Advanced Radiant Systems Cool-Space CSW-12-VD User manual

Page 1 of 16

MADE IN

USA

IMPORTANT SAFETY INFORMATION INSIDE

•Serious injury or death possible

•Read, understand, and follow all

safety information and

instructions in this manual before

using or servicing this product.

•Retain these instructions for

future reference.

CSW-12-VD

Portable Evaporative Cooler

A Product of Advanced Radiant Systems, Inc.

www.cool-space.com

sales@cool-space.com

Page 2 of 16

INDEX

Index

Page 2

Signal Word Definitions

Page 2

General Description and Use

Page 3

Specifications

Page 4

Wiring

Page 4

How Evaporative Cooling Works

Pages 5 & 6

Unpacking

Page 6 & 7

Assembly Instructions

Pages 7

Connecting the Water Supply

Page 8

Connecting the Electrical Supply

Page 8

Start-Up Procedure

Page 9

Maintenance

Pages 10 & 11

Troubleshooting

Page 12

Replacement Parts

Page 13

Warranty

Page 14

ATTENTION:

The table to the right provides

definitions of the signal words that

can be found throughout this

manual. These signal words are

used to express the severity of the

hazard at hand. The signal words

are generally used in conjunction

with safety symbols that correspond

to the text for that particular hazard.

As you read this manual, refer back

to this table when you are unsure of

the signal word definition.

Page 3 of 16

ELECTRICAL SHOCK HAZARD

FIRE HAZARD

•Serious injury or death may

occur.

•Do not use in locations

containing hazardous or

explosive atmospheres.

•Do not use outdoors in wet

conditions and in

unprotected locations.

This unit is a compact, self-contained, high-

efficiency portable evaporative cooler capable of

lowering existing temperatures by as much as 26

degrees. The unit draws air across water-

saturated high-efficiency cooling pads, causing a

gradual evaporation of the water, thereby

removing heat from the air. The 10-gallon

reservoir provides hours of operation without a

water supply.

Evaporative cooling is also environmentally

friendly, since it does not use chlorofluorocarbons

(CFC’s), and therefore does not contribute to

ozone depletion.

GENERAL DESCRIPTION & USE

Benefits

•Significantly reduces air temperatures

and generates a cooler and more

comfortable working environment

•Compact portable cooling system with

quiet fan axial blower design

•Easy to operate and maintain, plus an

economical solution for low cost spot

cooling

•Cooling media pad contains a paper

treated CELdek material with a rigid

protective edge coating (Munters MI-T-

edg ®) to extend the life of the pad,

plus provide added weather and algae

protection, durability, and formulated

to withstand repeated cleaning without

damage to the pad

•Ready to plug into any 120VAC

receptacle and hooks up to any

standard garden hose for direct water

supply

•Applications would include workshop

environments, material handling areas,

automotive shops, office areas, and

many more!

Features

•Reduces air temperatures up to 26-

degrees

•Cools an area of approximately 900

sq. ft. (30’ x 30’)

•4” thick highly efficient cooling pads

•Four 3” diameter swivel bearing

wheels, two locking, for easier

portability and positioning over many

surface types.

•Indented top for tool & product

placement

•Internal reservoir with water capacity

of 10 -gallons for remote applications,

includes oversize inlet opening for

reservoir filling.

•Auto fill hose connector for continuous

use with a garden hose

•Includes 17’ long cord with ground

fault 120 volt plug

Page 4 of 16

SPECIFICATIONS

Air Volume 3800-CFM (2200-CFM Low), 700-FPM @ 6FT

Fan Motor Variable

Cooling Media Type CELdek high cellulose paper treated media pads for effective cooling and resistance

to edge degradation. Cross-fluted design induces highly turbulent mixing of air & water

for optimum cooling and enhanced self-cleaning.

