AE Conversion INV250-45US RS485 User manual

Micro-Inverter

English

Installation-Manual

INV250-45US RS485

INV250-45US PLC

INV250-45US

INV350-60US RS485

INV350-60US PLC

INV350-60US

INV500-90US RS485

INV500-90US PLC

INV500-90US

Installation and Operation Manual for

INV250-45US RS485, INV250-45US PLC and INV250-45US

INV350-60US RS485, INV350-60US PLC and INV350-60US

INV500-90US RS485, INV500-90US PLC and INV500-90US

CONTACT INFORMATION

AEconversion GmbH & Co. KG

Geseker Str. 3

D-59494 Soest

Germany

http://www.aeconversion.com

info@aeconversion.com

OTHER INFORMATION

Product information is subject to change without notice.

All trademarks are recognized as the property of their respective owners.

Copyright © 2012 AEconversion GmbH & Co. KG. All rights reserved.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

THIS MANUAL CONTAINS IMPORTANT

INSTRUCTIONS FOR MODELS:

INV25045US, INV25045US PLC AND INV25045US RS485,

INV35060US, INV35060US PLC AND INV35060US RS485,

INV50090US, INV50090US PLC AND INV50090US RS485,

THAT SHALL BE FOLLOWED DURING INSTALLATION

AND MAINTENANCE OF THE MICROINVERTER.

3INV250-45US / INV350-60US / INV500-90US05.2014

Table of Contents

1.0 About this Manual 4

1.1 Important Safety Information 4

1.2 Scope 5

1.3 Target Audience 5

2.0 Storage and Transportation 5

2.1 Assembly, Installation, Operation and

Maintenance 5

2.2 Label 5

3.0 Notes on Liability, Warranty and Service 5

3.1 Guaranty and Warranty 5

3.2 Intended use and liability 6

3.3 Service 6

4.0 Product Description 6

4.1 Scope of Delivery 7

4.2 Dimensions 7

4.3 LED-Display 7

4.4 Protection Concepts 7

4.4.1 Network and System Protection 8

4.5 Derating 8

4.5.1 Derating as a function of input voltage 8

4.5.2 Derating as a function of ambient temp. /

wind speed 8

4.6 Connections Overview 8

4.6.1 Connections of PLC and NoCom Devices 8

4.6.2 Connections of RS485 Devices 9

5.0 Micro-Inverter Pre-Installation 9

5.1 Dimensioning of the PV-Generators 9

5.2 Compatibility and Capacity 10

5.3 Parts and Tools Required 10

5.4 Lighting Surge Protection 10

6.0 Installation Procedure 10

6.1 Measure AC at the Electrical Utility Connection 10

6.2 Install the AC Branch Circuit Junction Box 10

6.3 Attach the Micro-Inverter to the PV Racking 11

6.4 Connect the Micro-Inverters (AC-Connection) 12

6.4.1 AC-Connection of PLC and NoCom Devices 12

6.4.2 AC-Connection of RS485 Devices 13

6.5 Ground the System 13

6.6 Communication Set-up 13

6.6.1 RS-485 Communication 13

6.6.2 Powerline Communication 14

6.6.3 Without Communication 14

6.7 Complete the Installation Map 14

6.8 Connect the PV Modules 15

6.9 Start Software 15

7.0 Commissioning, Operation and Registration 15

7.1 Commissioning 16

7.2 Registering with Utility Company 16

8.0 Troubleshooting 16

8.1 Troubleshooting an Inoperable Micro-Inverter 16

8.2 Other Faults 16

8.3 Disconnecting a Micro-Inverter from the

PV Module 17

8.4 Installing a Replacement Micro-Inverter 17

9.0 Further Information 17

9.1 Disposal 17

9.2 Care 17

9.3 Laws, Regulations and Technical Rules 17

Appendix

Technical Data for INV250 18

Technical Data for INV350 19

Technical Data for INV500 20

Derating Diagrams for INV250 21

Derating Diagrams for INV350 22

Derating Diagrams for INV500 23

Certicate 25

Installation Map 26

Wiring Diagrams 208V 27

Wiring Diagrams 240V 28

4INV250-45US / INV350-60US / INV500-90US 05.2014

1.0 About this Manual

This manual describes important information to follow

during the installation and service of the AEconversion

Micro-Inverter. These instructions should always be

kept within reach of the inverter.

Since the documentation is updated frequently, please

visit the AEconversion website (www.aeconversion.

com/) for the latest information.

1.1 Important Safety Information

To ensure the safe installation and service of the

AEconversion Micro-Inverter, this manual uses the

following types of safety symbols to indicate dangerous

conditions and important safety instructions that are to

be noted:

WARNING!

This indicates a situation where failure to follow

instructions may be a safety hazard or cause equipment

malfunction. Use extreme caution and follow

instructions carefully.

NOTE: This indicates information particularly important

for optimal system operation. Follow instructions

closely.

Symbols to be noted:

Direct Current Supply Symbol:

Alternating Current

Supply Symbol:

Safety Instructions:

• Before installing the AEconversion Micro-Inverter,

please read all instructions and cautionary

markings in the technical documentation, about

the AEconversion Micro-Inverter System and the PV

equipment.

• CAUTION: Perform all electrical installations in

accordance with all applicable local electrical codes

and the National Electrical Code (NEC), ANSI/NFPA

70.

• Be aware that only qualied personnel should

install or replace AEconversion Micro-Inverters.

• Do not attempt to repair the AEconversion Micro-

Inverter; it contains no user-serviceable parts.

Tampering with or opening the AEconversion

Micro-Inverter will void the warranty.

• WARNING:

Be aware that the body of the AEconversion Micro-

Inverter can become very hot. The body can reach

temperatures over 70°C (158°F), when the ambient

temperature exceeds 25°C (77°F). To reduce risk

of burns, use caution when working with Micro-

Inverters.

• Do NOT disconnect the PV module from the

AEconversion Micro-Inverter without rst removing

AC power.

• The installation instructions shall indicate that the

wiring methods used shall be in accordance with

the Canadian Electrical Code, Part I.

• The PV array is not allowed to be earthed!

The micro inverter converts the power generated by

the PV modules from direct current into grid compliant

alternating current. For damages resulting from failure

to follow these instructions, we assume no liability.

When installing the inverter, please note the following

instructions for all assemblies and components of the

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

THIS MANUAL CONTAINS IMPORTANT INSTRUCTIONS

FOR MODELS:

INV25045US, INV25045US PLC AND INV25045US RS485,

INV35060US, INV35060US PLC AND INV35060US RS485,

INV50090US, INV50090US PLC AND INV50090US RS485,

THAT SHALL BE FOLLOWED DURING INSTALLATION

AND MAINTENANCE OF THE MICROINVERTER.

Ground Symbol:

5INV250-45US / INV350-60US / INV500-90US05.2014

safe operation.

• Never remove the solar generator from the inverter,

while it is connected to the electricity network.

• Make sure that before carrying out inspections and

maintenance, the inverter is disconnected from the

mains supply and is secured against restarting.

• CAUTION:

Perform all electrical installations in accordance

with the safety regulations all applicable local

electrical codes and the National Electrical Code

(NEC), ANSI/NFPA 70.

