Smart Lift SL 580 MAXI User manual

US SL 580 MAXI 03/2016

2

Table of Contents

Table of Contents 2

Introduction 3

EU Declaration of Conformity 4

General Description 5

Transport/Handling/Putting into operation/Storage/Technical Data 6

Safety Rules 7

Overview/ - General Description 8

Load Diagram. Safety Function for vacuum 9

Drive Operation and Vacuum function 10

Stop – Emergency stop 11

Control Panel 12

Main Switch. Battery 14

Battery Charger 15

View of Vacuum System. Top/bottom 16

Operation of Yoke 17

Stop-Down Troubleshooting 18

Stop-Down at Vacuum System 19

Stop-Down at movements 21

Control box for actuators 23-26

Stop-Down at drive 27

Dimensioned sketch 28

Wiring Diagram 29-31

US SL 580 MAXI 03/2016

3

Introduction

Congratulations on your new SL 580 MAXI

Smart LIFT has been designed and constructed so as to safeguard product users

against accidents as far as at all possible.

Unfortunately, certain functions in a machine cannot be safeguarded.

This is why safety rules have been prepared by way of warnings in this instruction.

Read these safety rules on the following pages before putting your Smart LIFT into

operation, and imagine how you may, in your daily use of the machine, ensure that

warnings and safety rules will be adhered to.

Yours Sincerely,

Nicolai Tange Jørgensen

Smartlift A/S

N.A. Christensensvej 39

DK - 7900 Nykøbing Mors

Telephone: +45 9772 2911

E-mail : smart@smartlift.dk

www.smartlift.dk

US SL 580 MAXI 03/2016

4

EU Declaration of Conformity

Manufacturer

Smart LIFT A/S

N.A. Christensensvej 39

DK - 7900 Nykøbing Mors

Hereby declares that:

The machine/system: Lift

Model/type: SL 580 MAXI – 1.36 hp

Serial No.:

Year/Month: 2016 /

has been made in conformity with Council directive

-Machine directive 2006/42EC

-Low voltage directive 2006/95/EC + 2014/35/EU

-EMC directive 2014/30/EU

The following standards have been applied:

DS/EN ISO 12100 (Safety of machinery - General principles for design -- Risk assessment and risk reduction)

DS/EN ISO 14121-2 (Safety of machinery - Risk assessment -- Part 2: Practical guidance and examples of

methods)

DS/EN ISO 13857 (Safety of machinery - Safety distances to prevent hazard zones being reached by upper and

lower limbs)

DS/EN ISO 13849-1 (Safety of machinery - Safety-related parts of control systems - Part 1: General principles for

design)

DS/EN 13155+A2 (Cranes - Safety - Non-fixed load lifting attachments)

DS/EN ISO 3691-1 (Industrial trucks - Safety requirements and verification - Part 1: Self-propelled industrial

trucks, other than driverless trucks, variable-reach trucks and burden-carrier trucks)

DS/EN ISO 3691-5:2015 (Industrial trucks - Safety requirements and verification - Part 5: Pedestrian-propelled

trucks)

DS/EN 60204-32 (Safety of machinery - Electrical equipment of machines - Part 32: Requirements for hoisting

machines)

DS/EN ISO 13856-3 (Safety of machinery - Pressure-sensitive protective devices - Part 3: General principles for

design and testing of pressure-sensitive bumpers, plates, wires and similar devices)

Date: Signature:

____________ ____________________________________

Nicolai Tange Jørgensen, Director

US SL 580 MAXI 03/2016

5

General Description/List of Spare Parts

Pos.nr.

Product

Number

Vacuum

1

Pump 007 BDC 24V

2

2

Suction Cup diam 15,75”

