AFFINIS GROUP SaniServ AccuFreeze User manual

“Reliability from the team that Serves the Best”

Operation Manual

AccuFreeze Shake Dispensers

SaniServ®

An AFFINIS GROUP Company

Distributor Name: ______________________________________________________

Address: _____________________________________________________________

Phone: _______________________________________________________________

Date of Installation: ____________________________________________________

Model Number: ________________________________________________________

Serial Number: _________________________________________________________

Installer/Service Technician: _____________________________________________

SERVICE: Always contact your SaniServ dealer or

distributor for service questions or service agency

referral. If your SaniServ dealer or distributor cannot

satisfy your service requirements, he is authorized to

contact the factory for resolution.

PARTS: Always order parts from your SaniServ dealer

or distributor. When ordering replacement parts,

specify the part numbers, give the description of the

part, the model number and the serial number of the

machine.

WARRANTY: Remove the Check Test Start (CTS)

form and fill it out in its entirety. Return the original

(white) copy to SaniServ. Dealer/Distributor retain

second (yellow) copy and Owner/Operator retain third

(pink) copy.

The Manufacturer's Limited Warranty is printed on the

reverse side of the Owner/Operator copy.

TO VALIDATE THE WARRANTY, THE CTS FORM

MUST BE COMPLETED AND RETURNED TO THE

FACTORY WITHIN 30 DAYS OF INSTALLATION.

Note: The Check Test Start function must be

performed by a qualified technician.

WARRANTY INFORMATION

I

IMPORTANT

II

Table of Contents

Illustrations

TABLE OF CONTENTS

Installation ......................................................................................................................................................................... 1

Installer’s Preoperational Check........................................................................................................................................ 2

Disassembly and Cleaning ................................................................................................................................................3

Assembly and Lubrication ................................................................................................................................................. 6

Sanitizing ........................................................................................................................................................................... 9

Operation...........................................................................................................................................................................9

Helpful Hints .................................................................................................................................................................... 11

Routine Maintenance....................................................................................................................................................... 12

Consistency Control System ...........................................................................................................................................14

Troubleshooting............................................................................................................................................................... 15

Fig. 1 Leg Installation ................................................................................................................................................... 1

Fig. 2 Control Switch .................................................................................................................................................... 2

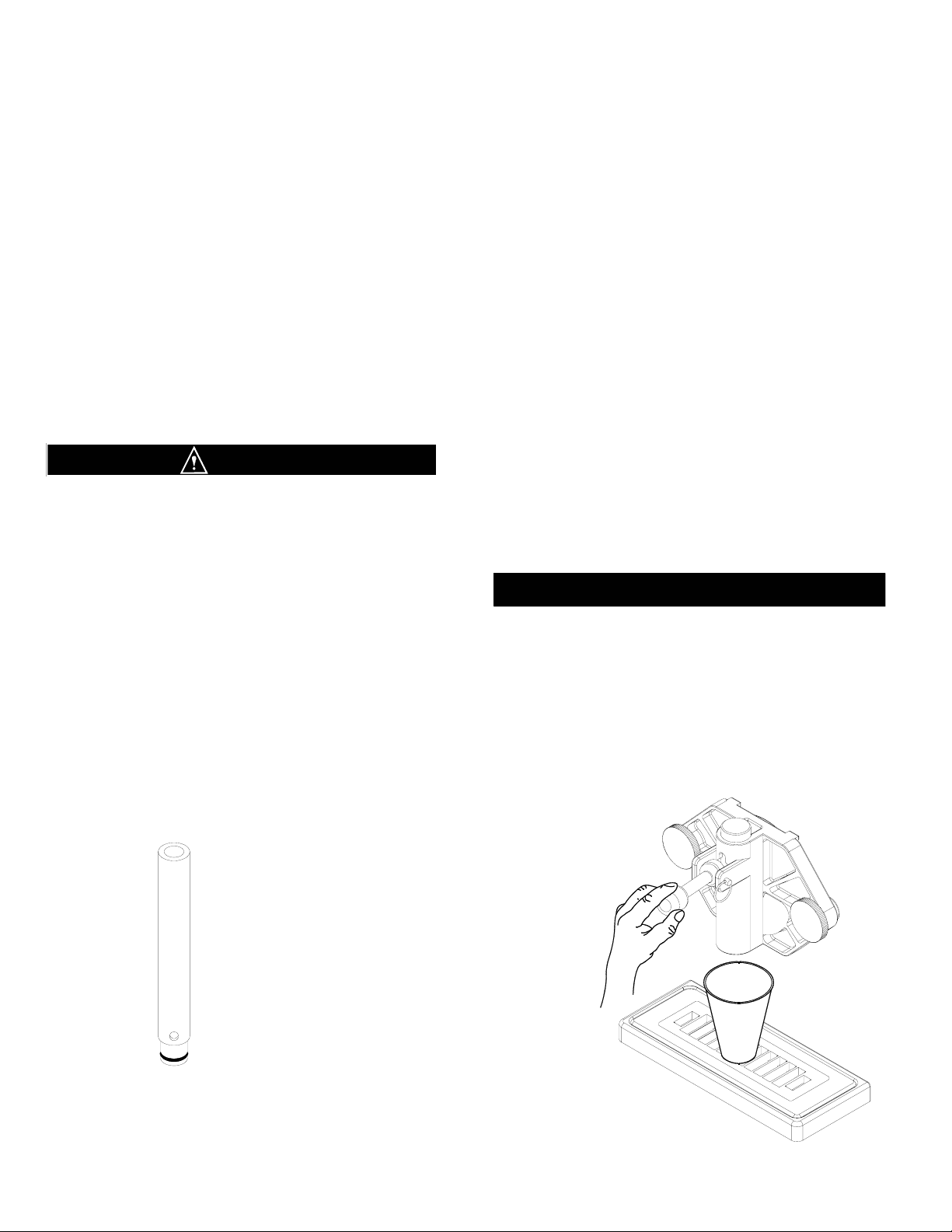

Fig. 3 Carburetor Tube ................................................................................................................................................. 3

Fig. 4 Dispensing Product ............................................................................................................................................3

Fig. 5 Front Plate Assembly ......................................................................................................................................... 4

