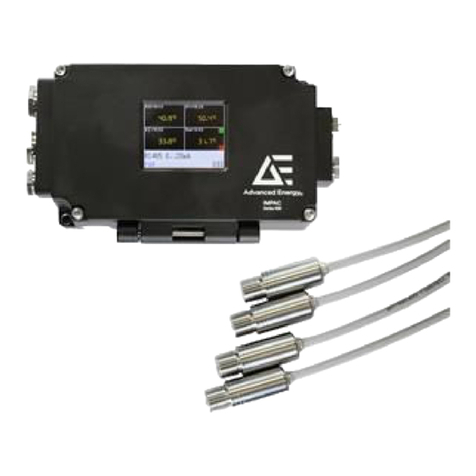

The heart of the LumaSense E2TQUASAR M8100-EXP Flare Monitoring System is the non-contact

infrared Electro-Optical package, which can be removed from the explosion proof housing for

repairs or replacement, while leaving all wiring and alignment of the system intact

(see Figure 1).

Figure 1: M8100 Housing and Electro-Optical Package

E2T QUASAR Flare Monitors Operation Manual Introduction •12

A sight-through optical system and selection of various optical resolutions (fields of view) enable

the QUASAR M8100-EXP to be positioned as far as 1/4 mile (400 m) from the stack being

monitored. Alignment on the target is accomplished using exceptional sight-through optics and

the M-3 Heavy Duty Swivel Mount.

Figure 2: Quasar M8100-EXP

The electronics allow for target movement, varying luminosity and a range of climate

conditions. The alarm contact closure delay can be adjusted for a specific location or application,

eliminating false alarms due to intermittent flames, wind, and/or transitory high smoke levels. A

single internally heated detector assures long-term stability and drift-free operation. The system

is complete with internal cooling base, air purge tube and swivel mount. An optional adjustable

pedestal stand allows for easy mounting.

2.2 System Features

Features of the QUASAR M8100-EXP Flare Monitoring System are as follows:

•Explosion-proof housing.

•4 … 20 mA output.

•The Quasar 8100-EXP PM & FM provide a switched 4mA (Flame) or 20mA (No Flame)

switched mA output.

•The Quasar 8100-EXP SM provides a mA span determined by the flame size of the

target flaring event. (Note: every span will be different for different flare

applications)

•On-board ALARM set point with normally open N.O. and normally closed N.C. relay

outputs. This Alarm Setpoint is delayed in the PM/FM from 2 seconds to 2 minutes.

The SM system has no delay.

•Climatic compensation adjustments.

•An Electro-Optical package that is easy to remove from the explosion-proof

housing, minimizing downtime and increasing reliability (see Figure 1).

•An internal heater and water/air cooler cavity for ambient temperature

compensation.

•High quality sight-through optics.

•Local status indication lights.

E2T QUASAR Flare Monitors Operation Manual Introduction •13

2.3 Principle of Operation

All objects above absolute zero emit infrared energy. The amount of energy emitted is

proportional to the body’s temperature. The QUASAR M8100-EXP collects this energy by means

of a focusing optical system concentrating the energy from a body onto a sensitive infrared

detector. Specialized amplification circuitry converts the signal received by the detector into a

DC level to activate relay and mA outputs for monitoring. The M8100-EXP utilizes amplitude

correction circuitry which, when initially set, will automatically correct for diminishing radiation

amplitude due to varying and/or adverse weather conditions.

2.3.1 Alarm Set Point

PM/FM - If the instrument detects a loss of signal fault, an adjustable delay timing circuit starts a

countdown to activate a “loss of signal” alarm. This delay circuit allows for loss of signal due to

wind or adverse conditions for a time period of two seconds to two minutes. This allows the

monitor to reacquire the flame before an alarm signal is sent, limiting false alarms due to

weather conditions. The alarm provides status by LED and Relay contacts.

SM - The alarm set point has no delay and activates in real time.

2.3.2 Relay Contacts

Denoted by their non-energized states, Normal Open (N.O.) and Normal Closed (N.C.) contacts

are common to a single Relay Common (Com), also known as “single pole double throw”

contacts.

