1

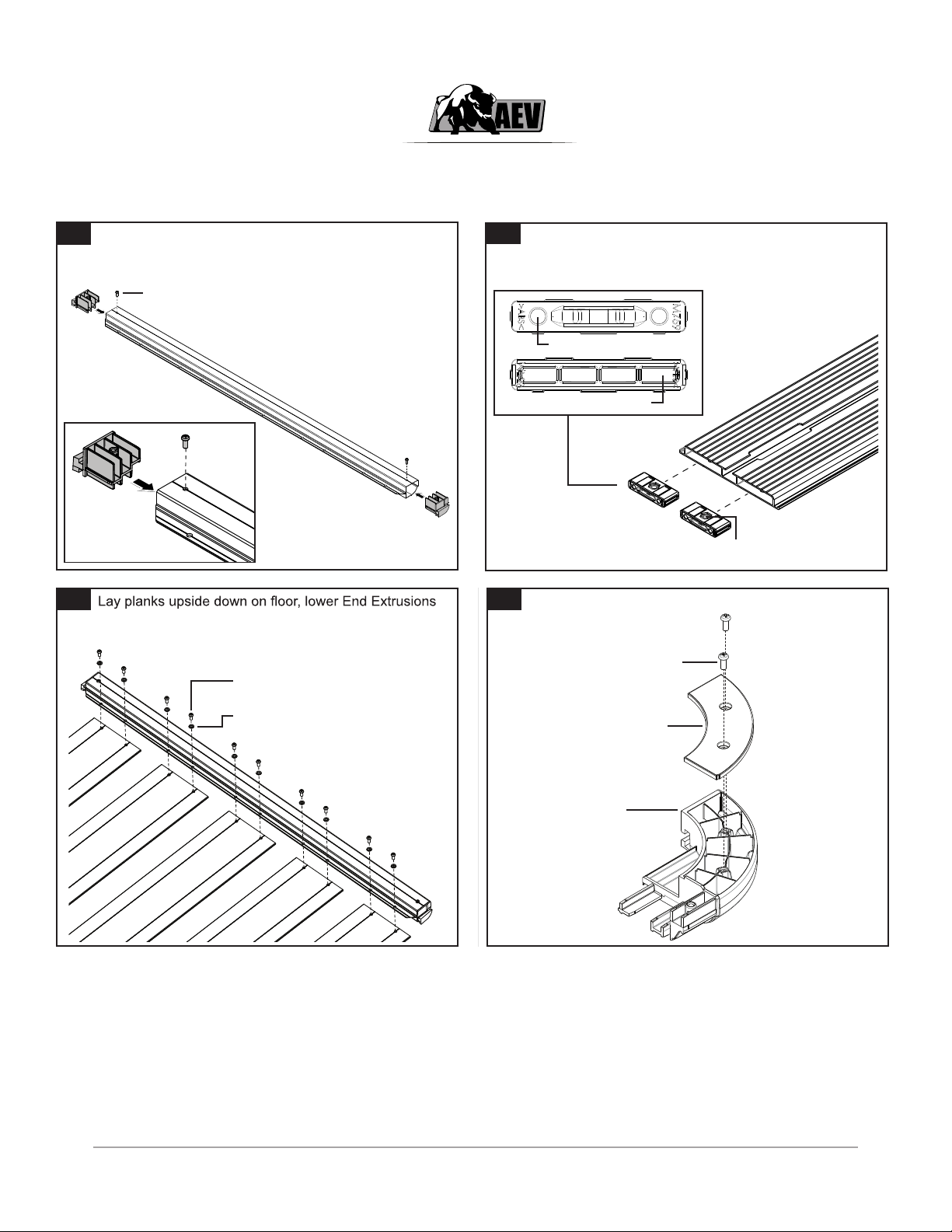

part i. Platform assembly

1Fit Corner T Mouldings to the Frame End extrusions. A

rubber mallet can be used to carefully tap the Moulding

in place.

M5x16mm Plastite Screws.

Fit the Plank Inserts into end of plank at both ends.

Orientation of inserts is critical. Carefully tap the Inserts

into place with a rubber mallet.

2

Nyloc Nuts must face up.

Holes face out.

Faces into Plank.