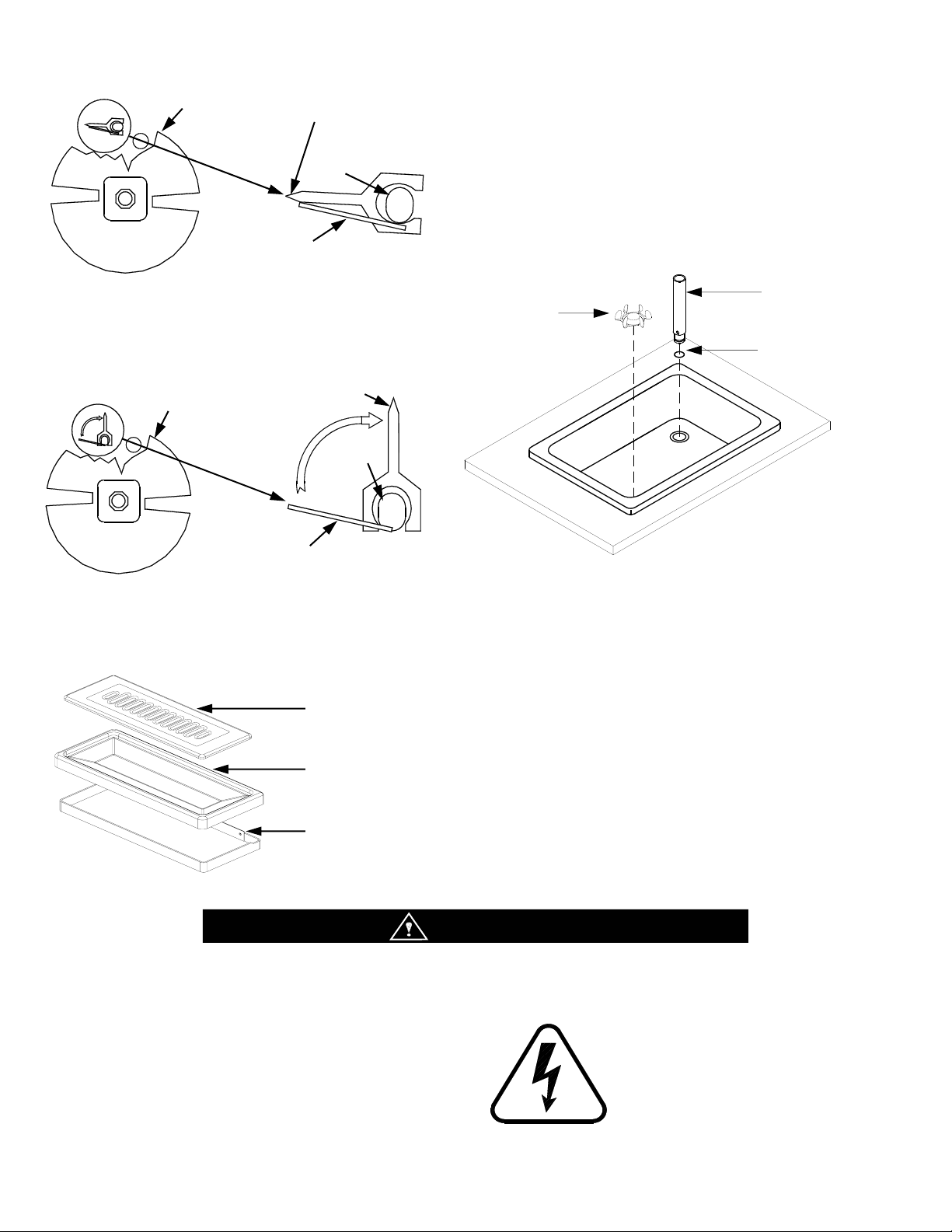

Fig. 6 O-Ring Removal.................................................................................................................................................4

Fig. 7 Carburetor Assembly.......................................................................................................................................... 4

Fig. 8 Dasher Assembly ............................................................................................................................................... 4

Fig. 9a Scraper Blade Removal ..................................................................................................................................... 5

Fig. 9b Scraper Blade Removal ..................................................................................................................................... 5

Fig. 10 Mix Pan Components......................................................................................................................................... 5

Fig. 11 Drip Tray Assembly............................................................................................................................................5

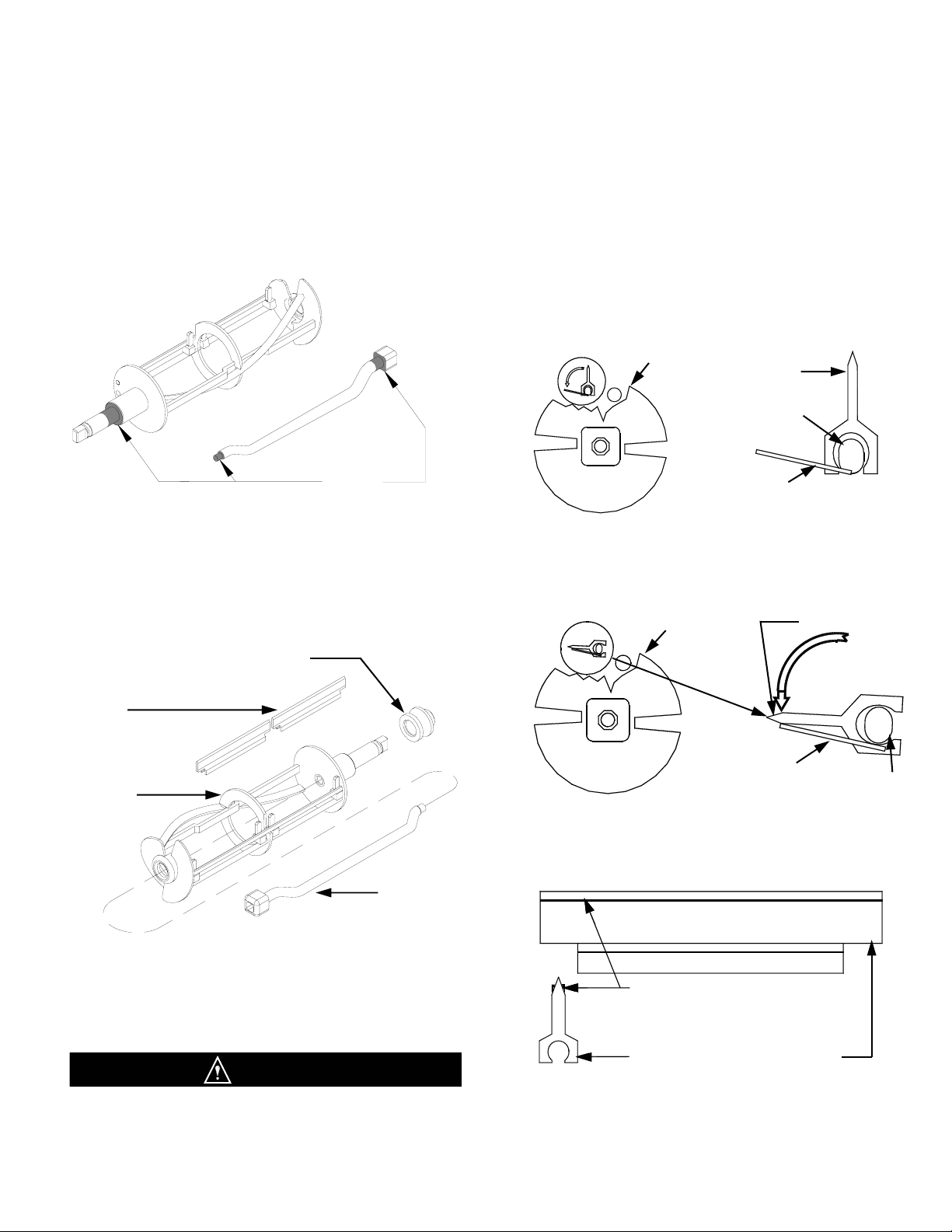

Fig. 12 Stator Rod and Dasher Lubrication .................................................................................................................... 6

Fig. 13 Dasher Assembly ...............................................................................................................................................6

Fig. 14 Scraper Blade Installation and Wear Mark.........................................................................................................6

Fig. 15 Dasher Installation.............................................................................................................................................. 7

Fig. 16 Dasher Installation.............................................................................................................................................. 7

Fig. 17 Dasher (Front View) ...........................................................................................................................................7

Fig. 18 Spigot Plunger Lubrication ................................................................................................................................. 7

Fig. 19 Front Plate Assembly .........................................................................................................................................8

Fig. 20 Mix Pan Assembly..............................................................................................................................................8

Fig. 21 Drip Tray Assembly............................................................................................................................................8

Fig. 22 Carburetor Tube Assembly ................................................................................................................................ 8

Fig. 23 Dispensing Product ............................................................................................................................................ 9

Fig. 24 Control Switch .................................................................................................................................................. 10

Fig. 25 Mix Pan Agitator ...............................................................................................................................................10

Fig. 26 Water Cooled Condenser Valve.......................................................................................................................11

Fig. 27 Scraper Blade Wear Mark ................................................................................................................................ 12

Fig. 28 Drip Chute ........................................................................................................................................................12

Fig. 29 Clean Sharp Condenser Fins........................................................................................................................... 12

Fig. 30 Consistency Adjustment Wiring Box ................................................................................................................ 14

Fig. 31 Consistency Hardness Control.........................................................................................................................14

INTRODUCTION and INSTALLATION

ALWAYS USE A SUFFICIENT NUMBER OF PEOPLE

OR MECHANICAL LIFTING EQUIPMENT TO

PROTECT ALL PERSONNEL FROM PERSONAL

INJURY DURING THE REMAINING STEPS.

