Afriso EURO-INDEX NB 220 User manual

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Umweltschutz

Lindenstraße 20

74363 Güglingen

Telefon

+49 7135 102-0

Service

+49 7135-102-211

Telefax

+49 7135-102-147

info@afriso.de

www.afriso.de

Read instructions before using device!

Observe all safety information!

Keep instructions for future use!

09.2013 0

854.001.0288

Operating instructions

Overfill prevention system

NB 220

Transducer:

NB 220 H (AC 230 V) # 53210

NB 220 H (DC 24 V) # 53219

NB 220 QS # 53213

NB 220 QSA # 53231

Level probe type 76 .. # 532..

Level probe UFS 01 # 53243-49

Overfill

prevention

system

Z-65.11-193

2 NB 220

Table of contents

1This instruction manual............................................................................................4

1.1 Precautions ..................................................................................................4

1.2 Explanation of symbols and typeface ..........................................................4

2Safety.......................................................................................................................5

2.1 Intended use.................................................................................................5

2.2 Predictable incorrect application..................................................................6

2.3 Safe handling ...............................................................................................6

2.4 Staff qualification..........................................................................................6

2.5 Modifications to the product .........................................................................7

2.6 Usage of spare parts and accessories.........................................................7

2.7 Liability information ......................................................................................7

3Product description..................................................................................................7

3.1 Function........................................................................................................8

3.2 Operating modes........................................................................................10

3.3 Application examples .................................................................................10

3.4 Versions .....................................................................................................11

4Technical specifications.........................................................................................12

4.1 Level probe.................................................................................................12

4.2 Dimensional drawings and technical specifications...................................15

4.3 Approvals, tests and conformities..............................................................17

5Transport and storage...........................................................................................18

6Mounting and commissioning................................................................................18

6.1 Mounting the level probe............................................................................18

6.2 Adjusting the level probe............................................................................19

6.3 Mounting the transducer ............................................................................20

6.4 Electrical connection ..................................................................................22

6.5 Commissioning the device .........................................................................23

6.6 Function test...............................................................................................24

7Operation...............................................................................................................25

8Maintenance..........................................................................................................25

9Troubleshooting.....................................................................................................26

10 Decommissioning, disposal...................................................................................26

11 Spare parts and accessories.................................................................................27

12 Warranty................................................................................................................27

13 Copyright ...............................................................................................................27

14 Customer satisfaction............................................................................................27

NB 220 3

15 Addresses..............................................................................................................27

16 Appendix................................................................................................................28

16.1 Certificate of expert....................................................................................28

16.2 Approval documents...................................................................................29

This instruction manual

4 NB 220

1 This instruction manual

This instruction manual is part of the product.

Read this manual before using the product.

Keep this manual during the entire service life of the product

and always have it readily available for reference.

Always hand this manual over to future owners or users of the

product.

1.1 Precautions

WARNING TERM

Type and source of the danger are shown here.

Precautions to take in order to avoid the danger are shown

here.

There are three different levels of warnings:

Warning term Meaning

DANGER Immediately imminent danger!

Failure to observe the information will result in

death or severe injuries.

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or severe injuries.

CAUTION Dangerous situation!

Failure to observe the information may result in

minor or severe injuries as well as damage to

property.

1.2 Explanation of symbols and typeface

Symbol Meaning

Prerequisite for an activity

Activity consisting of a single step

1.

Activity consisting of a several steps

Result of an activity

•

Bulleted list

Text

Indication on display

Highlighting Highlighting

Safety

NB 220 5

2 Safety

2.1 Intended use

The overfill prevention system NB 220, consisting of a transducer

and a level probe, may only be used to avoid overfilling of contain-

ers.

The overfill prevention system NB 220 is only suitable for operation

with stationary containers and stationary-use containers used for the

storage of the following liquids.

•Fuel oil EL as per DIN 51603-1

•Diesel fuel as per EN 590

•Biodiesel as per EN 14214

•Diesel/biodiesel mixtures as per DIN 51628

•Used gear and engine oils

•Hexanol 1

•Ethyl aceto-acetate (aceto-acetic ester)

•Acrylic acid 2-ethyl hexylene ester (2-ethyl hexylene acrylate)

•Cyclohexanol acetate

•Benzaldehyde

•Methyl aceto-acetate

•Nitrobenzene

•1.2-dichlorobenzene

•2.4 dimethylaniline (N, N dimethylaniline)

•n octanol (n octyl alcohol)

•Diethyloxalate

•Aniline

•Unused motor oils, gearbox oils and hydraulic oils

•Vegetable oil (also as per EN 51605)

•Oil/water mixtures (e.g. drilling oil or lubricating oil)

•Perchloroethylene and trichloroethylene

•Transformer oil

•Antifreeze agents

•Cleaning agent/water mixtures

•AdBlue® (urea solution) as per DIN 70070 (only level probe for

UFS 01, type 76 N, type 76 E)

as well as comparable water-polluting liquids with identical heat con-

ductivity.

Safety

6 NB 220

The 76 N level probe can be used in liquids against which stainless

steel (1.4301) is resistant.

Any use other than the application explicitly permitted in this instruc-

tion manual is not permitted.

2.2 Predictable incorrect application

The overfill prevention system NB 220 must never be used in the fol-

lowing cases:

•Hazardous area (Ex) and liquids

If the device is operated in hazardous areas, sparks may cause

deflagrations, fires or explosions.

2.3 Safe handling

This product represents state-of-the-art technology and is made ac-

cording to the pertinent safety regulations. Each device is subjected

to a function and safety test prior to shipping.

