3

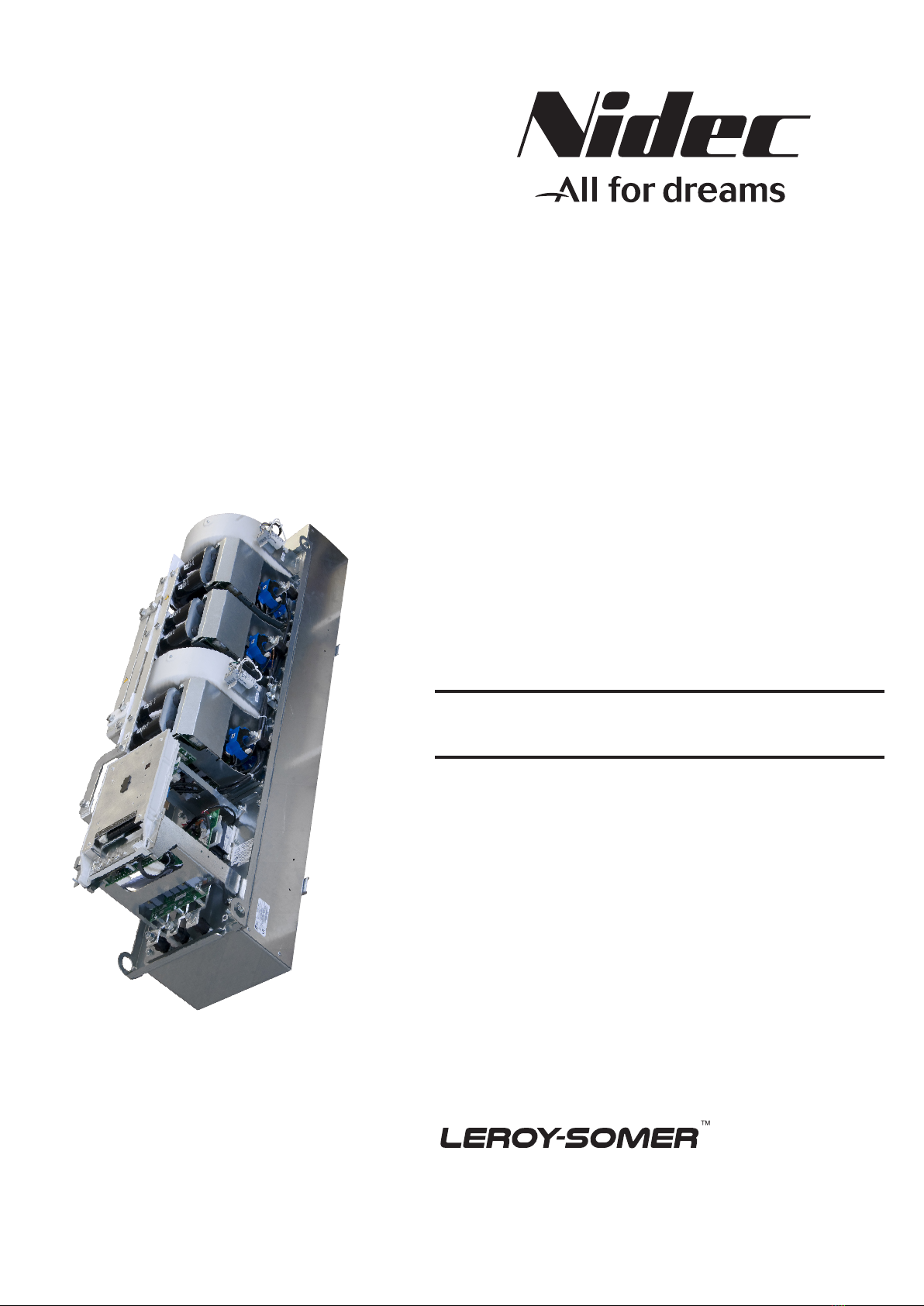

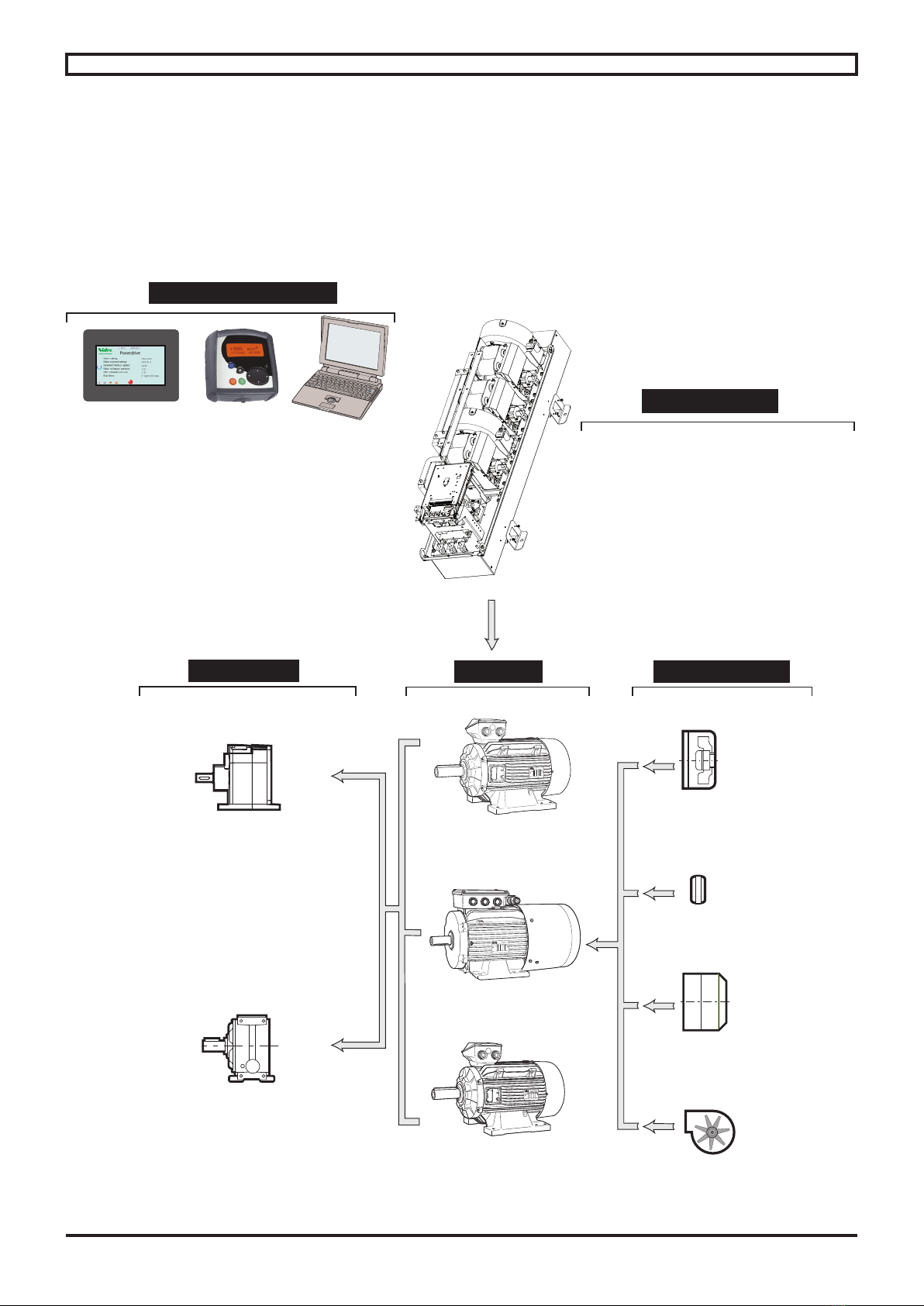

POWERDRIVE MD2CS Installation guide

4946 - 2017.12 / c

en

SAFETY AND OPERATING INSTRUCTIONS FOR VARIABLE SPEED DRIVES

(In accordance with the low voltage directive 2014/35/EU)

Throughout the manual, this symbol warns of consequences which can arise from inappropriate use of the drive, since

electrical risks can lead to material or physical damage as well as constituting a re hazard.