4

3

Check Valve ½", vacuum

2

5 Slide Valve w/lock, vacuum 2

6

Vacuummeter diam 40, stainless

2

10

Hose Set

1

11

Hose Coupling

2

12 Spiral Hoses 2

13

Vacuum Guard

2

14

Vacuum Hose diam 10 mm

2

15

Alarm light, Vacuum

1

16 Acoustic alarm, Vacuum 1

17

Line Filter VTF – 38-IN

2

19

Stainless spring on Yoke

4

20

Clamp MRX.80 P-M10-25

6

21 Actuator – Tilting function - LA 36 1

22

Actuator – Side Change- LA 36

1

23

Actuator – Telescopic Arm LA – 36

1

24

Actuator – Lift Arm LA – 36

2

Power supply

25 Battery 2 x 90A 2

26

Charger Blue Power Charger IP65

1

Wheels

27

Wheel, EK-MASSIV 16 – 30

2

30

Supporting wheel

2

24 V

31 Safety Switch/Telemecanique 1

32

Control Panel

1

33

Emergency Stop

1

34

Control, Lift Arm

1

35 Control, Telescopic Arm/Tilt 1

36

Control, Side Change

1

37

CE Connector

1

38

Ermax Main Switch 24 V

1

39 Fuse 30 Ampere Control

Various

40

Lock Split

1

41

Lift Eye

1

44

Battery indicator

3

45 Weight Blocks 10

46

Supporting Leg

2

Drive

47

Motor 1.36 hp/24 V

1

47a

On/OFF switch for Drive Motor

1

47b Fuse 80 Ampere Motor 1

48

Regulating Lever

1

49

Curtis Motor Control

1

50

Safety Clamp

1

51 Safety Switch 1

52

Forward and back switch

1

US SL 580 MAXI 03/2016

6

Transport/Handling

Smart Lift is for indoor handling and should only be used outdoors on a completely stable and firm

base.

May not be exposed to rain / snow and much moisture

Prior to transport, switch off electronics on main switch (pos. 38).

Smart Lift to be fastened securely in truck/trailer for transport.

Lifting by crane and similar: Always lift Smart Lift in lift eye intended for this purpose (pos. 41).

NEVER lift under Smart LIFT by forks (truck and similar)

Putting into operation

Prior to putting into operation, insert vacuum hoses, and charge battery fully. The operator must

have read the user manual and make sure that all security issues are respected. The user manual

must always be at hand by the machine.

If the yoke has been dismantled, be aware that the washer is placed between the castle nut and

the yoke.

Storage

Always switch off your Smart Lift on the main switch (pos. 38), before storage.

Smart Lift should always be kept dry. Moisture may affect the machine functionality.

Batteries should always be fully charged for long-term storage.

Technical Data

Total Height

55.9 in

Total Width

30.7 in

Total Length

66.9 in

Net Weight

1051 lb

Weight Blocks

48.5 lb x 10 pcs. = 485 lb

Total Weight incl. 10 weight blocks

1536 lb

24 V DC

Charger 110 V – CE connector

US SL 580 MAXI 03/2016

7

Safety Rules

Daily Use

Your Smart LIFT may only be used by persons who have been given qualified training in the

operation of this machine and its safety functions.

Before use, user should check that there are no loose objects on the machine since this would

entail breakdown and danger risks.

WARNING! Vacuum!

Working at the machine will entail danger if the various safety

devices, pressure gauge (pos. 6) and acoustic alarm (pos. 16) are

faulty.

Work may NOT be lifted until the light and acoustic alarms

(pos.15, pos. 16) have stopped.

Do NOT lift moist or greasy work by the suction cups.

WARNING! Risk of overturning!

This machine MUST stand on a horizontal, firm, and stable base,

with its supporting legs (pos. 46), unfolded.

WARNING!

Prior to using the lift yoke, check that nut and lock split have been securely

fastened.

Always see that (pos. 45) has been locked with lock split (pos. 40).

WARNING! Explosion Danger!

This machine may NOT be used in ATEX area. (Explosion danger

environment).

DANGER!

Staying under the lifted work is strictly prohibited.

PROHIBITED!

May NOT be used for lifting persons.

