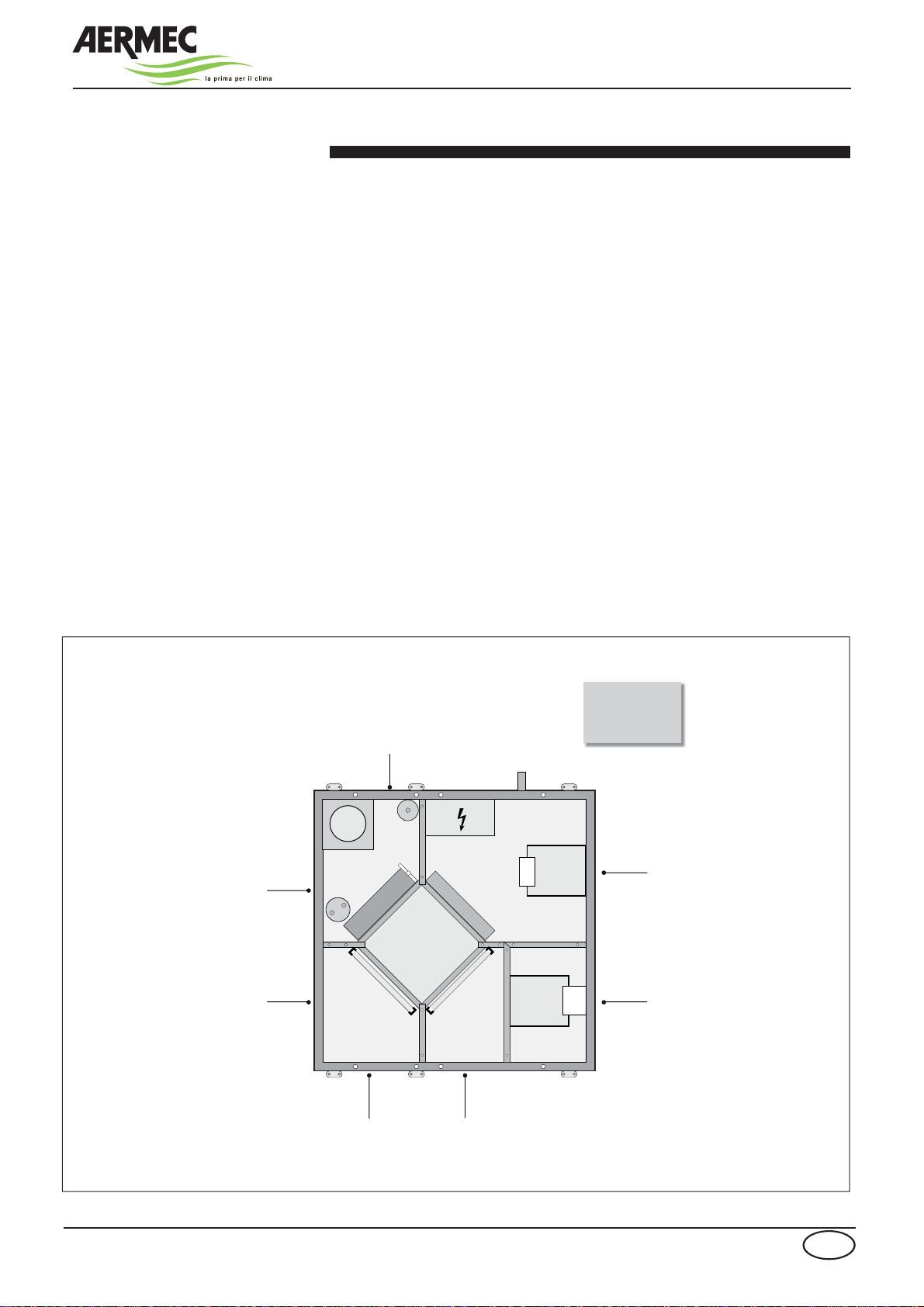

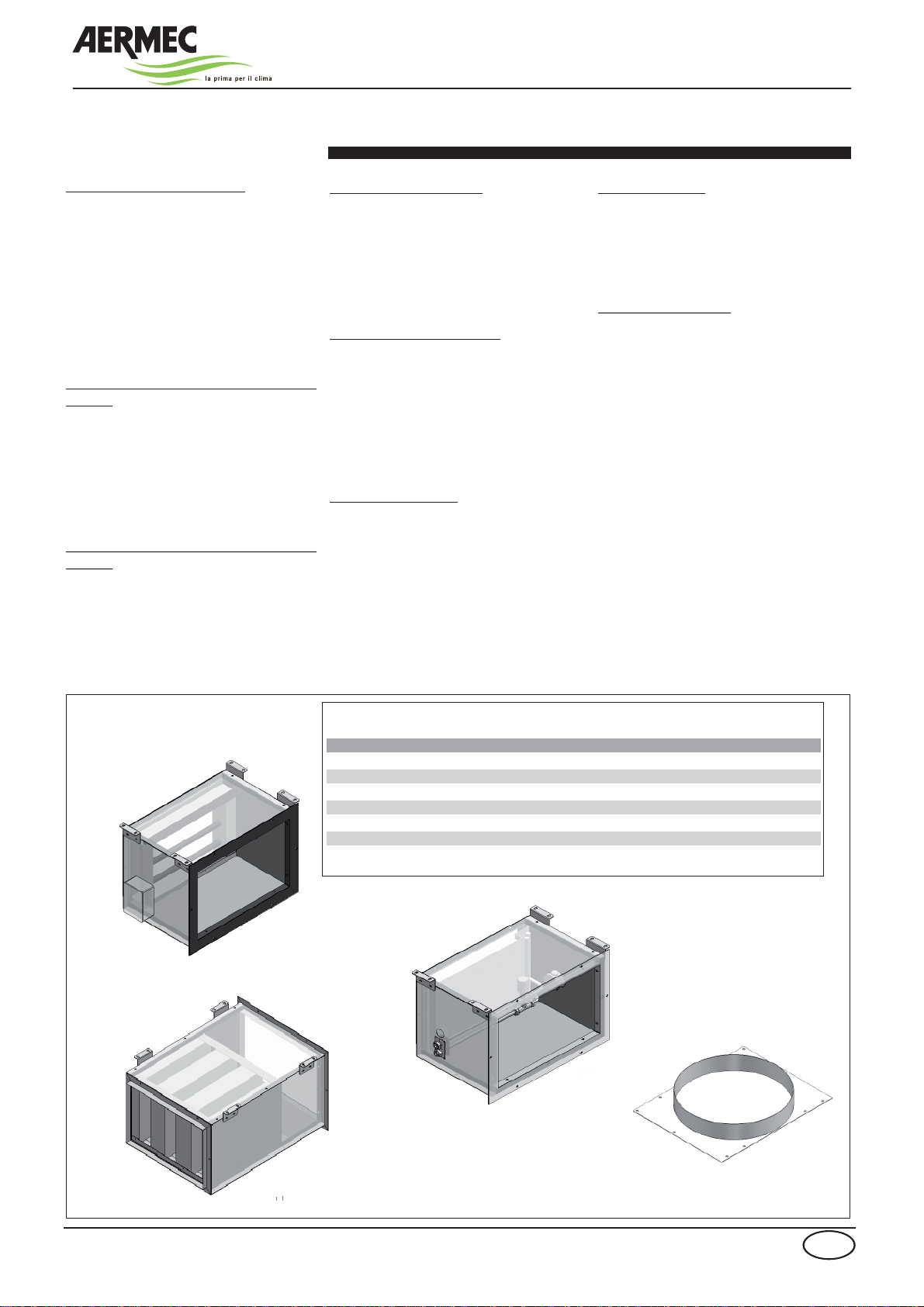

Heat recovery units with refrigeration circuit - URX_CF -

4

Selection and installation manual

GB

Remarks

This manual is an integral part of the

documentation enclosed with the unit.

It must be kept for future reference

and must accompany the machine

throughout its life.

The manual defines the purpose for which the

machine has been built and establishes its correct

installation and the limits of its use.

• This manual describes all the use, installation

and maintenance instructions of the subject

unit and the main accident prevention

standards.

• Carefully and thoroughly read all the

information referred to in this manual. Pay

particular attention to the norms accompanied

by the indication “DANGER” or “ATTENTION”

since, if not observed, may cause damage to

the unit or to people.

If any malfunctions are found out, whciha are not

included in this manual, please contact the local

After-Sales Service immediately.

• Aermec S.p.A. declines all liability for any

damage caused by the improper use of the

machine or the partial or superficial reading of

the information contained in this manual.

• Installation and maintenance must be

performed by qualified and experienced

personnel, having the requirements that

are foreseen by law 46/90 and/or the DL

380/2001 for the electrical/electronic

and air-conditioning installation, with

consequent registration at the local

CHAMBER OF COMMERCE, if this is

not so, Aermec S.p.A. declines all

responsibility regarding the safety of

the product.

THE MANUFACTURER DECLINES ALL

LIABILITY FOR DAMAGE TO THINGS OR

INJURY TO PERSONS AND ANIMALS

CAUSED BY THE FAILURE TO OBSERVE THE

INSTRUCTIONS AND STANDARDS IN THIS

MANUAL.

Although suitable risk analysis have been

performed during the design of the URX_

CF unit, PAY ATTENTION to the pictograms

on the machine which help understand the