• Connect the AEconversion Micro-Inverter to

the electricity network only after receiving prior

approval from the electrical utility company.

• The electrical connection to the central building

shall be performed only by a licensed electrician.

• If you mount the inverter at high altitude, avoid

possible falling risks.

• Do not plug electrically conductive parts into the

plugs and sockets! Tools and working conditions

must be dry.

• Do not under any circumstances interfere with or

manipulate the inverter or any other parts of the

system; it contains no user-serviceable parts.

• Inappropriate alterations can cause damage!

• Tampering with or opening the AEconversion

Micro-Inverter will void the warranty.

• The installation shall be done in accordance to the

wiring methods and wire diameters in accordance

with the National Electrical Code (NEC), ANSI/NFPA

70. Connection schemes refer also page 27 and 28.

• NOTE:

Do not connect the inverter to grids without an

earthed neutral conductor.

• The installation instructions shall indicate that the

wiring methods used shall be in accordance with

the Canadian Electrical Code, Part I.

2.2 Label

The label is located on the top side of the inverter.

The information on the label includes technical data,

type and serial number of the device as well as safety

instructions.

CAUTION:

Note that surfaces of equipment may be hot and create

a burn hazard.

3.0 Notes on Liability, Warranty and Service

Remarks on liability, warranty and service are listed

hereafter.

3.1 Guaranty and Warranty

AEconversion grants an implied warranty of 2 years

to the inverter from date of purchase. Furthermore,

AEconversion provides an additional limited warranty.

system.

In order to ensure faultless and safe operation of

this equipment, proper transport, expert storage,

installation, operation and maintenance is required.

During the operation of this equipment, certain

equipment parts carry hazardous voltages that can

cause serious injury or death. Always follow the

following instructions to minimize the risk of injury or

death.

1.2 Scope

This manual applies to the following micro-inverters:

• INV250-45US

• INV250-45US RS485

• INV250-45US PLC

• INV350-60US

• INV350-60US RS485

• INV350-60US PLC

• INV500-90US

• INV500-90US RS485

• INV500-90US PLC

1.3 Target Audience

This manual is for the installer of the types of inverters

listed in 1.2.

NOTE:

This guide assumes knowledge corresponding to a

recognized professional qualication as an electrician

and only qualied personnel should install or replace

AEconversion Micro Inverters.

WARNING!

These servicing instructions are for use by qualied

personnel only. To reduce the risk of electric shock, do

not perform any servicing other than that specied in

the operating instructions unless you are qualied to

do so.

2.0 Storage and Transportation

For storage and transport, the following warnings are to

be noted:

• All contacts should be kept dry and clean!

• Transport the inverter only in the given packaging.

2.1 Assembly, Installation, Operation and Maintenance

The following warnings must be observed:

• Before installing or using the AEconversion Micro-

Inverter, please read all instructions and note the

threats, warnings, and precautions.

• WARNING!

Proper grounding, wire sizing and appropriate

short-circuit protection must be provided to ensure

6INV250-45US / INV350-60US / INV500-90US 05.2014

For warranty questions, please see our warranty

disclaimer or contact your retailer or installer. If your

device has a defect or malfunction during the warranty

period, please also contact your retailer or installer.

Warranty claims are excluded for:

• alterations or repairs to the unit

• opening of the inverter, for example by unscrewing

the cover

• improper use of device

• improper and non-standard installation

• improper operation

• operating the equipment with defective safety

devices

• impact of foreign objects and force majeure

(lightning, surge, storm, re)

• inadequate or nonexistent ventilation of the device

• disregarding of safety regulations

• shipping damage

3.2 Intended use and liability

The AEconversion Micro-Inverter converts the power

generated by the PV modules from direct current into

grid compliant alternating current and supplies it to the

power network.

Any other or additional use is considered improper.

The manufacturer / supplier shall not be liable for any

resulting damages. The risk is carried solely by the

operator.

Intended use also includes compliance with the

instructions and installation manual. Some of the

documents that you need for the registration and

inspection of your photovoltaic system are included

in the installation instructions. The inverter can be

operated with a permanent connection to the power

network. The inverter is not designed for mobile use.

Changes to the inverter are generally prohibited. For

any changes in the system a qualied electrician must

be called in.

3.3 Service

We have already set high standards in the development

phase on the quality and longevity of the inverter. In

spite of all quality assurance activities, disturbances

may occur in exceptional cases. In these cases, you will

get the maximum possible support to eliminate the

problem quickly and without bureaucratic complexities.

Please contact our service department directly.

AEconversion Service:

+49 (0) 521 329471-0 / info@aeconversion.de

In order for the service department to respond quickly

and correctly, the following information is absolutely

necessary.

1) Details of the inverter:

Product description, type and serial number of the

inverter; this information can be found on the label on

the device.

Short description of the error:

• Did the fault occur immediately at the start or at a

later time?

• Is the fault is reproducible or occurs only

sporadically?

• What environmental conditions (radiation) were

present at the time of the error?

2) Information about the PV-generator

• What module manufacturer and type of module

was installed?

• What is the schematic of the PV-System?

4.0 Product Description

The AEconversion Micro-Inverter is individually

connected to one or two PV-module, depending on

technical specications. The Micro-Inverter converts the

direct current into grid compliant alternating current.

Through the individual conversion at each module,

the sun’s energy can ideally be used. In addition, the

micro-inverter solves another widespread problem in

conventional systems. Because of the series connection

in PV-systems using string- or central-inverters, the

PV-modules are codependent concerning performance.

If the performance of one PV-module drops, due to

shading or module mismatching for example, the

modules in the same string are aected negatively.

Through the individual connection in PV-systems using

micro-inverters the PV-modules work independently,

each at their maximum performance to increase energy

harvest.

The“plug-and play”-system eliminates connection

mistakes, making the installation safe and easy.

There are no high voltage DC circuits to handle and

installation time and costs are reduced.

Installations are eective ranging from small family

houses to large oce fronts and can be installed on

any available space, regardless of orientation, shading

or module tolerances. Each system can be rearranged

or upgraded with more PV-modules when needed,

for example with performance expansion or building

modications.

With the micro-inverter, it is possible to monitor the

performance of PV-systems on modular basis, which

enables comprehensive monitoring and fast problem

recognition. In that way, not only an increase in energy

earning can be provided, but also a decrease in energy

losses can be achieved by detecting and localizing

problems quickly and eectively.

7INV250-45US / INV350-60US / INV500-90US05.2014

The housing of the micro-inverter is NEMA 4 protected

and designed for operating temperatures from -25 °

C to 70 ° C. If the temperature inside the case exceeds

a certain value, the inverter will reduce the maximum

power to protect itself. Systems with micro-inverters

are easy to design and install. Each inverter can be

mounted to the mounting bracket below the PV

modules, however, recommended is a place where a

service can be performed easily.

An overview of the technical data of the inverter can be

found on pages 18-20.

4.1 Scope of Delivery

The package includes:

• Inverter

• End Caps (depending on version)

• Quick Start Guide and further information on CD

• AC connector and cap (depending on version)

4.2 Dimensions

W

H

D

Model Width

[mm]

Depth

[mm]

Height

[mm]

INV250-45US

INV350-60US

INV500-90US

314 211 67

INV250-45US RS485

INV350-60US RS485

INV500-90US RS485

314 211 67

INV250-45US PLC

INV350-60US PLC

INV500-90US PLC

314 211 67

4.3 LED-Display

During normal operation, the PV generators produce a

voltage when sucient daylight or sunlight is present.