US SL 580 MAXI 03/2016

8

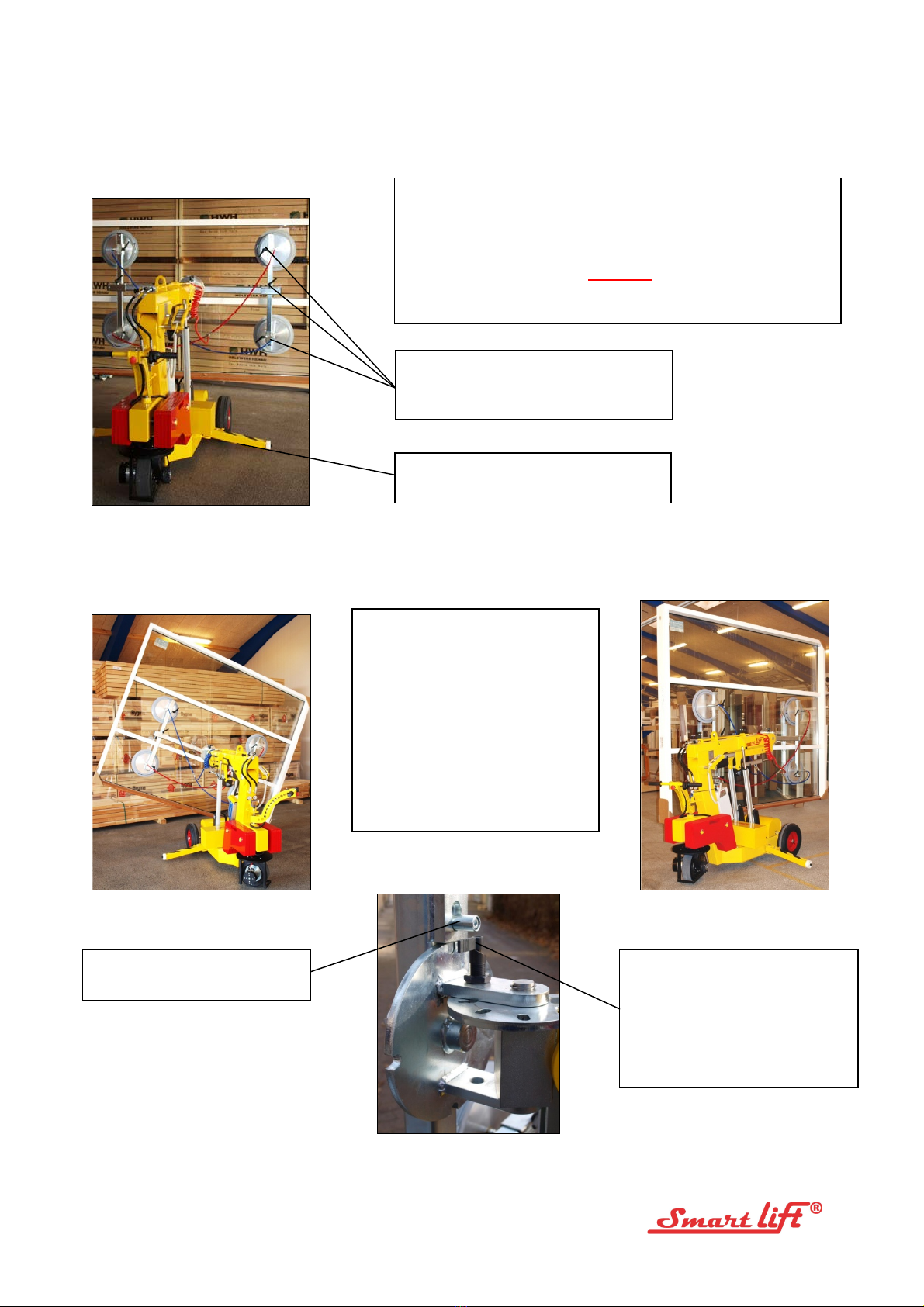

Overview/ - General Description

Adjustable yoke with clamp

2 - 4 stk suction cups diam.

