Advanced Power technologies ECLIPSE User guide

Page 1 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Application Guide-AG010

Title: ECLIPSE DFWT Install and Application Guide

Model: ECLIPSE &

TOTAL ECLIPSE

Written By: T. Williams & J. Mundackal

Date:

04/27/2020

Rev. C

Application Summary

The ECLIPSE is capable of providing Direct Fiber Winding Temperature using

enhanced Rare-Earth tipped probes that utilize blue LED technology or using

legacy phosphor tipped probes using red LED technology. The ECLIPSE with

DFWT may be applied on new transformers and can be used to replace legacy

fiber probe Monitors using red LED legacy phosphor fiber optic probes.

This application guide will discuss in detail:

•Theory of Operation

•New Transformer Application

•Retrofit Application

•Fiber Removal

•ECLIPSE Programming

•Testing

Contents

Table of Contents

1 DFWT Specifications

2 Theory of Operation

3 New Transformer Application

3.1 Required Accessories

3.1.1 Fiber Probes

3.1.2 Fiber Extension

3.1.3 Flange Plate

3.2 Optional Accessories

3.2.1 Flange Housing

3.3 Fiber Installation

Page 2 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

3.3.1 Handling of the Probe

3.3.2 Routing of Fiber

3.3.3 Key Spacer Insert Fabrication

3.3.4 Probe Placement

3.3.5 Routing the probes out of the winding

3.3.6 Routing probes to the flange plate optical couplers

3.3.7 Connector cleaning procedure

3.3.8 Flange Plate

3.3.9 Fiber Extensions

4 Retrofit Application

4.1 Required Equipment

4.2 Installation

5 Fiber Removal

6 ECLIPSE Programming

6.1 Configuration Settings

6.2 Set Point Settings

6.3 Naming Settings

7 Testing

Page 3 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

1 DFWT Specifications

➢Enclosure & Dimensions: 8.028 W x 4.882 H x 6.40 D Alodine

Aluminum

➢Front Panel Dimensions: 8.378 W x 5.686 H

➢Power Supply Input Operating Range: 38 VDC to 290 VDC or 120

VAC +/- 10% with Surge Protection Device, 10 Watts max.

➢Operating Temperature Range: -50 °C to +85 °C, 95% Relative

Humidity (non-condensing)

➢Temperature Measurement Accuracy: ± 2 °C Full Scale

➢Temperature Measurement Range: - 40 to 200 °C

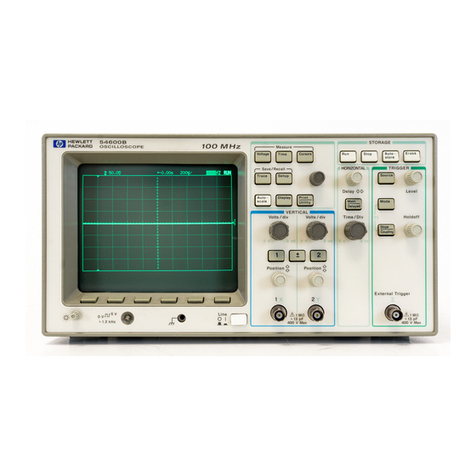

➢Communications Interfaces: Front Panel Mounted RS-232 DB-9

Null Modem interface

Ethernet: 10/100 Base-T metallic interface with transformer

isolation of 1,500 Volts AC RMS in accordance with IEEE/ANSI

802.3

➢Surge Withstand/Fast Transient: Relay outputs and station battery

inputs: ANSI C37.90.1

➢Electrostatic Discharge: IEC 801-2

2 Theory of Operation

Direct Fiber Winding Temperature uses either fluorescing tipped or

Gallium Arsenide (GaAs) tipped fiber optic probes inserted directly into the

winding of the transformer. Advanced Power Technologies provides

superior Rare-Earth tipped probes, which are produced by dipping the tip

of the glass fiber into a slurry of fluorescing Rare-Earth material and then

firing it to bond the slurry to the glass fiber. While GaAs technology was

thought to be an improvement in cost over phosphor, it may actually

create a serious long-term issue caused by very high electric stresses at

voltages equal to and above 230 kV that may cause partial discharge (PD)

