are factory-assembled and ready for installation.

This manual provides the installation, safety

and operating instructions for the Atmospheric Hot

Water Dispensers. We recommend all installation,

operating and safety instructions appearing in this

manual be read prior to installation or operation

of your Hatco Atmospheric Hot Water Dispenser.

Safety instructions that appear in this manual after

a warning symbol and the words WARNING

or CAUTION printed in bold face are very

important. WARNING means there

is the possibility of serious injury or death

to yourself or others. CAUTION means there

is the possibility of minor or moderate injury.

CAUTION without the symbol signifies the

possibility of equipment or property damage only.

Hatco Atmospheric Hot Water Dispensers

are a product of extensive research and field

testing. The materials used were selected

for maximum durability, attractive appearance

and optimum performance. Every unit is thoroughly

inspected and tested prior to shipment.

i

INTRODUCTION

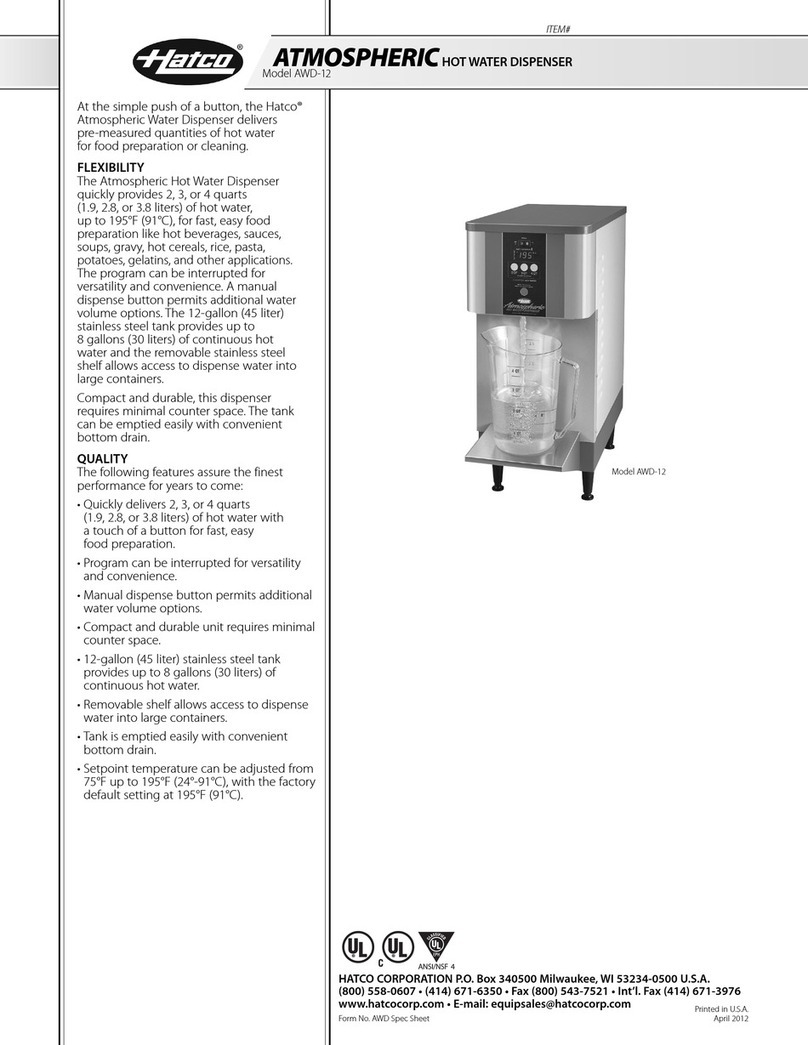

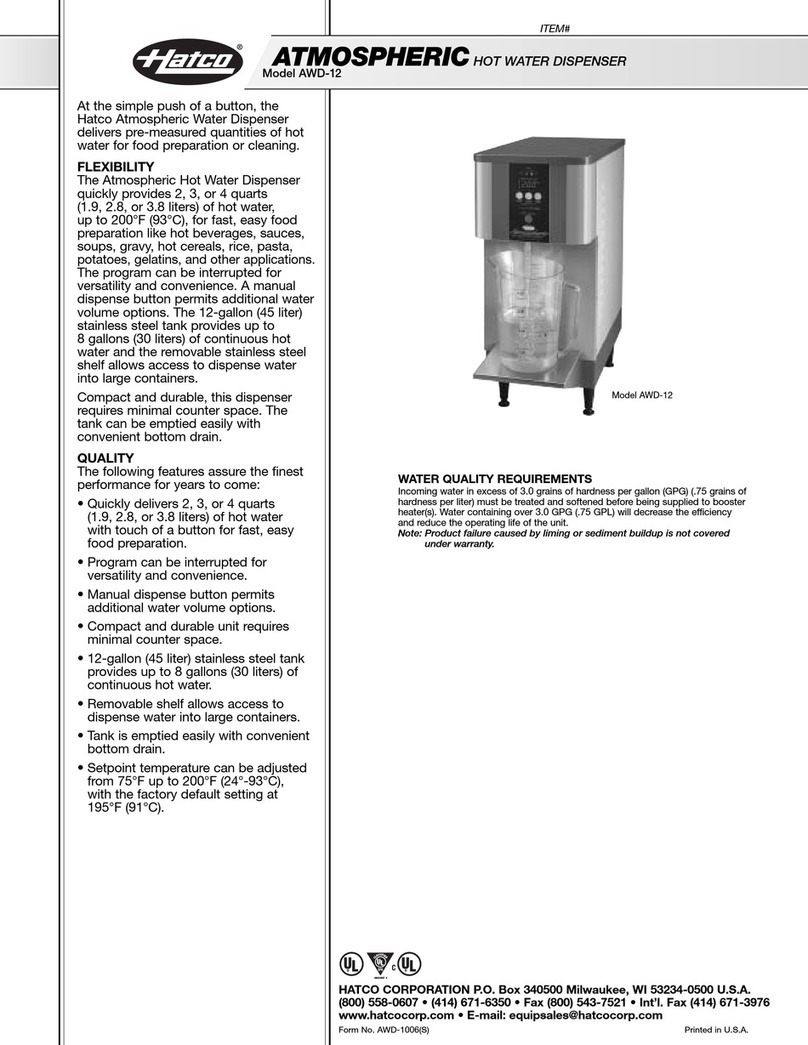

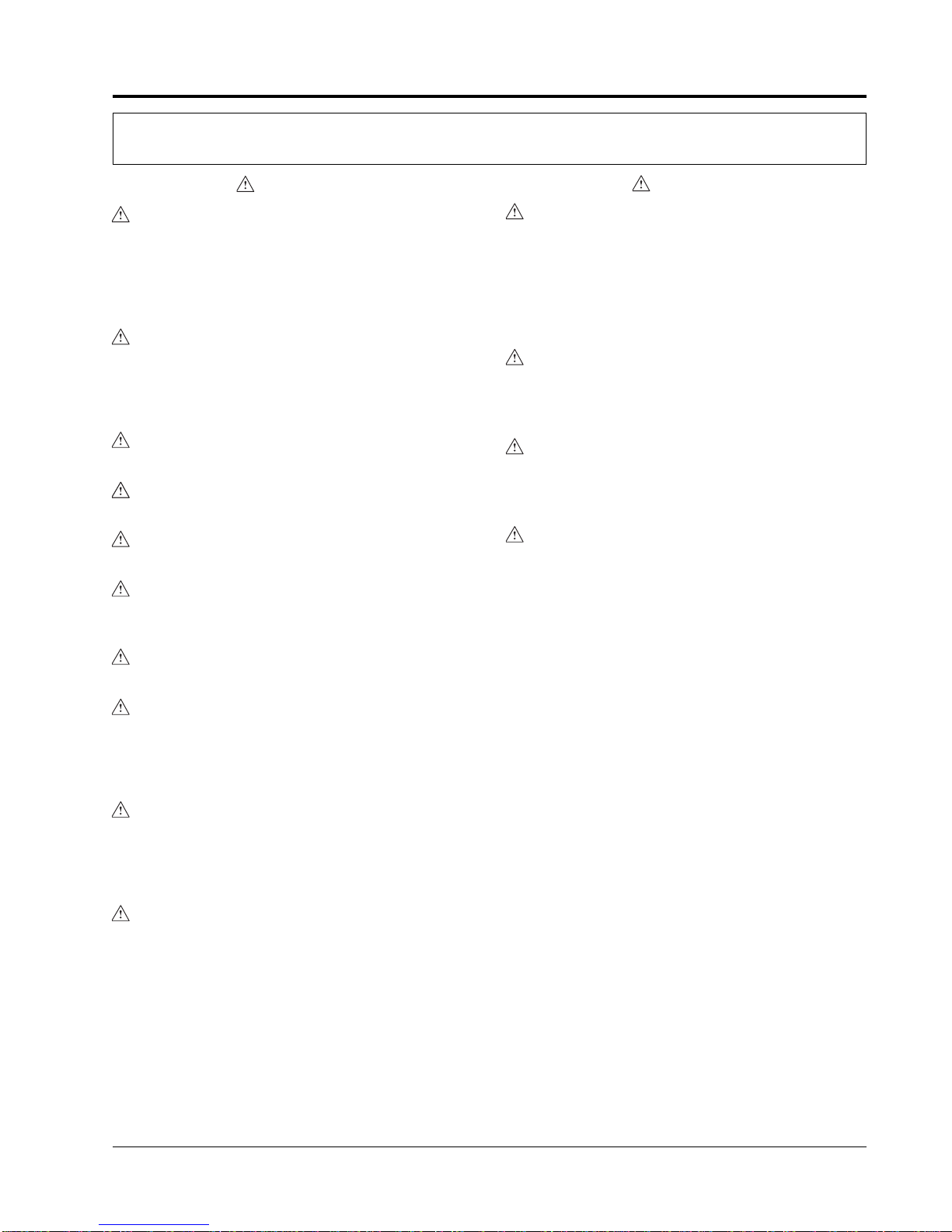

Hatco Atmospheric Hot Water Dispensers are

designed to deliver pre-measured quantities

of hot water for food preparation or cleaning.