Operate the product only when it is in perfect condition. Always

observe the operating instructions, all pertinent local and na-

tional directives and guidelines as well as the applicable safety

regulations and directives concerning the prevention of acci-

dents.

WARNING

Severe burns or death caused by mains voltage (AC

230 V,

50

Hz) in the transducer.

Do not expose the transducer to water.

Interrupt the mains voltage supply before opening the transduc-

er or before performing maintenance and cleaning work and

make sure it cannot be switched on by accident.

Do not tamper with the transducer in any way whatsoever.

WARNING

Burns, explosion, deflagration or fire caused by temperatures of

up

to +100 °C at the tip of the level probe.

Do not touch the tip of the level probe.

The transducer and the level probe must not be operated in

hazardous areas.

2.4 Staff qualification

Mounting, commissioning, operation, maintenance, decommissioning

and disposal may only be performed by companies that are special-

ised companies as per § 19 I of the German Water Management Act

Product description

NB 220 7

with additional expertise in the area of fire and explosion protection

unless such activities do not have to be performed by specialised

companies according to the applicable national directives or unless

the manufacturer of the level probe and the transducer has such ac-

tivities performed by his own, trained staff.

Electrical work may only be performed by trained electricians and in

compliance with all applicable local and national directives.

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to malfunctions and are prohibited for safety reasons.

2.6 Usage of spare parts and accessories

Usage of unsuitable spare parts and accessories may cause dam-

age to the product.

Use only genuine spare parts and accessories of the manufac-

turer (see chapter 11, page 27).

2.7 Liability information

The manufacturer shall not be liable in any form whatsoever for

direct or consequential damage resulting from failure to observe the

technical instructions, guidelines and recommendations.

The manufacturer or the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this device, in particular in case of improper use of the

device, misuse or malfunction of the connection, malfunction of the

device or of connected devices. The manufacturer or the sales

company shall not be liable for damage whatsoever resulting from

any use other than the use explicitly permitted in this instruction

manual.

The manufacturer shall not be liable for misprints.

3 Product description

The overfill prevention system NB 220 consists of a level probe and

a transducer. The level probe and the transducer are connected by

means of a two-wire signal cable.

The tip of the level probe is fitted with a PTC thermistor. During op-

eration, the PTC thermistor is heated and can distinguish between

gaseous and liquid media due to the different heat dissipation.

The transducer contains the following elements in an impact-

resistant plastic housing: display elements and controls as well as all

electronic components for signal processing and conversion of the

level probe signal into a digital output signal. The output signal is

available as a voltage-free relay contact.

