AEMC instruments GROUNDFLEX 6474 User manual

6474

User Manual

ENGLISH

GROUNDFLEX®ADAPTER

WITH AEMC

®

INSTRUMENTS

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC®Instruments

certifies that this instrument has been calibrated using

standards and instruments traceable to international

standards.

We guarantee that at the time of shipping your

instrument has met its published specifications.

NIST traceable calibration is only possible when

the Model 6474 is connected to the Ground Tester

Model 6472.

To obtain NIST calibration (for a nominal charge), the

instrument would need to be returned to our facility,

along with your Ground Tester Model 6472.

The recommended calibration interval is 12 months

and begins on the date of receipt by the customer. For

recalibration, please use our calibration services. Refer

to our repair and calibration section at www.aemc.com.

Serial #: ________________________________

Catalog #: 2136.03

Model #: 6474

Please fill in the appropriate date as indicated:

Date Received: _________________________________

Date Calibration Due: _______________________

Chauvin Arnoux®, Inc.

d.b.a AEMC®Instruments

www.aemc.com

2

GroundFlex®Adapter Model 6474

Table of Contents

INTRODUCTION ..................................................................................... 3

1.1 International Electrical Symbols...........................................................4

1.2 DenitionofMeasurementCategories.................................................4

1.3 ReceivingYourShipment.....................................................................4

1.4 OrderingInformation ............................................................................5

1.4.1 AccessoriesandReplacementParts......................................5

GROUNDFLEX®ADAPTER ...................................................................... 6

2.1 ControlFeatures ..................................................................................6

2.2 GroundFlex®Sensor ............................................................................7

2.2.1 CalibrationofGroundFlex®Sensors .......................................8

2.3 MeasurementsinAUTOMode...........................................................10

2.3.1 PreparationoftheGroundFlex®Adapter...............................10

2.3.2 MakingaMeasurement(ResistanceofLegs) ......................12

2.3.3 OtherMeasurements ............................................................14

2.4 MANUALModeandSWEEPMode ...................................................14

2.5 TowerTestingMeasurement ..............................................................16

2.5.1 ChoosingthepositionsfortheH,Selectrodes:....................16

SPECIFICATIONS................................................................................. 24

3.1 Electrical.............................................................................................24

3.2 Mechanical.........................................................................................26

3.3 Environmental ....................................................................................26

3.4 Safety.................................................................................................26

MAINTENANCE ................................................................................... 27

4.1 Maintenance.....................................................................................27

4.2 Cleaning...........................................................................................27

RepairandCalibration.................................................................................28

TechnicalandSalesAssistance ..................................................................28

LimitedWarranty .........................................................................................29

WarrantyRepairs ........................................................................................29

GroundFlex®Adapter Model 6474

3

CHAPTER 1

INTRODUCTION

WARNING

Thesesafetywarningsareprovidedtoensurethesafetyofpersonnel.

Pleaseread and complywiththeseprecautions:

• Thisinstrumentisprotectedfromaccidentalvoltagesofnotmorethan

50VwithrespecttoearthinmeasurementCATIV.Theguaranteedlevel

ofprotectionofthisequipmentmaybecompromisedifusedinamanner

notspeciedbythemanufacturer.

• Safetyistheresponsibilityoftheoperator.

• Allmetalobjectsorwiresconnectedtotheelectricalsystemshouldbe

assumedtobelethaluntiltested.Groundingsystemsarenoexception.

• Never exceed the maximum rated voltage and current, and the

measurementcategory.

• Never exceed the protection limits, and always comply with the

conditionsandplaceofuse,indicatedinthespecications.

• Donotusetheinstrumentoritsaccessoriesiftheyappeardamaged.

• Useaccessories that haveovervoltagecategory and service voltages

greaterthanorequaltothoseoftheinstrument(CATIV50V).Useonly

accessoriesthatcomplywithsafetystandards(IEC61010-2-031&32).

• Weartheappropriateprotectivegear(insulatingbootsandgloves).