15,75 In

14 – Vacuum Hoses

2 safety circuits

Flexible turning head on

telescopic arm

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

21 – Actuator tilt

23 – Actuator udskydning

24 – Actuator løftearm

41 – Lift Eye

27 – Wheel,

Massive

46 – Supporting Leg with

wheel

25 – Battery Box two 90 A

45 – Detachable weight

blocks

47 – Drive Motor with electric

brake function

Control Handle with

control for drive

motor

Double Vacuum

Chamber

Control Box

for actuators

Protective Screen for actuator

for side change and motor

change

US SL 580 MAXI 03/2016

9

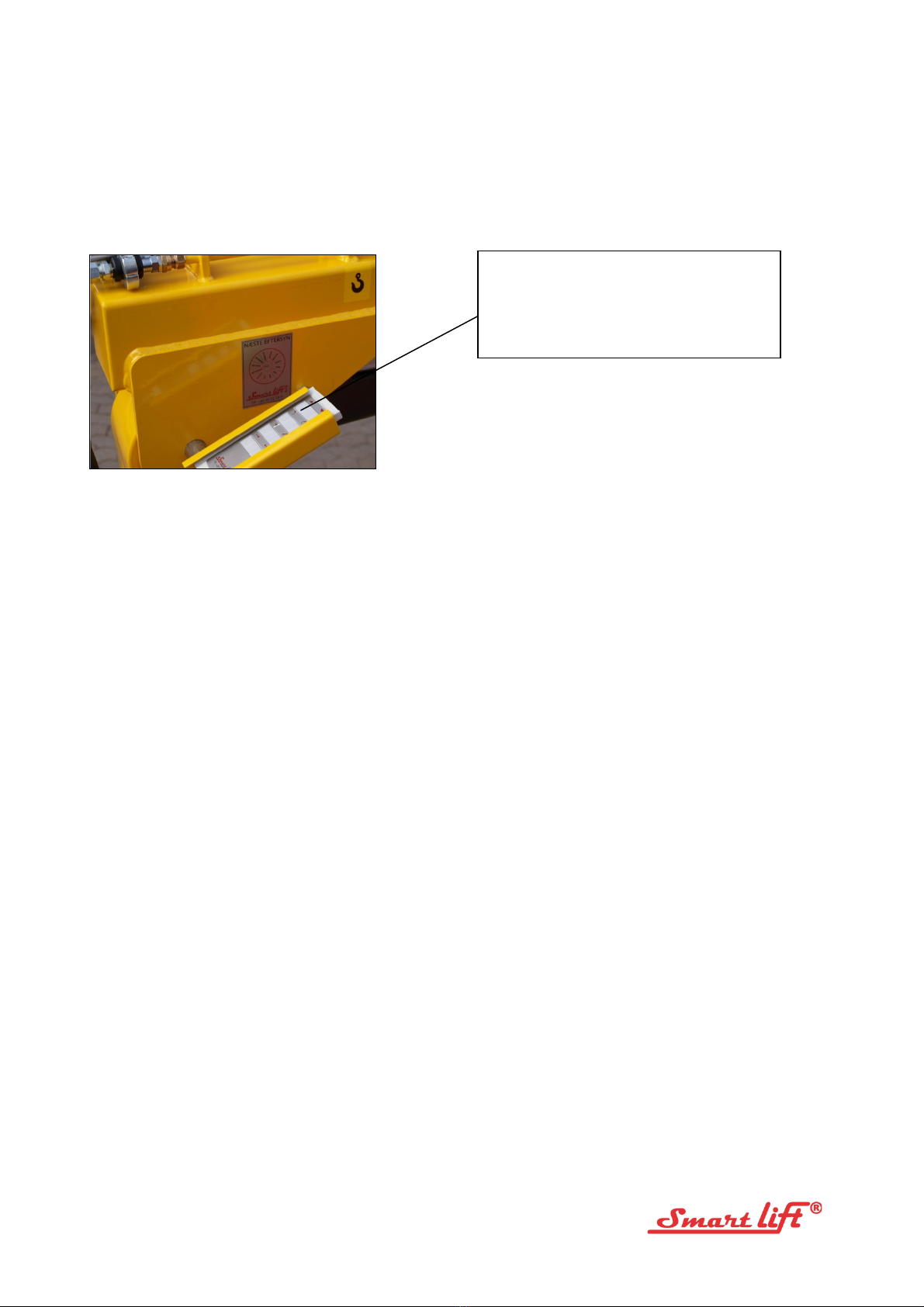

Load Diagram

Safety Function Vacuum

Safety Lock vacuum

33 – Emergency Stop

16 – Acoustic alarm vacuum

15 – Alarm light vacuum

44 – Battery Indicator,

on-button on

regulating lever(48)

must be on

NOTE!!