should there be voids at the interface between the glass fiber and GaAs

chip. Rare-Earth tipped probes can withstand electric stresses at voltages

in excess of 765 kV because the firing process produces a product that

has no voids between the Rare-Earth coating and the fiber. Therefore,

Rare-Earth tipped probes are preferred because of the risk should PD

develop and the cellulose insulation in the vicinity of the fiber probe is

compromised.

The ECLIPSE provides a pulse of light that excites the Rare-Earth

material coating where the decay rate is a function of temperature. The

ECLIPSE uses the decay rate to determine the temperature within ± 2 C

Page 4 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

using Advanced Power Technologies’enhanced blue LED phosphor

technology.

DFWT allows for the direct measurement of the winding hot spot

temperature rather than traditional methods such as simulated winding hot

spot temperature using a heated thermowell or calculated winding

temperature. The advantages of the DFWT include: faster response of

winding hotspot temperature when there is a sudden load change, more

accurate loss of life calculation, real-time dynamic loading, and real-time

cooling system failure detection.

3 New Transformer Application

3.1 Required Accessories

3.1.1 Fiber Probes

The fiber probes for within the tank are available in two

different lengths from stock 4 meters or 10 meters. The part

numbers are 1000252-4 and 1000252-10 respectively.

Figure 3.1 Fiber Probe

3.1.2 Fiber Extensions

The fiber extensions from stock are available in three

different lengths: 5, 10, and 20 meters. Fiber extensions

come four fibers to a set. The relevant part numbers are

1000253-5, 1000253-10, and 1000253-20 respectively.

Page 5 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Figure 3.2 Fiber Extensions

3.1.3 Flange Plate

The flange plate is 304 stainless and is supplied with a steel

ring that is to be welded on the side of the transformer tank.

Depending on the number of fibers required for installation in

the transformer tank, there are three different flange

configurations available: 4, 8, and 12 fiber probes. The three

assembly part numbers are 1000254-4, 1000254-8, and

1000254-12 respectively.

Page 6 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Figure 3.3 Flange Plate

3.2 Optional Accessories

3.2.1 Fiber Junction Box

A Fiber Junction Box can be provided by Advanced Power

Technologies. This enclosure provides protection against the

elements for the connections of the fiber extensions on the

Page 7 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

external side of the flange plate. The part number is:

1000255.

Figure 3.4 Fiber Junction Box

3.3. Fiber Installation

3.3.1 Handling of the Probe

- Avoid pulling the probes over sharp bends or corners

- Avoid straining and over-twisting the fiber

- Avoid dropping heavy objects on the probes or dragging

heavy objects over them, as this can crush the probe

fiber

3.3.2 Routing of the Fiber

Secure the probe using cloth or cotton strapping and tie it

only as firmly as necessary when routing the probe inside

the transformer.

NOTE

Do not use nylon cord, as this could overstrain the fiber.

3.3.3 Key Spacer Insert Fabrication

Key spacer inserts can be fabricated by modifying standard

paper spacers.

