Aeroflex GPSG-1000 User manual

Maintenance Manual

Positional Simulator

GPS/Galileo

GPSG-1000

EXPORT CONTROL WARNING: This document contains controlled

technology or technical data under the jurisdiction of the Export

Administration Regulations (EAR), 15 CFR 730-774. It cannot be

transferred to any foreign third party without the specific prior

approval of the U.S. Department of Commerce Bureau of Industry

and Security BIS). Violations of these regulations are punishable by

fine, imprisonment, or both.

PRELIMINARY

Subject to Export Control, see Cover Page for details.

GPSG-1000

GPS/Galileo Positional Simulator

PRELIMINARY

Maintenance Manual

PUBLISHED BY

Aeroflex

COPYRIGHT ©Aeroflex 2012

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise

without the prior permission of the publisher.

Original Release Nov 2012

10200 West York / Wichita, Kansas 67215 U.S.A. / (316) 522-4981 / FAX (316) 524-2623

Subject to Export Control, see Cover Page for details.

Table of Contents

Subject to Export Control, see Cover Page for details.

iii

Table of Contents

Chapter 1 - Introduction . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

GPSG-1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Interconnect Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

GPS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

SPS Standard Positioning Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Position Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

GPS Timekeeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 20

GNSS Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 21

GNSS Augmentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 22

GPS Modernization Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

The Galileo System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 29

Chapter 2 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . 2 - 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Preventive Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Tool Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

TBD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

EMC/Safety Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Chapter 3 - Calibration/Verification . . . . . . . . . . . . . . . . 3 - 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Testing Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Test Set Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Calibration Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Preliminary Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Test Set Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Reference Frequency Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Output Level Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Test Set Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Table of Contents

Subject to Export Control, see Cover Page for details.

iv

Verification Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Preset Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Remote Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Static Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

GPS Receiver Test and Loopback Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

External Trigger Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 16

Internal 10 MHz Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 20

External 10 MHz Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 21

VSWR at Antenna Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 23

VSWR at Direct Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 24

RF Output Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 25

RF Output Harmonics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 26

RF Output Spurious Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 28

RF Output Level at Antenna Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 30

RF Output Level at Direct Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 32

1 PPS Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 34

Chapter 4 - Remove/Install Procedures . . . . . . . . . . . . . 4 - 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Preliminary Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Tools Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

ESD and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Specified Replacement Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Inverting Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Connectors and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Preliminary Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Chapter 5 - Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Ship Unit, GPSG1000 (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Mechanical Assembly (A1A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Base Mechnical Assembly (A1A2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Chapter 6 - Assembly and Interconnect Drawings . . . . . 6 - 1

Drawings List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

GPSG-1000 Ship Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

GPSG-1000 Interconnect Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

GPSG-1000 MECHANICAL Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

GPSG-1000 driver board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

GPSG-1000 panel Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

GPSG-1000 168 Color, 12.1” SVGA TFT, 1000 NITS Assembly . . . . . . . . . . . . . . . . . . 6 - 9

Table of Contents

Subject to Export Control, see Cover Page for details.

v

GPSG-1000 panel touchscreen Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 10

GPSG-1000 touchscreen Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

GPSG-1000 base mech assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

GPSG-1000 GPS chasis mech Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 14

GPSG-1000 base card cage mech assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 15

GPSG-1000 torpedo Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

gpsg-1000 Digital PCB Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 18

gpsg-1000 rf upconverter PCB Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 19

gpsg-1000 rf combiner pcb Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 20

GPSG-1000 GPS RX pcb Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 21

gpsg-1000 auxiliary interface gps pcb Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 22

Appendix A - Pin-Out Tables . . . . . . . . . . . . . . . . . . . . .A - 1

Appendix B - Abbreviations . . . . . . . . . . . . . . . . . . . . .B - 1

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B - 1

Appendix C - Test Equipment . . . . . . . . . . . . . . . . . . . .C - 1

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C - 1

Appendix D - Controls and Connectors . . . . . . . . . . . . .D - 1

Front Panel Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D - 1

Rear Panel Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D - 3

List of Figures

Subject to Export Control, see Cover Page for details.