• CheckthatnoterminalisconnectedandtheswitchissettoOFFbefore

openingthedevice.

• Useonlythechargingunitsuppliedwiththeinstrumenttorechargethe

battery.

• Troubleshootingandmetrologicalvericationproceduresmustonlybe

performedbyqualied,approvedpersonnel,orthefactory.

• NOTE: Thepotentialsonthevariousrodsusedforanearthmeasurement

maybedierentifanearbyelectricalinstallationisdefectiveorcertain

weather conditions prevail (thunderstorms). It is up to the operator

to decide whether to continue or postpone measurements in these

situations.

4

GroundFlex®Adapter Model 6474

1.1 International Electrical Symbols

Signifies that the instrument is protected by double or reinforced insulation.

This symbol on the instrument indicates a WARNING that the operator must

refer to the user manual for instructions before operating the instrument. In

this manual, the symbol preceding instructions indicates that if the instructions

are not followed, bodily injury, installation/sample and/or product damage may

result.

Risk of electric shock. The voltage at the parts marked with this symbol may be

dangerous.

Ground/Earth symbol

In conformity with WEEE 2002/96/EC

1.2 Definition of Measurement Categories

CAT II: Formeasurementsperformedoncircuitsdirectlyconnectedtotheelectrical

distributionsystem.Examplesaremeasurementsonhouseholdappliancesor

portabletools.

CAT III:

Formeasurementsperformedinthebuildinginstallationatthedistributionlevel

suchasonhardwiredequipmentinxedinstallationandcircuitbreakers.

CAT IV: Formeasurementsperformedattheprimaryelectricalsupply(<1000V)such

asonprimaryovercurrentprotectiondevices,ripplecontrolunits,ormeters.

1.3 Receiving Your Shipment

Uponreceivingyourshipment,makesurethatthecontentsareconsistentwiththe

packinglist.Notifyyourdistributorofanymissingitems.Iftheequipmentappears

tobedamaged,leaclaimimmediatelywiththecarrierandnotifyyourdistributor

atonce,givingadetaileddescriptionofanydamage.Savethedamagedpacking

containertosubstantiateyourclaim.

GroundFlex®Adapter Model 6474

5

1.4 Ordering Information

NOTE: The GroundFlex®Adapter Model 6474 only operates in combination

with the Ground Tester Model 6472 Kit - 500ft.

GroundFlex®Field Kit (Model 6472 and 6474) .............................Cat. #2136.03

Includes: (Ground Tester Model 6472 Kit-500 ft (Cat #2135.54)); Model 6472, one carrying bag,

two 500 ft. color-coded leads on spools (red/blue), two 100 ft. color-coded leads (hand tied,

green/black), one 30 ft. lead (green), two 5 ft. color-coded leads (red/blue), 100/240V power

adapter with US power cord, optical USB cable, four T-shaped auxiliary ground electrodes,

set of ve spaded lugs, one 100 ft. tape measure, rechargeable NiMH battery pack, USB stick

with DataView software, ground tester workbook and user manual. GroundFlex® Adapter

Model 6474, four GroundFlex® sensors (5m), twelve color-coded rings, connection lead, two

extension leads on H reel (black/green) with color-coded alligator clips, one extra green and

black alligator clips, two BNC extension leads, calibration loop, three C-clamps, set of 2-reel

caddy’s, one inverter 12VDC to 120VAC watt (vehicle use), carrying case with wheels and

handle for meters and user manual.