Page 8 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

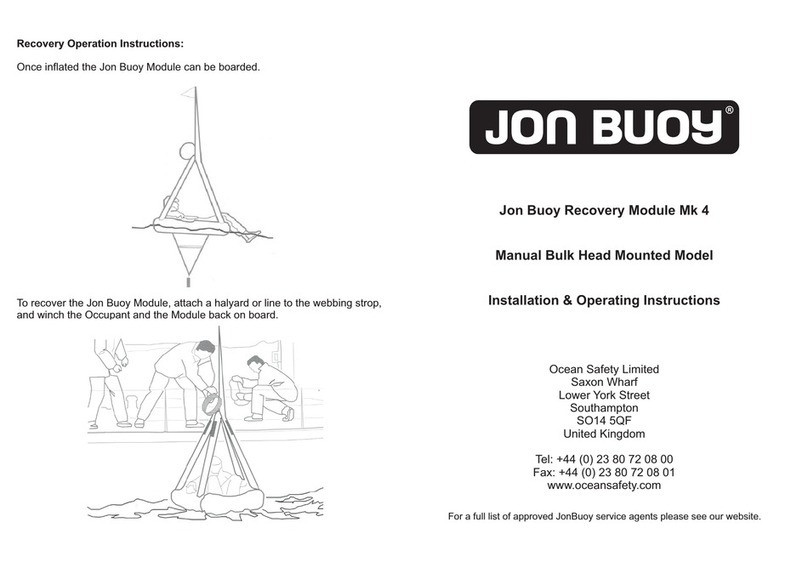

Figure 3.5 –Probe in spacer diagram

A 3mm diameter slot should be drilled into a standard spacer

as you can see in Figure 3.4. Be sure not to apply adhesive

near the tip of the probe as this can affect the temperature

readings. Adhesive may not even be necessary; the spiral-

wrapped probe wire fits quite snugly within a 3mm diameter

slot. Please do not apply sharp bends to the probe as it exits

the spacer and/or the winding.

Figure 3.6 –Probe tip inside modified spacer

Page 9 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Warning:

•Do not apply any adhesive near the tip of the probe

•Do not bend the tip of the fiber probes.

3.3.4 Probe Placement

The sensing part of the fiber optic probe is located at the tip

of the probe about 2 to 3 mm from the probe end. To monitor

the temperature of the windings, the probe tip should be

secured adjacent to the winding’s hottest spot.

Figure 3.7 –Modified spacers with probes installed inside

winding

3.3.5 Routing the probes out of the winding

•When installing the probes it is advisable to coil unused

portions in loops no smaller than 30 cm in diameter

•It is also preferable not to have the connector swinging

freely during dry out and assembly

•The coil and connector can be attached with a cotton

strapping on string.

•A good trick is to use a spool (cardboard or wood) to

keep the uninstalled fiber portion well organized.

Note: The dust cap (installed on the probe connector

end) should be left on the connector during the all the

installation process, until the connector is connected to

the optical coupler (feedthrough). This keeps the dust

and dirt away from the fiber tips. The dust caps for the

probes are made of Teflon, so they should be left on

the probes even during the heat runs, until the probes

are connected to their optical couplers.

Page 10 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

3.3.6 Routing probes to the flange plate optical couplers

Assuming the probe exits the winding beside the winding leads,

probes can all be run along the tops of the windings to the one wall of

the tank. The routing should be done only after the winding and core

assembly has been installed in the tank, the idea again being to

delay any probe installation steps as much as possible during the

manufacturing process.

Probes can be run through Bakelite tubing or any other stiff tubing or

secured using cotton strapping (do not over-tight) to any supporting

structure. Tubing that is flexible but stiff is dangerous as bending

could cause sharp edges which can damage the probe if it is jerked;

avoid using tubing or jacketing of this sort.

3.3.7 Connector cleaning procedure

Probe and extension connectors need to be cleaned to get the best

signal to the ECLIPSE fiber channels.

•Use optic grade wipes or clean cotton wipes and optical grade

99% isopropyl alcohol.

•Gently wipe the ferrule (specifically its end) in a circular

motion.

•Allow 10 seconds for the alcohol to evaporate.

3.3.8 Flange Plate

Weld the carbon steel ring on to the transformer wall where

the signal of the direct fiber probes will be brought out of the

transformer (location should be below oil level inside the

transformer)

Cut a hole in the transformer wall equal to or less than the

inside diameter of the steel ring.

Assemble the 304 stainless steel flange plate with welded

optical couplers to the steel ring; using the O-ring installed in

the groove and bolts with washers.