Product description

8 NB 220

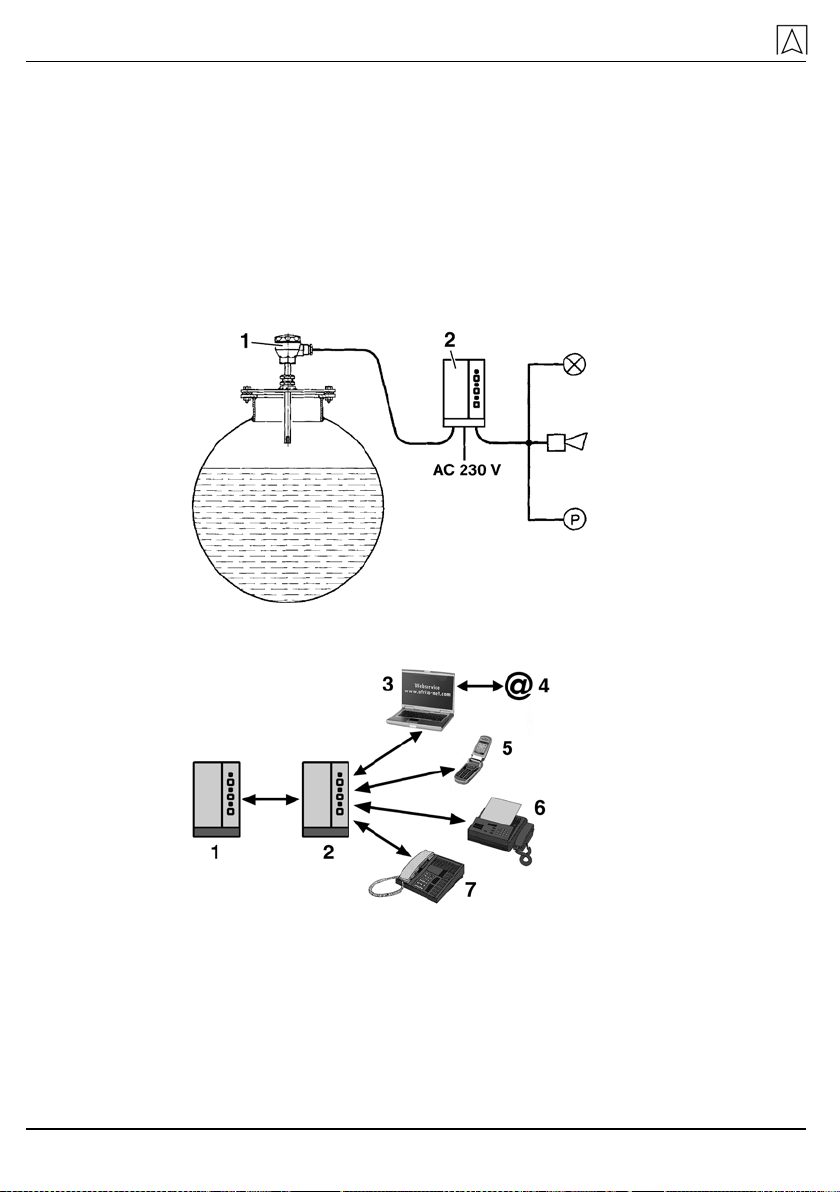

Fig. 1: Schematic overview of the overfill prevention system

1 Level probe 5a Signalling unit

2 Transducer 5b Control unit

4 Signal amplifier 5c Actuator

S Binary signal

3.1 Function

Level probe

The function principle of the level probe is based on the different

heat conductivity of liquid and gaseous fluids. A PTC thermistor at

the tip of the level probe is heated by the probe current of the trans-

ducer. The temperature and thus the electrical resistance of the PTC

thermistor increases in air. If the PTC thermistor is submerged into a

liquid, it cools down and its resistance decreases to almost the initial

value. The probe current is limited so that the PTC thermistor cannot

heat up again while it is submerged. In a gaseous fluid, the heating

up time of the PTC thermistor is between 2 seconds (at an ambient

temperature of +60 °C) and 2 minutes (at an ambient temperature of

-25 °C).

Transducer type NB 220 H

The transducer converts the changes in resistance of the PTC ther-

mistor into relay switching with binary signal output. The relay is de-

energised when the level probe tip has cooled down and also in the

case of power outage as well as a short circuit or wire break in the

connection between the level probe and the transducer. In this case,

the yellow LED at the transducer goes out. A green LED at the

transducer signals that the system is ready to operate.

Transducer type NB 220 QS

The transducer converts the changes in resistance of the PTC ther-

mistor into relay switching with binary signal output. A signal is gen-

erated when the level probe tip has cooled down and also in the

Product description

NB 220 9

case of power outage as well as a short circuit or line interruption in

the connection between the level probe and the transducer. The

transducer provides an audible and a visual alarm when a signal is

generated. The audible signal can be acknowledged by means of the

Acknowledge button. The visual signal remains active (red signal

lamp). When the level probe is no longer submerged, the visual sig-

nal is switched off and the system resumes 'ready' mode. A green

LED at the transducer signals that the system is ready to operate. In

addition, the alarm units mentioned above can also be connected.

Transducer type NB 220 QSA

The transducer converts the changes in resistance of the PTC ther-

mistor into relay switching with binary signal output. The scanner in-

tegrated into the transducer continuously monitors the function of the

PTC thermistor. The characteristic of the PTC thermistor (heating up

and cooling down behaviour) is checked several times per second

and without influencing the ongoing measurement process. This en-

sures immediate detection of a PTC that is no longer operative e.g.

due to external influences (corroded probe sleeve) so that the alarm

unit of the overfill prevention system immediately responds. The en-

ergy supplied to the PTC thermistor is precisely controlled for maxi-

mum reliability and a long service life. A signal is generated when the

level probe tip has cooled down and also in the case of power out-

age as well as a short circuit or line interruption in the connection be-

tween the level probe and the transducer. The transducer provides

an audible and a visual alarm when a signal is generated. The audi-

ble signal can be acknowledged by means of the Acknowledge but-

ton. The visual signal remains active (red signal lamp). Two relay

contacts are provided to make the signal externally available. In the

case of an alarm, one changeover contact is de-energised and one

changeover contact (e.g. for connection of a horn) is energised. After

acknowledgement, this changeover contact is de-energised again;

the second changeover contact remains de-energised. When the

level probe is no longer submerged, the visual signal goes out, the

changeover contact is energised and the system resumes 'ready'

mode. A green LED at the transducer signals that the system is

ready to operate. It is also possible to connect an external

acknowledge button. If the device fuse fails or in the case of power

outage, the green LED "Operation" at the transducer goes out and

the relay contact (changeover contact) is de-energised.

Product description

10 NB 220

3.2 Operating modes

The transducer is equipped with two output relays (1 changeover

contact, 1 normally open contact) to transmit the alarm signal to ex-

ternal devices. In the case of an alarm, the normally open contact is

energised and the changeover contact is de-energised.

The transducer can be operated with or without additional external

devices. External devices include units for audible and visible alarm

signal or remote alarm devices, building control systems, etc.