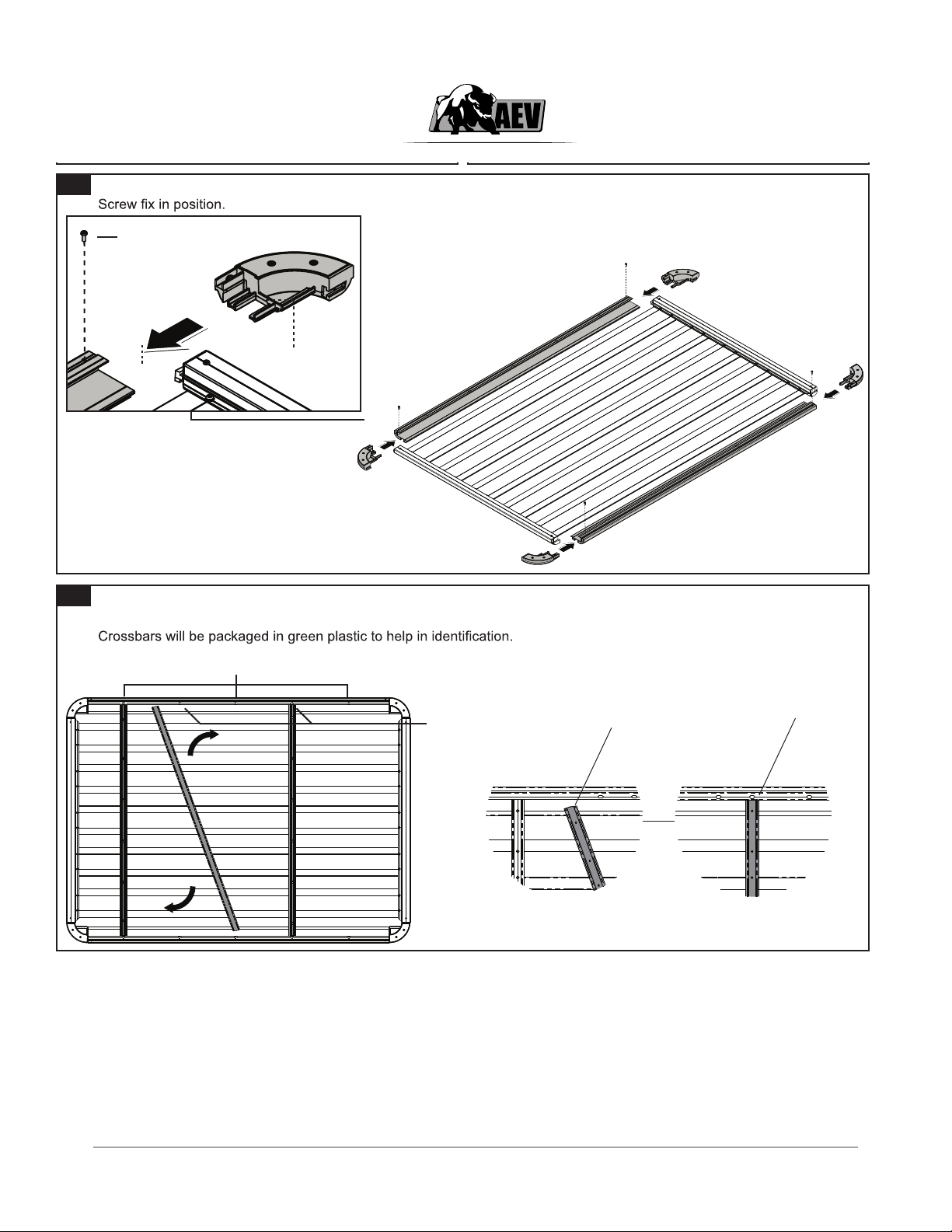

onto planks and fasten together using hardware supplied.

Do the same for the other end.

5

4

Place side extrusions upside down in position, slide corner mouldings onto T moulding and into extrusion simultaneously.

3

Fit all four cover plates to corner mouldings as shown.

M6x16mm Dome Socket

Head Screw.

M6 OD 12.5mm Flat Washer.

Corner Moulding.

Corner Moulding Cover.

M5x16mm Plastite Screw.