If this voltage at a certain level and corresponding time

period is applied to the inverter, the inverter starts to

feed into the grid. The inverter is equipped with an LED,

which gives information on the operating status and

causes for non-operation.

Feeding Operation:

Depending on the power the blink frequency is

increasing. The following blink frequencies show

percentages as a function of the device power:

0% to 3% LED 0.5 sec.„ON“ 2 sec.„OFF“

3% to 30% LED 0.5 sec„ON“ 1 sec.„OFF“

30% to 60% LED 0.5 sec„ON“ 0.5 sec„OFF“

60% to 85% LED 0.5 sec„ON“ 0.2 sec„OFF“

85% to 100% LED continuously„ON“

Non-feeding Operation:

When in non-feeding operation, the LED indicates

certain output stages, which are described hereafter.

These can be used to troubleshoot the inverter in case

of malfunction. Each stage indication starts with the

following sequence:

Sequence starts: 2 sec„ON“, 0.5 sec “OFF“

Output Stages:

Synchronization running:

LED 1sec„ON“ 0.5sec„OFF“, one pulse

AC Voltage not in tolerance range:

LED 1sec„ON“ 0.5sec„OFF“, two pulses

DC Voltage not in tolerance range:

LED 1sec„ON“ 0.5sec„OFF“, three pulses

AC and DC Voltage not in tolerance range:

LED 1sec„ON“ 0.5 sec„OFF“, four pulses

Internal over-temperature:

LED 1sec„ON“ 0.5 sec„OFF“, ve pulses

4.4 Protection Concepts

The following monitoring concepts and protection

plans are included in the AEconversion scope of

devices:

• Surge / varistors to protect the power

semiconductor

• temperature monitoring

• EMC lters to protect the inverter against high-

frequency power disturbances

• varistors to earth on the mains side to protect the

inverter against surge voltages

8INV250-45US / INV350-60US / INV500-90US 05.2014

4.4.1 Network and System Protection

According to the VDE-AR-N 4105, the last ve fault

conditions of the network and system protection

as well as the set action values and times must

be readable. For the device versions without a

communication interface and with integrated light

conductors, the data output is realized through the

LED.

For devices with a communication interface, the data is

additionally available via the integrated interface.

Activation of the output via light conductors:

• turn o AC

• LED signals the start of the output sequence

through 5 seconds„ON“

• LED puts out the data as a pulse pattern (duration

50 sec)

• LED signals the end of the output sequence

through 5 seconds„ON“

• LED turns to normal mode signaling

The LED output sequence must be recorded via video

(smartphone, digital camera, etc.) with a resolution

of 680x480DPI. This video is then analyzed using the

computer software. The software is included on the

supplied CD. After a successful analysis of the video, the

set values are displayed in plain text. When recording,

make sure that a few seconds each of the start and

end of the output sequence are recorded. The position

of the LED on the screen surface must always be kept

in the same position. Please note further instructions

when running the software.

Additional option for versions with communication

interface:

• Establish data communication between PC and

Inverter

• Load AEsolar software

• Check device via the corresponding menu item

4.5 Derating

Derating is the operation of a machine at less than its

rated maximum power in order to prolong its life or

safety reasons, which is described for the micro-inverter

hereafter.

4.5.1 Derating as a function of input voltage

Due to the maximum value of the input current from

the PV module of 11A, a maximum power results which

can be transformed by the inverter depending on the

input voltage. The limit of 11A is limited by the inverter

and cannot be exceeded. Similarly, the maximum

load of the PV module is limited to 250W/350W/500W

(depending on Inverter-Version). This results in the

following gradient of the maximum absorbed power as

a function of the input voltage from the PV module.

see Graph Derating diagram P pv / I pv on pages 21-24

4.5.2 Derating as a function of ambient temp. / wind speed

Dierent environmental conditions result depending

on the installation of the inverter. The ambient

temperature and air ow around the inverter aect

the inverter‘s performance capabilities. In the

inverter, a power control as a function of temperature

is integrated. The following charts represent the

maximum input power of the inverter over the ambient

temperature and wind speed.

see Graphs on pages 21-24:

- Derating diagram Ppv / T ambient 0m/s Wind Speed

- Derating diagram Ppv / T ambient 0,1 m/s Wind Speed

Please note that the performance capabilities of your PV

module decreases with increasing module temperature,

in general with about 0.4 % / °C. That means, a module

with 200W under STC conditions of 70°C and 1000 W/m²

provide only a maximum of 164W.

4.6 Connections Overview

The connections of the Micro Inverter are described

hereafter.

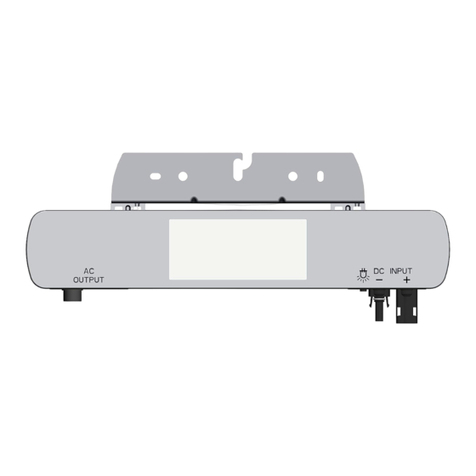

4.6.1 Connections of PLC and NoCom Devices

DC connector PV-

DC connector PV+

climatic membrane

AC connector

9INV250-45US / INV350-60US / INV500-90US05.2014

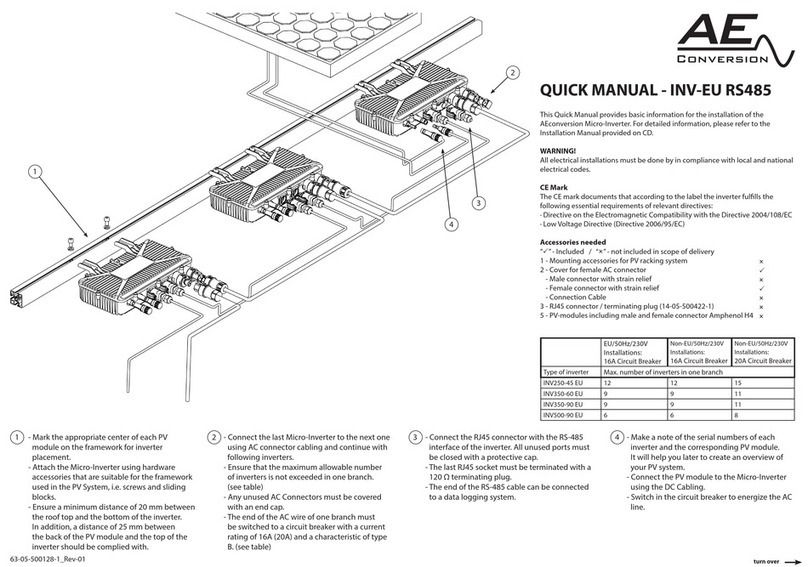

4.6.2 Connections of RS485 Devices

DC connector PV-

DC connector PV+

RS 485 interface 1

RS 485 interface 2

AC connector 1

AC connector 2

climatic membrane

5.0 Micro-Inverter Pre-Installation

The following instructions describe the aspects to be

noted before the installation of the Micro-Inverter.