Note: The dust caps will be supplied with Flange plate. The

dust caps should be left on all the available ports until the

fiber extensions connected to the ports. In case the

customer leaves the ports open, optical couplers

(feedthrough) may be contaminated with dust, dirt or

moisture. The contamination results in attenuation of the

light transmitted or reflected. Apply clean dry air (Air duster)

to the ports to remove the foreign particles. Do not use

compressed air.

Page 11 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

3.3.9 Fiber Extensions

Fiber extensions are only for external use outside the

transformer tank. One end should be connected to the flange

plate and the other to the ECLIPSE.

•Clean both ends of the fiber optic extension (Refer

section 3.3.7 for connector cleaning procedure) and

connect fiber end to the flange plate and other end to

the ECLIPSE fiber channels

•Hand tighten the knurled nut on the extension

connector to the connector of the flange plate

•Minimize the number of connect-disconnect cycles.

Note 1: Fiber optic extensions are built using fiber optic

components and they are fragile. The extensions must be

handled with the same care as for the probes to avoid cracks

and scratches.

Note 2: The dust caps should be left on both ends of the

connectors during the installation process, until the

connectors are connected to flange plate and ECLIPSE.

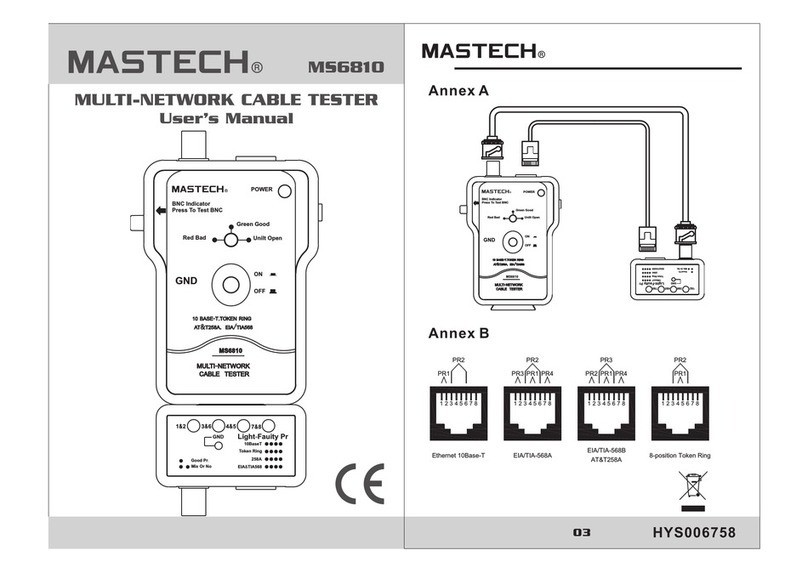

Figure 3.8 ECLIPSE back panel with 8 direct fiber channels

Page 12 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Note 1: The dust caps must be left on the ECLIPSE fiber

channels until the fiber extensions are connected

properly. This keeps the dust, dirt and moisture away

from the fiber channels.

Note 2: If the user leaves the fiber channels open it may

contaminated with dust, dirt or moisture. The

contamination results in attenuation of the light

transmitted or reflected. In that case it is advised to

blow out each of the fiber transceivers with clean dry

canned air. Do not use compressed air to clean the fiber

channels.

Note 3: It is recommended not to run the ECLIPSE

without the proper fiber probe connections to all the

available channels. Otherwise ‘DISABLED’ the fiber

channels in the ECLIPSE settings.

4 Retrofit Application

ECLIPSE DFWT replaces and upgrades existing phosphor tipped direct

fiber winding temperature monitoring instruments. This retrofit does not

require replacement of the fiber probes or fiber extensions if they are in

good working order. As mentioned, the ECLIPSE is not compatible with

GaAs fiber probes. Retrofitting an ECLIPSE is the lowest cost solution to

achieve a complete transformer monitoring platform. Maintenance is

required after the install. Its real-time winding hot spot calculation permits

real-time dynamic loading of the transformer.