4-20mA Outputs

•PM & FM: 4 or 20mA circuit outputs 4mA or 20mA depending on a preset signal level.

Standard output provides 4mA with a flame present, 20mA without a flame present.

This is a switched output.

•SM: mA circuit outputs a signal proportional to the relative amount of smoke detected.

2.4 Signal Path

Infrared (IR) energy is focused onto the detector through a rotating chopper wheel. The

chopper wheel provides the ability to stabilize and improve noise rejection. IR filters are

employed for the FM, PM, and SM models. By virtue of these select, application-specific IR filters,

the desired IR energy is allowed to pass and be amplified by the detector. Filters are located on

the chopper wheel for the SM and are located on the detector for the FM and PM.

The rotating chopper wheel creates a pulsing (on/off) signal, which is then selectively amplified

by the detector. The detector’s amplified signal is conditioned by chopper synchronized,

automatic amplitude control and stabilization circuits. This allows for compensation for

diminishing IR radiation due to climate conditions and is accomplished without operator

intervention.

After the signal is conditioned, it is further filtered and provides the input to subsequent; relay

driver, time delay and 4 … 20mA output control circuits.

2.4.1 SM: Smoke Monitor’s Dual Wavelength (2 color)

Unique to the QUASAR M8100SM-EXP is the use of 2 filters at separate wavelengths or colors.

These filters located on the chopper wheel, allow the electronics to selectively amplify the IR

energy of interest over the background IR energy, thus allowing the Smoke Monitor to

distinguish particulate (smoke) from the background flame that is present.

E2T QUASAR Flare Monitors Operation Manual Introduction •14

2.4.2 PM: Pilot Monitor’s Flame Sensitive Wavelength

The QUASAR M8100PM-EXP uses a single select filter allowing the electronics to amplify the IR

energy of interests over the background IR energy. This allows the Pilot Monitor to achieve high

sensitivity and dynamic range.

2.4.3 FM: Flare Monitor’s Flame Sensitive Wavelength

The QUASAR M8100FM-EXP uses a single select filter allowing the electronics to amplify the IR

energy of interests over the background IR energy. This allows the Flare Monitor to achieve high

sensitivity and dynamic range.

2.5 Quick Installation Procedure

This quick installation procedure may be used as a checklist if you are familiar with the

equipment. For complete instruction and safety precautions, refer to the appropriate sections of

this manual:

•Appendix E: Engineering Drawing 613-816, Service Connections

•Chapter 3, Mechanical Installation

•Chapter 4, Electrical Installation

•Chapter 10, Safety Assurances and Precautions

Warning: Service personnel shall be qualified to install and service electrical

equipment designed for areas classified as hazardous. At no time should the cover be

removed unless power is switched off first. When it is necessary to service the

instrument with the power applied, ensure proper safe environmental conditions exist

and that such maintenance is authorized and pursuant to safe conditions. See

Chapter 10, Safety Assurances and Precautions, for more information.

1. Installation Sight Assessment

a. Verify the location is within the instrument’s design capabilities and that the

field of view will yield acceptable performance. Refer to Chapter 3, Mechanical

Installation, for more information.

b. Confirm the instrument’s input power and signal output configuration is as

expected.

2. Mechanical - ensure the correct air requirements are met:

a. View port purge

b. Vortex cooler (if required)

3. Focus the instrument on the target (adjust the lens).

4. Electrical - (Reference: Section 10.2, Electrical Service Protection):

a. Connect the instrument power:

i. The power service type is marked on the Terminal Output PC Board;

verify that it corresponds to the service type being installed.

ii. Separate the power wires from the signal wires by routing through

separate conduit ports.

iii. Connect the service power to TB1 on the Terminal Output PC Board.