1.4.1 Accessories and Replacement Parts

Bag#6-CarryingBagforGroundKits............................................. Cat. #2119.82

TapeMeasure-AEMC®(100ft) .......................................................Cat. #2130.60

Setoftwo,14.5"T-shapedAuxiliaryGroundElectrodes..................Cat. #2135.39

OpticalUSBCable............................................................................Cat. #2135.41

Replacement-ConnectionLeadforModel6472/6474.................... Cat. #2135.75

Replacement-OneBNC(15m/50ft)ExtensionLead...................... Cat. #2135.76

Replacement-Setof12,GroundFlex®Rings

(red,yellow,brown,orange) .............................................................Cat. #2135.77

Replacement-GreenExtensionLead .............................................Cat. #2135.78

Replacement-BlackExtensionLead...............................................Cat. #2135.79

Replacement-Setof3,C-clamps....................................................Cat. #2135.80

Replacement-CalibrationLoop....................................................... Cat. #2135.82

Replacement-CarryingCase ..........................................................Cat. #2135.83

Replacement-OneGroundFlex®(5m /16ft)Sensor.........................Cat. #2135.92

Replacement-SafetyAlligatorClip(black) ......................................Cat. #5000.99

Replacement-SafetyAlligatorClip(green) .....................................Cat. #5100.06

GroundFlex®Sensor10M.................................................................Cat. #2135.87

Order Accessories and Replacement Parts Directly Online

Check our Storefront at www.aemc.com/store for availability

6

GroundFlex®Adapter Model 6474

CHAPTER 2

GROUNDFLEX®ADAPTER

2.1 Control Features

50V CAT IV

1-2-3-4

1-2-3

1-2

1

2

3

4

For Use with the

Ground Tester Model 6472

GroundFlex

®

Sensor

SENSOR TURNS

SENSITIVITY

To Model 6472

Overload

INPUT

1

2

3

4

GroundFlex®Adapter

MODEL 6474

2

4

1

6

5

3

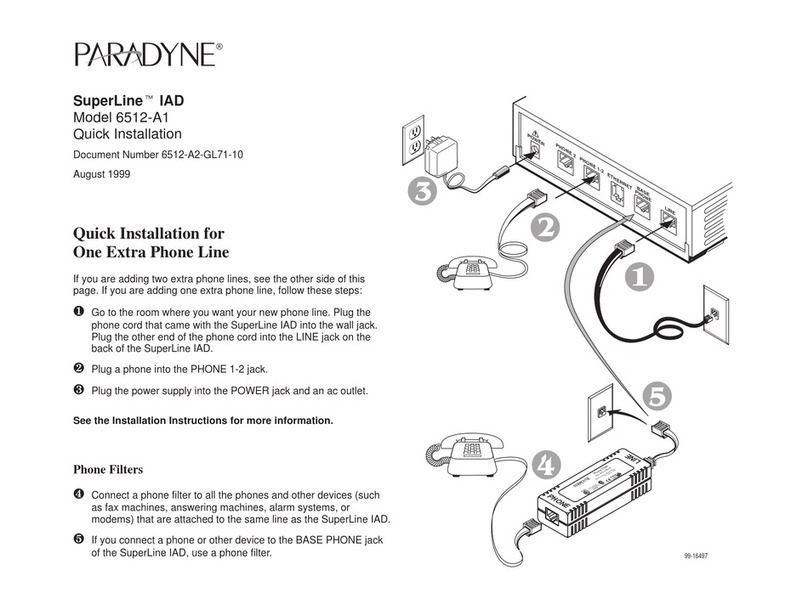

1. Inputs1through4forGroundFlex®sensors

2. ConnectorforconnectionleadtotheGroundTesterModel6472

3. OVERLOADindicator

4. SENSORTURNSselector:1,2,3or4

5. SENSITIVITYselector:x10,x1orx1/10

6. INPUTSELECTION:1,2,3,4,1-2,1-3or1-4

GroundFlex®Adapter Model 6474

7

2.2 GroundFlex®Sensor

TheGroundFlex®sensorsareplacedaroundaconductor(towerlegorpole)and

closed using a screw connector, which is part of the sensor. This closed loop

is then used to make a contact-free measurement of the current owing in the

conductor(leg)itiswrappedaround.

Thesesensorsarecurrentmeasurementclampsbutareabletoencloseobjects

thataremuchlarger.