Cooling Media Size 18" x 18" and 4" thick

Water Reservoir

Capacity 10 - gallons

Switch Variable

Cord 17’ long, 18 ga. 3-conductor cord GFCI

Protective Guard CSW-12VD Oscillating

Power Supply 120-VAC; 60 Hz; 3-Amps

Unit Dimensions 21-1/4" wide x 27-1/2" tall x 23” deep

Unit Weight 51 lbs. (without water in reservior)

Water Supply Standard garden hose connection or hand fill reservoir

WIRING

Page 5 of 16

To understand how the portable evaporative cooler works a basic understanding of psychrometrics is necessary.

Psychrometrics is the branch of thermodynamics devoted to the study of air and water vapor mixtures. The

psychrometric chart is a graphical representation of properties of moist air. To illustrate how the unit operates, some of

the relevant properties are described in this section followed by a sample application.

Dry-bulb temperature is measured with a thermometer. Dry-bulb temperature lines on the psychrometric chart are

the vertical lines. The wet bulb temperature is the lowest temperature that can be reached by evaporating water

into the air.

Dew-point temperature is the temperature to which a

given sample of air must be cooled so that moisture

will start condensing out of it. When air is saturated,

the dry-bulb, wet-bulb, and dew-point temperatures

will all be equal. The horizontal lines show the dew-

point temperature on the psychrometric chart.

Relative humidity is the amount of moisture in the air

relative to the amount of moisture the air would hold if

saturated at that dry-bulb temperature. Percent

humidity is not the same as relative humidity and is not

used in HVAC design. This graph shows the relative

humidity curves on the psychrometric chart.

HOW EVAPORATIVE COOLING WORKS

DRY BULB TEMP

WET BULB TEMP

DEW POINT TEMP

Page 6 of 16

Inspect your unit for any concealed shipping damage and report it immediately to your carrier. In addition to our

evaporative cooler the following items are included in a hardware pack and will need to be installed before

operating the unit.

UNPACKING

Non-Swivel w/ lock (qty. 2)

The following example illustrates the use of the psychrometric chart as it relates to evaporative cooling. Since

all of the items described above are properties, any two of them describe a state point on the psychrometric

chart. Once this point is determined, the values of all the other properties can be read from the chart. The

example below shows a Mollier type psychrometric chart for atmospheric pressure.

The dot shown is a state point and the following properties are known about the air/water mixture at this state.

Take the air/water mixture described by the state point above, with a dry-bulb temperature of 97°and 43% relative

humidity, for example. As the air passes through the cooling media on the unit, moisture is added to the air

increasing the relative humidity. This increase in relative humidity brings a decrease in dry bulb temperature. When

the relative humidity is raised to 70%, the dry bulb temperature has dropped to 86°F. When the humidity level

approaches 100%, the dry bulb temperature has dropped nearly 20°F to 78°F.

78°F

71°F

97°F

43%

WET BULB TEMP

DRY BULB TEMP

Dry-bulb temperature: 97°

Wet-bulb temperature: 78°

Dew-point temperature: 71°

Relative humidity: 43%

Swivel Casters: (qty. 2)

Page 7 of 16

Casters (4)

Screws (2)

Bottom of unit

Screws: (qty. 8)

ASSEMBLY

Wheel Assembly

Tools required: 7/16” nut driver

1.) Turn unit over and place on cardboard to

protect finish

2.) Align wheel plate with embedded nuts on

bottom of housing

3.) Attach using (2) screws

4.) Repeat steps 2 and 3 for each wheel

ELECTRICAL SHOCK HAZARD

•Serious injury or death may

occur.

•Disconnect from electrical

supply before and during

assembly of this product.

Pad Installation

1.) Remove pad retainer bar

2.) See page 12

Pads

Washer (2)

Screws (2)

Pad retainer bar

Page 8 of 16

Garden hose connection:

This unit comes equipped with pressure regulator a female garden hose adapter that can be connected to any standard

garden hose. The float will automatically maintain the correct water level. DO NOT over tighten as this may cause the

float assembly to rotate resulting in over filling of reservoir.

Stand-alone:

This unit can also be manually filled and moved into position. To fill the unit; simply remove the fill cap located on the

side of the housing, fill with water, and replace the cap. NOTE: Do not fill the reservoir past the max water line. Water

can easily spill from inside the unit when rolling the cooler on uneven surfaces or if the reservoir is overfilled.

