AFFINIS GROUP SanisServ 500 Series User manual

Operation Manual

500 Series

Soft Serve Twist Dispensers

SaniServ®

An AFFINIS GROUP Company

“Reliability from the team that Serves the Best”

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Distributor Name: _______________________________________________________

Address: ______________________________________________________________

Phone: _______________________________________________________________

Date of Installation: _____________________________________________________

Model Number: ________________________________________________________

Serial Number: _________________________________________________________

Installer/Service Technician: _____________________________________________

SERVICE: Always contact your SaniServ dealer or

distributor for service questions or service agency

referral. If your SaniServ dealer or distributor cannot

satisfy your service requirements, he is authorized to

contact the factory for resolution.

PARTS: Always order parts from your SaniServ dealer

or distributor. When ordering replacement parts, specify

the part numbers, give the description of the part, the

model number and the serial number of the machine.

WARRANTY: Remove the Check Test Start (CTS) form

and fill it out in its entirety. Return the original (white)

copy to SaniServ. The Dealer/Distributor retains the

second (yellow) copy and the Owner/Operator retains the

third (pink) copy.

The Manufacturer's Limited Warranty is printed on the

reverse side of the Owner/Operator copy.

TO VALIDATE THE WARRANTY, THE CTS FORM

MUST BE COMPLETED AND RETURNED TO THE

FACTORY WITHIN 30 DAYS OF INSTALLATION.

Note: The Check Test Start function must be performed

by a qualified technician.

WARRANTY INFORMATION

I

IMPORTANT

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Introduction........................................................................................................................................................................1

Installation..........................................................................................................................................................................1

Installer’s Preoperational Check........................................................................................................................................2

Disassembly and Cleaning................................................................................................................................................3

Assembly and Lubrication .................................................................................................................................................7

Sanitizing & Operation.....................................................................................................................................................10

Consistency Adjustment..................................................................................................................................................12

Routine Maintenance.......................................................................................................................................................13

Helpful Hints ....................................................................................................................................................................14

Troubleshooting...............................................................................................................................................................15

Service Record................................................................................................................................................................16

Fig. 1 Leg Installation...................................................................................................................................................1

Fig. 2 Control Switch....................................................................................................................................................2

Fig. 5 Carburetor Tube ................................................................................................................................................3

Fig. 6 Dispensing Product............................................................................................................................................3

Fig. 7 Front Plate Assembly.........................................................................................................................................4

Fig. 8 Front Plate Gasket Removal..............................................................................................................................4

Fig. 9 Spigot Plunger O-ring Removal..........................................................................................................................4

Fig. 10 Dasher Assemblies ............................................................................................................................................5

Fig. 11 Carburetor Tube ................................................................................................................................................5

Fig. 12 Mix Pan Reservoir Agitator.................................................................................................................................6

Fig. 13 Drip Tray Assembly............................................................................................................................................6

Fig. 14 Front Plate Assembly.........................................................................................................................................6

Fig. 15 Stator Rod and Dasher Lubrication....................................................................................................................7

Fig. 16 Stator Rod and Dasher Assemblies...................................................................................................................7

Fig. 17 Scraper Blade Assembly....................................................................................................................................8

Fig. 18 Dasher (Front View)...........................................................................................................................................8

Fig. 19 Spigot Plunger Lubrication.................................................................................................................................8

Fig. 20 Front Plate Assembly.........................................................................................................................................8

Fig. 21 Front Plate Gasket Installation...........................................................................................................................9

Fig. 22 Front Plate Assembly.........................................................................................................................................9

Fig. 23 Carburetor Tube ................................................................................................................................................9

Fig. 24 Mix Pan Components.........................................................................................................................................9

Fig. 25 Mix Pan Reservoir Mixout Probe.....................................................................................................................10

Fig. 26 Control Switch..................................................................................................................................................10

Fig. 27 Dispensing Product..........................................................................................................................................10

Fig. 29 Control Switch..................................................................................................................................................11

Fig. 30 Electronic Consistency Control Board..............................................................................................................12

Fig. 31 Spring Adjustment Mechanism.........................................................................................................................13

Fig. 32 Water-Cooled Condenser Flow Control Valve .................................................................................................14

Illustrations

Table of Contents

II

TABLE OF CONTENTS

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Introduction

ALWAYS CHECK ELECTRICAL SPECIFlCATIONS

ON THE DATA PLATE OF THE MACHINE. THE DATA

PLATE SPECIFICATIONS WILL ALWAYS

SUPERSEDE THE INFORMATION IN THIS MANUAL.