GroundFlex®sensorsareavailableinlengthsofuptoapprox24ft(8m)andcan

beplacedaroundobjects(suchastowerlegs)uptoinapprox8ftdiameter(2.7m).

50V CAT IV

1-2-3-4

1-2-3

1-2

GroundFlex

®

Sensor

To Model 6472

Overload

INPUT

1

2

3

4

8

GroundFlex®Adapter Model 6474

2.2.1 Calibration of GroundFlex®Sensors

Calibrationisnecessaryforanewsensor,onethatisnolongeridentiedwhena

sensorhasbeenreplaced,ormorethan2lengthsofextensioncableisused.The

calibrationcoecientsarethenstoredintheModel6474.

NOTE: Do not move or touch the GroundFlex®sensor or the calibration loop

during the calibration. This could cause errors.

Startbyidentifyingeachsensorusingtheidenticationringsthataresuppliedwith

theModel6474:(1)Brown (2)Red (3)Orange (4)Yellow

• ConnectthecalibrationloopbetweenterminalsHandEoftheModel6472.

• ConnecttheModel6472and6474togetherusingtheconnectioncable.

• ConnecttheGroundFlex®sensorwiththeBrownringtoInput1oftheModel

6474,theonewiththeRedringtoInput2,theonewiththeOrangeringtoInput

3,andtheonewiththeYellowringtoInput4.

• CoiltheGroundFlex®sensorfourtimesaroundinthecalibrationloopandclose

itusingitsscrewconnector.Placetheconnectorasfaraspossiblefromthe

calibration device.

6472 6474

GroundFlex®Adapter Model 6474

9

1. Settheswitchofthe6472toSET-UP.

2. SettheSENSOR TURNSswitchto4.

3. SettheSENSITIVITYswitchtox1.

4. SettheINPUT SELECTIONswitchto1.

1-2-3-4

1-2-3

1-2

1

2

3

4

SENSOR TURNS

SENSITIVITY INPUT

5. PresstheHz/OPTIONSbutton5times.

ThedevicestartsbycomparingthecurrentIIntinjectedbythedeviceintothe

calibrationlooptothecurrentIAmeasuredbytheGroundFlex®sensor.Ifthey

aredierent,the"CAL"symbolblinkstorecommendacalibration.

x 5

4

H

E

S

x

11

AUTO

mA

m A

NOTE: To avoid measurement errors, do not touch the GroundFlex®sensor or

the calibration loop during the calibration.

10

GroundFlex®Adapter Model 6474

6. Tostartthecalibration,press2nd + START.

7. ThedevicecalculatesandstoresacalibrationcoecientfortheGroundFlex®

sensorconnectedtochannel1.

4

H

E

S

x

11

AUTO

mA

m A

Thisoperationmustberepeatedforchannels2,3and4;theINPUT SELECTION

switchmustbesettothecorrespondingpositioneachtime.

Thecalibrationvaluesarenowstoredintomemory.

After calibration, the GroundFlex® sensors must always be connected to their

respectivechannels.

NOTE: Always connect the same sensor to the same input.

2.3 Measurements in AUTO Mode

2.3.1 Preparation of the GroundFlex®Adapter

TheGroundFlex®AdapterModel6474isdesignedtobeusedonlywiththeModel

6472device.Thetwoinstrumentsmustbeconnectedusingthespecialconnection

cablesupplied.TheModel6474hasnoON/OFFbutton,andispoweredonlyby

theModel6472,viathisconnectioncable.

TheModel6474is intendedprimarilytomeasurethecurrentthatowsthrough

ahigh-voltagetowertotheground.Youcanwrapupto4legsofthetowerseach

withaGroundFlex®sensorandmeasurethecurrentowingtoearththrougheach

ofthelegsorthroughseverallegs.

1. SettherotaryfunctionswitchtoGroundFlex®ontheModel6472.

WhenyouconnecttheGroundFlex®AdapterModel6474tothe6472,aself-

testwillbegin.Duringthistest,theOVERLOADchecklightonthe6474islit.