-Do not connect this unit to any water

source where the water pressure exceeds 60

psi. This will cause permanent damage to

the unit. Pressures above 60 psi must use a

pressure regulator. A pressure reducing

valve is installed on the float inlet.

-Do not fill the reservoir past the MAX water

level line indicator.

CONNECTING THE WATER SUPPLY

ELECTRICAL SHOCK HAZARD

•Serious injury or death may

occur.

•Disconnect from electrical

supply before and during

assembly of this product.

This cooler comes equipped with a 120-volt

power supply cord and should only be plugged

into a 120 VAC, 60 Hz branch circuit that

includes a properly sized over current protection

device (fuse or circuit breaker). Consult a

licensed electrician if there is a question about

adequacy of the electrical supply.

EXTENSION CORDS

Use only 3-conductor extension cords of

14AWG to 25 ft., 12AWG to 50 ft. & 10AWG to

100ft. length maximum. Do not use the

extension cord powering this cooler to power

any other appliances or electrical loads.

CONNECTING THE ELECTRICAL SUPPLY

ELECTRICAL SHOCK HAZARD

•Serious injury or death may

occur.

•Make certain the power

source conforms to

specifications on data label.

•Do not connect plug to power

supply without cooling pads

installed and fastened in

place.

Page 9 of 16

Initial start-up:

Clean out the Sump: Remove any foreign

material in the sump before start up. It is normal

for some debris to accumulate in the sump. It is

best to flush out the sump with water to clear any

debris.

Filling the unit with water: Once the unit

has been hooked up to a water source, turn the

water supply valve on and the unit will fill with

water. The float valve will shut off the water flow

when the reservoir is filled.

START-UP PROCEDURE

Do not operate the pump when the reservoir is dry. This will cause the pump to

fail and also void the warranty.

There are 4 factors to consider when determining where to place your evaporative cooler.

1. Fresh air supply: The inlet side of the unit (pad side) requires a constant, uninterrupted supply of fresh air for

maximum performance. A distance of 3 ft. of clear space is recommended.

2. Discharge airflow: The cool air discharged from the unit should be free of obstruction to allow the air to

circulate in order to maximize the cooling zone.

3. Ventilation: Allow cooled air to circulate away from discharge area of cooler. This ensures that the unit does

not re-circulate air that has already been through the evaporative cooling process.

4. Placement: The unit must be placed on a level surface to operate correctly. The units create an oval shaped

air pattern that can reach out as far as 20 feet. Obstacles such as racks and workbenches may interfere with

the cooling zone. An attempt should be made to locate the unit in such a manner that interruption of the air

pattern is held to a minimum. Multiple units may be required to cover large areas.

ELECTRICAL SHOCK HAZARD

•Serious injury or death may

occur.

•Disconnect from electrical

supply before servicing this

product.

Annual start-up:

At the beginning of each cooling season follow the same procedures as the initial start-up with some possible

exceptions. If the media was removed for the winter, it will have to be replaced (note instructions below on media

replacement). Check the condition of the media. If the flutes of the media are clogged with buildup of alkali deposits or

are otherwise damaged, consider replacing the media. This is the best time to make this decision while the unit is not

being used and may not be as critically needed.

Starting the pump: Allow the reservoir to fill before turning the pump on. Once the reservoir is full, the

pump switch may be turned to the ‘ON’ position.

Initial Washing of the Cooling Media: The media should be washed for several hours by running

the pump without any airflow through the media. This washing action will clean out any debris in the media

as well as reduce any odor and improve wetting ability.

Break in Period for Cooling Media: The media will reach its peak operating condition after about

100 hours of operation. The chemical constituency rigidifying agents in the media will then be set and will

not leach out further. Ignore any coloration in the water during this initial period.

If a strong odor persists, run the pump to flush the media with water, without airflow through the media, until

the odor disappears.

Page 10 of 16

ODOR CONTROL

One of the few inconvenient aspects of evaporative cooling is the control of unpleasant odors.