A 12 gallon (45 liter) stainless steel tank provides

up to 8 gallons (30 liters) of continuous,

temperature controlled water ranging from

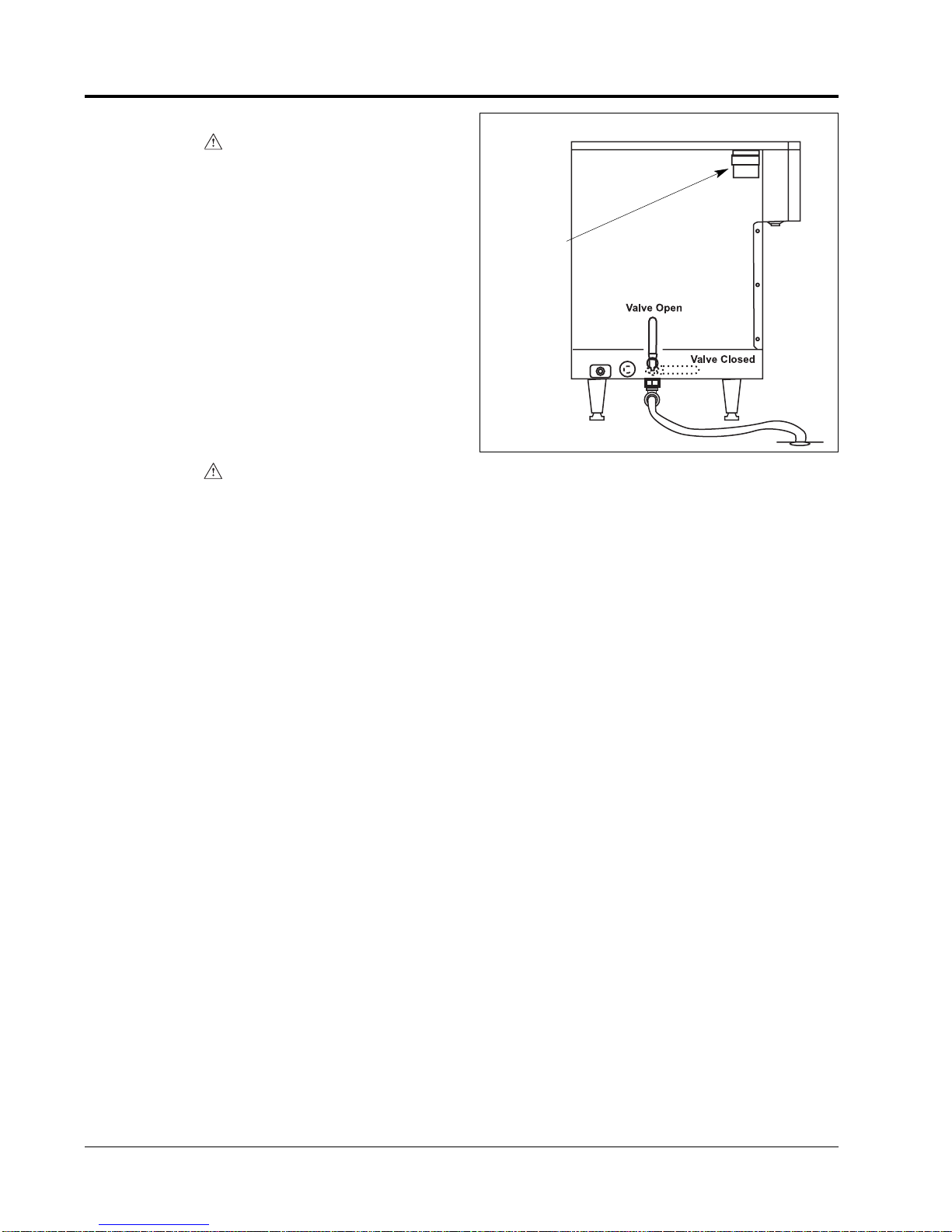

75°–195°F (24°–91°C). The tank may be emptied

easily using the convenient bottom drain.

Hatco Atmospheric Hot Water Dispensers design

features include an electronic temperature

controller with a digital temperature display, On/Off

switch, preset dispenser pushbuttons, including

a manual dispense function.

Standard equipment includes a stainless steel

base, a white granite powder coated body,

4" (10 cm) legs and a 6' (2 mm) electrical cord

and plug. All electric heating elements are metal

sheathed and controlled by a submersed

thermistor. The units are protected with a high-

temperature limit switch and low-water cutoff.