2. Connecttherequirednumberofsensorstochannels1,2,3,and/or4.

GroundFlex®Adapter Model 6474

11

NOTE: • The sensors have arrows to indicate a direction.

• All sensors should face the same direction.

(clockwise or counter-clockwise around the tower legs)

• All sensors should have the same number of wraps.

• Sensors should encircle both leg AND ground system.

6474

To the Model 6472

3. OntheModel6474,settheINPUT selectionswitchaccordingly.Youcanmea-

surethe currentowingthrough one GroundFlex®sensor (1, 2,3,or 4),or

throughseveralsensors(1,2or1,2,3),orthroughallofthesensors(1,2,3,

4).

4. Select how many times the sensor is wrapped around the conductor to be

measured(from1to4turns)usingtheSENSOR TURNSselectionswitch.

NOTE: To increase measurement sensitivity, we recommend when possible,

wrapping a maximum number of turns (up to 4) around the structure.

5. SettheSENSITIVITYswitchtothedesiredsensitivity:x1/10,x1,orx10.The

choiceofsensitivitydependsontheexpectedcurrentvalue.Asaprecaution,

alwaysstartwiththelowestsensitivity,x1/10,andincreaseitasneeded.

12

GroundFlex®Adapter Model 6474

2.3.2 Making a Measurement (Resistance of Legs)

1. PlaceauxiliaryelectrodesH (Z) and S (Y)onoppositesidesofthetower,as

farawayaspossible(100-150ft)and,ifpossible,perpendiculartothehigh-

voltageline(depthisnotimportant).Thiswilleliminateinterferencewiththe

measurementby stray voltages or currents induced underthehigh-voltage

line.

NOTE: The H (Z) and S (Y) electrodes can be placed in the same direction

if necessary. In this case, the S (Y) electrode should be placed at 62% the

distance of H (Z).

2. In order to avoid electromagnetic interference, it is best to unwind the full

lengthofeachcablefromthereel,tokeepthecablesasfarapartaspossible

ontheground,takingcarenottoformloops,andtoavoidplacingthecables

nearorparalleltometallicconductors(cables,rails,fences,etc.).Eectsof

interferencearemeasuredinmilli-ohms.

3. Connectthese auxiliary electrodes to the terminals H (Z) and S (Y) onthe

Model6472'sfrontpanel.

4. Important: TheterminalsES (Xv) and E (X)mustbeconnectedtoaconduct-

ingmetallicpartofthetowerlocatedabovetheGroundFlex®sensors.This

ensuresmeasurementofthecurrentowingdownwardandtowardstheearth

(otherwise,youwouldmeasurethecurrentowingupward,fromtheearthto

thetopofthetower).

Thiswilltelltheconditionoftheoverheadgroundconductor.

5. Connect the required number of GroundFlex® sensors to channels 1, 2, 3,

and/or4(thechannelsforwhichtheyarecalibrated)andplacetheGround-

Flex®sensorsaroundthelegsofthetower.

NOTE: The direction of coiling of the sensors around tower legs have no

effect on the measurement, but all of the GroundFlex®sensors must be

coiled in the same direction and have the same orientation (check arrow

direction on the sensor) and they must all have the same number of turns.

Sensors should encircle both leg AND ground system.

GroundFlex®Adapter Model 6474

13

E

S

H

RS

RH

ES

1

2

3

4

6474

6472

Overhead earth wire

High-voltage

lines

4 GroundFlex®sensors

connected with the

same orientation

WARNING: If the GroundFlex®Adapter Model 6474 is connected to the earth

tester, the earth potential connected to the terminals E (X) and ES (Xv) will

also be present at the BNC connectors of the GroundFlex®sensors and at the

connecting cable between the adapter and tester. Whenever any doubt exists

about this earth potential, the user should proceed to a voltage measurement

using the S (Y) and ES (Xv) terminals of the tester.