1. Raise the machine to install the four legs packed in

the mix pan or the four casters packed in a box on the

skid or on the front mounted drip tray. Be certain all

four are tight! Thread lock is suggested.

2. Carefully lower the machine to the floor and place it

where it will be installed.

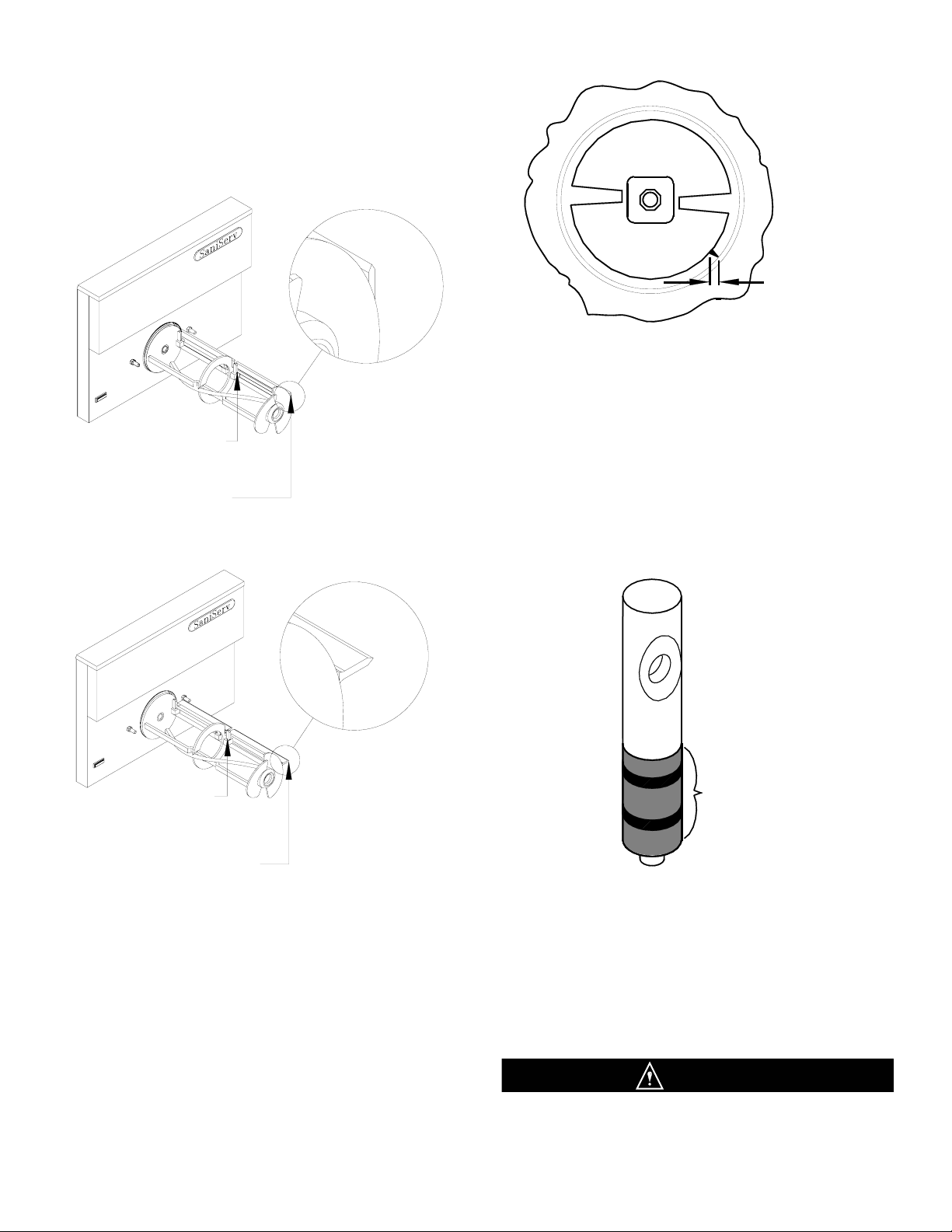

3. Level the unit by turning the bottom part of each leg

clockwise or counterclockwise (Fig. 1). The machine

MUST be level to operate properly.

A MINIMUM 6” (152 MM) CLEARANCE MUST BE

MAINTAINED AT THE REAR AND SIDES OF THE

MACHINE FOR ADEQUATE VENTILATION.

ALWAYS CHECK ELECTRICAL SPECIFlCATIONS

ON THE DATA PLATE OF THE MACHINE. THE

DATA PLATE SPECIFICATIONS WILL ALWAYS

SUPERSEDE THE INFORMATION IN THIS MANUAL.

4. Electrical and refrigeration specifications are

located on the data plate on the rear panel of the

individual machines. Consult local authorities for

information regarding plumbing and electrical codes in

your area. Remove the left and right side panels for

power hook-up.

Note: All SaniServ machines should have their

own dedicated circuits to prevent low voltage

conditions caused by other operating equipment.

5. The water line connections on water-cooled

machines is located on the back side of the

machine. The IN/OUT lines are clearly marked and

equipped with 3/4” garden hose fittings.

FAILURE TO PROVIDE FOR PROPER EARTH

GROUND ACCORDING TO LOCAL ELECTRICAL

CODES COULD RESULT IN SERIOUS ELECTRICAL

SHOCK OR DEATH. DO NOT USE EXTENSION

CORDS. INSTALL THE PROPER SIZE WIRE FOR

THE REQUIRED MACHINE AMPS. BE CERTAIN TO

OBSERVE LOCAL CODES IN SELECTING WIRE OR

CORD SIZE AND TYPE.

DO NOT TURN MACHINE

ON UNTIL THE

INSTALLER’S PRE-

OPERATIONAL

CHECK SECTION IS

COMPLETE.

Installation

Fig. 1

Minimum

Clearance

4”(102 mm) for

This manual provides a general system description of the SaniServ AccuFreeze Shake Dispensers. It has been

prepared to assist in the training of personnel on the proper installation, operation, and maintenance of the machines.

Read and fully understand the instructions in this manual before attempting

to install, operate, or perform routine maintenance on the machines.

The following sections of the manual must be performed in sequence:

1. Installation 4. Assembly & Lubrication

2. Installer's Preoperational Check 5. Sanitizing & Operation

3. Disassembly & Cleaning 6. Consistency Adjustment

Introduction

PAGE 1

WARNING

WARNING

IMPORTANT

Installer’s Preoperational Check

THE FOLLOWING ITEMS MUST BE PERFORMED BEFORE ATTEMPTING TO OPERATE THE EQUIPMENT:

INSTALLERS PREOPERATIONAL CHECK PAGE 2

Fig. 2

Control Switch

AUTO

CLEANOUT

O

F

F

O

F

F

1. Make certain that proper electrical connections have

been made. Plug power cord into power outlet.

2. Set each control switch (Fig. 2) to the “CLEANOUT”

position momentarily to verify the direction of rotation of

the dasher. Looking at the front of the machine, the

dasher should rotate counter-clockwise.

3. Set each control switch to the “OFF” position.

In the event the dasher turns clockwise, STOP and

do not proceed any further

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE UNIT

BE OPERATED IN THE “AUTO” POSITION FOR MORE

THAN THREE MINUTES WITH EMPTY FREEZING

CYLINDERS . DOING SO WILL RESULT IN DAMAGE

TO THE MACHINE.

CAUTION

Emptying Machine

Prior to the disassembly and cleaning of parts, the

machine must be emptied of product. Use the following

procedures (Steps 1 through 3). If this is first time

operation, disregard these steps.