1

List of Figures

TITLE PAGE

Assembly Interconnect Block Diagram) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

GPS System Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

GPS Satellite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

GPS Satellite Orbital Planes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

GPS SV Block Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

GPS SV Signal Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

GPS Monitor Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

GPS Navigation Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

GPS Almanac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Satellite Relative Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

GPS Received Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

GPS Received Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

GPS Code Correlation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

GPS Nav Data Recover by Moduo 2 Addition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

GPS Signal After De-spreading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

GPS Subframe Hand-Over Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14

GPS Pseudo Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

GPS Pseudo Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16

Triangulation using one known point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16

Triangulation using two known point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

Triangulation using three known point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

Triangulation using two known points in 3D space . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

Triangulation using three known points in 3D space . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 18

Multipath Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 18

Atmospheric Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 19

GPS v. UTC Time Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 20

SBAS Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 22

GPS Modernization Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

Galileo Satellite (GIOVE Test SV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 29

GPSG-1000 Radio Altimeter Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

GPSG-1000 Ship Unit (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

GPSG-1000 Ship Unit (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

GPSG-1000 Interconnect and Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

GPSG-1000 Mechanical Assembly (A1A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

GPSG-1000 Driver Board Assembly (A1A1A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

List of Figures

Subject to Export Control, see Cover Page for details.

2

GPSG-1000 Panel Control Assembly (A1A1A2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

GPSG-1000 168 Color, 12.1” SVGA TFT, 1000 NITS Assembly (A1A1A3) . . . . . . . . . . . 6 - 9

GPSG-1000 Touchscreen Assembly (A1A1A4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 10

GPSG-1000 Touchscreen Control Assembly (A1A1A5) . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

GPSG-1000 Base Mech Assembly (A1A2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

GPSG-1000 Base Mech Assembly (A1A2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 13

GPSG-100 GPS Chasis Mech Assembly (A1A2A2) . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 14

GPSG-1000 RAD/ALT Base Card Cage Mech Assembly (A1A2A2A1) . . . . . . . . . . . . . 6 - 15

GPSG-1000 RAD/ALT Base Card Cage Mech Assembly (A1A2A2A1) . . . . . . . . . . . . . 6 - 16

GPSG-1000 Torpedo Assembly (A1A2A2A1A1A1) . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

GPSG-1000 Digital PCB Assembly (A1A2A2A2A1) . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 18

GPSG-1000 RF Upconverter PCB Assembly (A1A2A2A2A2A1) . . . . . . . . . . . . . . . . . 6 - 19

GPSG-1000 RF Combiner PCB Assembly (A1A2A2A3A1) . . . . . . . . . . . . . . . . . . . . . 6 - 20

GPSG-1000 GPS RX PCB Assembly (A1A2A4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 21

GPSG-1000 Auxiliary Interface GPS PCB Assembly (A1A2A5) . . . . . . . . . . . . . . . . . 6 - 22

Ethernet Pin-Out Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 1

USB Host 1 Pin-Out Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 1

USB Host 2 Pin-Out Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 2

USB OTG Pin-Out Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 2

DC Power Connector Pin-Out Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 2

AUX Connector Pin-Out Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A - 3

Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D - 1

Test Set Rear Panel Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D - 3

PRELIMINARY

Subject to Export Control, see Cover Page for details.

i

ELECTROMAGNETIC COMPATIBILITY

Double shielded and properly terminated external interface cables must be used with this equipment

when interfacing with the RS-232 and Ethernet.

For continued EMC compliance, all external cables must be shielded and 3 meters or less in length.

NOMENCLATURE STATEMENT

In this manual, GPSG-1000, Test Set or Unit refers to the GPSG-1000 GPS/Galileo Positional Simulator.

PRELIMINARY

Subject to Export Control, see Cover Page for details.

ii

THIS PAGE INTENTIONALLY LEFT BLANK.

PRELIMINARY

Subject to Export Control, see Cover Page for details.

iii

Declaration of Conformity

The Declaration of Conformity Certificate included with the Unit should remain with the

Unit.

Aeroflex recommends the operator reproduce a copy of the Declaration of Conformity

Certificate to be stored with the Operation Manual for future reference.

PRELIMINARY

Declaration of Conformity

Subject to Export Control, see Cover Page for details.

iv

THIS PAGE INTENTIONALLY LEFT BLANK.