In addition, please note the important safety

information listed in 1.1.

5.1 Dimensioning of the PV-Generators

The selection of the PV generator is of central

importance to the design of a PV system. It is highly

relevant that the PV module ts to the inverter.

The number of PV modules connected in series must be

chosen so that the output voltage of the PV generator,

even in extreme outdoor temperatures does not

exceed the allowed input voltage range of the inverter.

In North America, module temperatures between

-15°C to +70°C should be assumed. Depending on the

installation of the generators and the geographical

location, temperatures of +60°C or +70°C are used

in the stress voltage calculation. Please note the

temperature coecient of PV modules. The following

criteria must be met for the voltage of the PV generator:

Uo (-15 ° C) <max. Input voltage

45 V and -15°C for INV250

60 V and -15°C for INV350

90 V and -15°C for INV500

The open circuit voltage of the connected PV generator

must be in the allowed input voltage range, even at

very low outdoor temperatures (-15°C). With a lowering

of the temperature of 25°C to -10°C, the open circuit

voltage at 12 V modules increases by approx. 2.8 V

per module (approx. 5.6 V at a 24 V module). The open

circuit voltage of the PV generator must be less than

45V for INV250, less than 60 V for INV350 and less than

90 V for INV500.

UMPP (+60°C)> min. Input voltage:

20 VDC for INV250

20 VDC for INV350

40 VDC for INV500

For the INV250-45US /-RS485 /-PLC this voltage is 20 V.

For the INV350-60US /-RS485 /-PLC this voltage is 20 V.

For the INV500-90US /-RS485 /-PLC this voltage is 40 V.

The UMPP-voltage of the connected circuit branch

should not fall below the allowable input voltage range,

even at very high module temperatures (+60°C). With

a temperature rise of 25°C to 60°C, the UMPP-voltage

decreases for 12 V modules to approximately 3.6 V per

module (7.2 V at a 24 V module).

The UMPP-voltage of the PV generator should be

at least 20V for INV250, 20V for INV350 and 40V for

INV500. If the UMPP-voltage falls below the allowed

input range, the system still works without problems.

In this state, it is not feeding the maximum possible

power into the grid, but slightly less. It does not aect

the inverter when a connected PV generator supplies

a higher than the maximum usable input power,

provided that the input voltage is within the acceptable

range.

It may happen that the inverter switches o for safety

reasons, if the PV generator provides more than the

max. DC input power of the inverter for a short time,

especially with changing cloud coverage and relatively

low-temperature conditions. Normally, the control of

the inverter is so dynamic that it continues to operate

without interruption.

Generally, in Central Europe a south orientation with

30° inclination should be chosen for optimum energy

yield of the PV array. The optimum power factor

for south-facing systems is 1.10 to 1.25. In an east-

west system the power factor can be chosen to 1.30.

Requirement is that all other values of the inverter are

met. For exposed locations in the mountains or in the

southern regions, a corresponding reduction (<1.15)

of the power ratio is required. For questions please

contact our customer service.

10 INV250-45US / INV350-60US / INV500-90US 05.2014

5.2 Compatibility and Capacity

The Micro-Inverters listed in Section 1.2 are compatible

with a wide variety of modules, starting with 48-cells up

to 96 cells modules, as long as it is provided that under

all occurring environmental inuences, the following

DC Input voltages are NOT exceeded:

45V for INV250

60V for INV350

90V for INV500

For more information, see Technical Data on pages 18-

20 in this manual.

Utility service requirements: 240V version works only

with split phase 240V service. The 208V version works

only with three phase 208V service, or 208 single phase

service.

5.3 Parts and Tools Required

You may need to provide other parts and tools that

could be required for installing a PV-System using

Micro-Inverters. These may include, but are not limited

to the following:

• Continuous grounding conductor, grounding

washers

• Number 2 Phillips screwdriver

• Sockets, wrenches for mounting hardware

• Torque wrench

• Mounting hardware suitable for module racking

5.4 Lighting Surge Protection

Lightning does not actually need to strike the

equipment or building where PV system is installed

to cause damage. Often, a strike nearby will induce

voltage spikes in the electrical grid that can damage

equipment. AEconversion Micro-Inverters have integral

surge protection. However, if the surge has sucient

energy, the protection built into the Microinverter can

be exceeded, and the equipment can be damaged.

Since the AEconversion Limited Warranty does not

cover “acts of God” such as lightning strikes, and

since lightning strikes can occur anywhere, it is best

practice to install surge protection as part of any solar

installation.

6.0 Installation Procedure

Please note the important safety information listed in

1.1 as well as the Assembly, Installation, Operation and

Maintenance Warnings listed in 2.1.

In the following section, an overview is given on how

the micro-inverter is to be installed.

Step 1 Measure AC at the Electrical Utility Connection

Step 2 Install the AC Branch Circuit Junction Box

Step 3 Attach the Micro-Inverter to the PV Racking

Step 4 Connect the Micro-Inverters (AC-Connection)

Step 5 Ground the System

Step 6 Communication Set-up

Step 7 Complete the Installation Map

Step 8 Connect the PV Modules

Step 9 Start Software

6.1 Measure AC at the Electrical Utility Connection

To ensure proper system operation, measure AC line

voltage at the electrical utility connection to conrm

that it is within range. Acceptable ranges are shown

below.

Three-phase 208 VAC

183 to 229 VAC L1 to L2 to L3

106 to 132 VAC L1,L2, L3 to neutral

Single-Phase 240 VAC

211 to 263 VAC L1 to L2

106 to 132 VAC L1, L2 to neutral

NOTE:

Check the labeling on the AC Cabling to be sure that

the cable matches the electrical utility service at the

site. Use 208 VAC (208 VAC three-phase) Cabling at

sites with three-phase 208 VAC service, or use 240 VAC

Cabling at sites with 240 VAC single-phase service. Use

240 VAC cable at sites with 208 single-phase service.

Please refer to page 27 (208V) and 28 (240V) for wiring

diagrams.

NOTE: The operation at grids with neutrals which

are not grounded is not allowed!

6.2 Install the AC Branch Circuit Junction Box

DANGER:

Risk of Electrical Shock. Be aware that installation of this

equipment includes risk of electric shock. Do not install

the AC junction box without rst removing AC power

from the PV-System.

WARNING:

Only use electrical system components approved for

wet locations.

WARNING:

Do NOT exceed the maximum number of micro-

inverters in an AC branch circuit as listed in 6.4.1

and 6.4.2 of this manual. You must protect each

micro-inverter AC branch circuit with a two pole 20A

maximum breaker.

WARNING:

Open all ungounded conductors of the cicuit to which

it is connected.

11INV250-45US / INV350-60US / INV500-90US05.2014

The installation of a circuit junction box does not

necessarily need to be installed for a PV-system with

micro-inverters to work. If however, circuit junction

boxes are installed, be sure to follow all common

installation security measures and install in accordance

with all applicable local electrical codes and the

National Electrical Code (NEC), ANSI/NFPA 70.