DO NOT INSERT ANY OBJECTS OR TOOLS INTO

THE MIX INLET HOLE, CARBURETOR TUBE HOLE,

OR FRONT PLATE DISPENSING HOLE WHILE THE

MACHINE IS RUNNING. DAMAGE TO THE

MACHINE OR PERSONAL INJURY MAY RESULT.

1. Remove the carburetor tube (Fig. 3) from the mix

inlet hole and lay in the bottom of the mix pan.

2. Set the control switch to the “CLEANOUT” position

and dispense all product from the freezing cylinder by

pulling downward on the spigot handle (Fig. 4) to empty

the machine.

3. Set the control switch to the “OFF” (center) position.

Close the spigot handle before proceeding to cleaning.

Disassembly and Cleaning Procedure

1. Fill the machine with cold water and set the control

switch to the “CLEANOUT” position. DO NOT use

hot water which could damage the machine. Let the

machine agitate briefly and drain the water by pulling

downward on the spigot handle. After the machine is

empty, set the control switch to the “OFF” position.

Repeat the above procedure as necessary to make

certain that all product is removed from the machine.

2. Prepare a suitable detergent and water solution at a

temperature of 125°to 130°F. DO NOT use an

abrasive detergent on any part of the dispenser.

DO NOT USE HOT WATER

DOING SO COULD DAMAGE YOUR MACHINE

3. Fill the mix pan with the cleaning solution. Make

certain that the machine is “OFF”. Clean the mix pan

thoroughly with a brush as the solution drains into the

freezing cylinder. Clean the mix inlet tube and the

carburetor tube holes with the brush provided.

Disassembly & Cleaning

CONSULT YOUR LOCAL HEALTH AGENCY FOR CLEANING AND SANITIZING REQUIREMENTS.

This unit does not come presanitized from the factory. Before serving product, the dispenser must be disassembled,

cleaned, lubricated, and sanitized. These instructions are general guidelines only. Cleaning and sanitizing procedures

must conform to local health agency requirements.

WARNING

DISASSEMBLY & CLEANING

Fig. 3

Carburetor Tube

Fig. 4

Dispensing Product

PAGE 3

IMPORTANT

4. Set the control switch to the “CLEANOUT” position

and agitate for approximately 1 - 2 minutes and then

drain the water by opening the spigot. After the unit is

empty, set the control switch to the “OFF” position.

5. Remove the front plate by turning the black plastic

knobs in a counterclockwise direction (Fig. 5).

Disassemble the front plate in the following manner:

DO NOT USE ANY TOOLS OR SHARP OBJECTS TO

REMOVE ANY O-RINGS FROM THIS MACHINE.

SHARP OBJECTS WILL DAMAGE THE O-RINGS.

a. Remove the faspin and spigot handle.

b. Remove the front plate o-ring.

c. With the spigot handle removed, push the spigot

plunger out the top of the front plate.

d. Remove the o-rings from the spigot plunger by

grasping the part with one hand and with a dry

cloth in the other hand, squeeze the o-ring upward.

When a loop is formed, grasp the o-ring with the

other hand and roll it out of its groove and off the

part (Fig. 6).

6. Remove the carburetor tube (Fig. 7) from the mix

pan. Disassemble and clean in the following manner:

a. Remove the o-ring from the bottom of the carb tube.

b. Clean the inside of the tube with the brush.

7. Remove the dasher assembly (Fig. 8) being careful

not to damage the scraper blades, then disassemble

in the following manner:

a. Remove and take apart the rear seal assembly.

b. Remove the stator rod from the dasher.

C. Remove the blades from the dasher (Fig. 9a)

by first rotating blade upward (Fig. 9b) and then

unsnapping one end from the support rod.

BLADES MUST BE REMOVED FOR CLEANING.

IMPORTANT

DISASSEMBLY & CLEANING

Fig. 5

Face Plate Assembly

Spigot Plunger

Faspin

Spigot

Handle

Front Plate

Front Plate O-ring

DO NOT LUBRICATE

Spigot Plunger

O-rings

Front Plate

Knobs

Fig. 6

O-Ring Removal

Fig. 7

Carburetor Tube Assembly

Scraper

Blade

Rear Seal

Stator Rod

Rear Bearing

Dasher

Fig. 8

Dasher Assembly

PAGE 4

O-ring

Mix

Inlet

Hole

9. Use the small diameter brush to clean all holes and

ports in the parts. DO NOT use an abrasive detergent.

10. After thoroughly washing the parts in the detergent

solution, rinse them in the rinse water. Place the parts

in the sanitizing solution for five (5) minutes and then

air dry to prepare for assembly and lubrication.

DO NOT wipe dry.

11. The remainder of the machine including the mix

pan and freezing cylinder must be cleaned in place

using a mild detergent solution. Clean the exterior with

a damp cloth. DO NOT use an abrasive cleaner on

exterior panels.

Dasher Front

View Scraper Blade

Blade Support

Tab

Support

Rod

Blade Support

Tab

Support

Rod

Dasher Front

View

Scraper Blade

WARNING

DISASSEMBLY & CLEANING

Drip

Drip Tray

Drip Tray

Support

ELECTRICAL

SHOCK HAZARD

Fig. 9a

Scraper Blade Removal

Fig. 9b

Scraper Blade Removal

PAGE 5

WHEN CLEANING THE MACHINE, DO NOT ALLOW EXCESSIVE

AMOUNTS OF WATER AROUND ANY ELECTRICALLY OPERATED COM-

PONENTS OF THE MACHINE. ELECTRICAL SHOCK OR DAMAGE TO

THE MACHINE MAY RESULT.

8. Apply a small amount of SaniGel to the bottom of the

mix pan agitator. Place the lubricated mix pan agitator

into the right front corner of the mix pan. Position the

mix pan agitator until you feel the magnets of the agitator

engage the magnets of the drive system beneath the mix

pan. DO NOT apply lubrication to the Mixout probe

located in the mix pan.

Mix Pan

Agitator

Carburetor

Tube

Carburetor

Tube O-ring

Fig. 10

Mix Pan Components

Fig. 11

Drip Tray

Assembly

1. Lubricate and assemble the dasher assembly in the

following manner:

a. Apply a generous amount of lubricant to the shoulder

of the dasher and the area of the shaft where the white

plastic portion of the assembled rear seal contacts the

shaft (Fig. 12). This is easily performed by running a 1/4”

bead of lubricant around the shoulder of the dasher.

b. Lubricate the two areas of the stator rod (Fig. 12)

and slide the stator rod into the dasher (Fig. 13). Be

certain that the end of the stator rod is inserted into the

hole at the rear of the dasher.

C. Assemble and install the rear seal with the rubber

portion toward the rear of the freezing cylinder as

indicated in Fig. 13.

DO NOT LUBRICATE THE BACK SIDE OF THE

RUBBER PORTION OF THE SEAL ASSEMBLY.

MACHINE COULD BE DAMAGED.

d. Install the scraper blades on the dasher assembly

by holding the blade perpendicular to the tabs

(Fig. 14a) and then snapping them over the flat area of

the support rod. Then rotate the blade downward in a

counterclockwise direction as viewed from the front of

the dasher (Fig. 14b).

Note: Reverse the blades at each cleaning to maintain

sharpness. In addition, the blades are equipped

with a wear mark (Fig. 14c). When the blade is

worn to this wear mark, they must be replaced.

Assembly & Lubrication

Use only food approved lubricants. Haynes Lubri-Filml (SaniServ part number 1150 is recommended and is available

from your local authorized SaniServ dealer or distributor. Lubrication must be performed daily.