E2T QUASAR Flare Monitors Operation Manual Introduction •15

Note: Secure power input lines together after connection to the

Terminal block to prevent an accidental hazardous live condition in the

unlikely event that a terminal screw becomes loose. Sleeve or tie

wrapping is acceptable.

b. Connect the instrument loops and alarm outputs:

i. Connect the lines as needed for Normal Open (N.O.) or Normal Closed

(N.C.) relay to the corresponding locations on TB2.

ii. Connect the mA lines to the corresponding (MA-) and (MA+) outputs on

TB2. Cable shield, if present, is NOT recommended to be connected to

the instrument.

5. Proceed to the following chapters to complete the start-up checklist:

a. Chapter 5: Pilot Monitor (PM)

b. Chapter 6: Flare Monitor (FM)

c. Chapter 7: Smoke Monitor (SM)

E2T QUASAR Flare Monitors Operation Manual Introduction •16

To ensure consistent document formatting, this page was intentionally left blank.

E2T QUASAR Flare Monitors Operation Manual Mechanical Installation •17

3Mechanical Installation

3.1 Getting Started

Each LumaSense E2TQUASAR M8100-EXP instrument is configured as per customer’s request.

The packing slip order number matches that of the instrument’s serial number. It is

recommended to confirm that the instrument’s configuration meets expectation, by reviewing

packing slip details.

Once you have determined the unit you received is the unit you ordered and it is in acceptable

condition, the unit is ready for installation. It would be a good idea to spend a few minutes

"getting to know" your QUASAR M8100-EXP.

Reference: Chapter 10 Safety Assurances and Precautions.

3.2 Sight Assessment

Care must be taken during installation to ensure that the sun will not be seen through the

optical sight path in any season or time of day. This requires that the instrument be located on a

true north-south axis ± 45 °. In the northern hemisphere, the monitor preferably should be

looking toward true north, while in the southern hemisphere it should be aimed toward true

south. Contact LumaSense for exceptions to these standard installation parameters.

Figure 3: Field of View Concept

3.2.1 Pilot Monitor (PM) Sighting

Recommended installation distance should be equal to the height of the flare stack from the

base of the flare stack. The maximum vertical angle for sighting the monitor is 45 ° above

horizontal. (See Appendix E Engineering Drawing 613-228) Targeting should include the

Pilot flames and have a spot size of 1.5x to 2x the flare diameter.

E2T QUASAR Flare Monitors Operation Manual Mechanical Installation •18

3.2.2 Flare Monitor (FM) Sighting

Recommended installation distance should be equal to the height of the flare stack from the

base of the flare stack. The maximum vertical angle for sighting the monitor is 45 ° above

horizontal. (See Appendix E Engineering Drawing 613-228)

Targeting should be just above the pilot flames, so that they are not included in the

measurement, or if this is not possible, then the gain should be reduced until the pilot flames

are not detected. The spot size of the system should be 3x to 4x the flare tip diameter.

3.2.3 Smoke Monitor (SM) Sighting

Recommended installation distance from the base of the stack is at least 1 to 2 times the stack

height. The maximum vertical angle for sighting the monitor is 45 ° above horizontal. The field

of view must be at least 4 to 5 times the stack top diameter when no wind is present.

3.2.4 Mounting Options

For easy mounting, alignment, and focusing on the target, a swivel mount with locking and

adjusting capability is provided (LumaSense’s M-3 Heavy Duty Swivel Mount). The M-3 Heavy

Duty Swivel Mount can be secured on a pedestal base model M-8 using a telescoping steel pipe

with a bolt down plate to secure the M-8 to a foundation. (See Figure 5) As an alternative, the

M-3 Heavy Duty Swivel Mount can be installed on a client supplied 2-inch schedule 40 pipe

mount.

Figure 4: Field of View Concept

E2T QUASAR Flare Monitors Operation Manual Mechanical Installation •19

Figure 5: Pedestal Mounting Concept

3.3 Ambient Temperature Limits

The ambient operating temperature limits of the QUASAR M8100-EXP are -40 °F (-40 °C) to

120 °F (50 °C). When the internal temperature drops below 40 °F (4 °C), an internal electric

heater activates to keep the internal temperature at or above 40 °F (4 °C). If the ambient

temperature is expected to be below -40 °F (-40 °C), additional heating or protection for the

instrument is required. If the ambient temperature is expected to be above 120 °F (50 °C), water

or Vortex Air cooling is required.