There are two primary causes of these odors:

1. Initial wetting of new pads

2. Poor maintenance and storage behaviors and/or poor quality water.

Your EVAP-series cooler has been delivered with pads that have never been wet. The same is

true of replacement pads. The resins and adhesives used to create these pads will give off an

odor during initial use that can last for a week or more. This can’t be avoided but it can be

minimized. As the cooler is used over time, algae and bacteria growth can occur. This can also

be minimized. Below are recommended actions to be taken to address noticeable odor due to

the above causes.

Odor from Initial Wetting of Pads

1. At first use of your new cooler or after

installing new replacement pads, make

certain there is lots of fresh air available

to the cooler.

2. Add one capful of liquid laundry fabric

softener to the water in the bottom

reservoir of the cooler.

3. The odor from initial wetting of pads

should disappear in approx. two weeks

of operation.

4. If odor does not disappear after two

weeks of operation, follow the steps for

“Periodic Odor Maintenance”.

Periodic Odor Maintenance

1. Make certain the cooler is full of fresh

water.

2. Flush the pads for 3 – 4 hours by

operating the pump only with the fan

off. Adjust flow control valve for

maximum rate of recirculating water

flow.

3. After flushing, empty the reservoir

through the front drain and clean out

any residual particulate in the

reservoir.

4. Refill reservoir with fresh water and

proceed to use the cooler.

5. Repeat the above steps as necessary

to eliminate odor.

Page 11 of 16

MAINTENANCE

Algae/Bacterial Control

Control with chemicals. Chlorine is the most

commonly used chemical to control organisms. It is

potentially dangerous and should be used with great

caution. One of the best methods to introduce chlorine

into the water circulation system is on the pressure side

of the pump on a continual or timed basis.

Note: Consult water treatment experts before

attempting chemical water treatment. Neither media

manufacturers’ nor equipment manufacturers’

warranties cover damage due to chemical water

treatment and warranty may be voided when chemicals

are used.

Other chemicals suitable for organism control include

hydrogen peroxide, bromine based oxidizers, and other

commercial products. It is important to maintain a 6 to 9

pH level after treatment.

Control without chemicals. With water, sunlight, and

nutrients, most organisms can survive. The water in the

media can be allowed to dry out and any organisms

living in the media will become dry and flaky. This can

then be flushed out at the next start up of the unit.

Shading the media will prevent the sunlight from

encouraging the growth of organisms. Nutrients are

available from the air itself, however in some instances,

phosphates and fertilizers are carried in the air stream

and should be avoided.

Flushing the media with fresh water and dumping

the sump water periodically is the best preventative

measure that can be taken.

This flush and dump action will actually prevent alkali

deposits and algae/bacteria from growing. There are

also some non-recirculating water distribution systems

available that provide a constant flushing/dumping

action.

Water Chemistry

Hard water contains relatively large amounts of

minerals, primarily calcium. A sample of water can

contain only a specific maximum amount of dissolved

solids in solution. If these concentrations increase

beyond a certain level, the excess minerals precipitate

out as a solid material. This precipitation will appear

as the familiar white residue left on the face of the

media. It is commonly referred to as alkali, calcium

depositions or salts. The same process occurs in the

desert when water collects in depressions and since

only pure water evaporates the minerals are left

behind. These are commonly referred to as “dry

lakes” or “salt flats”.

The build up of these minerals on the face of the

media does not because a problem until the airflow is

restricted. There is no easy way to remove these

deposits. The best solution to this problem is

preventive rather than corrective action and usually

requires simple actions such as media flushing with

fresh water and periodic dumping of the sump water.

Soft water is on the opposite side of the scale for

water chemistry as compared to hard water.

Basically, removing or diluting the effects of the

calcium in the water creates soft water. Soft water is

not to be confused with pure water. Pure water does

not contain or contains very small amounts of

minerals found in either hard or soft water. While

hard water can leave deposits in the media, soft water

can cause harm to the media by leaching out the

rigidifying agents. Either water condition can have

some adverse effects on the media.