PRELIMINARY

Subject to Export Control, see Cover Page for details.

v

Precautions

SAFETY FIRST - TO ALL OPERATIONS PERSONNEL

GENERAL CONDITIONS OF USE

This product is designed and tested to comply with the requirements of IEC/EN61010-1 ‘Safety

requirements for electrical equipment for measurement, control and laboratory use’ for Class I portable

equipment and is for use in a pollution degree 2 environment. The equipment is designed to operate

from installation supply Category II.

Equipment should be protected from liquids such as spills, leaks, etc. and precipitation such as rain,

snow, etc. When moving the equipment from a cold to hot environment, allow the temperature of the

equipment to stabilize before it is connected to the supply to avoid condensation forming. The

equipment must only be operated within the environmental conditions specified in the performance data.

This product is not approved for use in hazardous atmospheres or medical applications. If the

equipment is to be used in a safety-related application, such as avionics or military applications, the

suitability of the product must be assessed and approved for use by a competent person.

CASE, COVER OR PANEL REMOVAL

Opening the Case Assembly exposes the operator to electrical hazards that may result in electrical

shock or equipment damage. Do not operate this Test Set with the Case Assembly open.

SAFETY IDENTIFICATION IN TECHNICAL MANUAL

This manual uses the following terms to draw attention to possible safety hazards that may exist when

operating or servicing this equipment:

SAFETY SYMBOLS IN MANUALS AND ON UNITS

IDENTIFIES CONDITIONS OR ACTIVITIES THAT, IF IGNORED, CAN RESULT IN

EQUIPMENT OR PROPERTY DAMAGE, E.G., FIRE.

IDENTIFIES CONDITIONS OR ACTIVITIES THAT, IF IGNORED, CAN RESULT IN

PERSONAL INJURY OR DEATH.

CAUTION: Refer to accompanying documents. (This symbol refers to specific CAUTIONS

represented on the unit and clarified in the text.)

Indicates a Toxic hazard.

Indicates item is static sensitive.

AC TERMINAL: Terminal that may supply or be supplied with AC or alternating voltage.

CAUTION

WARNING

PRELIMINARY

Precautions

Subject to Export Control, see Cover Page for details.

vi

SAFETY FIRST - TO ALL OPERATIONS PERSONNEL (cont)

EQUIPMENT GROUNDING PROTECTION

Improper grounding of equipment can result in electrical shock.

USE OF PROBES

Refer to Performance Specifications for the maximum voltage, current and power ratings of any

connector on the Test Set before connecting it with a probe from a terminal device. Be sure the terminal

device performs within these specifications before using it for measurement, to prevent electrical shock

or damage to the equipment.

POWER CORDS

Power cords must not be frayed or broken, nor expose bare wiring when operating this equipment.

USE RECOMMENDED FUSES ONLY

Use only fuses specifically recommended for the equipment at the specified current and voltage ratings.

Refer to Performance Specifications for fuse requirements and specifications.

INTERNAL BATTERY

This unit contains a Lithium Ion Battery, serviceable only by a qualified technician.

EMI (ELECTROMAGNETIC INTERFERENCE

ELECTRICAL HAZARDS (AC SUPPLY VOLTAGE)

SIGNAL GENERATORS CAN BE A SOURCE OF ELECTROMAGNETIC

INTERFERENCE (EMI) TO COMMUNICATION RECEIVERS. SOME TRANSMITTED

SIGNALS CAN CAUSE DISRUPTION AND INTERFERENCE TO COMMUNICATION

SERVICE OUT TO A DISTANCE OF SEVERAL MILES. USER OF THIS EQUIPMENT

SHOULD SCRUTINIZE ANY OPERATION THAT RESULTS IN RADIATION OF A

SIGNAL (DIRECTLY OR INDIRECTLY) AND SHOULD TAKE NECESSARY

PRECAUTIONS TO AVOID POTENTIAL COMMUNICATION INTERFERENCE

PROBLEMS.

THIS EQUIPMENT IS PROVIDED WITH A PROTECTIVE GROUNDING LEAD THAT

CONFORMS WITH IEC SAFETY CLASS I. TO MAINTAIN THIS PROTECTION THE

SUPPLY LEAD MUST ALWAYS BE CONNECTED TO THE SOURCE OF SUPPLY

VIA A SOCKET WITH A GROUNDED CONTACT.