3.4 Cooling Requirements

If ambient temperatures in excess of 120 °F (50 °C) are anticipated during the operation of the

QUASAR M8100-EXP, cooling will be required by one of the following two methods:

3.4.1 Water Cooling

Provide cooling water at 60 °F (15 °C) maximum from a filtered source with a flow rate capable

of sustaining at least 10 gallons per hour (37.8 L/h) to the cooling cavity built into the underside

of the explosion-proof enclosure. This method allows operation in ambient temperatures up to

200 °F (93 °C). If the available cooling water temperature is above 60 °F (15 °C), then trial-and-

error testing will have to be performed to empirically set the appropriate flow rate. The flow

rate must be adequate to ensure that the electronics inside the explosion-proof enclosure do

not rise above 120 °F (50 °C).

E2T QUASAR Flare Monitors Operation Manual Mechanical Installation •20

Note: The cooling cavity is isolated from internal surface of explosion-proof

enclosure. See Appendix E Engineering Drawing 613-816, Service Connections.

3.4.2 Vortex Air Cooling

Connect a V208-15-H Vortex Air cooler to the cooling cavity built into the underside of the

explosion-proof enclosure. Provide filtered, dry, compressed air from a minimum 90 psig source

with a sustained flow rate capability of at least 10 SCFM to the vortex air cooler. This will result

in a temperature reduction up to 27 °F (3 °C) lower than the supply air. It is not necessary to over

cool the instrument. Instead, reduce the enclosure temperature to its specified operating limits

by adjusting the upstream pressure to the Vortex Cooler. If over cooling does occur, the heater

built into the system will activate and keep the electronics within limits.

Note: The cooling cavity is isolated from internal surface of explosion-proof

enclosure. See Appendix E Engineering Drawing 613-816, Service Connections.

3.5 Viewport Air Purge Requirements

A source of sustained dry instrument air with a flow rate through a regulator or needle valve

capable of sustaining 1 SCFM flow rate from a 20 psig or greater supply is required to keep the

lens clean.

3.6 Target Size and Focusing Range

The target size of the QUASAR M8100-EXP is a function of the distance from the lens to the

object under observation and the optical resolution set at the factory. The target area is a circle

reticle as viewed through the QUASAR M8100-EXP's sight-through optics. The diameter of the

detection area (Target Size) is represented by the reticle circle and is calculated using the

formula:

Target Size = D

R

Where D = the distance from the lens to the target.

R = the appropriate value from the following table

The resolution of the optics is application-

specific and determined at time of order.

Resolution

37.5

60

75

150

300

3.7 Focusing on the Target (Adjust Lens)

The objective lens locking and focusing screw and the eyepiece are both located on the top of

the infrared electro-optical package inside the explosion-proof enclosure (see Figure 6).

To focus, first rotate the eyepiece lens (Figure 6, item 1) in or out until the reticle is clear and

sharp. Next, slowly loosen the lens locking and focusing screw (see Figure 6, item 2). Move the

objective lens (see Figure 6, item 3) in or out with the focusing screw until the target is clear and

sharp. Tighten the screw; the focus is now set.

This manual suits for next models

3

Table of contents

Other Advanced Energy Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Lascar Electronics

Lascar Electronics PanelPilot M quick start guide

Gima

Gima FAT 2 user manual

DayTronic

DayTronic 4500 Quick reference guide

Rae

Rae UltraRAE PGM-7200 Operation and maintenance manual

Renogy

Renogy Battery Monitor manual

Keysight Technologies

Keysight Technologies B2980A Series Technical overview

ECO Sensors

ECO Sensors UV-100 Instructions for use

Powerfix Profi

Powerfix Profi Z22855 Operation and safety notes

LUDLUM

LUDLUM 177-84-1 manual

Fluke

Fluke Datapaq Reflow Tracker user manual

turck

turck B N -QR20-IOL Series Instructions for use

PCB Piezotronics

PCB Piezotronics IMI SENSORS ICP 621B40 Installation and operating manual