PH Range. A pH range of 6 to 9 is the acceptable

range for the media, the closer to the center the

better. The re-circulating system of the water

distribution allows the mineral content in the sump

water to become more and more intensive because

the same water is re-circulating. The pure water is

lost to evaporation while the minerals just continue to

build up. TDS is the abbreviation for “Total Dissolved

Solids” and represents, as the name implies, a way of

identifying a measurement of the mineral content.

CHEMICAL BURN HAZARD

POISONOUS GAS HAZARD

•Serious injury or death may

occur.

•Read, understand and follow

all chemical manufacturers’

instructions when using the

chemicals noted in these

pages.

Page 12 of 16

CHEMICAL BURN HAZARD

POISONOUS GAS HAZARD

•Serious injury or death may

occur.

•Read, understand and follow

all chemical manufacturers’

instructions when using the

chemicals noted in these

pages.

Removing the cooling media:

In order to perform any maintenance on internal

components the cooling pads must be removed to

access the inside of the unit.

Media removal / replacement is simple, if you follow

these instructions! The media is soft when wet so be

very careful when handling. The media has two

separate flute angles, which are transverse to each

other and alternate across the face of the media.

One flute is 45°and the other is 15°. The alignment

of the flute arrangement in relation to the direction of

airflow is critically important. The 45°flute must be

aligned upwards in the direction of the airflow. The

15°flute must be aligned downwards in the direction

of the airflow.

1. Using a 5/16” nut driver, remove the (2)

screws holding the pad retainer bracket in

place. Save all hardware.

2. The pad may be tilted out of the unit and

lifted out of the drain tray.

Note: Reinstall pads correctly; refer to sides of

pad material for airflow direction.

To keep your unit operating at peak efficiency, ensure that

the cooling pads are kept clean and dust-free. Dust and

other particles have an adverse effect on the media’s

ability to introduce water into the air stream. If the pad

surface becomes dirty or dusty, clean with a soft brush

and water.

Daily maintenance:

At start-up: It is best to run the pump several minutes

before the fan is started to clean out any debris on the

media.

At shut-down: When shutting down your evaporative

cooler at the end of each workday, the pump should be

turned off approximately 15 minutes before the fan is

turned off. This will allow the pads to drain and dry out.

This simple guideline will ensure long and efficient pad life

as well as help to control mildew and bacteria growth.

Periodic maintenance:

Depending on how often the unit operates, this procedure

should be performed anywhere from every week for

heavy use to monthly for light use.

1. Drain reservoir.

2. Remove cooling pads.

3. Clean out reservoir with either a towel or wet/dry

vacuum.

4. Reinstall pads and pad retainers.

ELECTRICAL SHOCK HAZARD

•Serious injury or death may

occur.

•Disconnect from electrical

supply before servicing this

product.

Annual shutdown / Storage:

1. Wash down the media to flush out all the debris.

2. Open the drain in the sump to drain out any

standing water.

3. Wash the interior of the unit to remove any

algae or micro-organisms as well as calcium

deposits. A weak dilution of muriatic acid will

help clean the alkali (calcium) deposits.

Commercial chlorine will kill and clean out the

algae.

4. Store the unit in a dry area and cover if possible

to prevent dust build-up.