The installation instructions shall indicate that the

wiring methods used shall be in accordance with the

Canadian Electrical Code, Part I.

6.3 Attach the Micro-Inverter to the PV Racking

To nd the optimal location for the inverter, a summary

of key criteria that should be considered is listed below.

Select an installation location so that the following

points will nd consideration:

• Ensure best possible access to the unit for

installation and any subsequent service.

• Ensure a minimum distance of 20 mm between the

roof top and the bottom of the inverter.

• In addition, we recommend a distance of 25 mm

between the back of the PV module and the top of

the inverter.

• The device is designed for attachment to the

mounting bracket under a PV module, but other

mounting options are possible.

• The free ow of air around the case must not be

hindered.

NOTE!

Because of the voltage of the PV generator, there is

a greater current ow on the DC side than on the AC

side. Due to this, there are higher losses on the DC side

with the same cable cross-sections and lengths. For

this reason, the placement of the inverter in the vicinity

of the PV module is useful. The line lengths on the DC

side should be kept as correspondingly short.

To Install the Micro-Inverter under the PV module,

please use suitable accessories corresponding to the

framework used, for example with the use of screws

and sliding blocks.

In order to mount the inverters on the PV-framework

below the PV-modules, note the following:

Select the approximate center of the PV module on

the mounting prole. Fasten the inverter centered

on this mark with the help of accessories that are

compliant with the AEconversion Micro-Inverter and

the framework used. This could be done by fastening

the inverter with screws and sliding blocks below the

inverter supports at the framework proles.

Mounting slots on the Micro-Inverter are 0.33 inches in

diameter. Maximum bolt size is 5/16 inch.

The two slots on the Micro-Inverter are 4 inches apart.

While installing, please note, that the inverter fastened

in the correct postition:

• the top (with label) must be facing upward

• the connectors must be facing down away from

framework

If an assembly to the PV-framework below the PV

modules is not possible, a more tting alternative is

possible:

For wall mounting, the inverter can be turned 180 °

and mounted to the wall with the back of the inverter.

The brackets of the inverter are designed to guarantee

sucient distance from the wall.

12 INV250-45US / INV350-60US / INV500-90US 05.2014

If using grounding washers (e.g., WEEB) to ground the

Micro-Inverter chassis to the PV module racking, choose

a grounding washer that is approved for the racking

manufacturer. Install a minimum of one grounding

washer per Micro-Inverter.

Please note the manufacturer’s installation instructions

for the grounding washers.

6.4 Connect the Micro-Inverters (AC-Connection)

NOTE:

When connections are made, standards and

regulations, as well as the safety information contained

in this manual must be followed.

NOTE:

Do not connect the inverter to grids without an earthed

neutral conductor.

Please note the important safety information listed in

1.1 as well as the Assembly, Installation, Operation and

Maintenance Warnings listed in 2.1.

Follow local regulations for work on electrical

installations.

The layout of the AC connection depends on the

version of the Micro Inverter. For both versions the

following applies:

Connect the inverters using the AC wiring from one

inverter to the next, in ways that are further explained

for each version in the following sections. However, for

both versions, it is important that the AC connections

are made only up until the maximum permitted

number of inverters in an AC power circuit is reached.

DO NOT exceed the maximum allowable number of

inverters in an AC power circuit, as noted in chapter

6.4.1 and 6.4.2.

Open AC connections at the end of an AC power circuit

must be sealed with a protective cap.

To achieve the degree of protection NEMA 4, all unused

PV input jacks and plugs must be sealed with caps.

At a relatively high resistance, i.e. with long line length

on the AC side, the feeding voltage increases at the

supply terminals of the inverter.

This voltage is measured by the inverter. If the voltage

at the supply terminals exceeds the grid over voltage

limit, the inverter shuts o due to grid over voltage. It is

essential to take this fact into account for the AC wiring

and dimensioning of the AC line.

If the PV system consists of more than one inverter, the

individual inverters are connected via connecting lines:

PIN L L1 (red)

PIN N L2 (black)

PE (green)

Make sure that you use suciently large cable cross-

sections to avoid major resistance between the

domestic distribution and the respective inverter.

Choose a cable quality which is sucient for the use in

your application.

The connector can accommodate a maximum cross

section of AWG 15 with a exible cable with cable core

end. In a rigid core cable, a connector with AWG 13 is

possible. Note the resulting maximum line length.

6.4.1 AC-Connection of PLC and NoCom Devices

For the Powerline Communication Version and the

Version without communication features:

The inverter is equipped with one AC terminal on

the right side of the connection area, a 20A 3-pin AC

connector. The supply is phase to phase 208V or 240V

depending on version. The inverters are connected

using 20A 3-pin AC extension cables and distribution

blocks, with one input and three outputs, to form a

continuous AC power circuit. On one strand (power

circuit), which is equipped with a 20A two pole circuit

breaker, up to 12 inverters can be operated. This circuit

breaker acts also as a pole switch to disconnect the

Inverter from the mains.

The distribution blocks are not included in scope of

delivery of the Micro Inverter, see accessories overview

for ordering details.

13INV250-45US / INV350-60US / INV500-90US05.2014

Open AC connections at the end of an AC power circuit

must be sealed with a protective cap. This cap must be

ordered, see accessories overview.

6.4.2 AC-Connection of RS485 Devices

INV350-60US RS485

For the RS-485 Communication Version:

The inverter is equipped with two AC terminals on

the right side of the connection area. The inverter has

two 3-pin AC connectors. The supply is single phase.

Connect the last Micro Inverter to the next one using

AC connector cabling and continue with following

inverters. The AC connectors are polarized dierently,

so that multiple inverters can be connected to form

a continuous AC power circuit. On one strand (power

circuit), which is equipped with a 20A two pole circuit

breaker, up to 12 inverters can be operated. This circuit

breaker acts also as a pole switch to disconnect the

Inverter from the mains.

Open AC connections at the end of an AC power

circuit must be sealed with a protective cap. This cap is

included.

6.5 Ground the System

Each AEconversion Micro-Inverter comes with a

grounding xture that can accommodate a 6-8 AWG

conductor.

Route a continuous grounding electrode conductor

through each of the micro-inverters to the NEC-

approved AC grounding electrode.

If you are not using grounding washers to ground the

micro-inverter chassis as described in step XY, follow

the step below.

Each AEconversion Micro-Inverter comes with a

grounding xture that can accommodate a 6-8 AWG

conductor.

Route a continuous grounding electrode conductor

through each of the micro-inverters to the NEC

approved AC grounding electrode. The racking and

module could be grounded to this conductor using a

crimp connection.

An alternative method would be to connect the micro-

inverter to the grounded racking using a grounding

washer approved for the racking.

6.6 Communication Set-up

The following sections describe how to set-up

communication (monitoring), depending on Version of

the Micro-Inverter.

6.6.1 RS-485 Communication

If your Micro-Inverter is not equipped with TIA485

(RS485) Interface, then this step can be skipped.