4.1 Required Equipment

The ECLIPSE DFWT can only be retrofitted onto transformers where

phosphor tipped fiber probes have been installed during the

manufacturing of the transformer. The fiber probes, flange plate or

equivalent, and fiber probe extensions should be available for direct

connection to the ECLIPSE from the previous installation.

4.2 Installation

Once the ECLIPSE has been mounted either in the transformer

control cabinet or NEMA enclosure, the fiber extensions from the

previous install can be directly connected to the back of the

ECLIPSE.

Page 13 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

5 Fiber Removal

Caution must be used to avoid damaging the fiber probe if it needs to be

removed from inside the tank. An O-ring on the connection interior of the

tank creates a seal to avoid oil leaks. As the fiber extension on the exterior

of the tank is connected, all the air within the flange plate termination is

pushed out, creating a vacuum. The fiber extension must be removed on

the external side of the flange plate prior to removal of the fiber connection

on the internal side. The interior connection should be removed by gently

pulling it while wiggling the connector to break the seal. Use caution

throughout this entire process so as to not damage the fiber and fiber

jacket.

6 ECLIPSE Programming

Programming of the ECLIPSE can be done via three different methods:

➢Front panel LCD and pushbutton interface

➢PC equipped with terminal emulation software

➢Built-in web-based graphical user interface (GUI)

Not every setting can be changed through the front panel LCD. Those

settings must be programmed either through the PC terminal connection

or via the web-based GUI.

ECLIPSE models configured to support Fiber Optic Temperature (DFWT)

have the ability to measure up to eight temperatures (FP1 –FP8) using

Rare-Earth tipped fiber optic temperature probes. These temperatures are

sampled at a rate of once per second. Advanced Power Technologies

temperature probes support a range of −100 to 200 ˚C within 2 ˚C

absolute accuracy between 40 and 140 ˚C. In addition, there are fiber

optic temperature probe alarm points (ALFPROBE1 –ALFPROBE8), one

per fiber probe channel. These alarms pick up when the ECLIPSE detects

a problem with one of the fiber probes, fiber probe extensions, and/or fiber

measurement channels, and the ECLIPSE is unable to acquire

temperature correctly on that channel. Settings associated with Fiber

Optic Temperature are explained below.

6.3 Configuration Settings

Configuration settings include APPLICATION, TYPE, and

CALIBRATION. Configure fiber optic probe channels to be of a

particular application based on the function for which they are being

used. For example, a fiber probe used for measuring top oil would

be configured with a probe application of “TOP OIL.” A fiber probe

used for measuring winding hotspot temperature directly would be

Page 14 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

configured as “GENERIC.”The TYPE defines a STANDARD

Advanced Power Technologies probe or an ALTERNATE type of

probe using another manufacturer’s phosphor technology. The

CALIBRATION can be ENABLED or DISABLED for each probe to

apply a previously generated channel-specific adjustment for

improved accuracy.

NOTE

Probe application functions are shared between all probes in ECLIPSE, including

standard non-fiber probes (application referred to as “Type” for RTD probes). It is

important to always configure the proper probe applications because the

ECLIPSE uses this information to internally assign probes for certain functions.

Failure to configure the probe applications properly could result in incorrect

operation.

NOTE

The ECLIPSE allows a maximum of one TOP OIL, one BACKUP TOP OIL, and

two LTC DIFF / LTC TANK probes. There is no limit on DISABLED/GENERIC

probes. If BACKUP TOP OIL probe is defined, the ECLIPSE will automatically

switch to BACKUP TOP OIL probe for the top oil temperature if the TOP OIL

probe fails.

Associated Settings:

Setting Names

Range

Description

Change

from Front

Panel

FP1

APPLICATION -

FP8

APPLICATION

DISABLED (0)

TOP OIL (1)

BACKUP TOP

OIL (2)

GENERIC (3)

LTC DIFF (4)

LTC TANK (5)

Configures the uses

(application) for each of the

fiber probes.