1 - General information

Depending on their degree of protection, variable speed drives

can contain unprotected live parts, which can be moving or

rotating, as well as hot surfaces, during operation.

Unjustied removal of protection devices, incorrect use, faulty

installation or inappropriate operation could represent a serious

risk to personnel and equipment.

For further information, consult the manual.

All work relating to transportation, installation, commissioning

and maintenance must be performed by experienced, qualied

personnel (see IEC 364, CENELEC HD 384 or DIN VDE 0100,

as well as national specications for installation and accident

prevention).

In these basic safety instructions, qualied personnel means

persons competent to install, mount, commission and operate the

product and possessing the relevant qualications.

2 - Use

Variable speed drives are components designed for integration in

installations or electrical machines.

When integrated in a machine, commissioning must not take

place until it has been veried that the machine conforms with

directive 2006/42/EC (Machinery Directive). It is also necessary

to comply with standard EN 60204, which stipulates in particular

that electrical actuators (which include variable speed drives)

cannot be considered as circuit-breaking devices and certainly

not as isolating switches.

Commissioning can take place only if the requirements of the

Electromagnetic Compatibility Directive (EMC 2014/30/EC) are

met.

The variable speed drives meet the requirements of the Low

Voltage Directive 2014/35/EU. The harmonized standards of the

DIN VDE 0160 series in connection with standard VDE 0660, part

500 and EN 60146/VDE 0558 are also applicable.