For the RS-485 Version, the following has to be noted:

To allow for remote monitoring of your PV system, the

inverters have two additional RS485 ports. The RS485

interface is used for remote communication. The RS485

communications can be established over a distance

of up to 1000 meters. In the case of an external power

limiting, the signal transmission is also performed via

the RS 485 interface.

Using this interface, several (max.32) inverters can be

monitored simultaneously. For this, each inverter has

its own address. The address setting is performed in

the service level. The system data is taken from the data

logger. Please refer to accessories overview for suitable

datalogger. For more information on these products,

see the respective manuals.

Using pre-assembled interface lines, the

communication between the inverters and the data

logger can be set up quickly and easily. For longer

distances between the inverters or the data logger,

please use free-attachable cable or a suitable data

cable; please refer to accessories overview for ordering

details.

14 INV250-45US / INV350-60US / INV500-90US 05.2014

The RS485 is a two wire (A, B) linear bus system. I.e.

the device has to be wired in a line. It is necessary to

put terminators on both ends. Adequate termination

resistors for the Micro-Inverters are available; please

refer to accessories overview for ordering details.

Additional the Bus master, generally a data logger,

has to provide a bias-network. When selecting a data

logger, please note the possibly necessary features of

the statutory requirements or technical directives from

Chapter 4. To choose the right data logger, you should

contact your retailer.

For the inverter, the external power limitation is

realized on the RS485 interface. For the construction of

communication, we recommend a twisted and shielded

data cable of the type Cat 5 / T568B.

The following gure shows the conguration of the

connector:

For communication only Pair 3 is needed.

So wire A of the RS485-Bus is connected to Pin 6 and

wire B to Pin 3. Additional Pin 8 and the cable shield are

connected to Earth to protect against electromagnetic

inuences. These wires as well as the shield must not

be connected at the bus master. It is recommended to

connect unused wires to the bus master GND.

To build up a low cost monitoring, AEconversion

provides the AP-Solar datalogger-software for free.

Additional, to connect the RS485-Bussystem to a

standard home PC, AEconversion recommends the

USB-Nano485/OP form cti (AEconversion Part Number

for ordering: 51-05-500009-1), which sets up the

RS485-signals to standard USB and provides selectable

termination resistor, bias network and GND connection.

6.6.2 Powerline Communication

If the Microinverter is equipped with a Powerline-

Communication-Interface this chapter describes how

to wire and monitor the system. With the Powerline-

Communication the data exchange takes place on the

AC-Lines. Therefore there’s no need for additional data

lines to the Microinverter. Using this interface, several

(max.32) inverters can be monitored simultaneously,

over a maximum distance of about 100 meters. For this,

each inverter has its own address. The address setting is

performed in the service level.

In combination with the PLC-Gateway, it’s possible to

build up a simple monitoring Network. The following

diagram shows how to connect the Micro-Inverters to

the Gateway:

The Gateway is needed to convert the Powerline-

Signals into standard RS-485. For more information on

the PLC-Gateway the please refer to separate Product

Manual. To build up a simple low cost monitoring with a

standard home PC please refer to 6.6.1.

6.6.3 Without Communication

The Micro-Inverter versions without communications

are not intended for comprehensive monitoring, and

therefore cannot be monitored using the AEconversion

Datalogger, Gateway or Software. For the user to

monitor the basic PV-system data, the user can install

an independent energy-monitoring-device.

6.7 Complete the Installation Map

The installation Map an aid to visualize the physical

location of each Micro-Inverter in your PV installation.

This will also simplify the setup of the virtual array using

the Software AP-Solar, which is included in the scope of

delivery.

Use the blank map on page 26 to record the locations

of each Micro-Inverter or create your own map as a top-

down view of the array. Write down the last 5 digits of

the Serial number at the respective Inverter location on

the map. With the software, the last 5 digits can be used

to identify the Micro-Inverters and rename them (e.g.

Inverter 1,2,3, …) for simplied identication.

15INV250-45US / INV350-60US / INV500-90US05.2014

6.8 Connect the PV Modules

NOTE: Completely install all Micro-Inverters and all

AC connections prior to installing the PV modules.

To ensure maximum security against dangerous touch

voltages, it is necessary to make sure that the DC

connection cables coming from the PV generator are

not in contact with the ground potential during the

installation of a photovoltaic system.

CAUTION:

- Risk of damage! Make sure the correct polarity at the

terminals!

- Check the PV generator for ground fault before you

connect it to the inverter.

Before you connect the DC cables to the inverter, check

if the maximum PV-module voltage is suitable for

feeding into the inverter. The presence of a PV module

voltage that is too high leads to the destruction of the

device. Pay attention to the increase of the open circuit

voltage of the solar eld at low temperatures!

Prior to the installation of PV modules, the inverter

should be fully installed and the AC connections

between the inverters should be performed. Install, if

possible, the PV modules above the respective inverter

to the PV-racking. The connection cables of the PV

modules are connected to the inverter on negative and

positive polarized PV plug and socket.

Before you begin, determine the polarity of the PV

module. Connect the positive terminal of the module

with the“+”marked input of the inverter. The negative

pole of the PV module is connected to the“-“ marked

input of the inverter.

This step is performed for all remaining PV modules,

each to the corresponding inverter without exceeding

the maximum number of inverters in a power circuit.

The exact use of the DC connectors is as follows:

Push together the cable coupler until it clicks. Correct

latching control by carefully pulling on the cable

connectors. When the compounds are fully engaged,

check that there are no sharp bends or kinks.

When disconnecting the cable couplings press the

mounting link together by hand and disconnect the

cable coupling.

The DC wiring of an inverter with a PV module looks

conceptually like this:

Inverter

ModuleConnectionCable

PV-Generator(modules)

6.9 Start Software

When the system is energized and the AP Datalogger or

Gateway detects all the installed Micro-Inverter, please

install the software on your personal computer to

ensure proper operation of the system.

For direction on how to use the software, please refer to

the Software User Manual.

7.0 Commissioning, Operation and Registration

The following Section describes the procedures for

Commissioning, Operating, and Registering the System.

16 INV250-45US / INV350-60US / INV500-90US 05.2014

WARNING:

Ensure that all AC and DC wiring is correct. Ensure that

none of the AC and DC wires are pinched or damaged.

Ensure that all AC junction boxes are properly closed.

7.1 Commissioning

1. Turn ON the AC-disconnect or circuit breaker on

each Micro-Inverter AC branch circuit.

2. Turn ON the main utility-grid AC circuit breaker.

Your system will start producing power after a ve-

minute wait time.

When commissioning for the rst time or when the

inverter was not supplied with a PV power for a

longer time, the inverter can require some connection

attempts over a period of 5 minutes to go in feeding

operation.

7.2 Registering with Utility Company

For registration and the acceptance process of a PV

system, please inform yourself concerning the details of

each utility.

Commissioning usually runs as follows:

• Submission of documents to the relevant local

Utility Company

• installation of the system

• installation of the meter by the Utility Company

For this purpose, the following documents are generally

required:

• application / completion notication by registered

installer

• site plan, setting out the property boundaries and

the site of the PV system

• overview diagram of the entire system with the

used equipment (pole diagram)

• datasheet for generating systems (utility

announcement)

• description of the protective device with

information about the type, circuit, make and

function

• description of the inverter or rather declaration and

clearance certicate information about the short-

circuit rating of switching devices

8.0 Troubleshooting

Adhere to all the safety measures described throughout

this manual. Qualied personnel can use the following

troubleshooting steps if the PV system does not

operate correctly.