Load diagram attached to

left side of machine

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

10

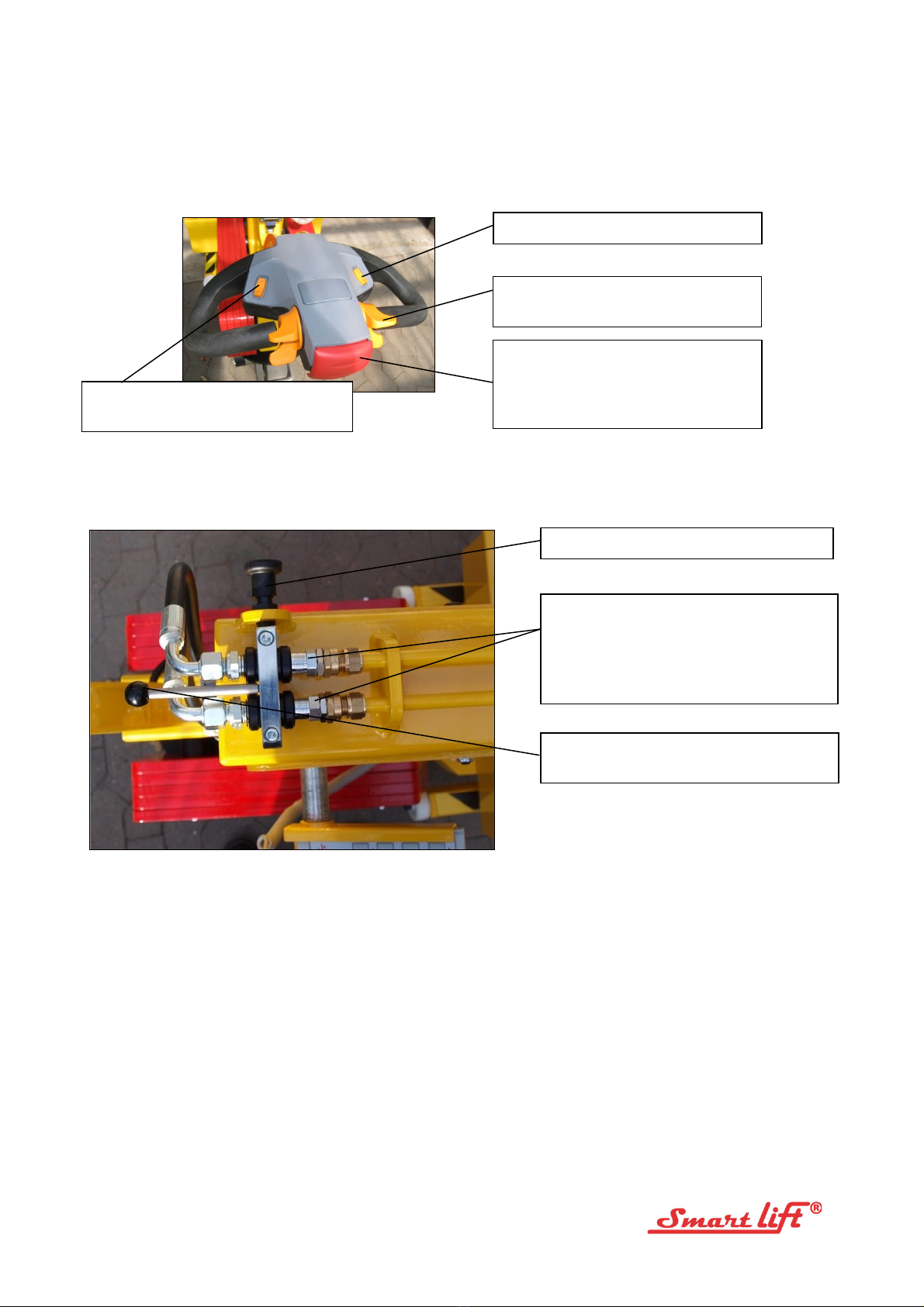

Drive Operation (forward and back)

Operation for VACUUM function: (machine viewed from above)

This function (pos. 5) will switch vacuum on and off. The vacuum pump is controlled

by a pressure gauge and will start the pump at 0.53, and will switch off at 0.62. The

vacuum function is activated by using the handle on the slide valve and is

deactivated by the same – simultaneously with pulling out the button on the safety

lock.

47 – On/Off- switch for Drive

Motor. Green light when ON

48 – Stepless speed control, forward

and back

51 – Safety Switch at back.

Machine moving forward

automatically by pushing from the

body

Fast and slow speed

5 – Slide Valve, activating and deactivating

vacuum suction.

Safety Lock for vacuum suction

Double vacuum circuit system always

providing at least suction on two cups.

Each suction cup approved for sucking

1278 lb

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

11

STOP/EMERGENCY STOP function:

The emergency stop button, ( pos. 33), has been placed on the actual control box.

This button will turn off the actuators, electric control, as well as the drive motor.

2 separate vacuum

chambers

6 – 2 vacuummeters. One for each circuit.

To show 0.5 – 0.7 for normal operation

Should show 0.5 – 0.7 for normal

operation

31 – Safety switch for overload on yoke.

For activation of disrupted machine see

section “Troubleshooting”

CE Identification Sign

Control Box, containing controls for

actuators, fuse 30 A for same.

