20

codice 09MAXX001

versione EN

revisione 01

Use and Maintenance Manual

MaxX

10.3 Daily check

Daily check carried out by the operator and the person in

charge of the handling of the system in which the MaxX is

installed/hanged up, to be carried out before starting the

operations of Normal Use of the MaxX. Refer to chapter 9

of this Manual for further information.

10.4 Frequent check

Control conducted on the basis of the working

environment, frequency and severity of use of the MaxX,

within time intervals not exceeding 3 months (unless there

are periods of inactivity).

TECNOMAGNETE suggests weekly, monthly and quarterly

checks according to the MaxX component.

10.5 Periodical check

Control conducted on the basis of the working

environment, frequency and severity of use of the MaxX,

within time intervals not exceeding 12 months (unless

there are periods of inactivity).

10.6 Maintenace - Warnings

MAINTENANCE OPERATIONS MUST BE CARRIED OUT

ONLY AND EXCLUSIVELY BY PERSONNEL TRAINED IN

ACCORDANCE WITH THE REGULATIONS

The main warnings to be taken during maintenance

operations are:

all maintenance must be carried out when the system is

stationary and with MaxX not connected to the crane,

etc.

repairs must be carried out by qualified personnel who

must scrupulously comply with the accident prevention

regulations in force in the country of destination

Always use the Personal Protective Equipment (PPE)

described in paragraph 1.8.

do not wear rings, watches, chains, bracelets, fluttering

clothes, etc. during maintenance operations

comply with the maintenance deadlines indicated

Replacements of components must only be made with

original spare parts to guarantee perfect operation

during cleaning operations, be careful not to use

grinding wheels, abrasive, corrosive or solvent materials

that could remove and/or make illegible numbers,

acronyms or information inscriptions located on MaxX.

10.7 Daily Maintenace

Maintenance to be performed at the end of the daily work

activity. Depending on the method, it can be carried out by

the operator or by the handler.