The unit electrical and plumbing connections

CONTENTS

Important Owner Information...............................i

Introduction ...........................................................i

Important Safety Instructions.............................1

Model Descriptions..............................................2

All Models........................................................2

Specifications.......................................................2

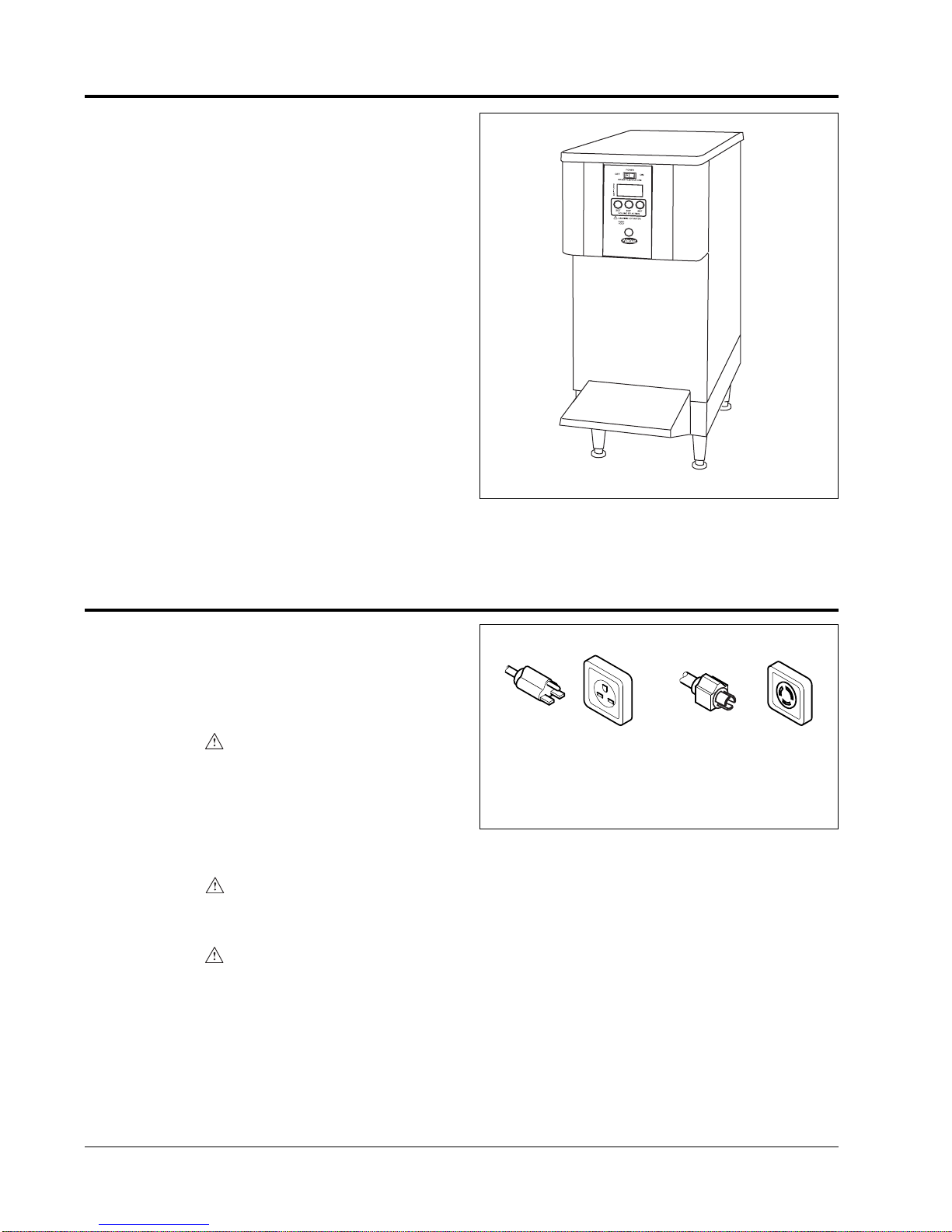

Plug Configurations.........................................2

Electrical Rating Chart ....................................3

Dimensions......................................................3

Statistics..........................................................3

Installation ............................................................4

Location...........................................................4