Airflow

Direction

Screws

Pad retainer

Pad material

Page 13 of 16

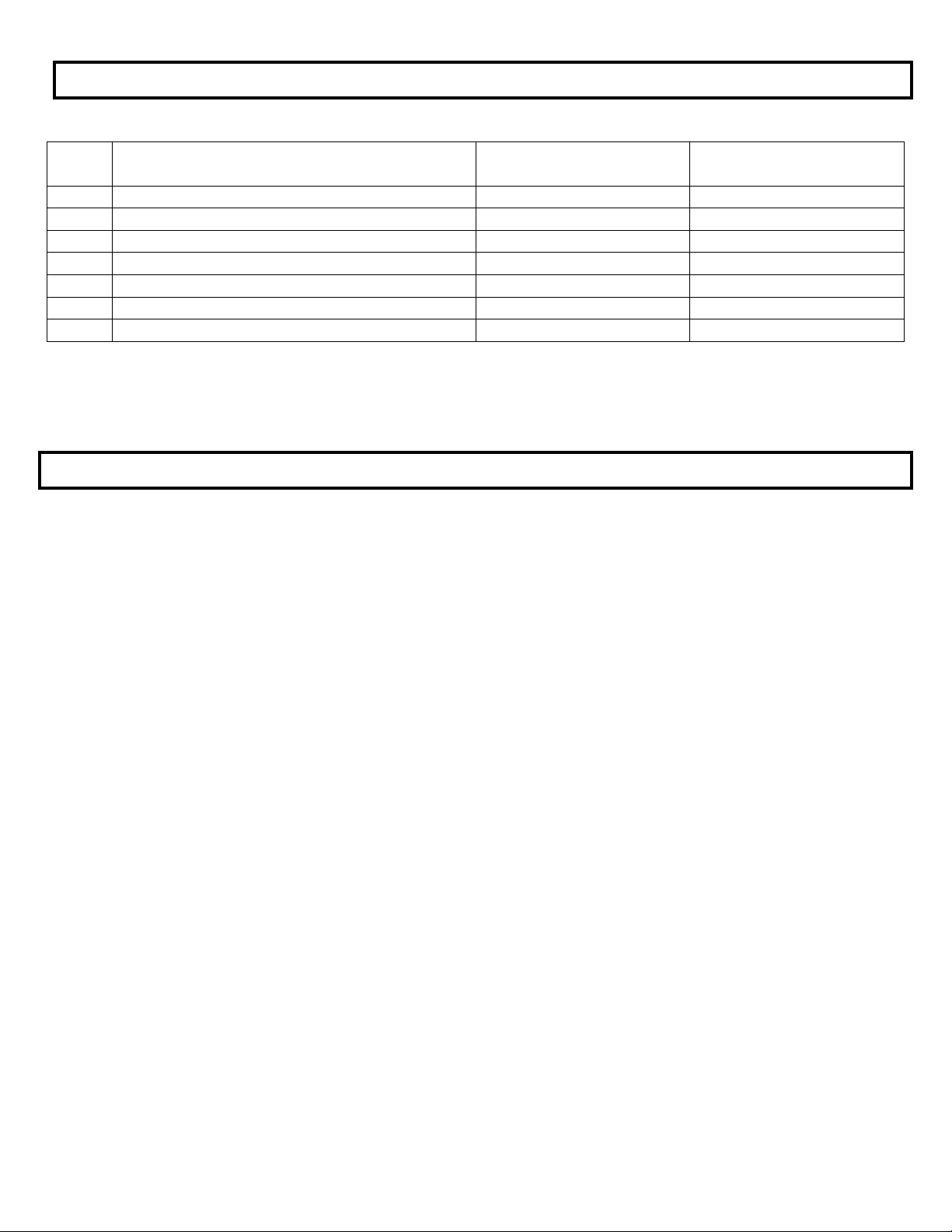

TROUBLESHOOTING

Fan System: The fan system consists of two primary elements: Fan Blade and Motor

Problem

Check

Solution

Fan won’t run and makes no sound.

Power cord, extension cord, switches, and circuit

breaker.

Reconnect power or extension cord.

Reset breaker.

Fan motor won’t run and makes a

humming sound.

Motor stalled (will not turn by hand).

Replace motor.

Breaker trips or fuse blows when fan is

started.

Motor stall.

Check power source for min. 115v/10 amp.

Extension cord adequacy.

Replace motor.

Upgrade power supply.

Replace with heavier cord.

Motor overheating and shutting off.

Restarting several minutes later.

Extension cord gauge too small.

Inlet air obstructed or too close to wall.

Faulty motor.

Replace with heavier cord.

Provide additional inlet clearance.

Replace motor.

Fan motor won’t run and switch makes

soft clicking sound.

Switch making good contact.

Replace switch.

Water Systems: The water delivery system consists of four primary elements: Water Hose, Float Assembly, Pump,

and Water Distribution Channel.

Problem

Check

Solution

Floor at side of the unit is wet.