Blade Support

Tab

Support Rod

Dasher Front View

Scraper Blade

Dasher Front

View

Blade Support

Tab Support Rod

Scraper Blade

Rotate Down

Counter

Clockwise

Scraper Blade Wear Mark

End

View

Side

View

ASSEMBLY & LUBRICATION

Lubricate

Shaded

Areas

PAGE 6

Fig. 14c

Scraper Blade Wear Mark

Fig. 14a

Scraper Blade Installation

Fig. 14b

Scraper Blade Installation

Fig. 12

Stator Rod and Dasher Lubrication

CAUTION

Scraper

Blade

Dasher

Stator Rod

Rear Seal and Bearing (Assembled)

Fig. 13

Dasher Assembly

e. Insert the dasher assembly into the freezing cylinder

as far as possible (Fig. 15) being careful not to damage

the scraper blades. Damage will occur to the scraper

blades and the dispenser will not operate properly if the

scraper blades are installed facing in a clockwise

direction (Fig. 16).

Fig. 15

Dasher Installation

Fig. 16

Dasher Installation

Note: The stator rod has been deleted from Fig. 15

and Fig. 16 for clarity only. They must be installed

for proper machine operation.

f. While maintaining force against the dasher, rotate it

slowly until the tongue of the dasher engages the

groove in the drive system at the rear of the cylinder.

The outer most portion of the dasher should be

recessed approximately 1/4” to 3/8” inside the freezing

cylinder. No part of the dasher should extend outside

the cylinder. Scraper blades should be visible (Fig. 17)

extending approximately 1/8” beyond the dasher.

.

CORRECT

Blades

Resting On Tabs

Blades Pointing In A

Counterclockwise

Direction

Fig. 17

Dasher with Blade (Front View)

2. Lubricate and assemble the front plate assembly in

the following manner:

a. Install the two o-rings on the spigot plunger by

rolling them onto the plunger. Seat the o-rings in

the grooves. Make certain that they are not twisted.

Smooth the lubricant into the grooves and over

the sides of the plunger assembly (Fig. 18).

Fig. 18

Spigot Plunger Lubrication

b. Slide the lubricated spigot plunger into the front

plate (Fig. 19) Align the spigot handle slot to the front.

c. Insert the spigot handle and secure with the faspin.

d. Install the front plate o-ring.

DO NOT LUBRICATE THE FRONT PLATE O-RING

LUBRICANT WILL MAKE THE FRONT PLATE LEAK

ASSEMBLY & LUBRICATION

Lubricate

Shaded Area

Approximately

1/8” Exposed

Blades Should

Rest On Tabs

Blades Should Not Point

In A Clockwise Direction

INCORRECT

PAGE 7

CAUTION

Fig. 19

Front Plate Assembly

e. Align the front plate to the freezing cylinder, place

the square pocket on the back side of the front plate

over the end of the stator rod, and secure the front

plate assembly to the machine with the two plastic

knobs. Turn both of the knobs in a clockwise direction

simultaneously. Tighten the knobs evenly. DO NOT

tighten one knob all the way down and then the other.

Doing so may result in front plate breakage. Only

moderate force is required. DO NOT over tighten. Set

the spigot plunger to the closed position.

3. DO NOT apply lubrication to the Mix out probe

located in the mix pan - see Fig. 20.

4. Install the drip tray and drip tray insert (Fig. 21).

Fig. 21

Drip Tray Assembly

5. Install the o-ring on the shake carburetor assembly

(Fig. 22). Apply lubricant sparingly over the o-rings.

Place the carburetor tube in the bottom of the mix pan

for sanitizing. Lubricant MUST NOT BLOCK the mix

inlet hole on the carburetor tube.

Fig. 22

Carburetor Tube Assembly

ASSEMBLY & LUBRICATION

Spigot Plunger

Faspin

Spigot

Handle

Front Plate

Front Plate O-ring

DO NOT LUBRICATE

Spigot Plunger

O-rings

Front Plate

Knobs

Drip Tray

Insert

Drip Tray

Drip Tray

Support

Remains

Attached to

Machine

PAGE 8

O-ring

Mix

Inlet

Hole

IMPORTANT

Mixout Probe

Fig. 20

Mix Pan Assembly

6. Proceed directly to the “Sanitizing” section.

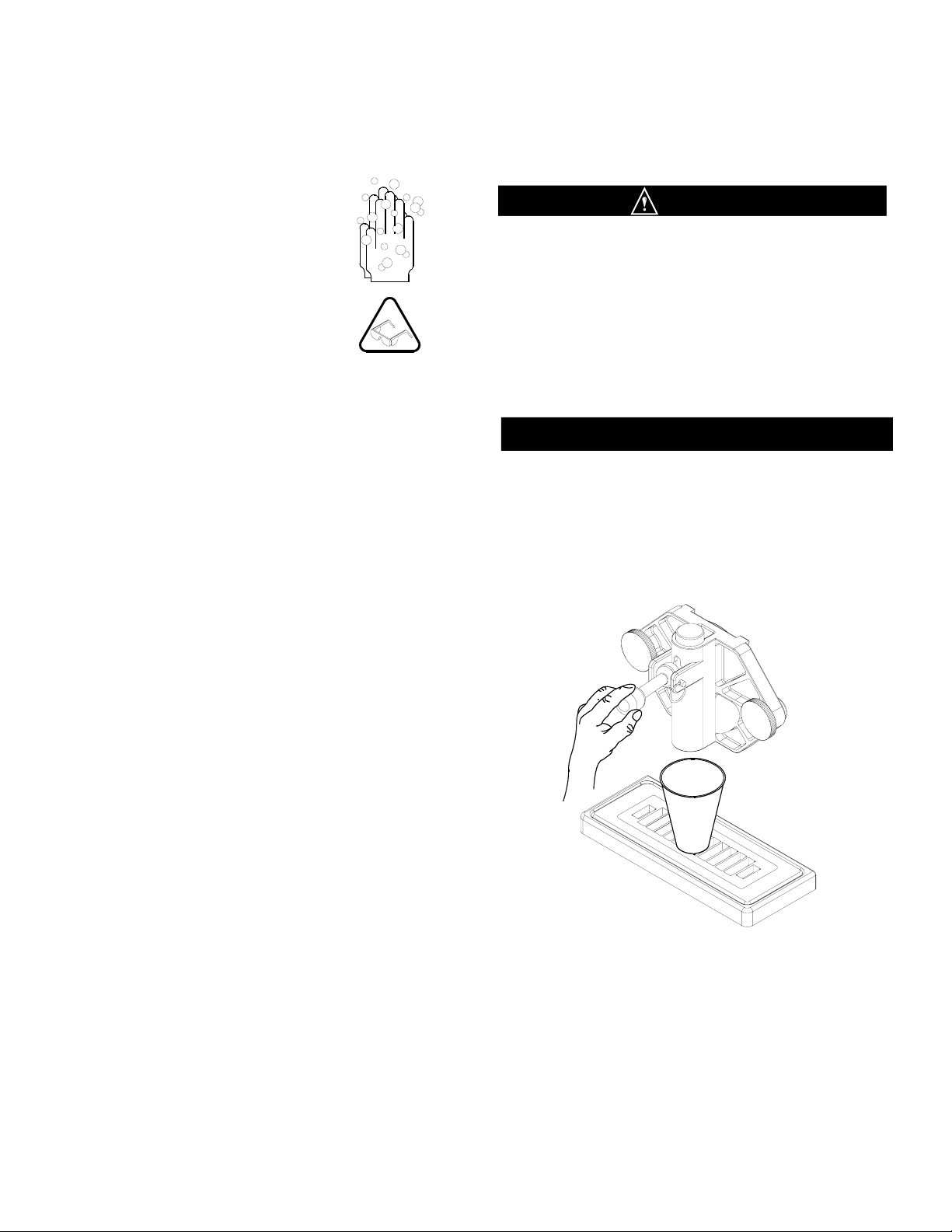

1. Wear eye protection. Wash hands with

a suitable antibacterial soap.

2. Prepare 2 to 3 gallons of sanitizing

solution equivalent to 200 ppm chlorine

residual - check local requirements.