Plumbing .........................................................4

Electrical..........................................................4

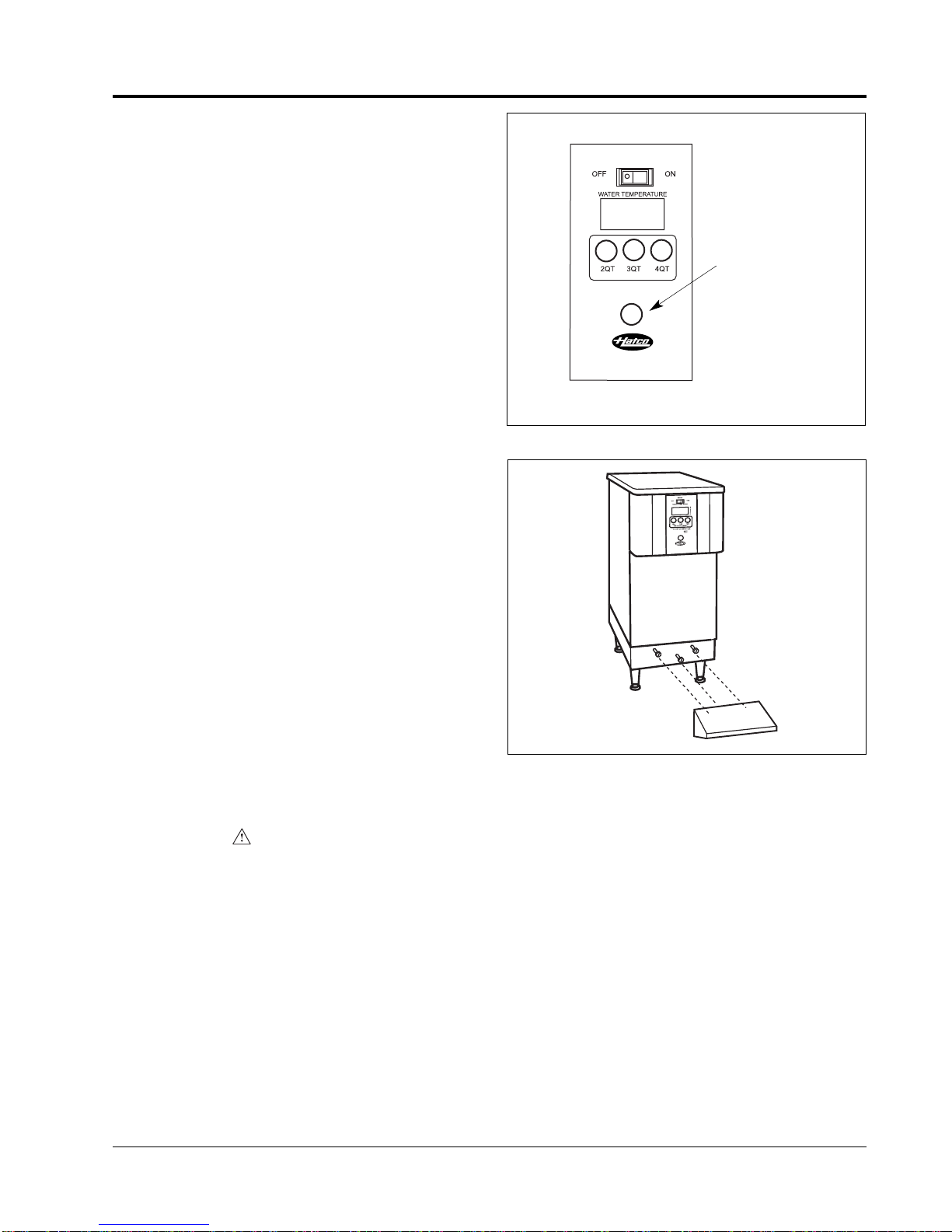

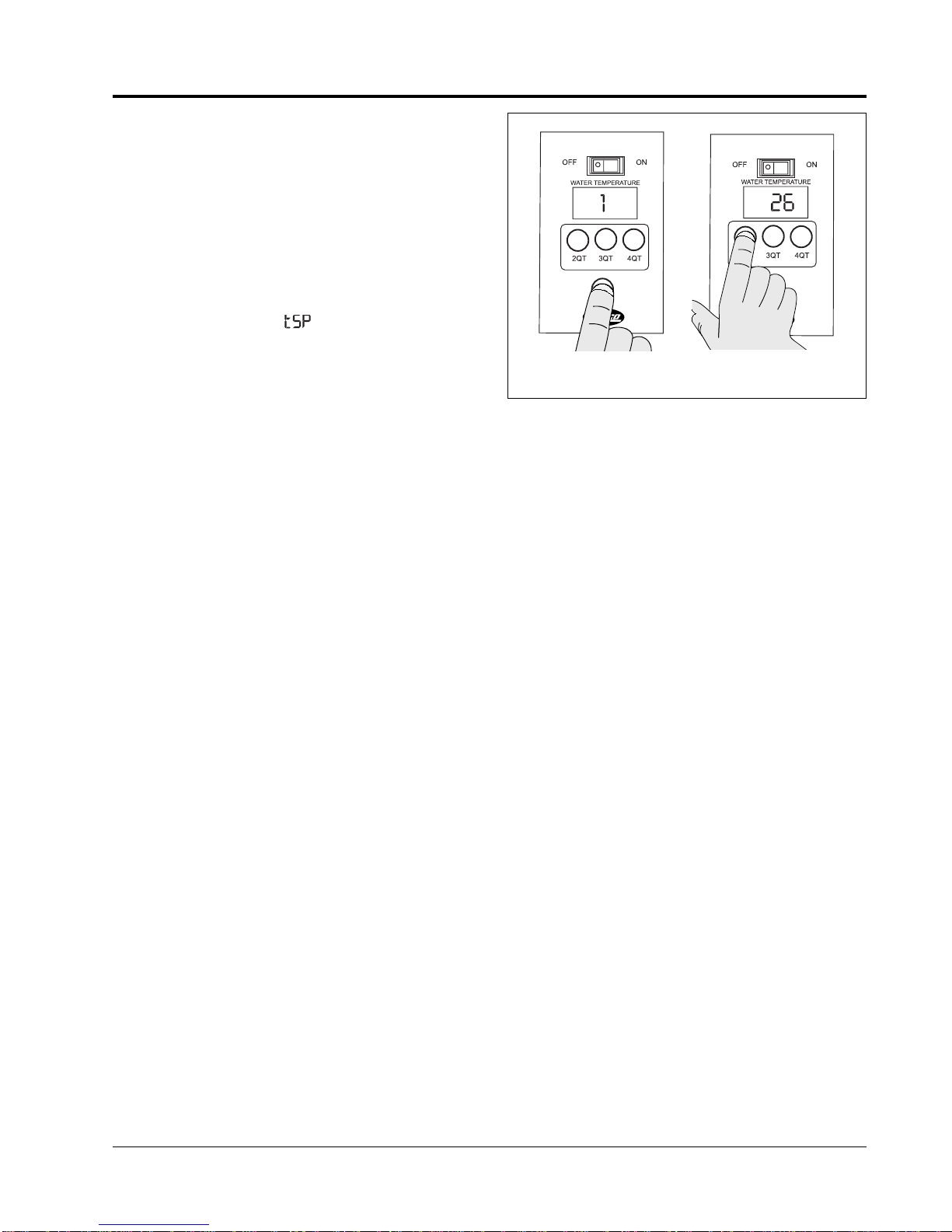

Operation..............................................................5

Start-Up...........................................................5

Dispensing Hot Water .....................................5

Error Codes.....................................................6

Programming the Dispenser ...........................6

Maintenance .........................................................8

General............................................................8

Cleaning Dispenser Exterior ...........................8

Draining the Dispenser....................................8

De-Liming the Dispenser.................................8

Resetting the High Temperature Safety Switch...9

Hatco Limited Warranty.....................................10

Authorized Parts Distributors............Back Cover

IMPORTANT OWNER INFORMATION

Record the model number, serial number

(identification decal located on the lower side

of the unit), voltage and purchase date of your

Atmospheric Hot Water Dispenser in the spaces

below. Please have this information available when

calling Hatco for service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: June to September –

8:00 a.m. to 5:00 p.m. C.D.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.D.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts & Service)

(414) 671-3976 (International)

Additional information can be found by visiting our

web site at www.hatcocorp.com

Form No. AWDM-0704

24-Hour 7-Day Parts & Service

Assistance available in the

United States and Canada

by calling (800) 558-0607.