Safety Procedures and Warnings

IMPORTANT: This manual tells you how to carefully and correctly use and operate the

stage.

lRead all parts of this manual before you install or operate the stage or before you do

maintenance to your system.

lTo prevent injury to you and damage to the equipment, obey the precautions in this

manual.

lAll specifications and illustrations are for reference only and were complete and

accurate as of the release of this manual. To find the newest information about this

product, refer to www.aerotech.com.

If you do not understand the information in this manual, contact Aerotech Global

Technical Support.

IMPORTANT: This product has been designed for light industrial manufacturing or

laboratory environments. If the product is used in a manner not specified by the

manufacturer:

lThe protection provided by the equipment could be impaired.

lThe life expectancy of the product could be decreased.

DANGER: To decrease the risk of electrical shock, injury, death, and damage to the

equipment, obey the precautions that follow.

lRestrict access to the stage when it is connected to a power source.

lDo not connect or disconnect electrical components, wires, and cables while this

product is connected to a power source.

lBefore you do maintenance to the equipment, disconnect the electrical power.

lUncouple or otherwise prevent motor-coupled machinery movement when you do

service to the equipment.

lMake sure that all components are grounded correctly and that they obey the local

electrical safety requirements.

lThe drive must contain a properly-sized fuse, matched to the motor cable wire size.

lSupply each operator with the necessary protection from live electrical circuits.

DANGER: Hot surfaces. The case temperature could exceed 70°C.

lDo not touch the motor while it is in operation.

lWait until the motor has cooled before you touch it.

DANGER: The motor is not rated for use in explosive atmospheres. Do not operate the

motor in the presence of potentially explosive mixtures of air-borne dust or

combustible vapors.

IMPORTANT: Equipment grounds must be in place and maintained to reduce the risk

of serious or potentially fatal injury from electric shock.

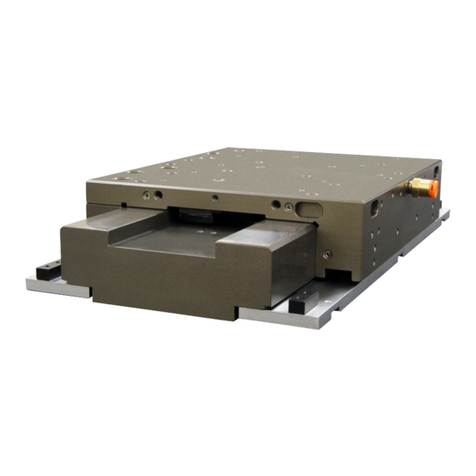

ANT95L Hardware Manual Safety Procedures and Warnings

www.aerotech.com 7