BE AWARE THAT THE SUPPLY FILTER CONTAINS CAPACITORS THAT MAY

REMAIN CHARGED AFTER THE EQUIPMENT IS DISCONNECTED FROM THE

SUPPLY. ALTHOUGH THE STORED ENERGY IS WITHIN THE APPROVED

SAFETY REQUIREMENTS, A SLIGHT SHOCK MAY BE FELT IF THE PLUG PINS

ARE TOUCHED IMMEDIATELY AFTER REMOVAL.

DO NOT REMOVE INSTRUMENT COVERS AS THIS MAY RESULT IN PERSONAL

INJURY. THERE ARE NO USER-SERVICEABLE PARTS INSIDE.

CAUTION

WARNING

PRELIMINARY

Precautions

Subject to Export Control, see Cover Page for details.

vii

SAFETY FIRST - TO ALL OPERATIONS PERSONNEL (cont)

STATIC SENSITIVE DEVICES

INTEGRATED CIRCUITS AND SOLID STATE DEVICES SUCH AS MOS FETS,

ESPECIALLY CMOS TYPES, ARE SUSCEPTIBLE TO DAMAGE BY

ELECTROSTATIC DISCHARGES RECEIVED FROM IMPROPER HANDLING, THE

USE OF UNGROUNDED TOOLS AND IMPROPER STORAGE AND PACKAGING.

ANY MAINTENANCE TO THIS UNIT MUST BE PERFORMED WITH THE

FOLLOWING PRECAUTIONS:

• BEFORE USE IN A CIRCUIT, KEEP ALL LEADS SHORTED TOGETHER EITHER

BY THE USE OF VENDOR-SUPPLIED SHORTING SPRINGS OR BY INSERTING

LEADS INTO A CONDUCTIVE MATERIAL.

• WHEN REMOVING DEVICES FROM THEIR CONTAINERS, GROUND THE HAND

BEING USED WITH A CONDUCTIVE WRISTBAND.

• TIPS OF SOLDERING IRONS AND/OR ANY TOOLS USED MUST BE

GROUNDED.

• DEVICES MUST NEVER BE INSERTED INTO NOR REMOVED FROM CIRCUITS

WITH POWER ON.

• PC BOARDS, WHEN TAKEN OUT OF THE SET, MUST BE LAID ON A

GROUNDED CONDUCTIVE MAT OR STORED IN A CONDUCTIVE STORAGE

BAG. REMOVE ANY BUILT-IN POWER SOURCE, SUCH AS A BATTERY,

BEFORE LAYING PC BOARDS ON A CONDUCTIVE MAT OR STORING IN A

CONDUCTIVE BAG.

• PC BOARDS, IF BEING SHIPPED TO THE FACTORY FOR REPAIR, MUST BE

PACKAGED IN A CONDUCTIVE BAG AND PLACED IN A WELL-CUSHIONED

SHIPPING CONTAINER.

CAUTION

THIS EQUIPMENT CONTAINS PARTS

SENSITIVE TO DAMAGE

BY ELECTROSTATIC DISCHARGE (ESD).

CAUTION

PRELIMINARY

Precautions

Subject to Export Control, see Cover Page for details.

viii

SAFETY FIRST - TO ALL OPERATIONS PERSONNEL (cont)

TOXIC HAZARDS

BERYLLIA

Beryllia (beryllium oxide) is used in the construction of some of the components in this equipment.

This material, when in the form of fine dust or vapor and inhaled into the lungs, can cause a respiratory

disease. In its solid form, as used here, it can be handled safely, however, avoid handling conditions

which promote dust formation by surface abrasion.

Use care when removing and disposing of these components. Do not put them in the general industrial

or domestic waste or dispatch them by post. They should be separately and securely packed and clearly

identified to show the nature of the hazard and then disposed of in a safe manner by an authorized toxic

waste contractor.

BERYLLIUM COPPER

Some mechanical components within this instrument are manufactured from beryllium copper. This is an

alloy with a beryllium content of approximately 5%. It represents no risk in normal use.

The material should not be machined, welded or subjected to any process where heat is involved.