3. Pour the solution into the mix pan.

4. Using a sanitary brush, wipe the

solution onto the sides of the mix pan,

over the mix out probe, and the underside of the lid.

5. Set the control switch to the “CLEANOUT” position

and let the unit agitate for approximately 3 to 5 minutes.

NOTE: DO NOT set the control switch to the “AUTO”

position. Doing so would freeze the sanitizing

DO NOT INSERT ANY TOOLS OR OBJECTS INTO

THE MIX INLET HOLE, CARBURETOR TUBE HOLE,

OR THE DISPENSING HOLE IN THE FRONT PLATE.

DAMAGE TO THE MACHINE OR PERSONAL INJURY

MAY RESULT.

6. Set the control switch to the “OFF” position and

drain the solution from the machine. Proceed directly

to the “Operation” section of this manual.

DO NOT RINSE OUT THE MACHINE

Sanitizing

Prior to operation, the machine must be sanitized. The unit must have already been cleaned and lubricated.

Note: Sanitize immediately before use, not several hours before or the previous evening.

WARNING

IMPORTANT

Operation

Always start with a cleaned and sanitized dispenser as per previous instructions. Use only fresh mix when charging the

units. Following these instructions is critical to the maximum operating efficiency of the machine.

1. Remove the carburetor tube from the bottom of the

mix pan and set aside in a sanitary location.

2. Place a 16 oz. Cup under the spigot and open the

spigot handle. Pour approximately one quart of fresh

product mix into the mix pan. (This will chase the

sanitizing solution from the mix pan and freezing

cylinder.) Close the spigot handle when the sanitizer

is purged from the system. (Fig. 23).

3. Once the sanitizer solution has been purged from

the machine, fill the mix pan full of product mix.

(carburetor tube is not installed). Bubbling is normal.

NOTE: DO NOT POUR SHAKE PRODUCT MIX

DIRECTLY ONTO THE MIX PAN AGITATOR WHEN

YOU FILL THE MACHINE.

Fig. 23

Dispensing Product

PAGE 9

SANITIZING & OPERATION

Prior to proceeding, make sure that the carburetor

tube holes are clean and free of old product debris

or lubricant. A blocked carburetor tube will cause

incorrect product consistency and/or damage the

machine if product should freeze too thick.

4. Once mix pan is at least one-half full, and bubbling

has ceased, install the carburetor tube into the hole in

the mix pan with a gentle twisting motion.

5. Move the control switch to the “AUTO” position

and the unit will start in 3-5 seconds.

6. Allow the compressor to cycle 3-4 times dispensing

a sample of the product after each cycle to check for

consistency. If the machine is not dispensing the

product at the desired consistency after four full cycles,

refer to the Consistency Control Section of this manual.

Initial pull-down time is 10-15 minutes, but may vary

due to product mix and ambient conditions.

8. Replace the mix pan lid and always operate the

machine with the lid on the mix pan reservoir.

There must be product in the mix pan for machine

to start.

NOTE: WHEN REFILLING THE MIX PAN DURING

DAILY OPERATION, DO NOT POUR SHAKE OR

SOFT SERVE MIX DIRECTLY ONTO THE MIX PAN

AGITATOR.

If the agitator stops turning during machine operation,

a. turn off the machine

b. reposition the agitator with a sanitized utensil - see

sanitizing instructions for sanitizing procedure

c. follow the instructions for starting the machine.

PAGE 10

IMPORTANT

Fig. 24

Control Switch

CAUTION

OPERATION

Fig. 25

Mix Pan Agitator

Helpful Hints

HELPFUL HINTS

PAGE 11

Front Plate: This component is the plastic device from

which the product is dispensed. It is designed and

manufactured for strength and durability. However,

through improper use, the front plate can be damaged.

Use the following information for proper care:

a. Do not over tighten the knobs.

b. Always tighten knobs evenly. Do not attempt to

turn one knob all the way down and then one of

the other three knobs. Doing so will bind the front

plate and could result in breakage.

c. Improper installation of the stator rods can cause

breakage. The stator rods must be properly

seated in the dasher before installing the front

plate. If the stator rods are improperly installed,

subsequent tightening of the knobs will break the

front plate.

d. DO NOT attempt to wash the front plate or any

other components in a dishwasher.

Mix Out Light: When the mix out light comes on, the

mix pan is low on mix. The mix pan must be filled with

fresh product mix immediately to prevent air from

entering the freezing cylinder starving the machine and

causing freeze-up and vibration. If this condition occurs,

set the selector switch to the “OFF” position. Remove

the carburetor tube and add mix to the low mix pan until

the freezing cylinder stops bubbling. Replace the

carburetor tube with a gentle twist, then return the

control switch to the “AUTO” position.

Filling: Always fill the machine with fresh product at the

start of each day.

Drip Tray: This should be removed daily and cleaned

to remove residue.

Mix Pan Lid: Be certain to leave the lid in place on top

of the machine to prevent any foreign materials from

contaminating the mix.

Mixing: Make certain that the product mix is prepared

according to label instructions.

Sanitizing: Do not soak plastic parts in sanitizer

overnight. Doing so can cause the plastic parts to

become brittle and lead to premature failure.

Mix Pan Agitator: If the mix pan agitator stops turning

during operation of the machine, turn off the machine,

reposition the agitator with a sanitized utensil, and

follow the instructions for starting the machine.

DO NOT POUR PRODUCT MIX DIRECTLY ONTO

THE AGITATOR WHEN YOU FILL THE MACHINE.

Treat the mix pan agitators as any other small parts

such as the scraper blades. Follow the same cleaning

and sanitizing instructions.

Winter Storage: To protect the unit during seasonal

shut-down, it is important that the dispenser be stored

in the proper manner. Use the following procedures:

1. Turn off ALL power to the machine.

2. Wash all parts that come in contact with the mix

with a warm mild detergent solution. Rinse in clear

water and dry parts thoroughly.

3. Store the loose parts such as the mix pan

components, front plate parts, and the dasher

assembly parts outside of the machine.

4. Do not lay heavy objects on the plastic or rubber

parts.

5. Cover the machine and all loose parts to protect

them from dust or other contaminants while in

storage. Place the machine in a dry location.

6. On water-cooled units, disconnect the water

lines. Use compressed air to blow out all

remaining water in the condenser. Insert a

screwdriver (Fig. 26) to open the water valve.

Note: Failure to purge the machine of water

can result in severe damage to the cooling

system. This task should be performed by a

qualified service technician.

Fig. 26

Water-Cooled

Condenser Valve

Routine Maintenance (Trained Service Technician)

Routine Maintenance (Owner-Operator)

ROUTINE MAINTENANCE

Scraper Blade Wear Mark

End

View

Side

View

Fig. 27

Scraper Blade Wear Mark

CONDENSER FINS ARE VERY SHARP

USE EXTREME CAUTION WHEN CLEANING

Quarterly: Thoroughly clean the condenser fins on all

air-cooled machines. Remove all lint and dust with a

vacuum cleaner or compressed air (Fig. 29) to clean

fins. A dirty condenser greatly reduces refrigeration

capacity and efficiency. When using compressed air,

place a damp cloth on the opposite side of the

condenser to catch the flying dirt or lint.

Annually: Check the belts for signs of wear or cracking.

Remove panels and clean all parts inside of the machine

including the base, side panels, fan blades, condensers,

etc.

Fig. 28

Drip Chute

DISCONNECT THE MACHINE FROM ITS POWER

SOURCE(S) BEFORE PERFORMING ANY ROUTINE

MAINTENANCE. PERSONAL INJURY OR DAMAGE

TO THE MACHINE COULD RESULT IF THIS

PRACTICE IS NOT OBSERVED.