4. Electrical and refrigeration specifications are

located on the data plate on the rear panel of the

individual machines. Consult local authorities for

information regarding plumbing and electrical codes in

your area. Model 522 has two power hook-ups, 30

amps for single phase or 20 amps for three phase per

side. When operating only the right side on 522 models,

power must be applied to the left side for the cooling

fans to operate. Remove the left and right side panels

for power hook-up.

Note: All SaniServ machines should have their own

dedicated circuits to prevent low voltage conditions

caused by other operating equipment.

5. The water line connections on water-cooled

machines are located on the back side of the machine.

The IN/OUT lines are clearly marked and equipped

with 3/4” garden hose fittings.

Note: These water lines are installed on water-cooled

machines only.

FAILURE TO PROVIDE FOR PROPER EARTH

GROUND ACCORDING TO LOCAL ELECTRICAL

CODES COULD RESULT IN SERIOUS

ELECTRICAL SHOCK OR DEATH.

DO NOT USE EXTENSION CORDS

DO NOT TURN MACHINE ON

INTRODUCTION & INSTALLATION

This manual provides a general system description of the SaniServ Soft Serve Twist Dispensers. It has been prepared to

assist in the training of personnel on the proper installation, operation, and maintenance of the machines.

Please read and fully understand the instructions in this manual before attempting to install, operate, or perform routine

maintenance on the machines.

The following sections of the manual must be performed in sequence:

1. Installation 4. Assembly & Lubrication

2. Installer's Preoperational Check 5. Sanitizing & Operation

3. Disassembly & Cleaning 6. Consistency Adjustment

PAGE 1

IMPORTANT

WARNING

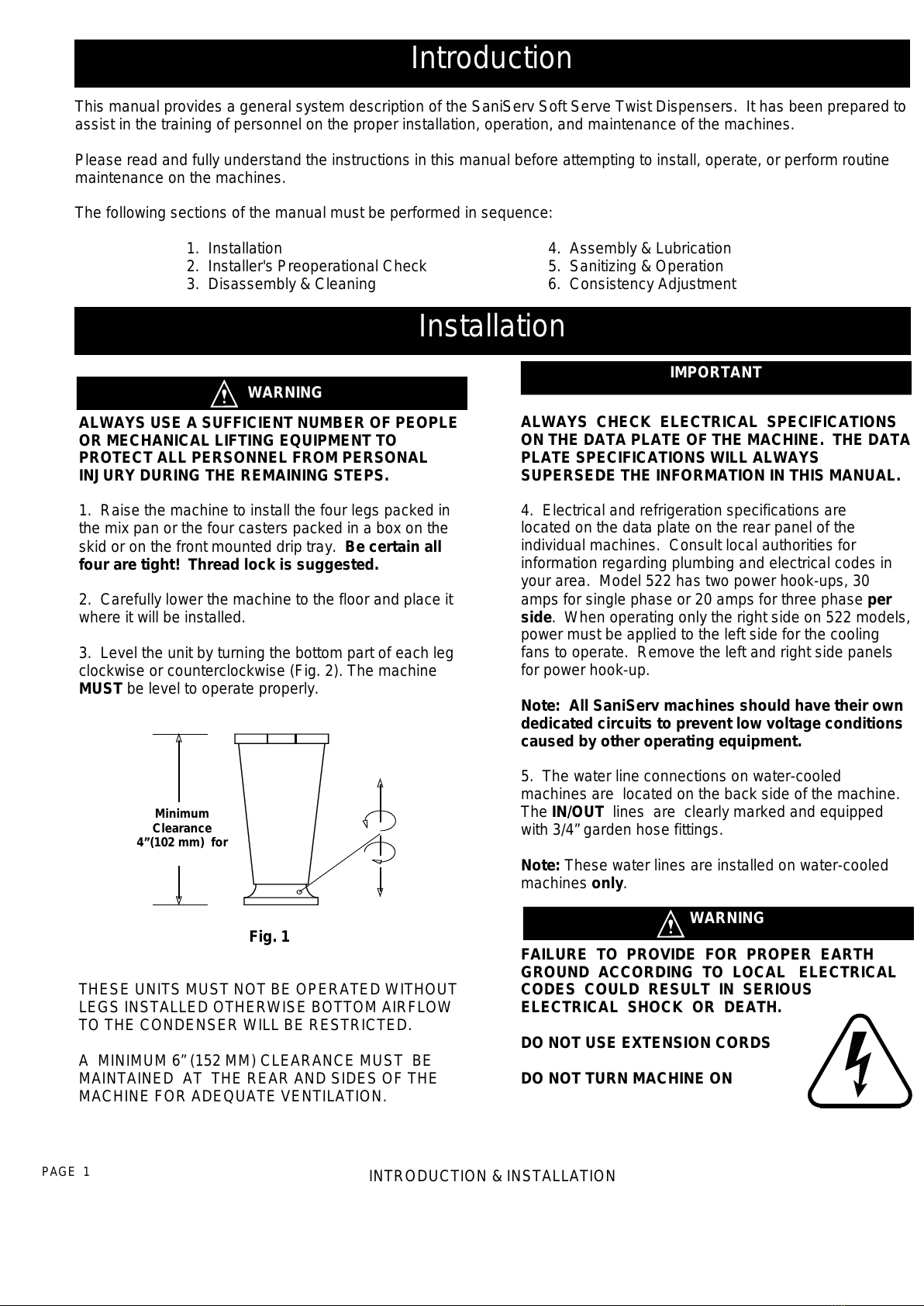

Installation

ALWAYS USE A SUFFICIENT NUMBER OF PEOPLE

OR MECHANICAL LIFTING EQUIPMENT TO

PROTECT ALL PERSONNEL FROM PERSONAL

INJURY DURING THE REMAINING STEPS.

1. Raise the machine to install the four legs packed in

the mix pan or the four casters packed in a box on the

skid or on the front mounted drip tray. Be certain all

four are tight! Thread lock is suggested.

2. Carefully lower the machine to the floor and place it

where it will be installed.

3. Level the unit by turning the bottom part of each leg

clockwise or counterclockwise (Fig. 2). The machine

MUST be level to operate properly.

THESE UNITS MUST NOT BE OPERATED WITHOUT

LEGS INSTALLED OTHERWISE BOTTOM AIRFLOW

TO THE CONDENSER WILL BE RESTRICTED.

A MINIMUM 6” (152 MM) CLEARANCE MUST BE

MAINTAINED AT THE REAR AND SIDES OF THE

MACHINE FOR ADEQUATE VENTILATION.

Fig. 1

Minimum

Clearance

4”(102 mm) for

WARNING

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Installer’s Preoperational Check

THE FOLLOWING ITEMS MUST BE PERFORMED BEFORE ATTEMPTING TO OPERATE THE EQUIPMENT.