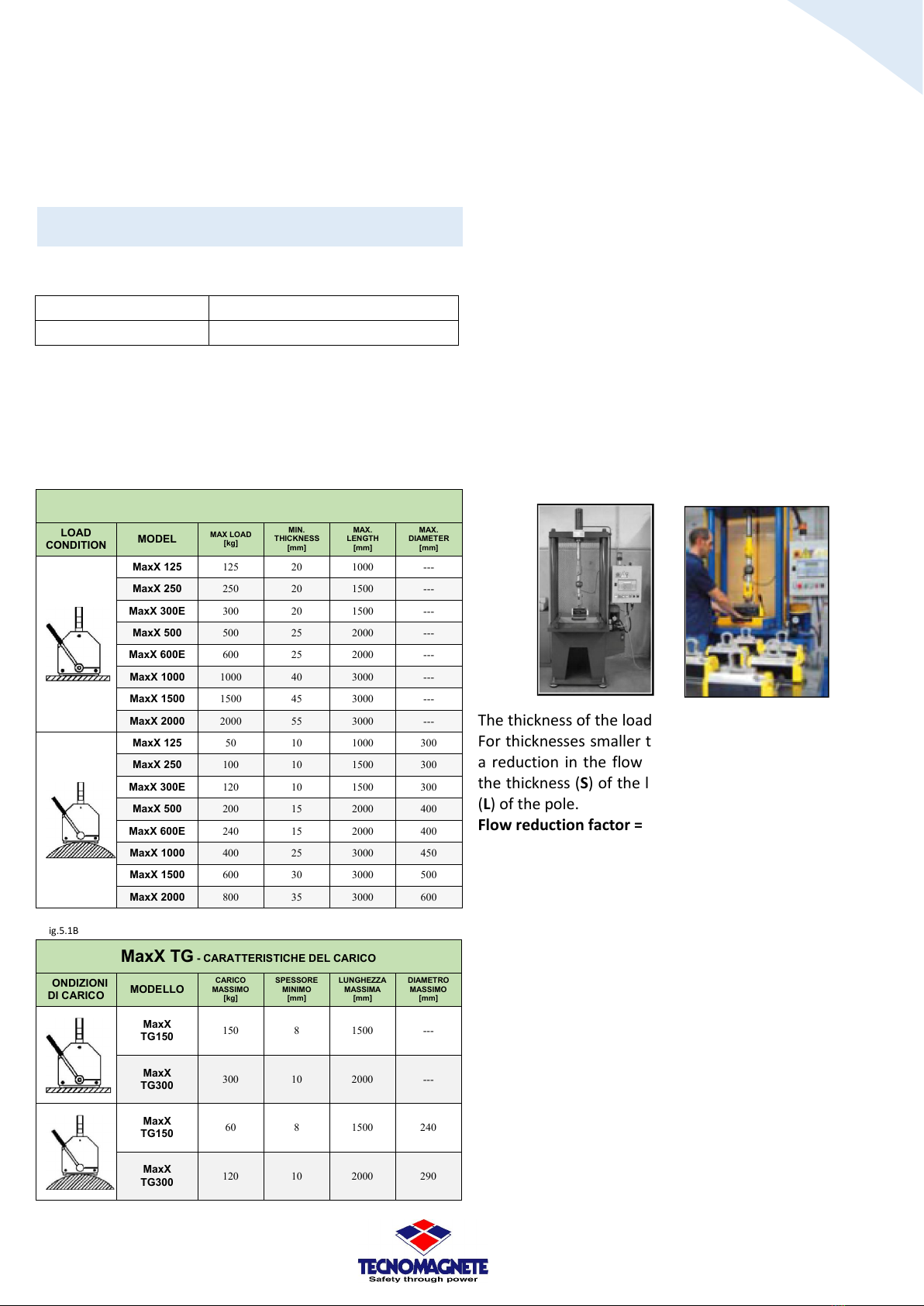

For the Operational Test of the MaxX lever, it must be

placed on an iron plate resting on the ground or on a

support suitable for supporting the weights of both the

plate and the MaxX. The iron plate must have a minimum

thickness as indicated in sub-paragraph 3.2.4 (Fig.3.2.4A

and Fig.3.2.4B).

10.8 Frequent maintenance

Maintenance to be performed at the end of the work

activity within intervals of time not exceeding 3 months

(unless periods of inactivity).

The maintenance that requires a monthly frequency is

deducted from the consideration of a work activity usually

carried out on a shift of 8÷10 hours per day.

10.9 Periodical maintenance

Maintenance to be performed at the end of the work

activity within intervals of time not exceeding 12 months

(unless there are periods of inactivity).Annualmente per il

MaxX is mandatory to perform a functional and

operational test using a suitable dynamometric equipment

(this test is defined as a tear-off test).

TECNOMAGNETE is able to provide you with adequate

technical assistance to carry out the tear-off test.