Daily: Inspect the machine for signs of product leaks

past seals and gaskets. If proper assembly does not

stop leaks around gaskets or seals, check for improper

lubrication and worn or damaged parts. Replace parts

as needed.

Periodically: Inspect the scraper blades (Fig. 27) to

see that they are straight and sharp. If worn, damaged

or warped, the blades will not scrape the cylinder walls

correctly and the freezing capacity will be reduced.

Clean the drip chute assembly (Fig. 28) with warm water

and detergent solution.

Fig. 29

Clean Sharp Condenser Fins

WARNING

WARNING

PAGE 12

This page intentionally blank

PAGE 13

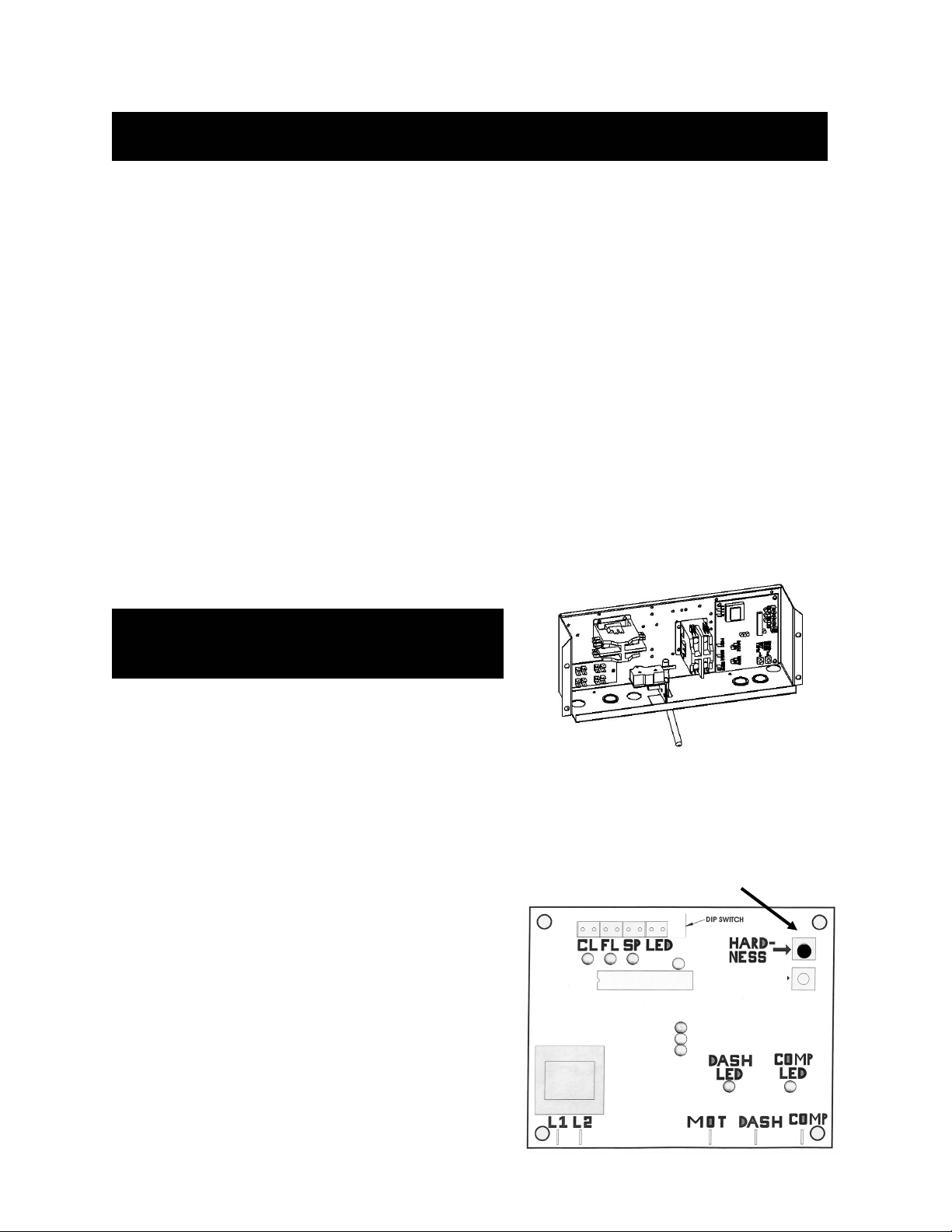

Consistency Adjustment

Consistency adjustment is done by adjusting the

potentiometer on the electronic control board (ECB).

The ECB is located behind the front wiring box cover

above the front dispensing plate.

1. Remove two Phillips screws on the underneath

side of the wiring box cover. The ECB is located

on the left side of the wiring box as show in Fig. 30.

2. Locate the black potentiometer labeled

HARDNESS as shown in Fig. 31. By turning the

potentiometer to the right (clockwise) it will

increase the thickness and lower the product

temperature. Turning the potentiometer to the left

(counter clockwise) will decrease the thickness and

raise the temperature.

3. Reinstall the wiring box cover and reconnect the

power.

4. Run the unit with product and allow the

refrigeration system to cycle TWO times.

5. Draw product from the machine and check for

desired consistency.

6. Repeat procedure if required.

NOTE: ONLY TURN THE POTENTIOMETER IN

SMALL INCREAMENTS.

If you cannot adjust the product consistency to your

desired thickness, contact your local Certified

SaniServ Service Provider.

CONSISTENCY ADJUSTMENT

Fig. 31

Hardness Control

CAUTION

BEFORE PROCEEDING

DISCONNECT THE POWER

Electronic Consistency Control

This machine is designed with an electronic control board to manufacture Frozen Shake Beverage

Only! Do not attempt to operate the machine with other type products. Operating unit with non-

shake products will damage the machine and factory warranty will be voided.

DO NOT ADJUST THE MACHINE!

Improper consistency is due to improperly mixed product

This equipment has been tested at the factory with shake product and has been shipped with FACTORY

PRE-SETS. Shake product temperature will range from 25-28 degrees. If you feel a consistency adjust-

ment is needed, check the temperature of the dispensed product before making an adjustment. If your

product is within these temperature ranges and the consistency is incorrect, you may have improperly

mixed product.

ADJUSTING THE MACHINE TO COMPENSATE FOR IMPROPERLY MIXED PRODUCT MAY CAUSE

PRE-MATURE COMPONENT FAILURE AND MAY VOID WARRANTY.

CAUTION !

PAGE 14

Fig. 30

Wiring Box

SH

TROUBLESHOOTING GUIDE

PAGE 15

Please make these simple checks prior to contacting you service provider. Because adjustments to the machine are not covered

under the terms of warranty, these tips can save you time and money. If you feel you are not comfortable performing trouble-shooting

su

gg

estions

,

p

lease contact

y

our local certified service

p

rovider.

Machine will

not start

Make sure electrical cord is correctly seated in the electrical receptacle.

Check circuit breaker in electrical panel.

Product is

Soft

Do not make a consistency adjustment at this point. Always check product temperature first. Should be

between 25-28 degrees. If using a soft serve product and temperature is lower than listed, product is

broken down. See Product Breakdown in glossary section. Replace with fresh product.

Check for properly mixed product. Replace as necessary

If using Re-run product, remove product and add fresh mix.

Confirm that the carbtube has been installed. Product will not thicken without carbtube.

Check for dull scraper blades. Blades should be sharp. Replace every 6 months.

Check Condenser for dirt or obstructions. See Quarterly Maintenance

Confirm that the condenser fan is running.

Confirm 6” of airflow on all both sides and back of machine.

High ambient temperature. Recommended machine ambient temperature not to exceed 82 degrees.

Product is too

Thick

Check for properly mixed product.

Confirm freezing cylinder is not starved of product. See glossary (Starved Cylinder)

Check product temperature. Should be betwee 25-28 degrees.

Check for missing scraper blade or stator rod. Check dasher assemblies.

