7

INV250 / INV350 / INV50008.2013

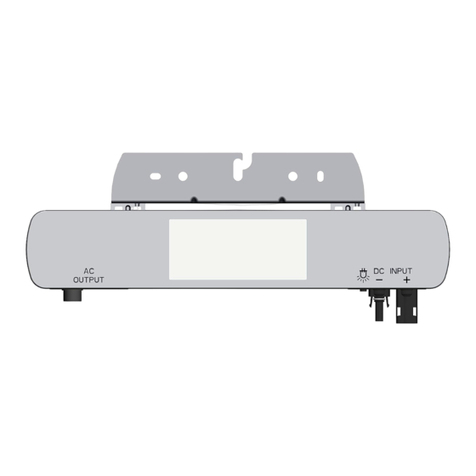

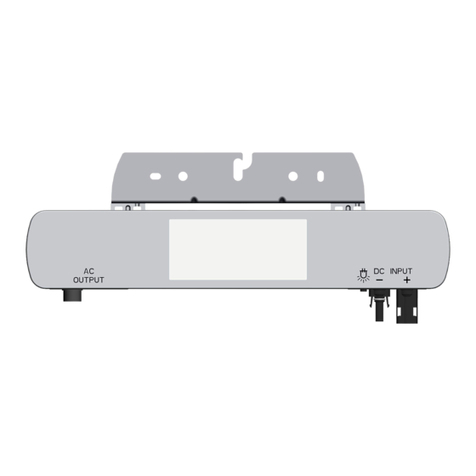

5.3 LED-Display

During normal operation, the PV generators produce a voltage

when sucient daylight or sunlight is present. If this voltage at

a certain level and corresponding time period is applied to the

inverter, the inverter starts to feed into the grid. The inverter is

equipped with an LED, which gives information on the operating

status and causes for non-operation.

Feeding Operation:

Depending on the power the blink frequency is increasing. The

following blink frequencies show percentages as a function of

the device power:

0% to 3% LED 0.5 sec.„ON“ 2 sec.„OFF“

3% to 30% LED 0.5 sec„ON“ 1 sec.„OFF“

30% to 60% LED 0.5 sec„ON“ 0.5 sec„OFF“

60% to 85% LED 0.5 sec„ON“ 0.2 sec„OFF“

85% to 100% LED continuously„ON“

Non-feeding Operation:

When in non-feeding operation, the LED indicates certain

output stages, which are described hereafter. These can be used

to troubleshoot the inverter in case of malfunction. Each stage

indication starts with the following sequence:

Sequence starts: 2 sec„ON“, 0.5 sec “OFF“

Output Stages:

Synchronization running:

LED 1sec„ON“ 0.5sec„OFF“, one pulse

AC Voltage not in tolerance range:

LED 1sec„ON“ 0.5sec„OFF“, two pulses

DC Voltage not in tolerance range:

LED 1sec„ON“ 0.5sec„OFF“, three pulses

AC and DC Voltage not in tolerance range:

LED 1sec„ON“ 0.5 sec„OFF“, four pulses

Internal over-temperature:

LED 1sec„ON“ 0.5 sec„OFF“, ve pulses

5.4 Protection Concepts

The following monitoring concepts and protection plans are

included in the AEconversion scope of devices:

• Surge / varistors to protect the power semiconductor

• temperature monitoring

• EMC lters to protect the inverter against high-frequency

power disturbances

• varistors to earth on the mains side to protect the inverter

against surge voltages

• BISI (Bi-directional security interface ) network monitoring

for personal protection and to prevent islanding according

to VDE0126-1-1 / VDE AR-N 4105

5.5 Network and System Protection

According to the VDE-AR-N 4105, the last ve fault conditions

of the network and system protection as well as the set action

values and times must be readable. For the device versions

without a communication interface and with integrated light

conductors, the data output is realized through the LED.

For devices with a communication interface, the data is

additionally available via the integrated interface.

Activation of the output via light conductors:

• turn o AC

• LED signals the start of the output sequence through 5

seconds„ON“

• LED puts out the data as a pulse pattern (duration 50 sec)

• LED signals the end of the output sequence through 5

seconds„ON“

• LED turns to normal mode signaling

The LED output sequence must be recorded via video

(smartphone, digital camera, etc.) with a resolution of

680x480DPI. This video is then analyzed using the computer

software. The software is included on the supplied CD. After a

successful analysis of the video, the set values are displayed in

plain text. When recording, make sure that a few seconds each

of the start and end of the output sequence are recorded. The

position of the LED on the screen surface must always be kept

in the same position. Please note further instructions when

running the software.

Additional option for versions with communication interface:

• Establish data communication between PC and Inverter

• Load AEsolar software

• Check device via the corresponding menu item

6.0 Operating Conditions

The selection of the PV generator is of central importance to the

design of a PV system. It is highly relevant that the PV module

ts to the inverter.

6.1 Dimensioning of the PV-Generators

The number of PV modules connected in series must be

chosen so that the output voltage of the PV generator, even in

extreme outdoor temperatures does not exceeded the allowed

input voltage range of the inverter. In Central Europe, module

temperatures between -15°C to +70°C should be assumed.

Depending on the installation of the generators and the

geographical location, temperatures of +60°C or +70°C are used

in the stress voltage calculation. Please note the temperature

coecient of PV modules. The following criteria must be met for

the voltage of the PV generator:

Uo (-15 ° C) <max. Input voltage

45 V and -15°C for INV250

60 V and -15°C for INV350

90 V and -15°C for INV500