1. Setthe3switches(Inputs,TurnsandSensitivity)oftheGroundFlex®Adapter

accordingtotheconnectionmade.

2. StartthemeasurementbypressingtheSTART/STOPbutton.

1

AUTO

k

Ω

mA

V

H

S

ES

E

S

x

12

Todisplaythemeasurementparameters,pressDISPLAY several times.

14

GroundFlex®Adapter Model 6474

Thedevicedisplaysthefollowingparameters:

RSEL,US-ESanditsfrequency,ISEL,R-Act(RPASS),U-Act(US-ESanditsfrequency,

UH-Eanditsfrequency),I-Act(ISELanditsfrequency).

TomeasuretheresistancesofelectrodesH (Z) and S (Y),oriftheresistanceof

theelectrodesistoohigh,startthemeasurementbyalongpress(approx2sec)of

theSTART/STOPbutton(youwillheara2ndbeep).

RH,RS,UH-E,IH-Ewillbedisplayed.

2.3.3 Other Measurements

AsexplainedinStep4onthepreviouspage,terminalsES (Xv) and E (X)mustbe

connectedtoametallicpartofthetowerabovetheGroundFlex®sensor in order to

measurethecurrentowingISELdownwardthroughthesensortowardstheearth

tomeasuregroundresistanceoftheleg.

IfconnectionsES (Xv) and E (X)areplacedbelowtheGroundFlex®sensor,the

lattermeasuresthecurrentowingtowardsthetopofthetowerviatheoverhead

groundconductoratitstop,andyoucaninthiswayevaluatethequality of this

overhead ground conductor.

You can even make this measurement without moving the contacts of ES (Xv)

and E (X) on the tower by simply passing the 2 connecting cables through the

GroundFlex®sensor.ThecurrentinconnectingcableE(X) andthecurrentthrough

thelegofthetowerthencanceleachotherout.

Youcanalsomeasureany leakage currents(I-Act)owingthrougheachlegof

thetowerinnormaloperationofthehigh-voltageline.Ifyounddierentleakage

currentsineachleg,buttheycanceloutwhenaddedtogether,youcanconclude

thatthesecurrents,inducedbytherotatingeldofthehigh-voltagelines,indicate

an earthing faultofthetowervia the overhead ground wire at the tip of the

mast.

2.4 MANUAL Mode and SWEEP Mode

Use the Hz/OPTIONS button and ► button to change to MANUAL mode. The

followingparameterscanbemodied:

• 128Hzblinks Changethetestfrequency

• Testvoltageblinks Switchbetween10,16,32and60V

Youcanalsoperformafrequencysweepandasmoothing.

GroundFlex®Adapter Model 6474

15

Inthesweepmode,themeasurementscanbemadeatfrequenciesupto5kHz.

Onasingletower,frequenciesintheorderof5kHzdonotalwaysentailinductive

eects, but the "current loops" formed by the adjacent towers and the return

channelthroughthegroundmayresultininductancesthatcanbedetectedonly

athighfrequencies.

Anequivalentdiagramofthecomponentsformingthiscircuitisasfollows:

Point of injection

of the current

Overhead

earth wire

LLL

Rpylon

Next pylon

to the left

Pylon

measured

Next pylon

to the right

A measurement in sweep mode (SWEEP) of an installation like this having 10

towersgivesthefollowingresultsassuminganearthresistanceRpylon of10Ωfor

eachtowerandaninductanceLof550µH for the link via the overhead ground

conductoratthetipofthetowers:

Impedance of the towers

0

2

4

6

8

10

12

14

16

0100020003000 4000 5000

F (Hz)

Z (ohm)

MeasurementofatowerearthimpedancewithGroundFlex®

sensors

Conventional4polemeasurement

Measurementintothetopofatower(iterativenetworkimpedance)

16

GroundFlex®Adapter Model 6474

2.5 Tower Testing Measurement

1. ConnectthegreenCurrent(E)andblackVoltage(ES)testleadstothe

groundingsystemtobetestedusingseparatecables.Connectionpoints

shouldbesidebysideandabovetheGroundFlex®(Rogowski)coilwhen

testingtowerlegresistanceand/orimpedance.