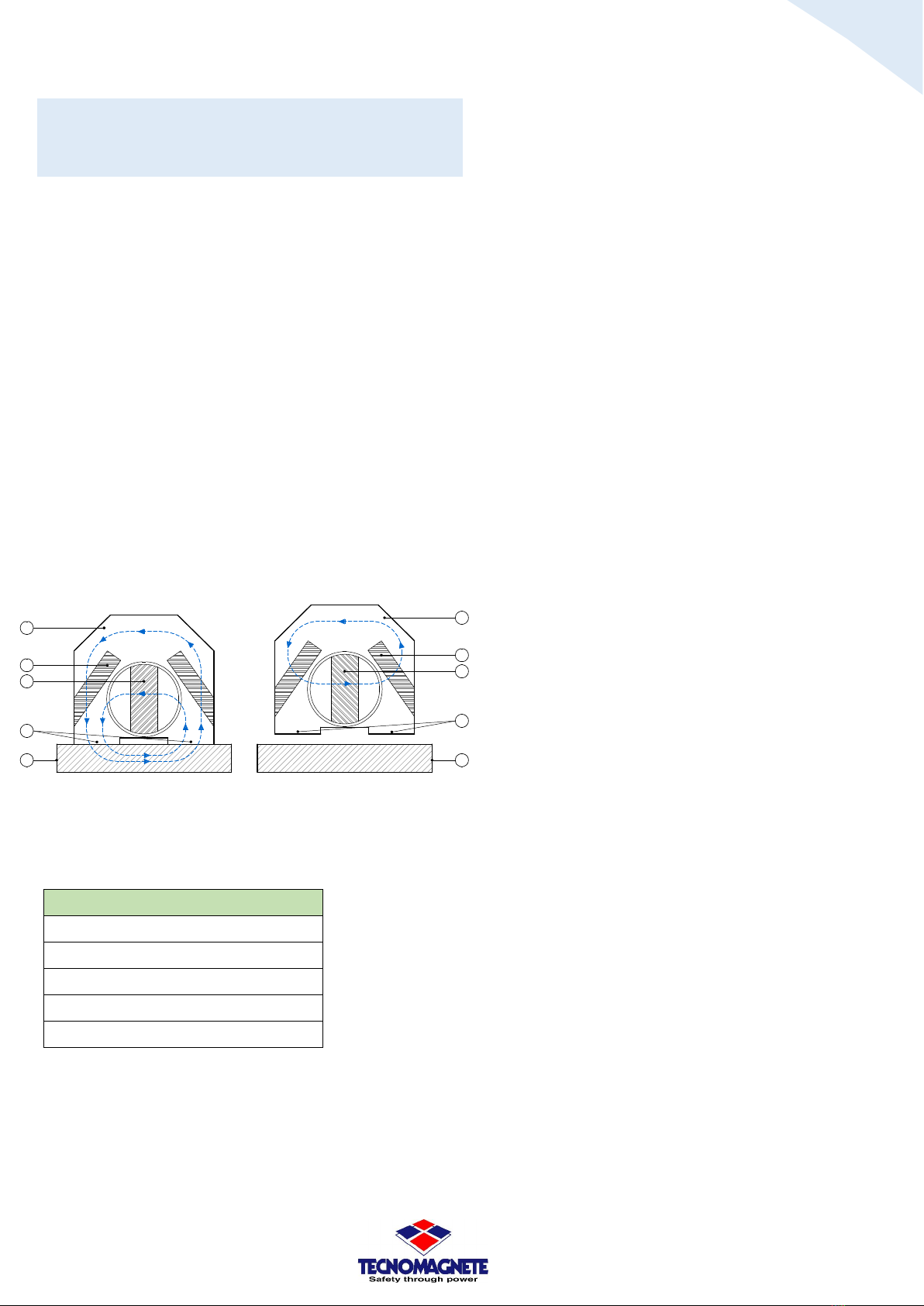

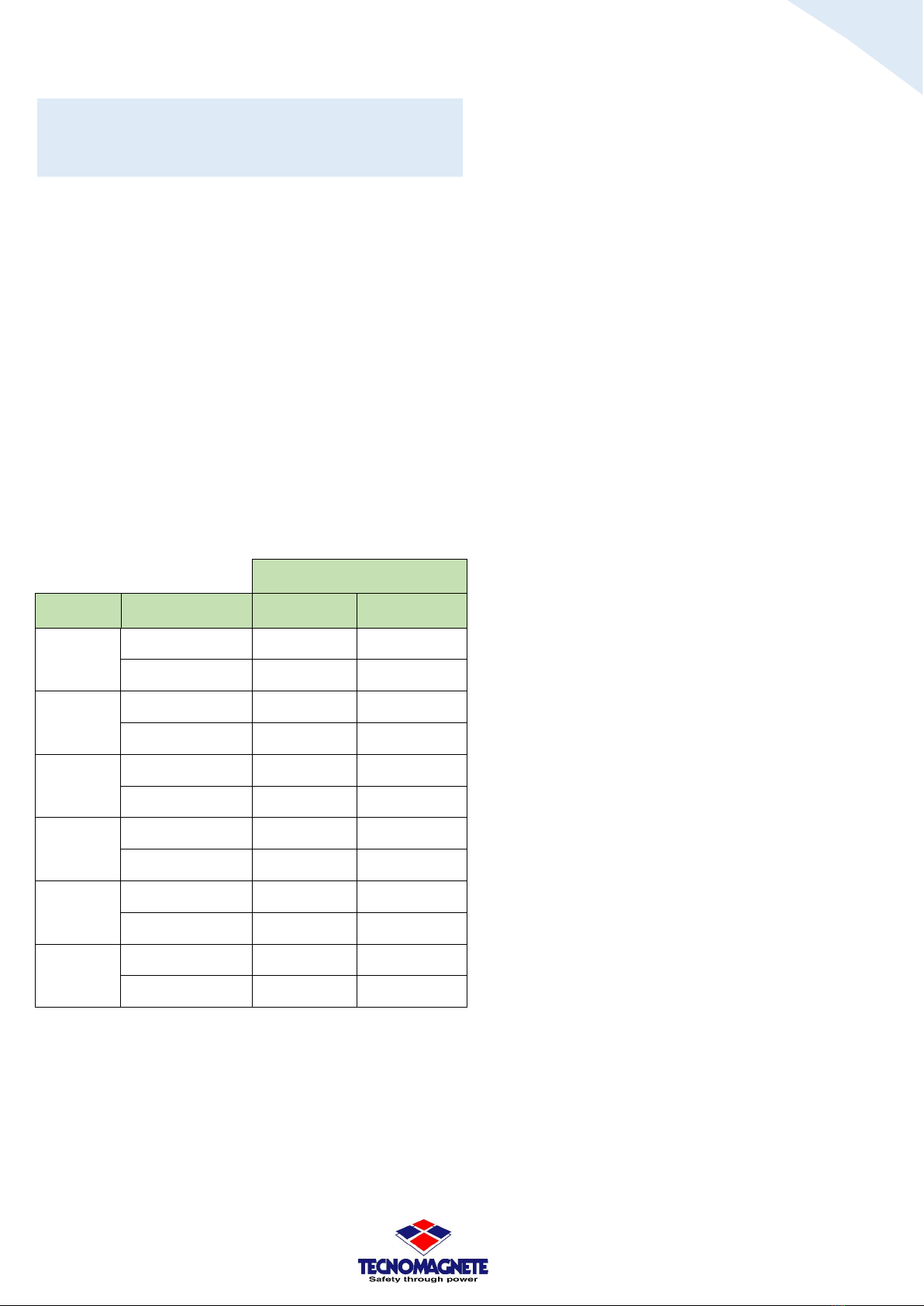

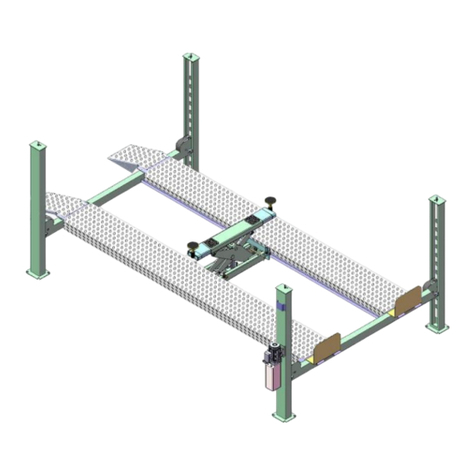

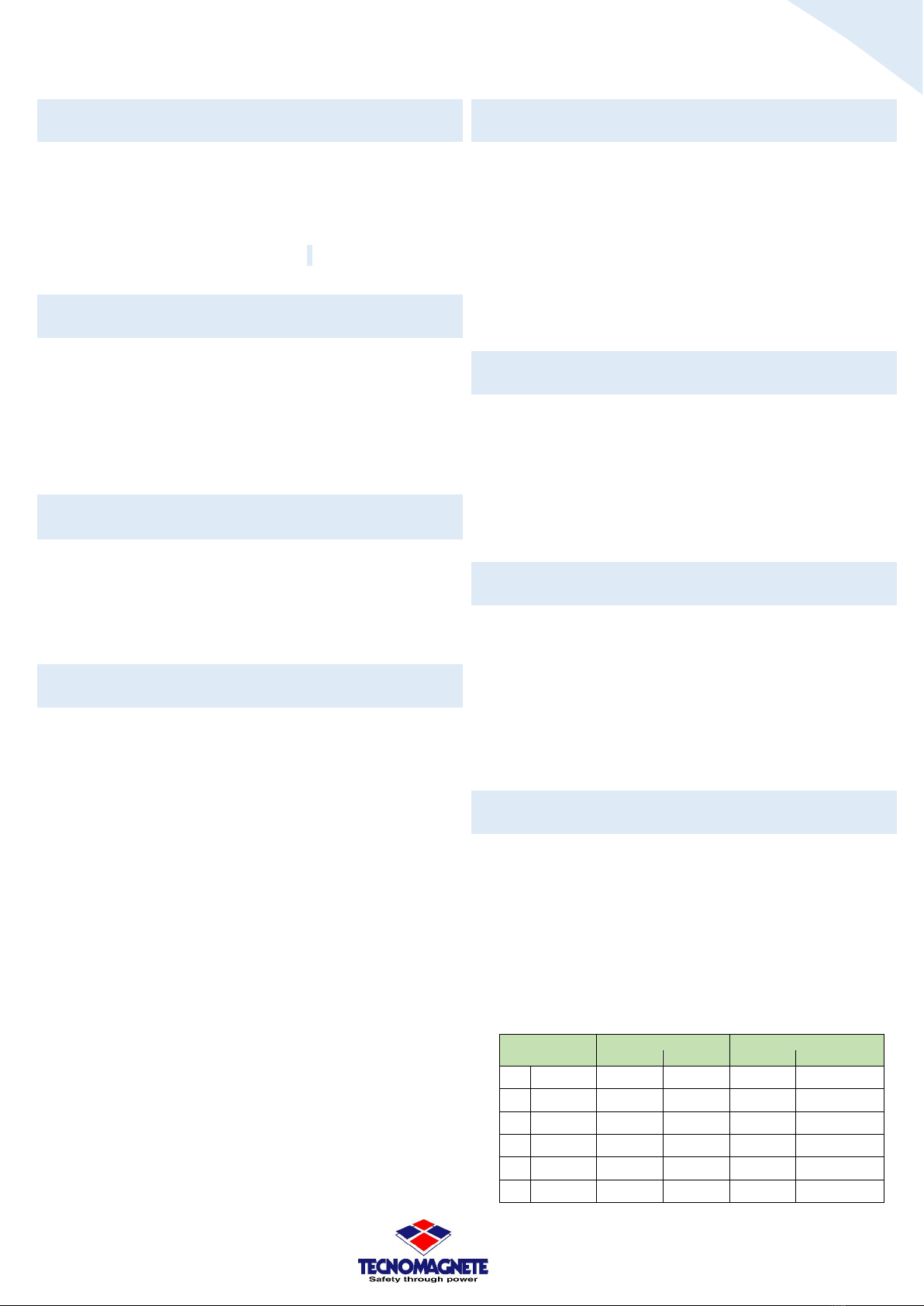

10.10 Tightening of screws

The table Fig.10.10 gives the values for the axial preload P

and the corresponding values for the tightening moments

M to be applied to the screws. The table applies to

hexagonal head screws type UNI 5737-65 and cylindrical

head screws with hexagonal socket type UNI 5931-67.

The chosen friction coefficient is 0.14 valid for machined

surfaces blackened or oiled. The tightening torque must be

applied slowly with torque wrenches.

Fig.10.10

Thread

M 6x1 9000 10,4 15200 17,5

M 8x1,25 16400 24,6 27700 41,6

M 10x1,5 26000 50,1 43900 84,6

M 12x1,75 37800 84,8 63700 143

M 14x2 51500 135 86900 228

M 16x2 70300 205 119000 346