16 – Acoustic alarm for

missing vacuum suction

15 – Alarm light for missing

Vacuum suction

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

Battery-indicator

US SL 580 MAXI 03/2016

12

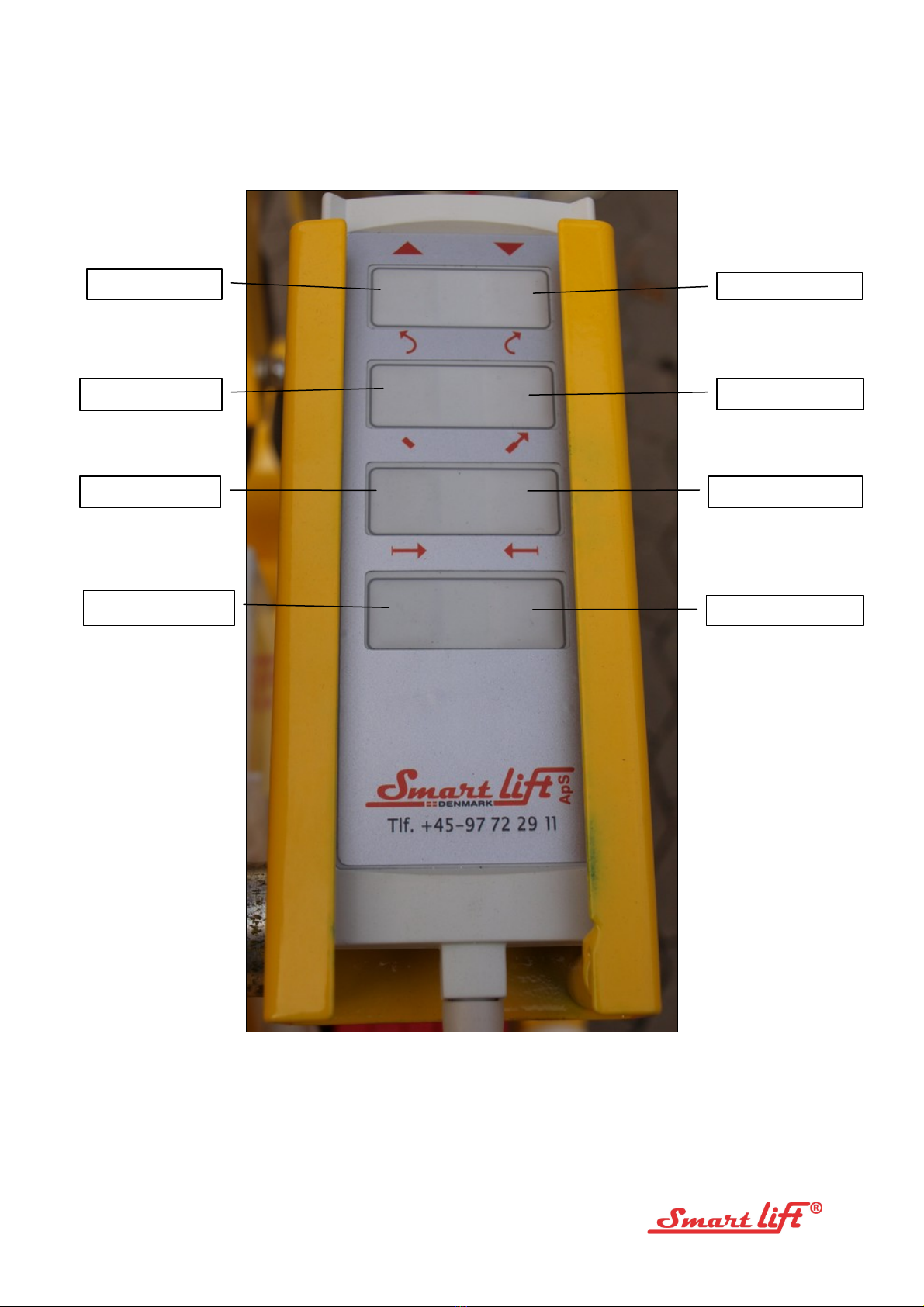

Control Panel (pos. 32) for operation of lift arm telescopic

arm, tilting of yoke, and side change

:

It is important that users read the function description below so that the operator

will be familiar with the machine mode of operation

Smart LIFT is operated manually. This machine generally has four functions which

may be operated individually or simultaneously

UP/DOWN function:

This function will make the arm move either up or down. This movement is

performed via the actuators, (pos. 24).

TILT Function:

This function makes the work turn round. This movement is performed by actuator,

(pos. 21).

TELESCOPIC Function:

This movement is performed via actuator which is placed under the lift arm (pos.

23).

SIDE DISPLACEMENT Function:

This movement is performed via actuator which is placed between the two front

wheels. (pos. 22).

32 – Operation panel placed in special

holder on the machine right hand side. May

be kept manually free out of holder but be

aware that the connector may not come

loose at the control box

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

13

Control Panel

Lift Arm down

Tilt backwards

Telescopic arm out

Side displacement

Lift arm up

Tilt forward

Telescopic arm

Side displacement

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

14

Main Switch:

Main switch for all electric functions is placed on the battery case by the lift actuators. Turn the

switch clockwise to switch on the electric connection on the machine, and the opposite way to

switch off all.

Battery Case:Battery Charger:

The battery case contains two 12 volt

batteries connected in series for 24 volt

operation. The batteries are maintenance

free

Integrated 24 volt charger with 110 volt CE

connector. The charger can also be used as a

voltage unit without having the battery

connected. PLEASE NOTE the charger is not

sparkless in this position.