3.3 Application examples

1 Level probe

2 Transducer

Fig. 2: Overfill prevention system at stationary containers

1 Transducer

2 AFRISO event

reporting system

3 Internet

4 E-mail

5 Mobile phone

6 Fax

7 Telephone

Fig. 3: AFRISO event reporting system for remote reporting

Product description

NB 220 11

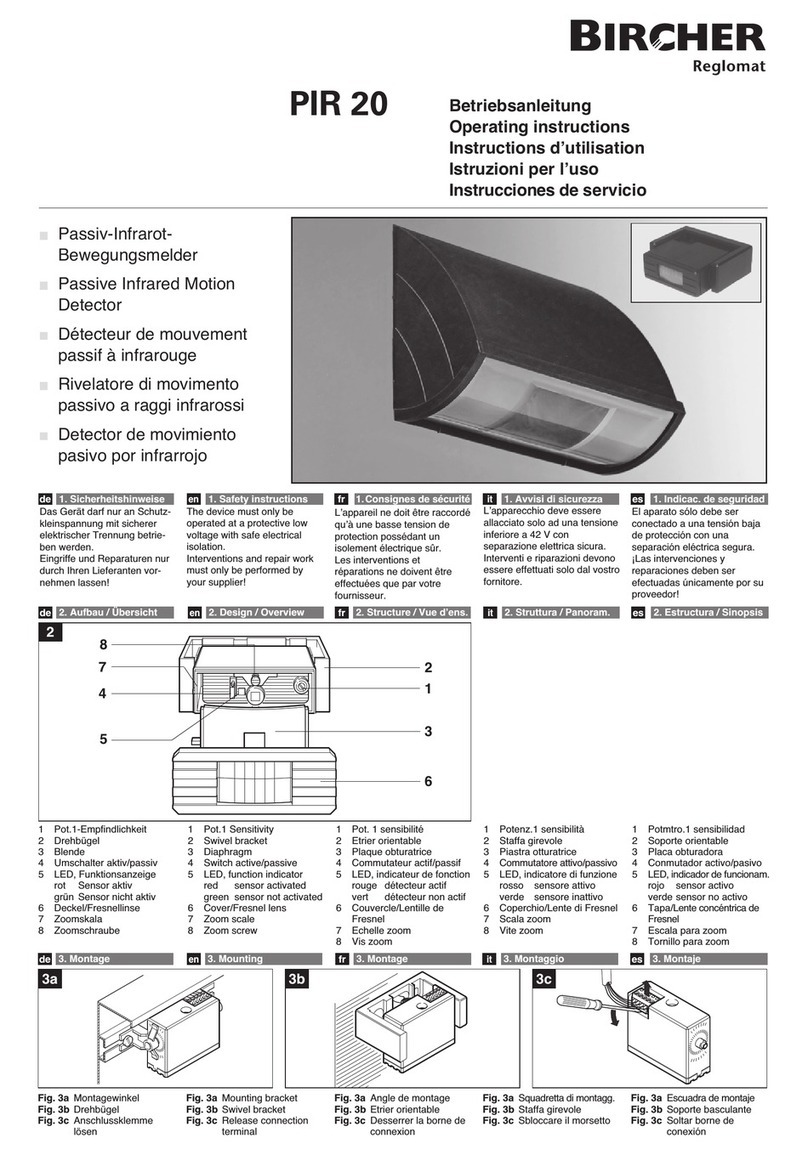

Fig. 4: Transducer with mounting frame for panel mounting; right:

panel cut out

3.4 Versions

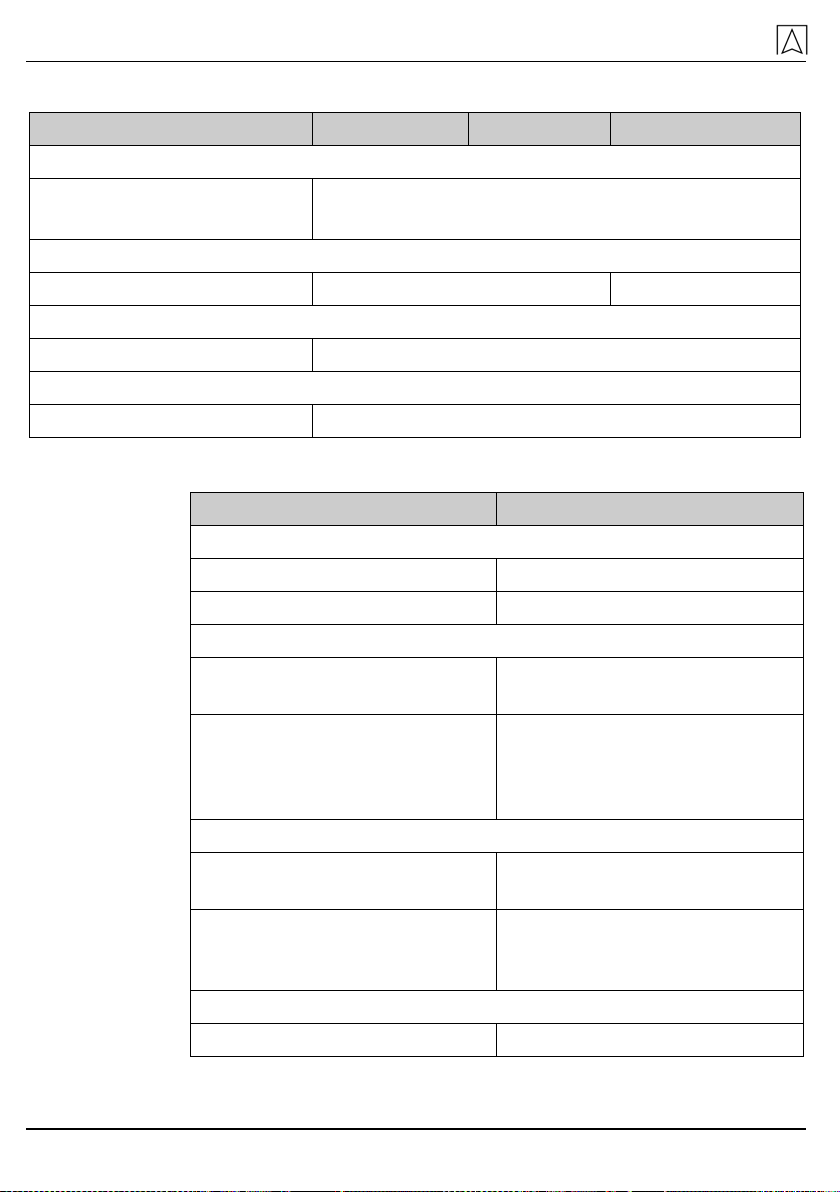

Table 1: Level probes

Type Version

76 .

.