Figure 1

2. WraptheGroundFlex®coilsaroundthetower'sleg(s).Byincreasingthe

numberofturnsaroundthetower'sleg(s), theresultingmeasurementswill

bemorerobust. Allcoilsmusthavethesamenumberofturnsaroundeach

towerleg.

3. Installallcoilsinthesamerotationaldirection,eitherclockwiseor

counterclockwise.ThecoaxcablesontheGroundFlex®sensorshavearrows

toindicatetherotationaldirectionthatmustbeconsistentbetweentower

legs.Ontowerswith3or4legs,thesensorsmustbeinsequencefromone

legtothenext.

Figure 2

2.5.1 Choosing the positions for the H, S electrodes:

1. Ifpossible,positiontheHandSelectrodes90°totheHighVoltage(HV)line,

andplaceonetotheleftandtheothertotherightwithrespecttotheHV

transmissionline.Ifthisisnotpossible,stayatleast30°oparalleltotheHV

line.Theminimumdistanceshouldbe150–300ft(50-100m).Neverplace

anelectrodewithintheminimumdistancefromtheHVlineand/orparallelto

theHVline.

2. ConnecttheHelectrodeusingthered(H)leadandtheSelectrodeusingthe

blue(S)lead(seeFigure2).

GroundFlex®Adapter Model 6474

17

NOTE:TheresistancefortheHandSelectrodestoearthshouldeachbebelow

1kΩtoensuregoodtestresults.

Figure 3

3. Forthemostaccuratemeasurements,rollthecablecompletelyoutto

eliminateanyinductanceproblemsinlocationswithhighoverheadenergy

fromtheHVline.Normallyerrorsareinthemilliohmregionwhenthecables

arenotfullyremovedfromthespool.

4. Conrmthattheumbilicalcableconnectionbetweenthe6472and6474is

secure.Checkthepositionoftherotaryswitches(Input,SensorTurnsand

Sensitivity)onthe6474tobesuretheymatchthetestrequirements(see

Figure4).

5. Makesurethenumberofturnsbetweentowerlegsarethesame.The

numberofturnsmustcorrespondtothenumberofturnsusedontheinstalled

GroundFlex®coilsoneachtowerleg.

Figure 4

6. Useinputswitchposition"1-2-3-4"formeasurementofthetotalpylonearth

currentonfourlegtowers.Usethecorrespondingswitchpositionfor2(1-2)

and3(1-2-3)legtowers.

7. Startthetestwithx10amplication.

8. Turntherotaryswitchonthemodel6472totheGroundFlex®position.The

6474amplierwillturnonafterthe6472ispoweredonandthecalibration

oftheconnectedGroundFlex®sensorswillbeveried.TheOverloadLED

willcomeonforafewsecondsduringpowerup.IfthisLEDisashing

continuouslyandthe6472isbeepingcontinually,thenthecurrentinthe

GroundFlex®sensor(s)aretoohighfortheselectedamplication.Reduceto

X1andthentoX1/10ifnecessary.Ifitisstillpresentinthe1/10position,then

reducethenumberofturnsoftheGroundFlex®sensors.

18

GroundFlex®Adapter Model 6474

First check (see Figures 5, 6, 7, and 8):

1. PresstheDISPLAYbuttonuntilU-Act.andUS-ESorUH-Eisshown.U-Act.

referstoliveactualvoltage.US-ESequalsmeasuredvoltagebetweenSand

ES. DisturbancevoltagemeasurementsontheSProbeandtheHAuxiliary

electrodewillruncontinuouslyaslongasatesthasnotbeeninitiatedwith

theSTARTbutton.