38 – Main Switch, switching off all

functions on el. on the machine

25 – Two 90A

26 –Charger

37 – 110 Volt

CE–connector

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

15

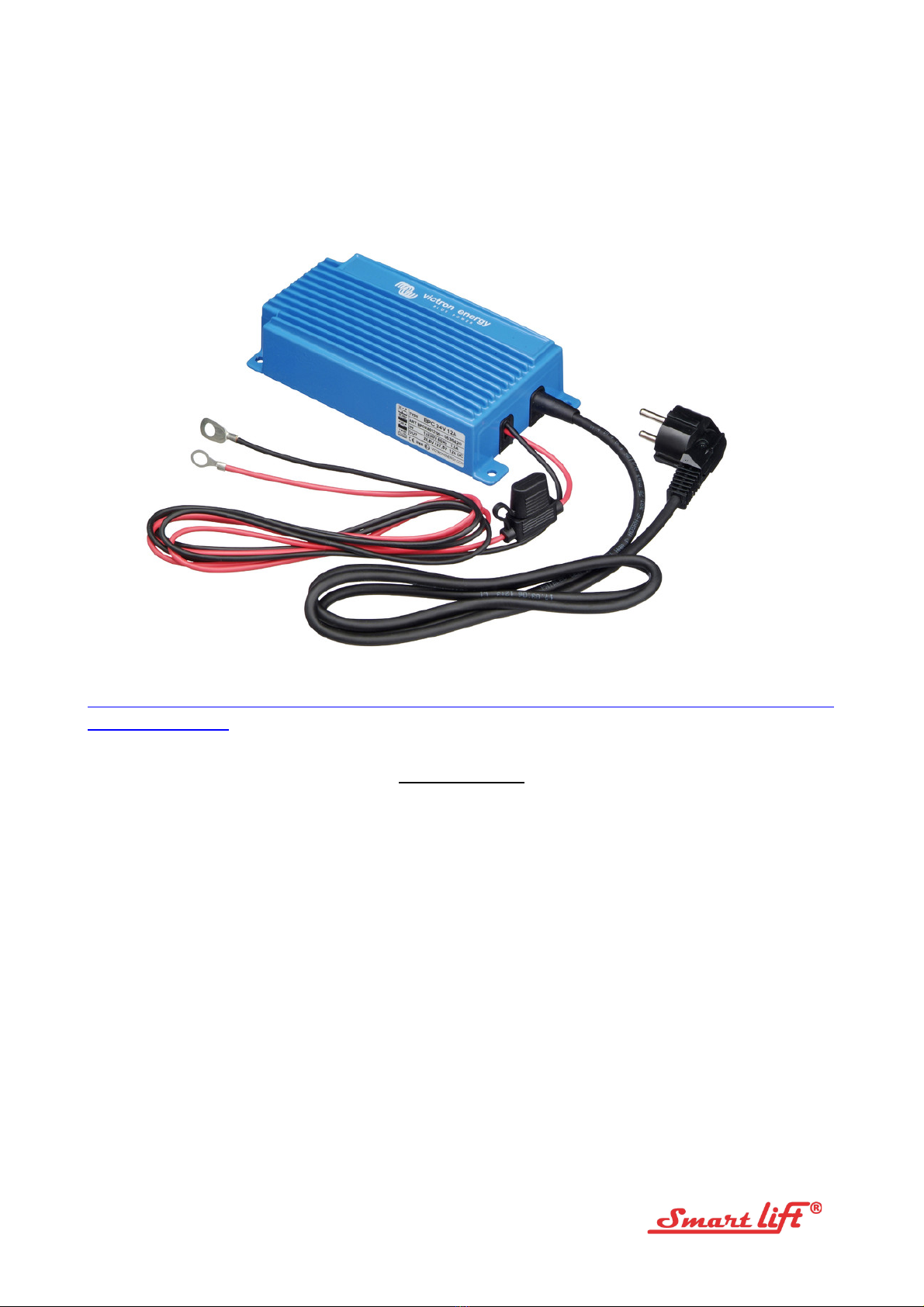

Battery charger Victron Energy - Blue Power Charger IP65

For complete manual refer to:

https://www.victronenergy.com/upload/documents/Datasheet-Blue-Power-Battery-Charger-IP65-

90-135VAC-EN.pdf

INDICATIONS:

LED indication Description

Yellow LED on: battery being charged.

Yellow LED on and green LED on: absorption charge.

Green LED on: battery fully charged, float charge.

US SL 580 MAXI 03/2016

16

View of Vacuum System

Top of machine

Bottom of machine

(drive and vacuum)

5 – Slide valve with safety lock,

activating and deactivating vacuum

suction

6 – Vacuum meters for 2-circuit vacuum suction.

11 – Hose couplings for 2 circuits

BLUE CIRCUIT / RED CIRCUIT

2-4 suction cups with

spiral springs

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright

© 2006 Copyright.