WARNING: Do not attempt to repair the AEconversion

Micro-Inverter; it contains no user-serviceable parts. If

it fails, please contact APtonics’ Service Department to

assist.

For further troubleshooting, see LED-Indicators in

chapter 4.3.

8.1 Troubleshooting an Inoperable Micro-Inverter

To troubleshoot an inoperable Micro-Inverter, follow

the steps in the order shown:

1. Verify the connection to the utility grid. Make sure

that the utility frequency and voltage are within

allowable ranges listed in the Technical Data section

on pages 18-20 of this manual.

2. Make sure that the utility power is present at the

inverter in question by rst removing AC and

then DC power. Do NOT under any circumstances

disconnect the DC wires while the Micro-Inverter is

producing power.

3. Check the AC distribution blocks between all

the Micro-Inverters. Check that each inverter is

energized by the electricity network as described in

the previous step.

4. Any AC disconnects need to be checked if they are

operating correctly and closed.

5. Check to see if the PV module DC voltage is within

the allowable range shown in the Technical Data

section on pages 18-20 of this manual.

6. Verify that the DC connections between the Micro-

Inverter and the PV module are connected properly.

7. If the problem persists, please call customer

support at AEconversion.

8.2 Other Faults

Other faults are reported to the AP-Solar Software. Refer

to the AP-Solar Installation and Operation Manual for

troubleshooting procedures.

WARNING:

Be aware that only qualied personnel should

troubleshoot the PV array or the AEconversion Micro-

Inverter.

WARNING:

Never disconnect the DC wire connectors under load.

Ensure that no current is owing in the DC wires prior

to disconnecting. An opaque covering may be used to

cover the module prior to disconnecting the module.

WARNING:

Always disconnect AC power before disconnecting the

PV module wires from the AEconversion Micro-Inverter.

The AC connector of the rst Micro-Inverter in a branch

circuit is suitable as a disconnecting means once the

AC branch circuit breaker in the load center has been

opened.

WARNING:

Open all ungrounded conductors of the circuit to which

it is connected.

17INV250-45US / INV350-60US / INV500-90US05.2014

8.3 Disconnecting a Micro-Inverter from the PV Module

Please note the important safety information listed in

1.1 as well as the Assembly, Installation, Operation and

Maintenance Warnings listed in 2.1.

Follow local regulations for work on electrical

installations.

WARNING:

- Risk of death by electric shock on live connections!

Even after disconnecting the electrical connections,

there are still perilous voltages present in the inverter.

- Wait ve minutes or so until you do further work on

the inverter.

For adjustment, maintenance and repair work, you

need to turn o the inverter.

• Switch o the grid by activating the circuit breaker

(disable external locking mechanisms).

• Check for zero-potential after the shutdown.

To ensure the Micro-Inverter is not disconnected from

the PV modules under load, adhere to the following

disconnection steps in the order shown:

1. Disconnect the AC by opening the branch circuit

breaker.

2. Disconnect the rst AC connector in the branch

circuit.

3. Cover the module with an opaque cover.

4. Using a DC current probe, verify there is no current

owing in the DC wires between the PV module

and the Micro-Inverter. Care should be taken when

measuring DC currents, most clamp-on meters

must be zeroed rst and tend to drift with time.

5. Disconnect the PV module DC wire connectors

from the Micro-Inverter.

6. Remove the Micro-Inverter from the PV array racking.

8.4 Installing a Replacement Micro-Inverter

Attach the replacement micro-inverter to the PV

module racking using hardware recommended by your

module racking vendor. If you are using grounding

washers to ground the chassis of the micro-inverter,

the old grounding washer should be discarded, and a

new grounding washer must be used when installing

the replacement micro-inverter. For torque values

please refer the recommendations for installation of the

washer vendor.

1. If you are using a grounding electrode conductor

to ground the micro-inverter chassis, attach the

grounding electrode conductor to the micro-

inverter ground clamp.

2. Connect the AC cable of the replacement micro-

inverter and the neighboring micro-inverters to

complete the branch circuit connections.

3. Energize the branch circuit breaker and verify that

the replacement inverter is working properly by

checking the indicator light.

4. Initiate a device scan with the AP-Solar Software.

9.0 Further Information

The following sections provide further guidance to the

inverter.

9.1 Disposal

Dispose of the packaging in accordance with

generally applicable laws and regulations. Keep the

environmental requirements for recovery, reuse and

disposal of materials and components.

9.2 Care

The surface of the inverter should generally be kept free

of dust and dirt.

9.3 Laws, Regulations and Technical Rules

In preparing the current solar technology systems for

the respective country laws and regulations are to be

noted for country, federal, European, and international

levels.

The generally accepted engineering standards

considered to apply, which are usually formulated in

the form of standards, guidelines, rules, regulations

and technical rules of state and federal agencies,

utility companies, and professional associations and

committees for the relevant department.

Through the installation of solar panels / solar system,

the requirements for roong, waterproong and

exterior wall cladding according to the rules of the

German Roong Trade, or equivalent national and

international guidelines and standards are to be

considered.

An examination of stability, the thermal protection

and the aging behavior is required for retrospective

installation.

To comply with the regulations on accident prevention,

the use of safety systems (safety belt, scaolding,

arresting gear, etc.) may be required. These security

systems are not included and must be ordered

separately.

The installation must be performed by professionally

qualied and authorized personnel with an approved

training certicate (by a state or national organization)

for the respective department.

Inside the inverter, there are NO serviceable or

exchangeable parts. The inverter may neither be

opened by the customer nor the system installer.

FCC Compliance

This equipment has been tested thru FCC part 15 Class

B. The unit complies with the dened standard.

During the unit is under inuence of strong electric

elds the unit may be disturbed. This may cause

random reduction of output power or a short time shut

down of the unit. After the electric eld is removed, the

unit will return to normal operation.

18 INV250-45US / INV350-60US / INV500-90US 05.2014

Technical Data for INV250-45

Input

· Maximum PV power: 250 W

· Maximum DC voltage: 45 V

· Min./Max. start voltage: 18 V / 45 V

· MPP range: 20 ... 40 V

· Maximum DC current: 11 A

Output

· Maximum AC Power: 240 W

· Nominal Current: 1.0 A

· Power factor: > 0.99

Eciency

· Peak inverter eciency: 93.5 %

· European eciency: 91.4 %

· Nominal MPP eciency: 99.8 %

Features

· Communication Versions: Powerline / RS-485 / No Com

· MSD integrated acc. to VDE AR-N 4105

· Safety class: Class I

Mechanical Data

· Operating Temperature: -25 °C ... +70 °C

· Night time power consumption: 30 mW

· Max. altitude a.s.l.: 2000 m

Housing

· 314 mm x 267 mm x 66.5 mm (BxHxT)

· Weight: 2.5 kg

· Cooling: natural convection

· Enclosure mterial: aluminum

· Protection Degree:

IP65 (50Hz-Version) / NEMA 4 (60Hz-Version)

50 Hz-Version

· Nominal AC voltage: 230 V

· Nominal AC voltage range: 184 V ... 264 V

· Frequency: 50.0 Hz

· Frequency range: 47.5 Hz ... 51.5 Hz

· Productsafety: IEC 62103:2003, IEC 62109-1:2010, IEC

55011B, EN 50178:1997

· EMC: EN 61000-6-2, EN 61000-6-3

60 Hz-Version

· Nominal AC voltage: 208 V or 240 V

· Nominal AC voltage range: 184V ... 264V

· Frequency: 60.0 Hz

· Frequency range: 59.5 Hz ... 60.3 Hz

· Productsafety: UL 1741:2010, IEEE 1547:2003,

CSA C22.2

· EMC: FCC Part 15 Class B

AEconversion GmbH & Co. KG

INV250-45

Micro-Inverter

Description

The AEconversion Micro-Inverter INV250-45 converts

the generated energy into grid-compliant alternating

current. For this, the INV250-45 is directly connected

to a module. The Individual conversion allows optimal

utilization of solar energy.