Without marking -25 °C to +50 °C fluid temperature

H High temperature -25 °C to +80 °C fluid temperature

A Probe tube Ø 16 mm, process connection G¾

E In addition to A: Cable length 3 m (standard)

C In addition to A: Cable length 3 m (standard)

M In addition to A: Cable length 3 m (standard)

N In addition to A: Completely made of stainless steel

for UFS 01 Probe tube Ø 16 mm, process connection G¾, stainless steel,

-25 °C to +50 °C fluid temperature

Table 2: Transducer

Type Version

NB 220 H Visual alarm, one voltage-free changeover contact

NB 220 QS Visual and audible alarm, external connections connected to auxiliary

power

NB 220 QSA Visual and audible alarm, two output relays, external alarm acknowl-

edgement possible

Technical specifications

12 NB 220

4 Technical specifications

4.1 Level probe

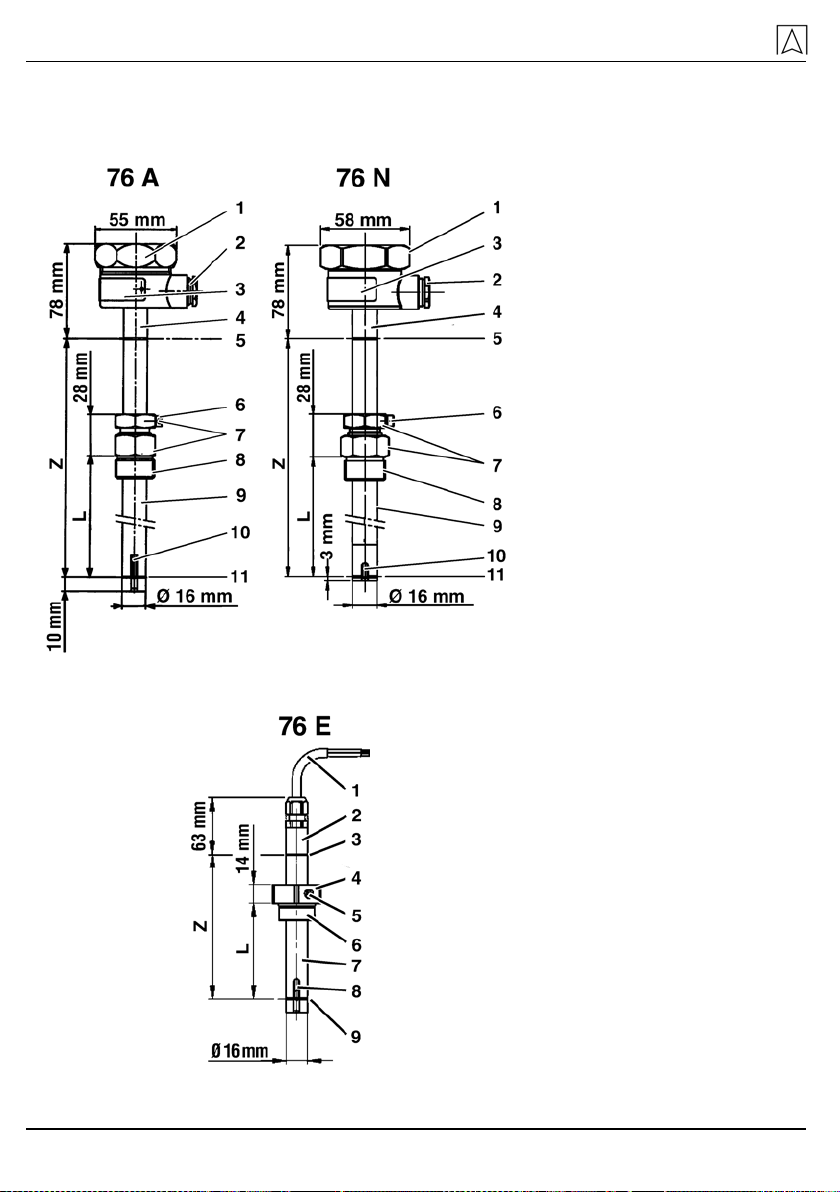

1 SW 52

2 PG 11

3 Nameplate

4 Probe length, embossed

5 Marking groove

6 Locking screw

7 SW 27

8 Screw fitting G¾

9 Probe tube

10 PTC thermistor

11 Response point

L Response length

Z Probe length

Fig. 5: Level probe types 76 A and 76 N

1 Connection cable, 3 m

2 Probe length, embossed

3 Marking groove

4 Screw fitting

5 Locking screw

6 Screw fitting G¾

7 Probe tube

8 PTC thermistor

9 Response point

L Response length

Z Probe length

Fig. 6: Level probe type 76 E

Technical specifications

NB 220 13

1 Cable LiYY 2 x 1 standard

3 m long

2 Probe length, embossed

3 Marking groove

4 Locking screw

5 SW 27

6 Screw fitting G¾

7 Response point

8 Response length em-

bossed

L Response length

Z Probe length

Fig. 7: Level probe type 76 C, 76 M

1 Embossed probe length

2 Marking groove

3 Locking screw

4 O ring

5 Screw fitting G¾

6 Response point

L Response length

Y Check dimension

Z Probe length

Fig. 8: Level probe for UFS 01

Technical specifications

14 NB 220

Table 3: Technical specifications

Parameters for UFS 01 Type 76 ._ Type 76 .H

General specifications

Probe length

(embossed on probe tube) Standard: 100/200/300/400/500 mm

Special versions up to 3000 mm, graduation: 100 mm

Operating temperature range

Medium -25 °C to +50 °C -25 °C to +80 °C

Supply voltage

Nominal voltage Max. DC 13 V

Electrical safety

Degree of protection IP 54 EN 60529

Table 4: Materials (wetted parts)

