20. TROUBLESHOOTING

•If the salt concentration is correct (1- 2 kg/m3 MgCl2or 0.75 - 1.5 kg/m3NaCl): The cell is reaching its end of life. As of this moment check the intensity every 15-20 days.

•When polarity 2 does not reach intensity of Polarity 1, we recommend substituting the cell for a new one if it happens during the summer period. If it happens during winter,

change the cell before the next summer period.

Polarity 1 reaches maximum intensity, but polarity 2 (auto clean) does not reach maximum intensity

•Check if ON/OFF switch is illuminated.

•Check the connection wire between display and motherboard.

•Check the 3.15 A fuse of the device – it could have tripped due to overload.

•Check the power supply – 230V/50Hz.

•If the problem persists contact TECHNICAL SERVICE

•Lower hydrolysis cell intensity.

•If your system includes automatic Redox control, check the Redox setpoint value.

Reduce it by 50 to 100 mV.

•If your system includes free chlorine measurment, adjust the setpoint value.

•Check redox probe and calibrate it if necessary.

•Check the free chlorine probe and calibrate it.

Blank display Excess of chlorine in the water

•Attention: At 1200 TDS, 50 - 80% and the warning “LOW” is normal

• Low water temperature.

•Check the salt concentration (TDS) in water.

•Check the cell status (it may be incrusted or calcied).

•Clean the cell according to the instructions in section 19.

•Check that the cell is not worn out (remember that the cell is guaranteed for

5,000 hours, approx. 2-3 years of summer usage).

Hydrolysis does not reach the setpoint value

•Very hard waters with a high pH and total alkalinity: balance water adjusting pH

and total alkalinity.

•Check to ensure that the system automatically changes polarity approximately

every 300 minutes.

•Consult with our technical service to consider accelerating the polarity change

(auto-cleaning) . WARNING: Accelerating the polarity change decreases the cell

life (5,000 hours) proportionally. Don’t go below 200 minutes!

•If the crust is not foaming when in contact with acid, it might be Struvite. In this

case do not use anymore MgCl2, use only NaCl.

Cell incrusted in less than 1 month

•Check gas and paddle ow detector cable.

•Clean for incrustations of the paddle ow detector at the top of the cell housing.

•Check to see if system is free of air (gas detector must always be submerged).

•Metallic elements lack standardised earth connection. Contact an electrician to

solve the problem.

•Rusted components are not stainless steel (minimum 316/V4A/1.4571).

•The salt concentration (TDS) is too high.

•Attention Stainless Steel parts must be cleaned regularly

Hydrolysis display shows FLOW Rust on metallic components in the pool

WARNING

Keep chemical levels in pool as instructed in this manual.

