6IREPPY - 1404 - 4238051_01

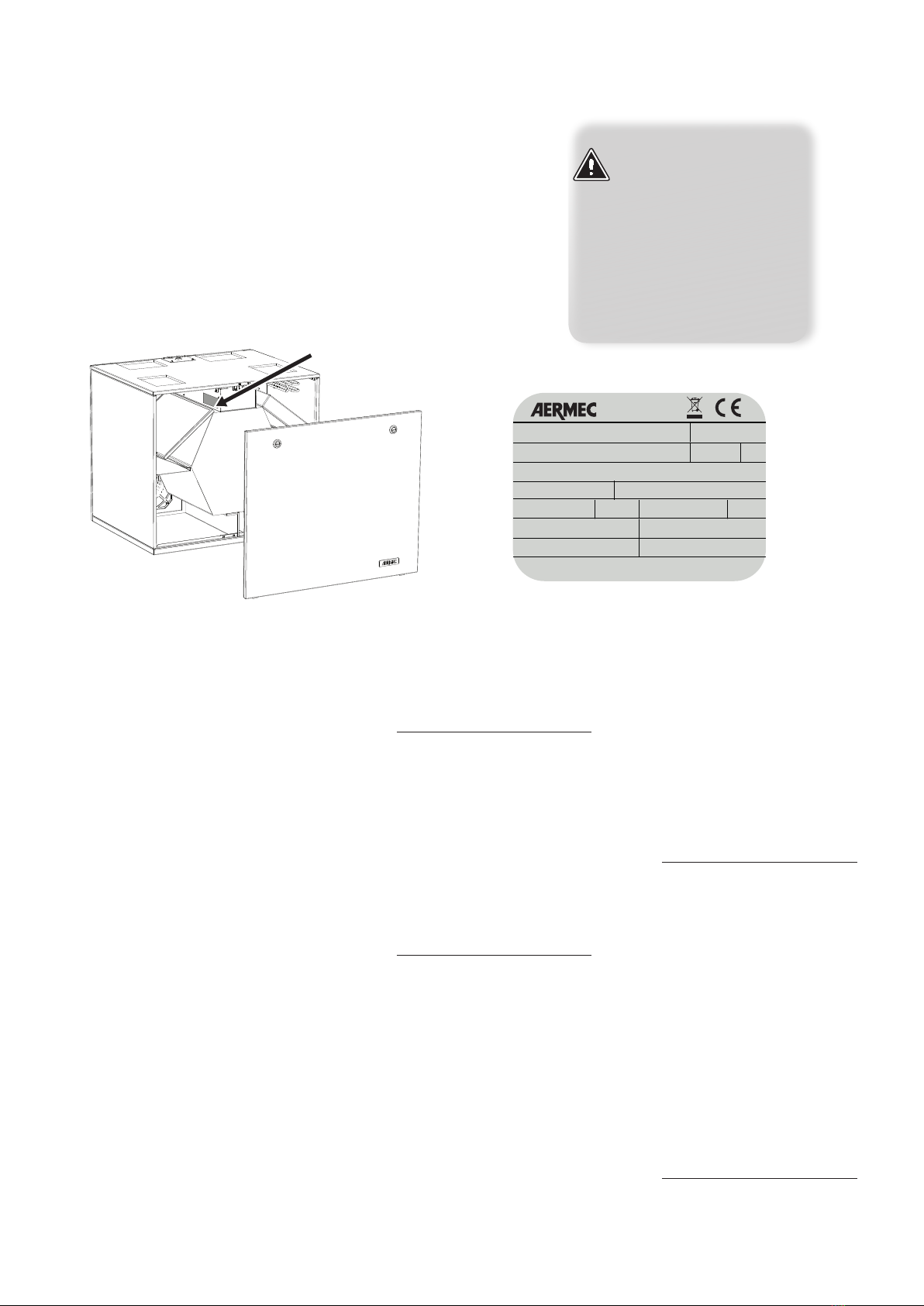

The AERMEC RePuro units are manu-

factured in accordance with recog-

nised technical standards and safety

regulations. They are designed for the

renewal and treatment of ambient

air, and they must be used for the

purpose for which they are intended

and their performance character-

istics. All contractual and extra-

contractual liabilities causing damage

to persons, animals or objects or

through errors of installation, control

or maintenance or from improper use

are excluded by the Company. Any

uses not expressly indicated in this

manual are not permitted.

1.1. CONSERVATION OF DOCU

MENTATION

Consign the instructions with all the

complementary documentation to

the user of the accessory who will as-

sume responsibility for the conserva-

tion of the instructions so that these

are always available in case of need.

Carefully read this document. The

execution of all the works must be

carried out by qualified personnel, in

accordance with the national regula-

tions.

It must be installed in such a way

to make maintenance and/or repair

functions possible.

Do not modify or tamper with the

accessory as this may cause danger

for which the manufacturer will not

accept any responsibility for damages

caused. The warranty is voided if the

above instructions are not followed.

1.2. SAFETY WARNING AND

INSTALLATION STANDARDS

−The unit must be installed by a

competent and qualified technician,

and in accordance with the legislation

applicable in the country of installa-

tion.

AERMEC assumes no responsibil-

ity for damage caused by failure to

observe these instructions.

−Instructions essential for the proper

installation of the equipment are

shown here. The final touches to all

the operations are however left to

the experience of the installation en-

gineer in accordance with the specific

needs.

−Before commencing any works

it is necessary to CAREFULLY READ

THE INSTRUCTIONS AND MINIMISE

ANY RISKS BY TAKING APPROPRIATE

SAFETY PRECAUTIONS.

−All relevant personnel must be

made aware of the procedures and

possible risks that may arise at the

time of installation of the unit.

−The unit must be installed in such a

way as to make easy ordinary main-

tenance (filter cleaning) and special

maintenance as well as access to the

heat exchanger.

−WARNING! : It is absolutely

forbidden the operate the unit

without the 4 nozzles connected to

the ducting system.

−DANGER : The fan is located

immediately beneath the nozzles. It is

absolutely forbidden to insert hands

or objects. Power the unit only after

the 4 nozzles are connected to the

ducting system.

−ATTENTION: In order to

protect the unit against short circuits,

mount a magnet circuit breaker

omnipolar switch on the power

supply line. In order to avoid any

danger due to the accidental rearm-

ing of the thermal cut-out device, this

appliance must not be powered with

an external switching device, such as

a timer, or be connected to a circuit

that is regularly powered or discon-

nected from the service

−ATTENTION: The appliance

can be used by children over the age

of 8 and by people with reduced

physical, sensory or mental capabili-

ties or without experience or neces-

sary knowledge, as long as they are

supervised or have been instructed

on the safe use. Of the appliance and

on the understanding of the dangers

inherent to it. Children must not play

with the appliance. The cleaning and

maintenance to be carried out by the

user must not be carried out by

children without supervision.

OPERATING LIMITS of the unit:

Maximum air temperature: 50°C

Maximum differential pressure be-

tween the two fluids: 2000 Pa

Versions without pre-heating

element

Minimum outdoor air temperature:

-10°C *

Versions with pre-heating element

(R)

Minimum outdoor air temperature :

-15°C *

* With external air temperature <

0°C the microprocessor controller in-

tervenes to reduce the risk of forma-

tion of frost within the heat recovery

unit. If the outside air temperature is

less than the limits, the microproces-

sor controller stops the unit opera-

tion.

1. GENERAL WARNINGS