M5x16mm Plastite Screws.

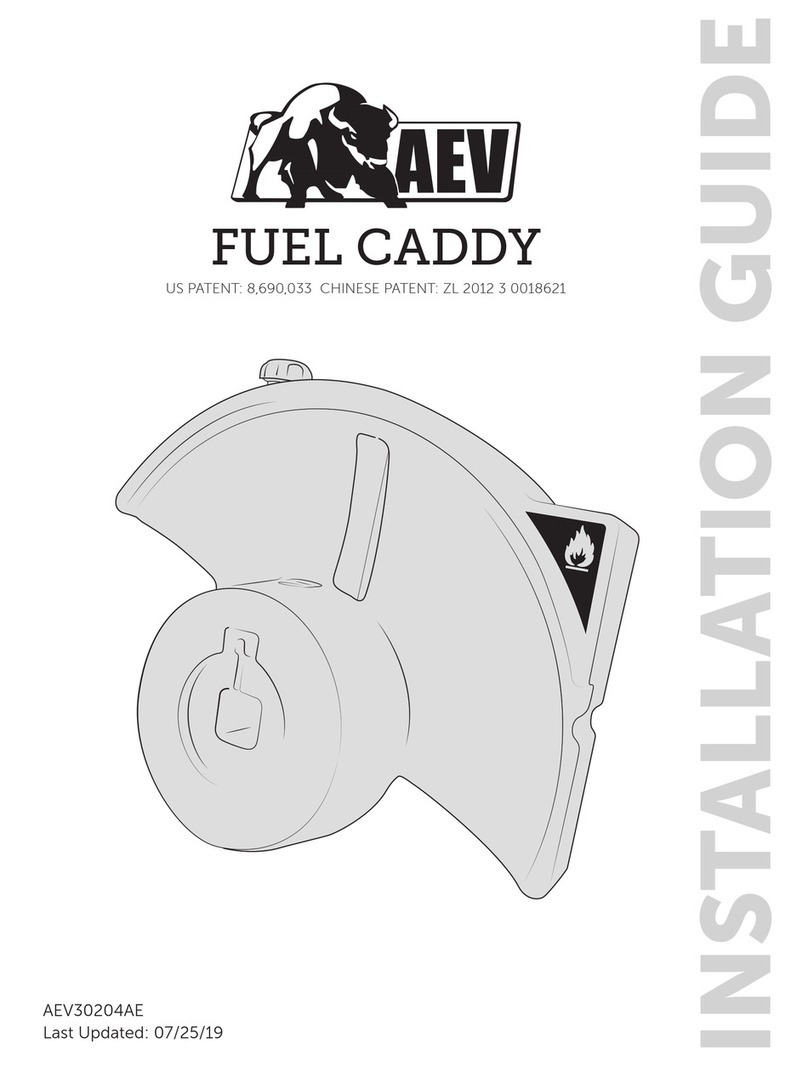

6With the assembly still upside down, place the Crossbars in at an angle and rotate under the lip of the Frame Side

Extrusions. Note: Be sure to use the correct order of Crossbars for the installation as seen bellow ( the AEV Type 1

Before Rotation After Rotation

Cut corners

facing outside

of tray

Crossbar sitting

under bottom lip and

aligned with slot.

Crossbar Type 1 (clear bag)

Crossbar

Type 2

(green bag)

onto planks and fasten together using hardware supplied.

Do the same for the other end.

5

4

Place side extrusions upside down in position, slide corner mouldings onto T moulding and into extrusion simultaneously.

3

Fit all four cover plates to corner mouldings as shown.

M6x16mm Dome Socket

Head Screw.

M6 OD 12.5mm Flat Washer.

Corner Moulding.

Corner Moulding Cover.

M5x16mm Plastite Screw.

M5x16mm Plastite Screws.

6With the assembly still upside down, place the Crossbars in at an angle and rotate under the lip of the Frame Side

Extrusions. Note: Be sure to use the correct order of Crossbars for the installation as seen bellow ( the AEV Type 1

Before Rotation After Rotation

Cut corners

facing outside

of tray

Crossbar sitting

under bottom lip and

aligned with slot.

Crossbar Type 1 (clear bag)

Crossbar

Type 2

(green bag)