It must be disposed of as “special waste.”

It must NOT be disposed of by incineration.

LITHIUM

A Lithium battery is used in this equipment.

Lithium is a toxic substance so the battery should in no circumstances be crushed, incinerated or

disposed of in normal waste.

Do not attempt to recharge this type of battery. Do not short circuit or force discharge since this might

cause the battery to vent, overheat or explode.

INPUT OVERLOAD

SOME OF THE COMPONENTS USED IN THIS EQUIPMENT MAY INCLUDE RESINS

AND OTHER MATERIALS WHICH GIVE OFF TOXIC FUMES IF INCINERATED.

TAKE APPROPRIATE PRECAUTIONS, THEREFORE, IN THE DISPOSAL OF THESE

ITEMS.

REFER TO PRODUCT SPECIFICATIONS FOR MAXIMUM INPUT RATING OF ANT

AND T/R CONNECTORS TO AVOID INPUT OVERLOAD.

WARNING

CAUTION

PRELIMINARY

Subject to Export Control, see Cover Page for details.

ix

Preface

SCOPE

This Manual contains instructions for maintaining the GPSG-1000.

ORGANIZATION

This manual is composed of the following chapters:

CHAPTER 1 - INTRODUCTION

Chapter contains general Test Set information and theory of operation.

CHAPTER 2 - TROUBLESHOOTING

Chapter contains system and module level troubleshooting procedures.

CHAPTER 3 - VERIFICATION/CALIBRATION PROCEDURES

Chapter describes system and module level verification and calibration procedures.

CHAPTER 4 - REMOVE/INSTALL PROCEDURES

Chapter contains procedures for removing and installing maintainable parts and

assemblies.

CHAPTER 5 - PARTS LIST

Chapter identifies customer serviceable parts and assemblies.

CHAPTER 6 - ASSEMBLY AND INTERCONNECT DRAWINGS

Chapter contains system level interconnect and assembly drawings.

APPENDIX A - PIN-OUT TABLES

Contains diagrams and pin identification for external connectors.

APPENDIX B - ABBREVIATIONS

Lists acronyms and terms used throughout manual.

APPENDIX C - TEST EQUIPMENT REQUIREMENTS

Lists equipment needed to perform verification and calibration procedures.

APPENDIX D - CONTROLS & CONNECTORS

Identifies front and rear panel controls and connectors.

PRELIMINARY

Preface

Subject to Export Control, see Cover Page for details.

x

THIS PAGE INTENTIONALLY LEFT BLANK.

PRELIMINARY

Subject to Export Control, see Cover Page for details.