INSTALLER’S PREOPERATIONAL CHECK PAGE 2

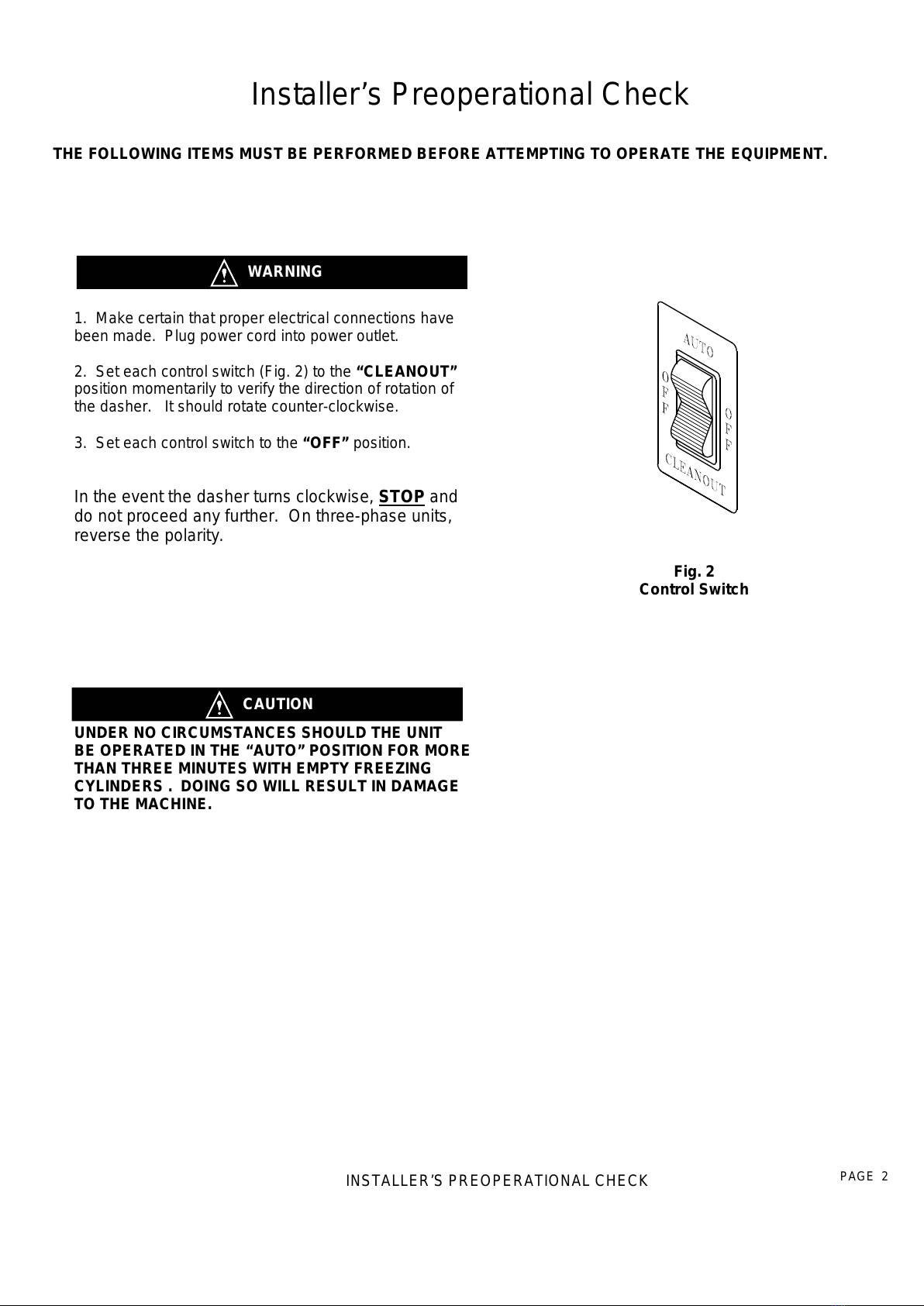

Fig. 2

Control Switch

1. Make certain that proper electrical connections have

been made. Plug power cord into power outlet.

2. Set each control switch (Fig. 2) to the “CLEANOUT”

position momentarily to verify the direction of rotation of

the dasher. It should rotate counter-clockwise.

3. Set each control switch to the “OFF” position.

In the event the dasher turns clockwise, STOP and

do not proceed any further. On three-phase units,

reverse the polarity.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE UNIT

BE OPERATED IN THE “AUTO” POSITION FOR MORE

THAN THREE MINUTES WITH EMPTY FREEZING

CYLINDERS . DOING SO WILL RESULT IN DAMAGE

TO THE MACHINE.

CAUTION

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Table of contents

Other AFFINIS GROUP Dispenser manuals

Popular Dispenser manuals by other brands

BOWMAN

BOWMAN CL003-0111 manual

SIKA

SIKA Power Cure operating instructions

Silver King

Silver King Majestic SK12MAJ Technical manual and replacement parts list

Franke

Franke F3Dn Twin Service manual

HURAKAN

HURAKAN HKN-MT1 manual

STIEBEL ELTRON

STIEBEL ELTRON UltraHot Plus Operation and installation instructions