Component Material

for UFS 01

Probe tube, screw fitting stainless steel 1.4571

O ring Viton

Type 76 A/C

Screw fitting

Seal Brass

Vulkollan

Probe tube

Ring

Sensor holder

O ring

Stainless steel 1.4301-1.4571

Spring steel 1.1248, galvanised

Plastic POM GF 25 %

Elastomer Viton

Type 76 E

Screw fitting

Seal Plastic PE-HD

NBR

Probe tube

Sensor holder

O ring

Stainless steel 1.4301-1.4571

Plastic POM GF 25 %

Viton

Type 76 M

Screw fitting Brass

Technical specifications

NB 220 15

Component Material

Probe tube

Ring

Sensor holder

O ring

Stainless steel 1.4301-1.4571

Spring steel 1.1248, galvanised

Plastic POM GF 25 %

Viton

Type 76 N

Screw fitting

Seal Stainless steel 1.4301-1.4571

Vulkollan

Probe tube/sensor holder (with-

out seal) Stainless steel 1.4301-1.4571

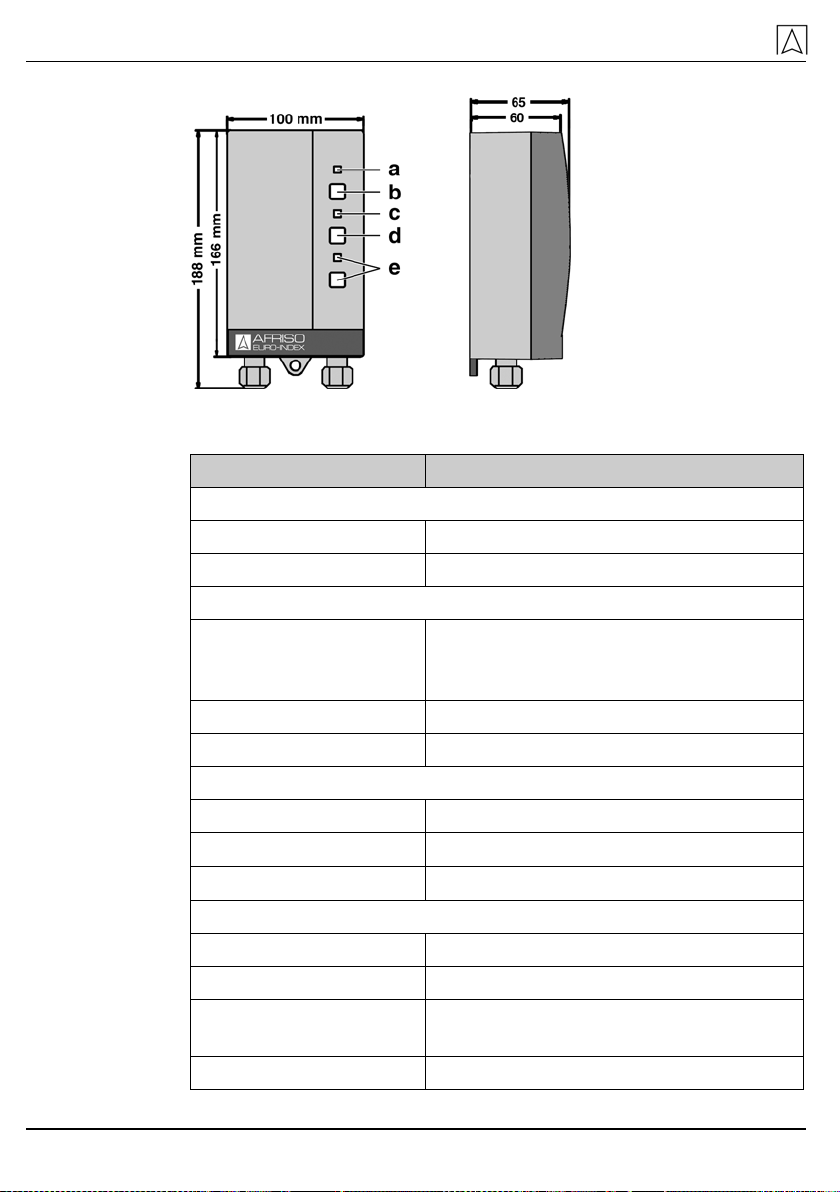

4.2 Dimensional drawings and technical specifications

a Probe

b Green pilot lamp

Fig. 9: NB 220 H

a Relay

b Green pilot lamp

c Audible alarm

d Visual alarm and

acknowledge button

Fig. 10: NB 220 QS

Technical specifications

16 NB 220

a Green pilot lamp

b Test button

c Red alarm lamp

d Acknowledge

button

e Without function

Fig. 11: NB 220 QSA

Table 5: Technical specifications transducer

Parameters Value

Operating temperature range

Ambient -20 °C to +60 °C

Storage -25 °C to +60 °C

Supply circuit

Power supply:

NB 220 H, NB 220 QSA

NB 220 QS

24 V, 110 V, 230 V, 50 Hz or DC 24 V

230 V, 50 Hz

Power input Max. 4 VA or 6 W

Mains fuse NB 220 QSA M 32 mA

Output circuit NB 220 H

Outputs 1 voltage-free changeover contact

Alternating voltage ≤250 V; ≤4 A, cos ϕ≥0.7; max. 500 VA

Direct voltage ≤250 V; ≤0.25 A; max. 50 W

Output circuit NB 220 QS

Pump, ampl., etc. 230 V, 50 Hz, max. 50 W

External lamp 230 V, 50 Hz, max. 100 W

External acknowledge

button 230 V, 50 Hz

External horn 230 V, 50 Hz, max. 50 W

Technical specifications

NB 220 17

Parameters Value

Output circuit NB 220 QSA

Outputs 1 voltage-free changeover contact, can-

not be acknowledged, 1 voltage-free

changeover contact, can be acknowl-

edged

Alternating voltage ≤250 V; ≤4 A, cos ϕ≥0.7; max. 500 VA

Direct voltage ≤250 V; ≤0.25 A; max. 50 W

Acknowledgement circuit NB 220 QSA

Voltage ≤12.6 V

Current ≤20 mA

Power ≤60 mW

Cable glands at transducer NB 220 QSA

The centre rubber piece can be replaced

with a cable gland M20.