manual better, rapidly catching the attention

of the reader concerning the risks which

can not be avoided or sufficiently limited

through the use of technical protection

means and measures.

GENERAL HAZARD SIGNAL

Carefully adhere to all the indications

next to the icon.

Failure to comply with the instructions may

generate hazardous situations with possible

damage to the health of the operator and user in

general.

DANGEROUS ELECTRICAL

VOLTAGE SIGNAL

Carefully adhere to all the indications

next to the icon.

The signal indicates components of the unit or, in

this manual, specifies actions that could generate

electrically-related risks.

GENERAL PROHIBITION SIGNAL

Carefully adhere to all the indications

next to the icon that limit actions in

order to guarantee better operator safety.

MAIN WARRANTY

CONDITIONS

• The warranty does not cover payment for

damages cause by the incorrect installation

of the unit by the installer.

• The warranty does not cover payment for

damages cause by the improper use of the

unit by the user.

• The manufacturer is not responsible for

accidents to the installer or user that are

due to the improper use and incorrect

installation of the unit.

The warranty is not valid when:

• the maintenance and repairs have been

performed by unauthorised persons or

companies;

• the unit has been previously repaired or

modified with spare parts that are not

original;

• the unit has not undergone suitable

maintenance;

• the instructions described in the present

manual have not been followed correctly;

• unauthorised modifications have been

made.

N.B.:

The Manufacturer reserves the right at

all times to make any modification for

the improvement of its product and is

not obliged to add these modification

to machines of previous manufacture,

which have already been delivered or

are being built.

The warranty conditions are any subject

to the general sales conditions at the

moment the contract is finalised.