Check for sticking spigot lever and or switch. If stuck in the up position, will cause unit to run continually.

Front Plate

Leaking

Confirm front plate o-ring is not ripped or torn. Replace if necessary. Replace seals and o-rings every six

months.

Do not lubricate front plate o-ring.

Confirm spigot plunger o-rings are not ripped or torn. Replace if necessary. Replace every six months.

Confirm spigot plunger o-rings are lubricated daily.

Tighten front plate knobs evenly.

Confirm stator rod is not worn or grooved.

Product

leaking from

the drip chute

and or drip

tube.

Rear Seal is worn. Replace. Note: Replace seals, o-rings and gaskets every six months.

Do Not Lubricate the rubber portion of the rear seal

The shaft of the dasher where the rear seal is installed must be lubricated daily.

Confirm stator rod is not worn or grooved.

Front plate knobs loose.

Squeaking ,

chirping

noises and or

vibration

heard.

Use properly mixed product. Replace as necessary.

Confirm freezing cylinder is not starved of product. See glossary (Starved Cylinder)

Check lubrication

Confirm all panel screws are installed and tightened

Adjust width of drip tray bracket.

Check for dull scraper blades. Blades should be sharp. Replace every 6 months.

Product in

mix-pan too

warm. (soft

serve /shake

machines)

Refrigerate product prior to use.

Confirm storage source of product at 40 degrees or below.

Maintain product level of ½ to ¾ full in mix-pan reservoir.

Confirm magnetic agitator is installed and turning.

Mix-pan lid must be installed at all times to prevent foreign materials contaminating product and to insulate

product in the mix-pan .

Who to

contact for

service and

parts

If you do not have a local service and parts provider, contact your SaniServ Dealer/Distributor. Visit

www.saniserv.com to locate a Distributor (Sales Section) or a Service Agent (Technical Support Section).

Note: Refer to

g

lossar

y

for those items selected in bold.

Standard Units

TROUBLESHOOTING GLOSSARY

Troubleshooting Glossary

Ambient Temperature. The temperature of the air in the immediate vicinity of the operating machine. High am-

bient temperature can reduce the capacity with an air-cooled condenser.

Capacity. The total capacity of frozen product that a freezer can produce in a given period usually stated in gal-

lons per hour (G.P.H.).

Carbtube. Flow control device that allows product and air to be blended together. The air added to the product is

labeled as over-run. The over-run helps provide a thick and rich product. If the carbtube is not used the product

will be heavy, wet, grainy, will not thicken and product temperatures will be lower than the specified 18-21 degrees

soft serve and 25-28 degrees shake. Carbtubes are not used in frozen beverage machines.

Condenser. The part of the refrigeration mechanism that receives hot, high-pressure refrigeration gas from the

compressor and cools gaseous refrigerant until it returns to a liquid state.

Consistency. The viscosity or thickness of the product in the freezing cylinder.

Consistency Control. A control that senses the thickness or viscosity of the product in the freezing cylinder.

Dasher. The part of the freezer that scrapes frozen product off the inside of the freezing cylinder and blends the

product. In a gravity freezer, this assembly also moves the product forward to be dispensed.

Front Plate. Seals the front of the freezing cylinder and provides a means for dispensing the product. On gravity

fed freezers, the front plate indirectly holds the dasher in place via the stator rod. It also provides compression for

the rear seal.

Freezing Cylinder. The part of the refrigeration mechanism in which the refrigerant vaporizes and absorbs heat.

This is the part of the freezer where the liquid product is frozen.

Magnetic Agitator. Installed in the mix-pan reservoir and used to maintain product temperatures and prevent

product separation. The bottom of the agitator must be lubricated.

Mix-pan. Is the top container that product is poured into. It is used as storage until product is needed for the

freezing cylinder. Soft Serve and Shake machines have refrigerated mix-pans to prevent bacteria from forming.

Mixing Product / Product Temperatures. If your using a product that has to be mixed with water or other ingre-

dients, it is imperative the product is mixed consistently everyday. If not, the machine will not run consistent and

could possibly damage components. This is very important with frozen (slush) beverages. Always mix to the

product manufactures recommendations. The machine is designed to operate with a frozen product that falls

within these temperatures (soft serve 18-21 degrees, yogurt 17-20 degrees, shake 25-28 degrees, non-alcoholic

frozen beverage 25-28 degrees and alcoholic frozen beverage 18-22 degrees).

Overrun. The volumetric increase of product from the liquid to the solid state due to the incorporation of air into

the frozen product. Overrun is states as a percentage.

Product Breakdown. The decline in frozen product quality resulting from excess agitation or temperature varia-

tions of product that has been in the freezing cylinder too long. Product, which has broken down, may be grainy,

wet and or heavy. Product breakdown is easily detected by taking the temperature of the dispensed product.

Temperatures will always be lower than recommended product temperatures.

PAGE 16

TROUBLESHOOTING GLOSSARY

Troubleshooting Glossary

Rear Seal. This part is stationary during operation and must not move. When installed and lubed properly, seals

mix in cylinder. When installed and lubed improperly, it causes main shafted bearing failure.

Rerun. The reuse of previously frozen product after it has melted to a liquid. Rerun is obtained when emptying a

freezer for periodic cleaning. Use caution when using rerun as it may contain high bacteria or Coli count, which

could contaminate the fresh mix with which it is combined. Freezers should never be started with rerun. If used at

all, it should be blended with fresh mix at a ratio of seven parts new mix with three parts old mix, after initial

freeze-down with fresh mix.

Scraper Blades. The component that scrapes the frozen product from the freezing cylinder surface. Blades must

be sharp, as dull blades will leave product on the freezing cylinder, insulating the mix from the refrigerant.

Spinner Assembly. An externally installed or internally installed component used to blend a base product with

flavoring or other particulate.

Spigot Plunger. The mechanism on the front plate through which the product is dispensed.

Starved Cylinder. A starved cylinder is often mistaken for a freeze up or product too thick. A starved cylinder

(starving) is created when a larger percentage of frozen product is dispensed from the freezing cylinder than the

percentage of liquid product entering the freezing cylinder from the mix-pan. There are several causes of starving.

1. Overdrawing: Dispensing more product from the machine than it’s designed to do. This would occur if a ma-

chine were undersized for its application.

2. Inserting the carbtube prior to pouring the initial product into the mix-pan at the start of each day. This forms a

vacuum and traps a large percentage of air in the cylinder; therefore the cylinder will not fill with product.

3. When carbtube hole setting is not set on the correct hole size for the amount of product being drawn. Exam-

ple, if several customer dispense product from the machine with the carbtube set on the small hole, it will not

allow the freezing cylinder to be replenished with product in a timely manner. Change carbtube setting to a

larger hole.

4. Carbtube not being cleaned, thus allowing product build-up in the carbtube holes. This restricts product from

entering the freezing cylinder.

5. Mix out light not working therefore not alerting operator the need to add product.

6. Pouring frozen or semi frozen product into the mix-pan reservoir. This will form a blockage in the carbtube

hole and not allow liquid product to flow into the cylinder.

7. Mix-pan too cold, allowing product to freeze in mix-pan and restricting product flow.

Stator Rod. Acts as a bearing surface. Helps enfold air for overrun. Transmits compression to the rear seal.

Helps mechanical torque system sense torque. Be sure to lubricate.

PAGE 17

Table of contents

Other AFFINIS GROUP Dispenser manuals

Popular Dispenser manuals by other brands

Sureshot Dispensing Systems

Sureshot Dispensing Systems AC2-GP Operation manual

Hatco

Hatco ATMOSPHERIC AWD-12 Series Installation and operating manual

Georgia Pacific

Georgia Pacific 54010 reference guide

Toto

Toto TS125R quick start guide

BOWMAN

BOWMAN Signature BD111-0033 Installation

Metasys

Metasys META TOUCH Instructions for use