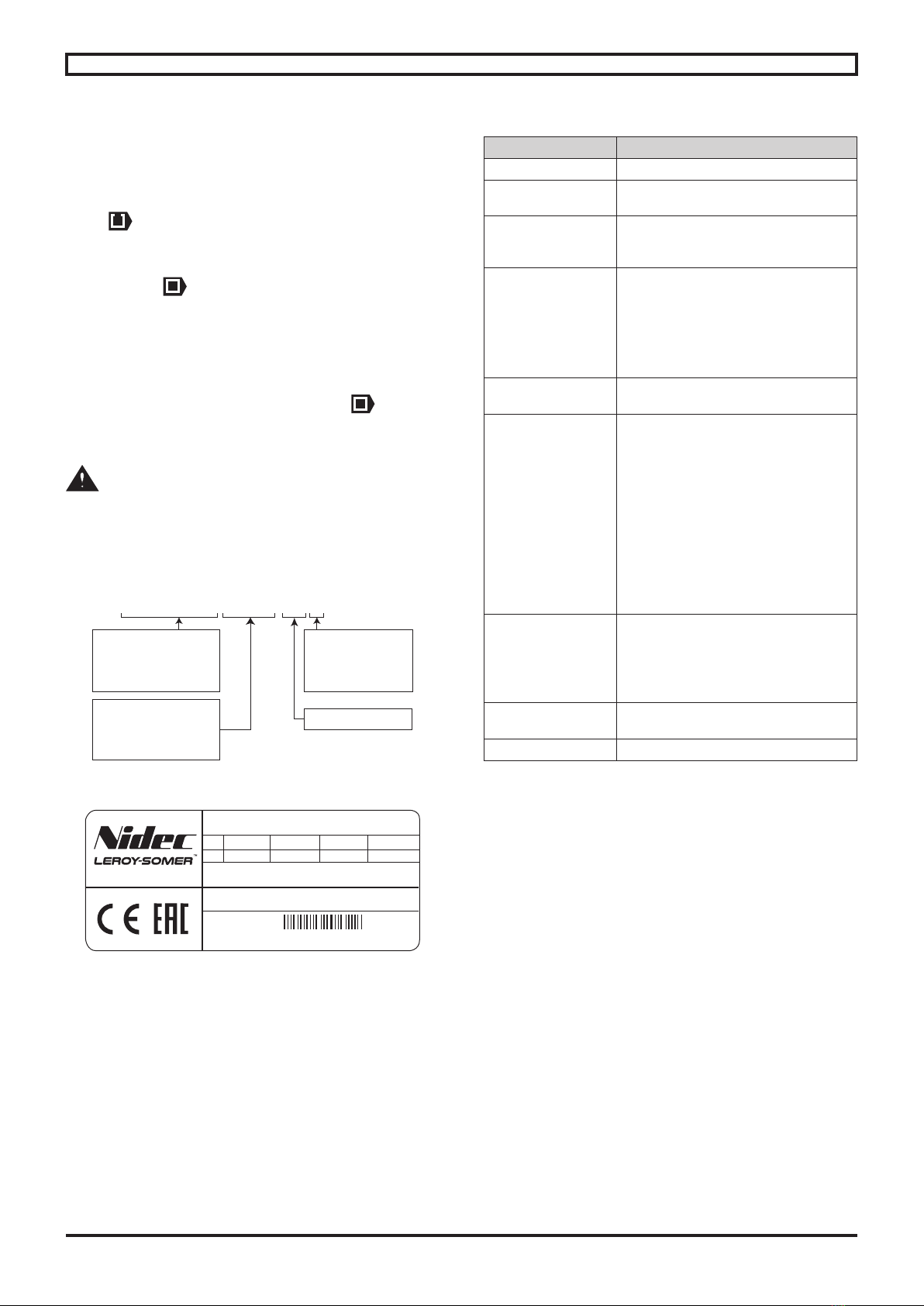

The technical characteristics and instructions concerning the

connection conditions specied on the nameplate and in the

documentation provided must be observed without fail.

3 - Transportation, storage

All instructions concerning transportation, storage and correct

handling must be observed.

The climatic conditions specied in the technical manual must be

observed.

4 - Installation

The installation and cooling of equipment must comply with the

specications in the manual supplied with the product.

Variable speed drives must be protected against any excessive

stress. In particular, there must be no damage to parts and/

or modication of the clearance between components during

transportation and handling. Avoid touching the electronic

components and contact parts.

Variable speed drives contain parts that are sensitive to

electrostatic stresses and can easily be damaged if handled

incorrectly. Electrical components must not be exposed to

mechanical damage or destruction (risks to health!).

5 - Electrical connection

When work is performed on variable speed drives that are

powered up, the national accident prevention regulations must

be respected.

The electrical installation must comply with the relevant

specications (for example conductor cross-sections, protection

via fused circuit-breaker, connection of protective conductor).

More detailed information is given in the manual.

Instructions for an installation which meets the requirements

for electromagnetic compatibility, such as screening, earthing,

presence of lters and correct laying of cables and conductors,

are given in the documentation supplied with the variable speed

drives. These instructions must be followed in all cases, even

if the variable speed drive carries the CE mark. Adherence to

the limits given in the EMC legislation is the responsibility of the

manufacturer of the installation or the machine.

6 - Operation

Installations in which variable speed drives are to be integrated

must be tted with additional protection and monitoring devices

as laid down in the current relevant safety regulations, such

as the law on technical equipment, accident prevention

regulations, etc. Modications to the variable speed drives

using control software are permitted.

Active parts of the device and the live power connections must

not be touched immediately after the variable speed drive is

powered down, as the capacitors could still be charged. In view

of this, the warnings xed to the variable speed drives must be

observed.

Permanent magnet motors generate electrical energy while

they are rotating, even when the drive is switched off. In this

case, the drive continues to be powered by the motor terminals.

If the load is capable of turning the motor, a switching device

must be provided upstream of the motor to isolate the drive

during maintenance operations.

During operation, all doors and protective covers must be kept

closed.

7 - Servicing and maintenance

Refer to the manufacturer’s documentation.

See the Maintenance section in this document.

This manual is to be given to the end user.

SAFETY AND OPERATING INSTRUCTIONS FOR VARIABLE SPEED DRIVES