2. PresstheDISPLAYkeyagainuntilU-Act.andUH-Eisshown.UH-Eequals

themeasuredvoltagebetweenHandE.ThefrequencyofUS-ESorUH-E

appearswhenthecorrespondingvoltageishigherthan0.1V.Themeasured

voltageiscausedbythecurrentowingthroughthetowerintotheEarth.

3. CheckifthevaluesforUH-EandUS-ESareequal.WhenUH-EequalsUS-

ES,theelectrodesareplacedfarenoughfromthepotentialinuenceofthe

towerlegs.

4. Ifoneofthevaluesissmallerthantheothervalue,youshouldrepositionthe

electrodethatshowsthesmallervoltagefurtherawayfromtheHV-lineand

checkUS-ESandUH-Eagain.

5. PresstheSTART-buttonwhenbothmeasurementsareequaltoeachother

forareliableactivemeasurement.WhenbothUS-ESandUH-Earecloseto

zero,thentheHV-lineisnotinserviceortheoverheadgroundconductoris

completelycorrodedordisconnected.Inthiscase,thetotalpyloncurrentwill

bealsonearlyzero.

6. PresstheDISPLAYbuttonuntilISELappears.Thisisthetotalpylonearth

currentandismeasuredbythe4GroundFlex®sensors(channels1-2-3-4

selectedfora4legtower).

Figure 7 (model 6472)

Figure 6

Figure 5

GroundFlex®Adapter Model 6474

19

7. Next,presstheDISPLAYbuttonuntilRPASSappears.Aleakagecurrent

I-SEL,wheninducedinthepylon,producesavoltagedropUS-ES(potential

dierencetoEarth)ontheearth-resistanceofthepylon.OncetheI-SEL

andUS-ESvaluesareknown,the6472cancalculateRPASS(passive

earthresistance).Ithastheadvantageofbeingmeasuredatthenominal

frequencyofthenetworkbutisalsoinuencedbytheloaductuationsinthe

networkandbythepotentialinuenceoftheHV-line.Whenthetowerearth

resistanceisactivelymeasuredandisnearlyequaltoRPASS,theresultwill

bereliable;otherwise,thepotentialrelationshipduringtheactiveandpassive

measurementwillbedierent.

Figure 8 (model 6472)

Second check (See Figures 9):

1. CurrentsinthetowerlegsaremeasuredcontinuouslyaslongastheSTART-

buttonhasnotbeenpressed.Switchthemodel6474toINPUT1.SelectISEL

on6472withDISPLAYbutton.

Figure 9

2. Checkthecurrentineachtowerlegbyswitchingthrougheachchannelin

sequencewhilenotingthemeasurementsofeach.Youcanndcorroded

and/ordisconnectedearthconnectionsasindicatedbyreadingsthatshowno

currentow.

3. Checkthesumofalllegcurrentchannels.Ifthetotalisapproximatelyequal

tothesumoftheallindividuallegcurrents,thenthestaticwire(overhead

groundconductor)isbondedtothetowerproperly.Ifnot,thisconnectionis

probablycorrodedandonlyasmallcurrentwillbeowinginthetowerlegs,

whichwillbeinducedinthetowergrounding.Thesumwillbeverylow,but,

despitethat,singlecurrentsmaybehigherbecausetheycanowindierent

directions.ThemeasurementofRPASSforindividuallegshasnovalue.

Evenwhenindividuallegsarenotconnectedtogether.Belowgroundlevel,

theywillstillinuenceeachother.

Other manuals for GROUNDFLEX 6474

2

Table of contents

Other AEMC instruments Adapter manuals

Popular Adapter manuals by other brands

Dolphin

Dolphin MXH94 Series user guide

Devolo

Devolo Magic 1 WiFi 2-1 manual

Digi

Digi Connectware Series Hardware Installation and Cable Guide

Allied Telesis

Allied Telesis AT-2712FX Installation and user guide

NETGEAR

NETGEAR HDX111 - Powerline HD Plus Ethernet Adapter datasheet

Sling Media

Sling Media Slinglink quick start guide