The micro-inverter INV250-45 operates up to a maximum

power of 250W with a maximum PV input voltage of 45V.

In systems with central or string inverters, the series

connection of the PV modules often causes energy

losses. If the output from a module drops, for example

through shading, it reduces the performance of the

whole string. This problem is solved by micro-inverters,

because in systems with these inverters, the modules

work independently and guarantee the highest

possible.

www.aeconversion.com | info@aeconversion.com

19INV250-45US / INV350-60US / INV500-90US05.2014

Technical Data for INV350-60

Input

· Maximum PV power: 350 W

· Maximum DC voltage: 60 V

· Min./Max. start voltage: 18 V / 60 V

· MPP range: 20 ... 50 V

· Maximum DC current: 11 A

Output

· Maximum AC Power: 330 W

· Nominal Current: 1.4 A

· Power factor: > 0.99

Eciency

· Peak inverter eciency: 93.5 %

· European eciency: 91.8 %

· Nominal MPP eciency: 99.8 %

Features

· Communication Versions: Powerline / RS-485 / No Com

· MSD integrated acc. to VDE AR-N 4105

· Safety class: Class I

Mechanical Data

· Operating Temperature: -25 °C ... +70 °C

· Night time power consumption: 30 mW

· Max. altitude a.s.l.: 2000 m

Housing

· 314 mm x 267 mm x 66.5 mm (BxHxT)

· Weight: 2.5 kg

· Cooling: natural convection

· Enclosure mterial: aluminum

· Protection Degree:

IP65 (50Hz-Version) / NEMA 4 (60Hz-Version)

50 Hz-Version

· Nominal AC voltage: 230 V

· Nominal AC voltage range: 184 V ... 264 V

· Frequency: 50.0 Hz

· Frequency range: 47.5 Hz ... 51.5 Hz

· Productsafety: IEC 62103:2003, IEC 62109-1:2010,

IEC 55011B, EN 50178:1997

· EMC: EN 61000-6-2, EN 61000-6-3

60 Hz-Version

· Nominal AC voltage: 208 V or 240 V

· Nominal AC voltage range: 184 V ... 264 V

· Frequency: 60.0 Hz

· Frequency range: 59.5 Hz ... 60.3 Hz

· Productsafety: UL 1741:2010, IEEE 1547:2003,

CSA C22.2

· EMC: FCC Part 15 Class B

AEconversion GmbH & Co. KG

INV350-60

Micro-Inverter

Description

The AEconversion Micro-Inverter INV350-60 converts

the generated energy into grid-compliant alternating

current. For this, the INV350-60 is directly connected

to a module. The Individual conversion allows optimal

utilization of solar energy.

The micro-inverter INV350-60 operates up to a maximum

power of 350W with a maximum PV input voltage of 60V.

In systems with central or string inverters, the series

connection of the PV modules often causes energy

losses. If the output from a module drops, for example

through shading, it reduces the performance of the

whole string. This problem is solved by micro-inverters,

because in systems with these inverters, the modules

work independently and guarantee the highest possible

return.

www.aeconversion.com | info@aeconversion.com

20 INV250-45US / INV350-60US / INV500-90US 05.2014

Technical Data for INV500-90

Input

· Maximum PV power: 500 W

· Maximum DC voltage: 90 V

· Min./Max. start voltage: 40 V / 90 V

· MPP range: 40 ... 80 V

· Maximum DC current: 11 A

Output

· Maximum AC Power: 480 W

· Nominal Current: 2.1 A

· Power factor: > 0.99

Eciency

· Peak inverter eciency: 95.0 %

· European eciency: 94.0 %

· Nominal MPP eciency: 99.8 %

Features

· Communication Versions: Powerline / RS-485 / NoCom

· MSD integrated acc. to VDE AR-N 4105

· Safety class: Class I

Mechanical Data

· Operating Temperature: -25 °C ... +70 °C

· Night time power consumption: 30 mW

· Max. altitude a.s.l.: 2000 m

Housing

· 314 mm x 267 mm x 66.5 mm (BxHxT)

· Weight: 2.5 kg

· Cooling: natural convection

· Enclosure material: aluminum

· Protection Degree:

IP65 (50Hz-Version) / NEMA 4 (60Hz-Version)

50 Hz-Version

· Nominal AC voltage: 230 V

· Nominal AC voltage range: 184 V ... 264 V

· Frequency: 50.0 Hz

· Frequency range: 47.5 Hz ... 51.5 Hz

· Productsafety: IEC 62103:2003, IEC 62109-1:2010,

IEC 55011B, EN 50178:1997

· EMC: EN 61000-6-2, EN 61000-6-3

60 Hz-Version

· Nominal AC voltage: 208 V or 240 V

· Nominal AC voltage range: 184 V ... 264 V

· Frequency: 60.0 Hz

· Frequency range: 59.5 Hz ... 60.3 Hz

· Productsafety: UL 1741:2010, IEEE 1547:2003,

CSA C22.2

· EMC: FCC Part 15 Class B

AEconversion GmbH & Co. KG

INV500-90

Micro-Inverter

Description

The AEconversion Micro-Inverter INV500-90 converts

the generated energy into grid-compliant alternating

current. For this, the INV500-90 is directly connected to

one or two modules. The Individual conversion allows

optimal utilization of solar energy.

The micro-inverter INV500-90 operates up to a maximum

power of 500W with a maximum PV input voltage of 90V.

In systems with central or string inverters, the series

connection of the PV modules often causes energy

losses. If the output from a module drops, for example

through shading, it reduces the performance of the

whole string. This problem is solved by micro-inverters,

because in systems with these inverters, the modules

work independently and guarantee the highest possible

return.

www.aeconversion.com | info@aeconversion.com

This manual suits for next models

8

Table of contents

Other AE Conversion Inverter manuals

AE Conversion

AE Conversion INV-EU Series Installation guide

AE Conversion

AE Conversion INV315-50EU User manual

AE Conversion

AE Conversion INV250-45EU RS485 User manual

AE Conversion

AE Conversion INV315-50EU Installation guide

AE Conversion

AE Conversion INV250-45EU PLC User manual

AE Conversion

AE Conversion INV315-50EU User manual

AE Conversion

AE Conversion PS350 User manual