Yes

Page 15 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Setting Names

Range

Description

Change

from Front

Panel

FP1 TYPE –

FP8 TYPE

STANDARD (0)

ALTERNATE (1)

STANDARD option for

Advanced Power Technologies

Probe.

ALTERNATE for other

manufacturer’s Phosphor

Technology Probe

Yes

FP1

CALIBRATION-

FP8

CALIBRATION

ENABLED (0)

DISABLED (1)

To enable or disable

calibration for each probe. Any

change to CALIBRATION must

be made after the probe

phosphor TYPE has been set

Yes

6.2 Set Point Settings

A single fiber probe set point includes a pickup setting and a

dropout setting for the measured temperatures. There are four

pickup/dropout setting pairs for each fiber probe and up to eight

total fiber probes. The syntax is as follows:

•“FSP11 PCKUP” and “FSP11 DROUT” are the pickup and

dropout set points for fiber probe 1, level 1. The first

numerical digit designates the fiber probe channel (1-8),

while the second digit designates the pickup/dropout pair

that is used (1-4).

•When the temperature reaches the pickup setting, the set

point picks up, and when it falls below the dropout, the set

point drops out. The fiber probe set points can also work as

under-temperature set points. To do this, simply set the

pickup setting to a value below the dropout. When the

temperature drops below the pickup setting, the set point

picks up, and when it rises above the dropout, it will drop

out.

Page 16 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Associated Settings:

Channel

Settings

Range

Change

from

Front

Panel

FT1

FSP11 –FSP14 PCKUP &

DROUT

-100 to +200 ˚C

Yes

FT2

FSP21 –FSP24 PCKUP &

DROUT

-100 to +200 ˚C

Yes

FT3

FSP31 –FSP34 PCKUP &

DROUT

-100 to +200 ˚C

Yes

FT4

FSP41 –FSP44 PCKUP &

DROUT

-100 to +200 ˚C

Yes

FT5

FSP51 –FSP54 PCKUP &

DROUT

-100 to +200 ˚C

Yes

FT6

FSP61 –FSP64 PCKUP &

DROUT

-100 to +200 ˚C

Yes

FT7

FSP71 –FSP74 PCKUP &

DROUT

-100 to +200 ˚C

Yes

FT8

FSP81 –FSP84 PCKUP &

DROUT

-100 to +200 ˚C

Yes

6.3 Naming Settings

The following table includes custom naming for the analog and

binary points relating to fiber optic temperature measurement within

the ECLIPSE. All naming settings are up to 12 characters.

Associated Settings:

Settings

Description

Change from

Front Panel

FP1 NAME –FP8 NAME

Fiber probe names

No

ALFPROBE1 NAME –ALFPROBE8

NAME

Fiber probe alarm names

No

Page 17 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Settings

Description

Change from

Front Panel

FSP11 NAME –FSP84 NAME

Fiber probe set point names

No

NOTE

If ALFPROBEn alarm picks up, consider swapping the fiber on that channel with

the fiber from another working channel at the back of the ECLIPSE as a

troubleshooting starting point. If the alarm goes away when another working fiber

is connected to that channel, then the problem is not with the fiber channel but

with the fiber probe and/or fiber extension on that channel. Next step is to return

everything to the original positions and attempt to swap fiber extensions at the

flange plate with another working channel and observe whether the alarm goes

away. If the alarm goes away, it is fiber extensions that are causing the problem;

if not then it is the fiber probe that’s causing the problem. One important

troubleshooting rule is to only make one change at a time. Following these

troubleshooting steps should help determine whether the problem is in the

ECLIPSE fiber measurement channel, fiber probe, or fiber probe extension.