Cable gland Cable diameter

M16 4.0-8.8 mm

M20 8.0-12.5 mm

4.3 Approvals, tests and conformities

NB 220 has the Technical Approval of the German Institute for Build-

ing Technology with the approval number Z-65.11-193 and complies

with the Construction Products Directive (89/106/EEC), the EMC Di-

rective (2004/108/EC) and the Low Voltage Directive (2006/95/EC).

Transport and storage

18 NB 220

5 Transport and storage

CAUTION

Damage to the device due to improper transport.

Do not throw or drop the device.

Protect from wetness, humidity, dirt and dust.

CAUTION

Damage to the device due to improper storage.

Store the device in a clean and dry environment.

Only store the device within the permissible temperature

range.

Protect from wetness, humidity, dirt and dust.

6 Mounting and commissioning

6.1 Mounting the level probe

Always observe all pertinent national and local safety regula-

tions and all regulations concerning the prevention of accidents

when working on the container.

Choose a mounting position for the level probe that keeps the

overfill prevention system from generating false alarms caused

by splashes of the liquid or by air flow.

If possible, install the level probe vertically so that residual liquid

can drip off of the sensor.

Table 6: Cable lengths of the level probes

Type Cable length

Cable cross section 1 mm² Cable cross section 1.5 mm²

for UFS 01 50 m 100 m

76 .. 500 m 750 m

Type 76 ..: In the case of short connections, you may also use a

smaller cable cross section.

The level probes 76 C, 76 E and 76 M are equipped with a cable end

2 x 1 mm², standard 3 m long. Use a suitable terminal box to connect

the cable.

Mounting and commissioning

NB 220 19

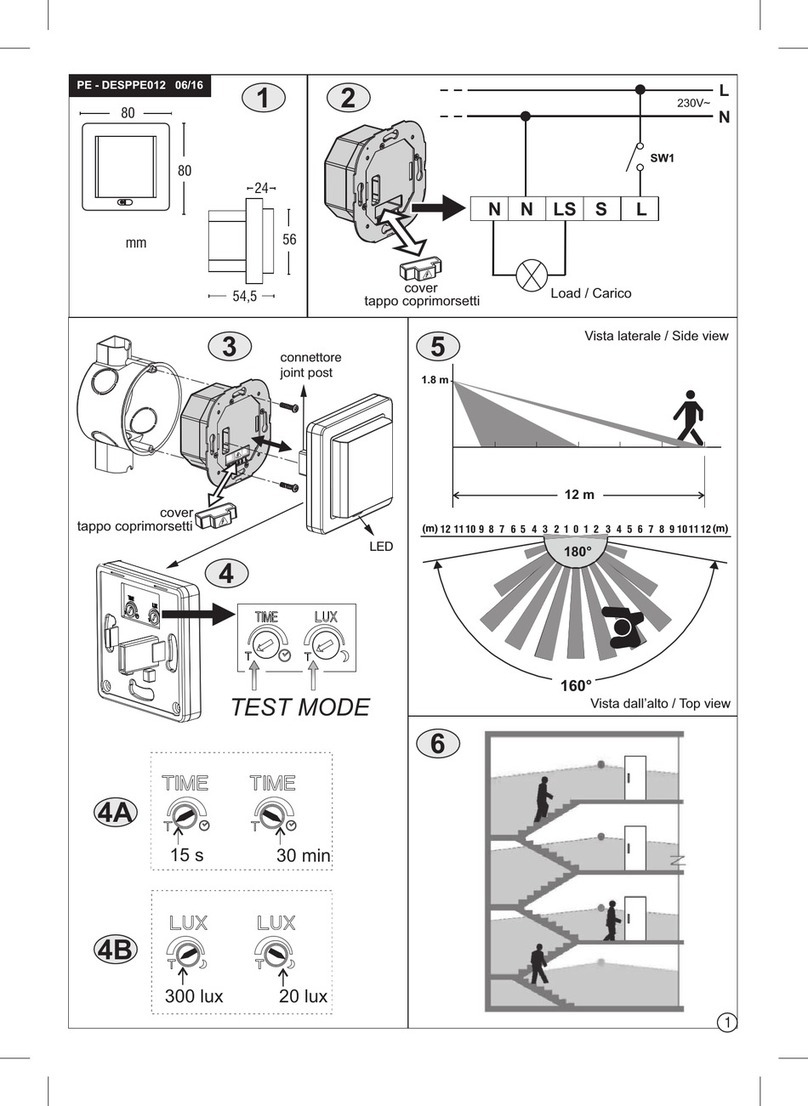

6.2 Adjusting the level probe

1 Embossed probe length Z

2 Marking groove

3 Response point PTC thermis-

tor

A Response level

H Tank height

L Response length

S Connection piece height

Y Check dimension

Z Probe length

Fig. 12: Adjusting the level probe

1. Determine the response height A of the overfill prevention sys-

tem based on the permissible filling level in the tank, using ap-

pendix 1 of the construction and testing principles for overfill

prevention systems.