1 - 1

Chapter 1 - Introduction

1.1 PRINCIPLES OF OPERATION

1.1.1 GPSG-1000

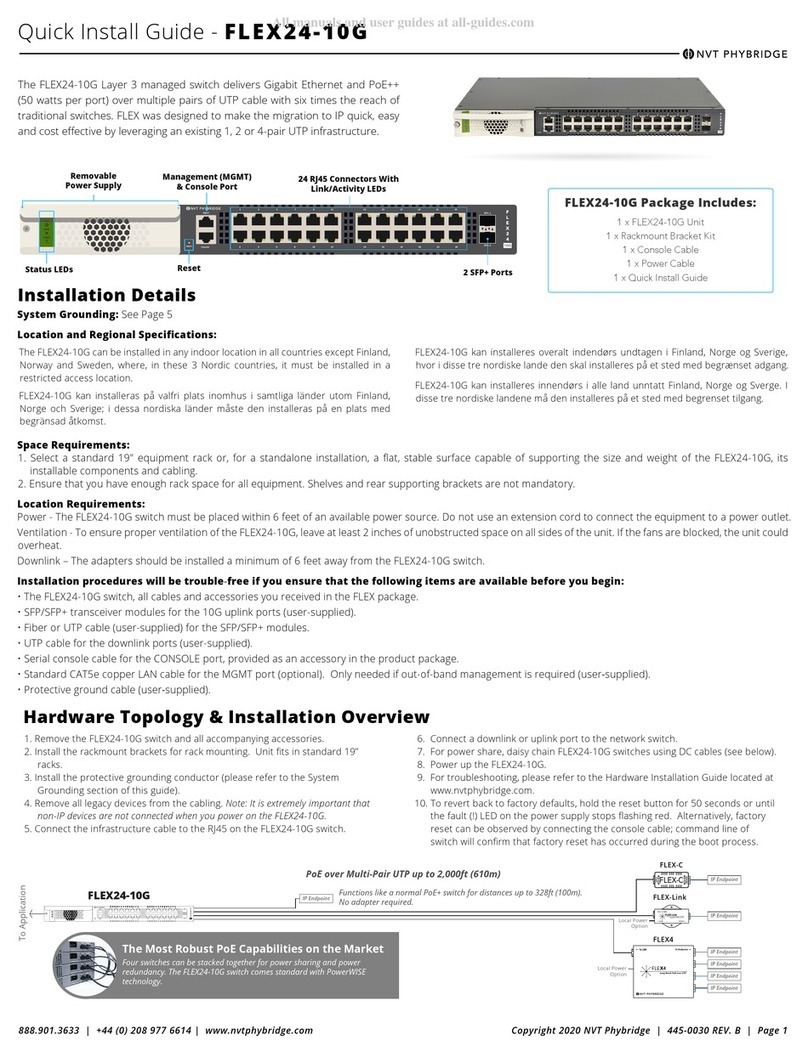

Control Panel Assembly

The Control Panel Assembly, provides On/Off, Home Buttons and Status LED’s.

Power Supply Assembly

The Power Supply Assembly is responsible for supplying power for module operation and

providing +5 Volt bias for applied power status.

Converter Assembly

The Converter Assembly provides the Test Set’s AF, RF and Modulated Output signals.

RF Combiner Assembly

The RF Combiner Assembly provides Signal Attenuation and 10MHz system reference.

PXI Backplane Assembly

The PXI Backplane Assembly routes electrical signals between the various system

assemblies.

Rear Panel Assembly

The Rear Panel Assembly provides access to Tests Set’s Input/Output connectors and AC

charger.

Satellite Simulation

The orbit parameters for each satellite are configurable in terms of the standard

Keplerian (almanac) elements. The almanac used for simulation may selected from a list,

maintained by a file management system. The files may obtained from the built in GPS

receiver, as a current almanac load or may be loaded from a USB flash drive in Yuma

.alm format.

The standard Keplerian elements (almanac) are used to calculate the enhanced Keplerian

Elements (ephemeris), which are in turn used to generate the satellite motion, and are

broadcast as part of the navigation message.

As almanac data is typically valid for several days, the GPSG-1000 does not update the

standard Keplerian (almanac) elements during the course of the simulation.

PRELIMINARY

Introduction

Subject to Export Control, see Cover Page for details.

1 - 2

The GPSG-1000 computes the enhanced Keplerian (ephemeris) elements by

extrapolation of the configured standard Keplerian (almanac) elements. Any enhanced

Keplerian elements not includedin the standard Keplerian elements are set to zero. The

GPSG-1000 generates updated enhanced Keplerian (ephemeris) elements at a fixed time

interval of 4 hours, this being the update rate supported by both GPS and Galileo.

The GPSG-1000 generates in real time the positions of all simulated Satellites i.e.

positions are not be pre-computed for the entire simulation run.

Satellite Selection

For each simulated GNSS system the GPSG-1000 will perform an independent satellite

selection process and if the total number of visible satellites exceeds the maximum

number of hardware channels allocated to that system, then the GPSG-1000 will select

those satellites which approximate the minimum DOP for that system. The GPSG-1000

updates its satellite selection every 60 minutes.

Note: In the case of the 6 channel GPSG-1000, with large numbers of simulated satellites

it becomes possible for many more satellites to be visible at the user location than there

are available hardware satellite channels. If this happens the GPSG-1000 allocates

channels on a 'best effort' basis but does allow the operator to override the selection

manually.

The GPSG-1000 allows the operator to manually replace any selected satellite with

another visible satellite from the same GNSS system, with the manually selected satellite

remaining selected until it is no longer visible, or until it is manually replaced. The

manually de-selected satellite will remain eligible for re-selection at the next automatic

update.

Other manuals for GPSG-1000

3

Table of contents