Page 18 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

7Testing

For testing fiber channels, a connection will need to be made to the

ECLIPSE through the front panel-mounted DB-9 connector with the

following port settings:

• Baud Rate: 19200 bits per second

• One start bit

• 8 bits of data

• No parity

• One stop bit

• No flow control

Operation has been verified with HyperTerminal Private Edition and Hyper

Access. It is recommended that the terminal emulation be set for either

ANSI or TTY, the font set to Courier New, and the file transfer protocol set

to Xmodem. The pinout of this port is designed to use a 9-pin female to 9-

pin male null modem cable. After properly configuring the terminal

emulation program, press the Enter key on PC keyboard to view the MAIN

MENU.

MAIN MENU

1. SETTINGS

2. STATUS

3. REPORTS

4. TOOLS

5. FILE TRANSFER

6. LOG OFF

Enter Code:

To access details for each fiber channel enter “ /f ” on the line labeled

“Enter Code”and press the Enter key on the PC keyboard. The following

details are available for each FOT channel:

Enter Code: /f

FOT CHANNEL #1:

writes:

reads:

triggers:

Page 19 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

validTemp:

calibrates:

dataNotRdy:

dataMissed:

tempRangeErrs:

triggerFails:

timeoutErrs:

E1Errs:

E2Errs:

E3Errs:

LOErrs:

HIErrs:

LEDHighErrs:

SigLowErrs:

SigHighErrs:

autoResetErrs:

calibrateFails:

LedPercent:

maxLedPercent:

SignalPercent:

maxSignalPercent:

measTemp:

Version:

Field Descriptions:

Field

Source

Description

Comments

writes

Main Proc.

# write commands

(including TRIGGERs)

since power-up

reads

Main Proc.

# read commands since

power-up

triggers

Main Proc.

# TRIGGER commands

since power-up

Command initiates a

temperature

measurement

validTemp

Main Proc.

# valid temperatures

received since power-

up

calibrates

Main Proc.

# number of successful

calibrations since

power-up

Calibration is for APT

factory use only

dataNotRdy

Main Proc.

# "data not ready"

indications since power-

up

Not an error

dataMissed

Main Proc.

# "data missed"

indications since power-

Page 20 of 21

AG010 ECLIPSE DFWT Install and Application Guide Rev 20200427

Field

Source

Description

Comments

up

tempRangeErrs

Main Proc.

# temperature

measurements out of

range since power-up

DFWT board reported a

temperature less than

−100 C or greater than

200 C

triggerFails

Main Proc.

# failed TRIGGER

commands since

power-up

timeoutErrs

Main Proc.

# times measurement

interval expired since

power-up

No measurement

received from DFWT

board within 30

seconds

E1Errs

Main Proc.

# E1 errors reported by

DFWT board since

power-up

“baseline level error”

E2Errs

Main Proc.

# E2 errors reported by

DFWT board since

power-up

“signal level error”

E3Errs

Main Proc.

# E3 errors reported by

DFWT board since

power-up

“Tau out of range”

LOErrs

Main Proc.

# LOErrs reported by

DFWT board since

power-up

“Temperature too low”

HIErrs

Main Proc.

# HIErrs reported by

DFWT board since

power-up

“Temperature too high”

LEDHighErrs

Main Proc.

# times LED percent >

100% since power-up

SigLowErrs

Main Proc.

# times signal percent <

75% since power-up

SigHighErrs

Main Proc.

# times signal percent >

100% since power-up

autoResetErrs

Main Proc.

# autonomous reset

errors since power-up

“Autonomous Reset” is

reported by the DFTW

board

calibrateFails

Main Proc.

# number of calibration

failures since power-up

Calibration is for APT

Factory use only

LedPercent

DFWT

board

Most recent LED

Percentage times 10

reported by DFWT

board (0–1000)

Strength of outgoing

signal relative to

maximum LED power

output

maxLedPercent

Main Proc.

Maximum LED

Percentage value since

power-up (0–1000)

This manual suits for next models

1

Table of contents