2. The permissible filling level can be calculated as per TRbF 280

section 2.2. Consider a switching delay of

≤

2 seconds.

3. Calculate response length L as follows:

L = (H – A) + S

For inspection, the response length L can be calculated as fol-

lows without dismounting of the level probe:

L = Z – Y

4. Adjust response length L at the level probe (L = distance be-

tween the hex face of the screw fitting and the response point of

the PTC thermistor).

5. When the level probe is installed, the correct adjustment of the

response height can be checked using the check dimension Y

(Y = distance between marking groove and hex face of the

screw fitting).

6. Tighten the locking screws to lock the probe tube.

7. Screw the screwed thread with the O ring into the existing tank

connection piece.

The response length is embossed in the case of level probes with a

fixed response length. The response length is the distance between

the hex face and the marking groove at the protective sleeve of the

sensor at the lower end of the level probe.

Mounting and commissioning

20 NB 220

Level probe with screw fitting 76 ...

1. Determine the response length on the basis of the tank data and

adjust it.

2. Tighten the upper compression gland screw and the locking

screw of the screw fitting to lock the probe tube.

3. Apply suitable, resistant sealing material to the screwed connec-

tion thread and screw it into the existing tank connection piece.

Level sensor with fixed screw fitting 76 M

1. Since the response length of the level probe is not variable

(probe tube and screw fitting are permanently connected), you

must determine the exact length on the basis of the tank dimen-

sions and specify it when ordering.

2. Apply suitable, resistant sealing material to the screwed connec-

tion thread and screw it into the existing tank connection piece.

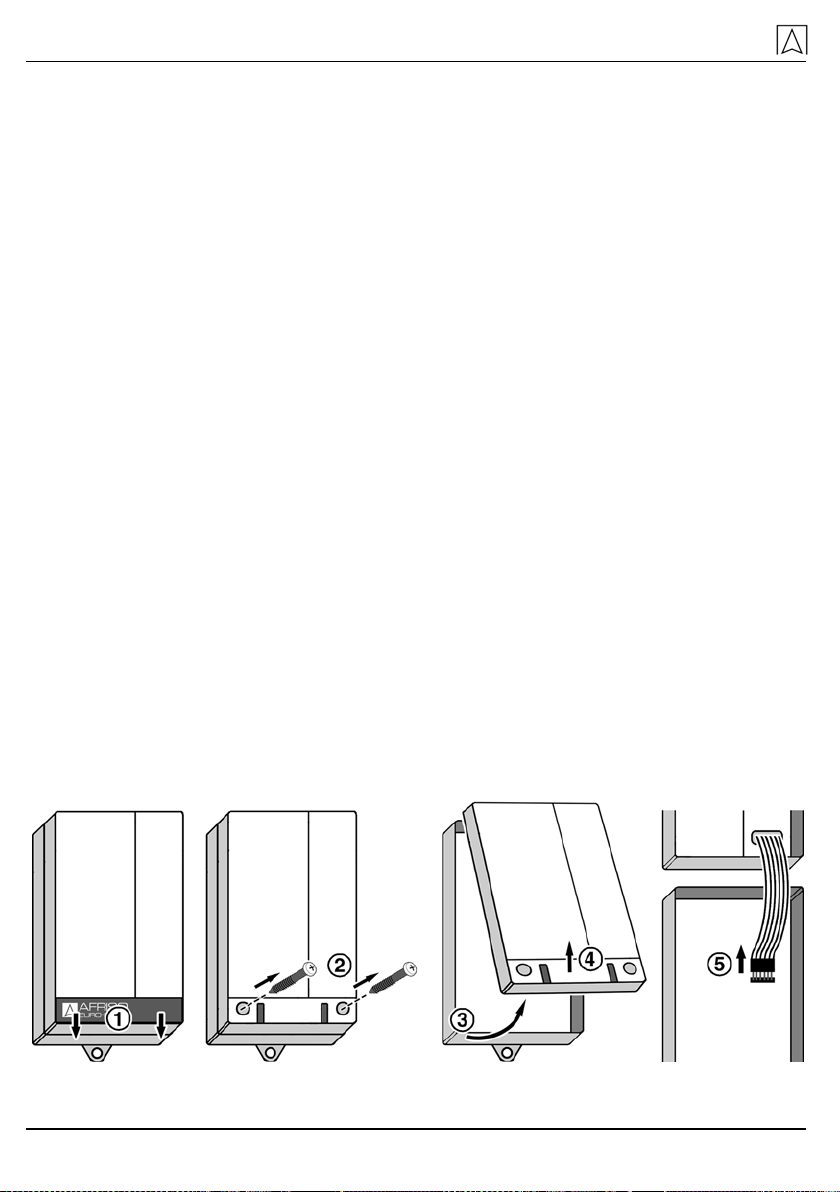

6.3 Mounting the transducer

Mount the transducer to an even, rigid and dry wall at eye level.

The transducer must be accessible and easy to oversee at all

times.

The transducer must not be exposed to water or splash water.

Do not mount the transducer in damp rooms.

The maximum ambient temperature at the transducer must not

be exceeded.

In the case of outdoor installation, protect the transducer from

direct atmospheric influences and mount it into an additional

housing with degree of protection IP 54 or higher.

1. Open the transducer.

Table of contents

Other Afriso EURO-INDEX Security Sensor manuals