1 – 2 vacuum pumps 24 volt

3 – Check valves – double circuit

17 – line filters – double circuit

49 – Curtis controller for

drive

47B – Fuse 80A for driving

engine

22 – Actuator for side shift

© 2006 Materialet er ophavsretligt beskyttet

www.smartlift.dk

© 2006 Materialet er ophavsretligt beskyttet

www.smartlift.dk

US SL 580 MAXI 03/2016

17

Operation of Yoke

Turning vertically Turning horisontally

For max. stability at transport of sucked work, the

suction cups are to be centred and adapted to the

transport work chosen. Operation of yoke with

sucked work should always be conducted with

caution

46 – supporting legs always to be

unfolded during work with the machine

20 – 6 clamps for setting of width and

height for suction cups mounted on the

yoke

Smartlift MAXI may with sucked

work turn round 3600 vertically

and 1800horizontally.

NB !!

Always be aware that all

handles and locks are

locked and in position

Positioning bolt. Keeping the

turning head locked in fixed

position when yoke is required to

be turned to one of the sides.

Span 180⁰

Safety locking pawl for turning

vertically 360

⁰

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

18

Stop-Down Troubleshooting

On any fault on Smartlift, first look into the options below:

•Has anything visible been broken, or is anything unusual, about the machine ? Is there any

murmuring or noise?

•Have the batteries been charged, and the main switch switche d on? (the On/Off button on the

drive handle shall have been switched on (lighting) to read battery voltage on battery indicator)

•Has the emergency stop button switched the machine off? (located on grey control box)

•Has the safety switch been switched off on account of overloading (placed under pressure

switches)?

•Is the hose set intact, and has it been connected correctly?

Troubleshooting and remedying of faults will be divided into 3 overall categories:

1. Vacuum (machine capacity for sucking work)

2. Movements controlled via control panel up and down function of lift arm, telescoping

of lift arm, tilting of yoke, side displacement of machine.

3. Drive controlled by regulating lever – Forward and back function of machine

Vacuum

Moveing of

actuators

Drive

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

19

Stop-Down at Vacuum System

If – vacuum pump will not run.

Always check that there is power on the machine, and that it has not been disconnected by switch or by

fuse in the control box. Relay for pump may also be defective.

If – vacuum pump runs constantly.

Check that the slide valve is closed (should be closed to generate vacuum). Read pressure gauge (should be

about 0.60)

If – the pressure gauge is constantly about 0.7 or more.

In that case, there will be a fault on the vacuum guard.

If – the pressure gauge is constantly appr. 0.55 or less, and the pump is running.

In that case there would be a fault on the vacuum pump, or leak on the hose connection between check

valve and vacuum pump?

If – the pressure gauge indication drops after the main switch has been disconnected, and the slide

valve closed.

In that case, there will be a fault – leak between slide valve and check valve. Pressure gauge, slide valve or

vacuum guard may be defective. If hoses are dismantled at couplings, and the pressure continues to drop,

the fault will be with the slide valve.

If – the vacuum pump starts and runs constantly, possibly with dropping pressure, when the slide

valve is opened, in connection with suction of work.

Check that all suction cups bear correctly on the work. I.e. that the particular suction cup is parallel with the

work, and that no parts of the suction cups protrude from the work (IMPORTANT!!).

If – the vacuum pump starts and stops at very brief intervals.

Dismantle spiral hoses at couplings and close the slide valve if this has not been done already. If the

vacuum pump still starts and stops at very brief intervals, there may be a fault on the check valve.

If – the vacuum pump starts and runs, and stops at brief intervals, possibly with dropping pressure

on one or both pressure gauges, when the slide valve is opened, after correct suction of work.

Slide valve with safety

lock for activation and

deactivation of vacuum

suction.

Vacuum suction on both

pressure gauges to be

0.62 between 0,6 -0,7)

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

US SL 580 MAXI 03/2016

20

Close slide valve. Disconnect one vacuum circuit at hose coupling, and then open the slide valve for vacuum

suction again. If the vacuum suction on the pressure gauge for disconnected circuit is now constantly 0.6,

there will be a fault on the hose set or at the suction cups in disconnected vacuum circuit. Test the same

procedure in case of fault on the other vacuum circuit system. You may listen for leaks.

Vacuum Guard (two)

Vacuum Guard light green when

pump is running (2 circuits)

Vacuum guard light - red when

vacuum suction has been

attained

(Note: Frame no.)

© 2006 Copyright. www.smartlift.dk

© 2006 Copyright. www.smartlift.dk

Vacuum pump

Check valves – 2 circuits + filters

© 2006 Materialet er ophavsretligt beskyttet

www.smartlift.dk

© 2006 Materialet er ophavsretligt beskyttet

www.smartlift.dk

Bottom of Smartlift MAXI

Table of contents

Other Smart Lift Lifting System manuals