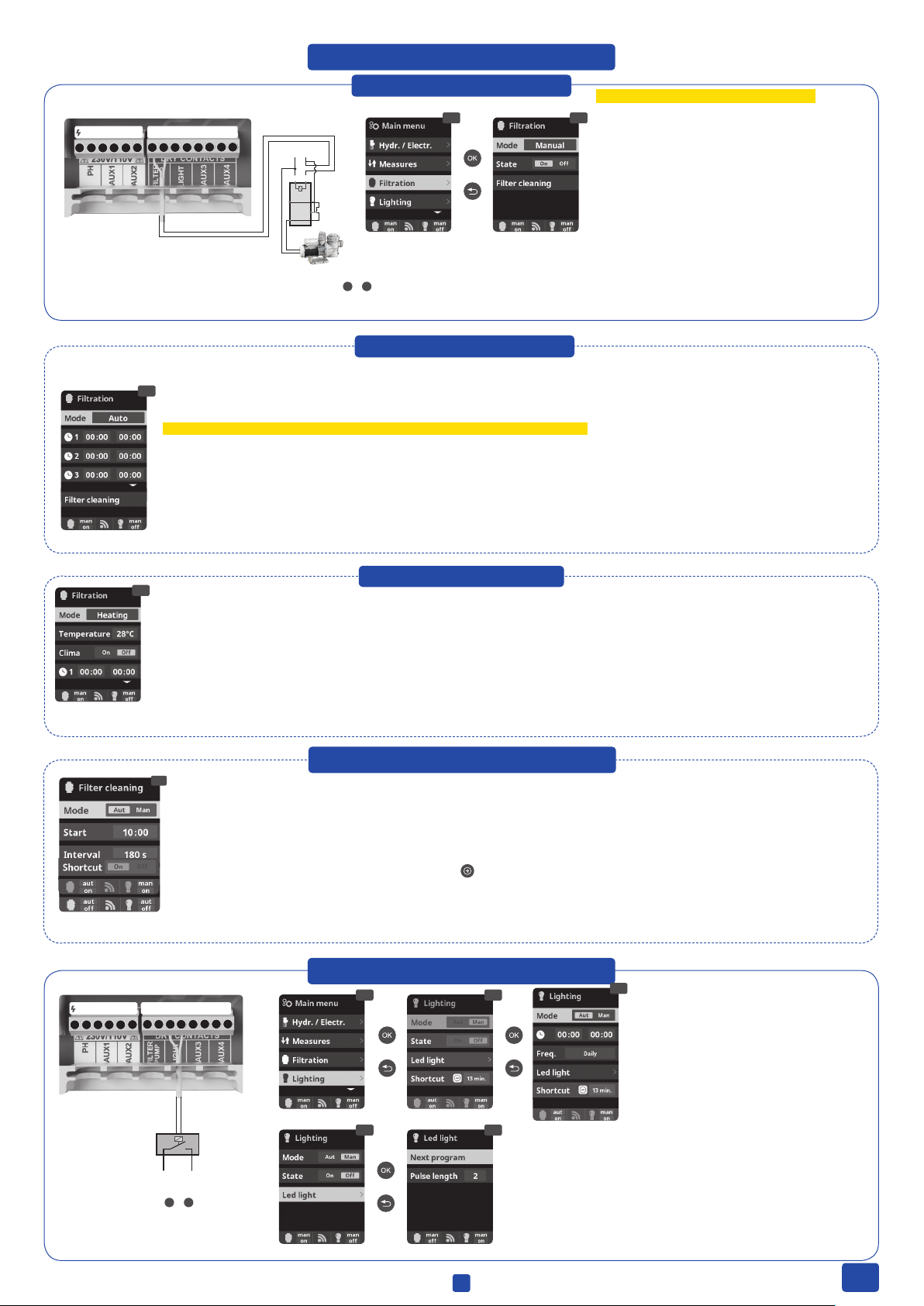

CLEANING FILTER

Very Important: Make sure the cell is off while cleaning/backwashing the lter. If the system controls the ltration pump, use the option “lter cleaning” of the programmed

ltration mode. See section 5 – Filtration / Filter Cleaning of the General Installation Guide.

VERY IMPORTANT

Remember that the system needs some time to adapt to your pool (up to 14 days)!

SECURITY

To avoid accidents, children should not handle this product unless supervised by an adult. Children should be supervised at all times when in or near a spa, pool or jacuzzi.

HANDLING AND DOSING DANGEROUS CHEMICALS

Chemicals should be handled with extreme caution. When preparing acid, always add acid to water, never add water to acid, because very dangerous gases may be produced.

•Increase the ltration hours to 24 hours

•Increase the hydrolysis level (to 100%).

•Increase the salt concentraion (TDS) in the water. Setpoint app. 1200 ppm.

•In an outdoor pool: Add ACO®to the water.

•Check if the reagents in test kit are in date.

•Check if the temperature or number of users has risen.

• If you want a higher chlorine level you have to increase the salt concentration.

Attention: Higher risk of corrosion!