Water inlet hose is loose at supply

hose.

Tighten connections and/or replace

hose washers.

The unit overflows from reservoir.

Float valve hose is loose at bulkhead

fitting or at float valve.

Water pressure is too high to allow

float valve to shutoff (60psi max).

Float valve is not seating properly.

Tighten connections and/or replace

hose washers.

Reduce water pressure by adding an

inline pressure reducer.

Check float valve.

Replace float

Water leaking from drain valve.

Make sure drain nut is secure.

Tighten drain nut.

Too many dry streaks in the pads.

Holes in water distribution tray are

blocked.

Remove distribution tray and clean

Water spitting from the unit.

Hose connection loose.

Tighten hose.

Replace hose and washer.

Pump motor will not run when switch

is turned on.

Check switch, cord and circuit

breakers.

Replace switch and reset breaker.

ELECTRICAL SHOCK HAZARD

•Serious injury or death may

occur.

•Disconnect from electrical

supply before servicing this

product.

Page 14 of 16

ITEM

NO.

DESCRIPTION

PART NO.

QUANTITY

1

FAN ASSEMBLY

CS-F12-VD 60HZ

1

2

ON/OFF SWITCH

CS-E110

1

3

VARIABLE SWITCH

CS-E187-VD 60HZ

1

4

PUMP

CS-E12-101

1

5

FLOAT

CS-P053.1

1

6

PAD MEDIA KIT

CS-A12-101

1

COMMON REPLACEMENT PARTS

DO NOT DISCARD FAULTY PARTS! THEY MUST BE RETURNED IN ORDER TO RECEIVE WARRANTY CREDIT

WARRANTY

WARRANTY

Your COOLSPACE unit is guaranteed against any defective material or workmanship

for a period of 12 months from your date of original purchase. Please call (800) 557-

5716 to receive a returned goods authorization number to return and receive any

defective parts. Shipping costs for returns are at the expense of the customer.

It is our goal to have satisfied Customers, and to provide you with any support you may

need. If you have any questions about our product, operation or are having technical

problems please call 1-800-557-5716.

IN CASE OF PRODUCT FAILURE:

Please have the following information ready when you call:

1. Model Number and Serial Number.

2. Proof of purchase.

3. Description of the problem encountered with product.

SELLER'S LIABILITY

Seller will not be liable for any loss, damage, cost of repair, incidental or

consequential damages of any kind, whether based on warranty, contract or

negligence, and arising in connection with the sale, use or repair of the Products.

Seller's maximum liability shall not in any case exceed the contract price for the

Products claimed to be defective or unsuitable.

RETURNED GOODS

Equipment may be accepted for return with in 90 days of shipment, when

authorized by us with our return labels. Request necessary permission and

special Return Authorization Tags. Currently listed equipment in new and unused

condition, and in factory sealed cartons, may normally be returned for full credit

less 25% (minimum charge $20.00) charge for handling, repacking and

restocking, and less transportation charges both ways, at net prices prevailing at

time of purchase or time of return, whichever is lower. Advanced Radiant

Systems, Inc., however, reserves the right to refuse any return, at our discretion,

and is not responsible for error. All special, custom made or equipment with

special finishes, and modified versions of cataloged numbers are not returnable.

All returned merchandise is subject to inspection. Unsalvageable and damaged

merchandise will be credited at salvage value or less costs of repairs.

DAMAGED GOODS

Minimum charge on replacement will be waived if order is accompanied by

copy of proof of claim submitted to carrier. No repair, replacement, or other

adjustment by the customer is authorized by us, unless so stated in writing

by our Sales Service department.

Page 15 of 16

COOLSPACE®Warranty Form

Date Purchased: __________________________

Purchased From: _______________________________________________

Model Number: CSW- __________ Serial Number: ___________________

Company: _____________________________________________________

Contact: _______________________________________________________

Address: _______________________________________________________

Phone Number: __________________ Fax Number: ___________________

You must complete this form and return within fifteen (15) days of initial

purchase to validate your cooler’s warranty. Please call COOLSPACE

®

(800) 557-5716 if you have questions.