Free chlorine level doesn’t reach the setpoint

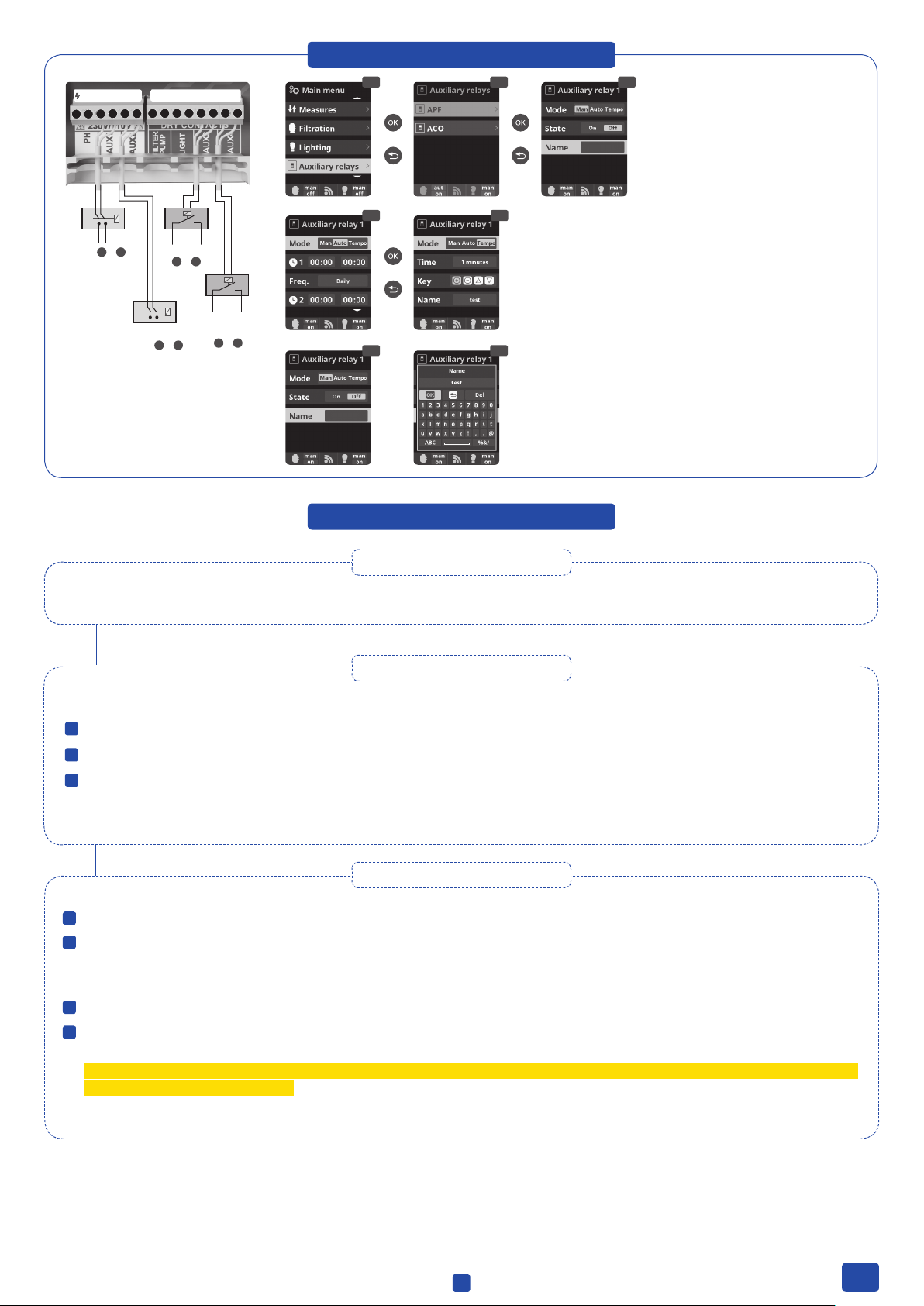

•The maximum dosing time (standard 999 min.) is accomplished and the pH-

Minus dosing pump stops in order to avoid the acidication of the water.

•To delete the message and to restart the metering press ESC ( ). Do the

following verications in order to preclude errors on the device: Verify if the pH

probe reading is correct (if not, calibrate the probe or substitute it with a new

one); Verify if the acid/base reservoir is full and if the dosing pump is working

correctly; Verify the variable speed of the dosing pump.

Alarm AL3 and pH dosing pump stopped

Dosing pump is not working properly

21. IMPORTANT NOTES

•Check fuse on the right side of the dosing pump

• Check (and change) the dosing speed

• Check electrical connections

• Check tubes and ttings for leaks

• Check if injection valve is blocked

• Check if suction lance/suction weight is blocked

• Check if error message «TANK» appears. If yes replace bottle, if not check the

polarity of the suction lance or replace the suction lance

9EN