Please fax or mail this completed form to:

Fax to: (317) 485-0118

Mail to: COOL-SPACE

®

Warranty Dept.

315 N. Madison St.

Fortville IN 46040

Submit online: www.COOL-SPACE.com under the CONTACT tab.

www.cool-space.com

Page 16 of 16

IMPORTANT NOTICE:

DO NOT RETURN TO PLACE OF PURCHASE.

Please call 800-557-5716 for technical service support and warranty information

315 North Madison Street, Fortville IN 46040

Phone: 317-577-0417 – Fax: 317-485-0118

1-800-557-5716

www.cool-space.com

sales@cool-space.com

REV 06/14jw PN CSW-VD MANUAL

If you have questions about the product you have

purchased or would like to leave us feedback, please

contact us via our website www.cool-space.com or by

calling 1-800-557-5716.

Table of contents

Popular Air Cleaner manuals by other brands

Aprilaire

Aprilaire 1510 installation instructions

Philips

Philips GP7101 user manual

Apriaire

Apriaire 2210 owner's manual

Rinnai

Rinnai Airo AAP240 Operation & installation manual

AllerAir

AllerAir AirMedic+ Series Operation and maintenance manual

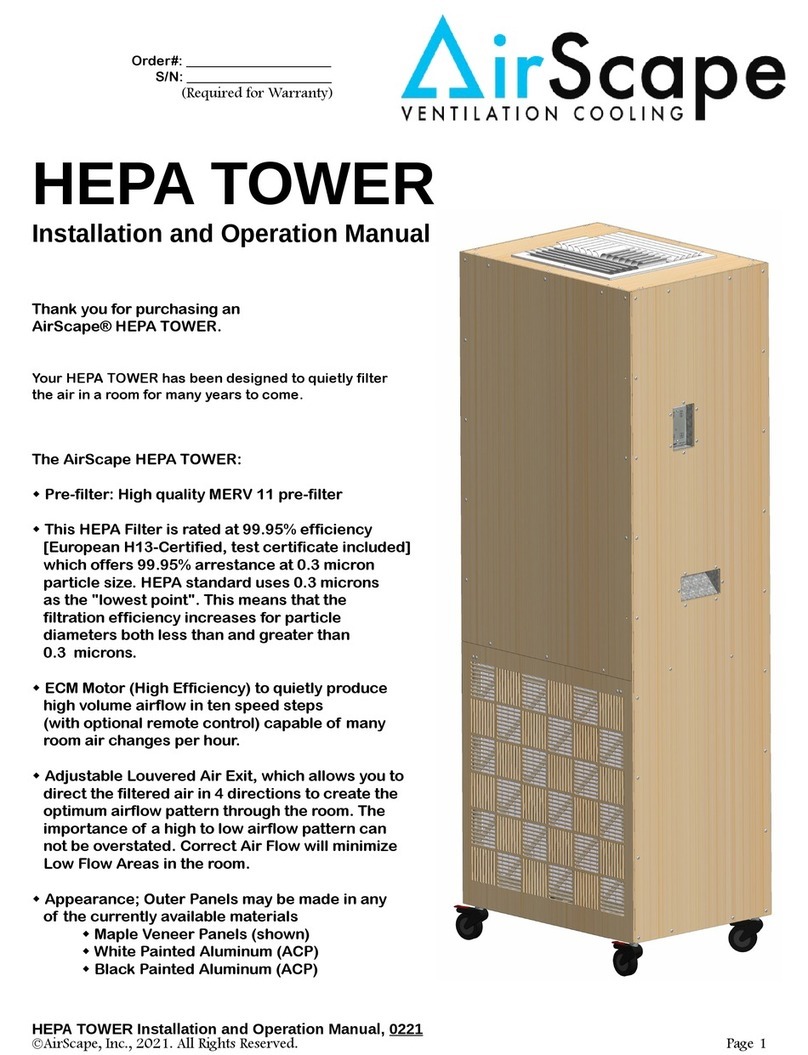

AirScape

AirScape HEPA TOWER Installation and operation manual