Afriso EURO-INDEX 43790 User manual

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Umweltschutz

Lindenstraße 20

74363 Güglingen

Telefon +49 7135-102-0

Service +49 7135-102-211

Telefax +49 7135-102-147

www.afriso.de

Read instructions before using device!

Observe all safety information!

Keep instructions for future use!

01.2011 0

854.001.0512

Operating Instructions

Leak Detector Pressure Type

Europress

Europress # 43790

... in protective housing # 43795

... in protective housing

with heating # 43796

Leckanzeiger

Z-65.23-3

2 Europress

Contents

1This instruction manual............................................................................................4

1.1 Precautions ..................................................................................................4

1.2 Explanation of symbols and typeface ..........................................................4

2Safety ......................................................................................................................5

2.1 Intended use ................................................................................................5

2.2 Predictable incorrect application ..................................................................6

2.3 Safe handling ...............................................................................................6

2.4 Staff qualification..........................................................................................6

2.5 Modifications to the product .........................................................................7

2.6 Usage of spare parts and accessories.........................................................7

2.7 Liability information ......................................................................................7

3Product description..................................................................................................8

3.1 Function........................................................................................................9

3.2 Operating modes..........................................................................................9

3.3 Application examples .................................................................................10

4Technical specifications.........................................................................................11

4.1 Approvals, tests and conformities ..............................................................12

5Transport and storage ...........................................................................................13

6Mounting and commissioning................................................................................13

6.1 Safety information on mounting .................................................................13

6.2 Installation site ...........................................................................................13

6.3 Installing the leak detector .........................................................................14

6.4 Electrical connection ..................................................................................15

6.5 Connection line ..........................................................................................17

6.6 Drying filter .................................................................................................21

6.7 Valve settings .............................................................................................22

6.8 Commissioning the device .........................................................................23

7Operation...............................................................................................................23

7.1 Alarm condition ..........................................................................................23

7.2 Function test...............................................................................................24

8Maintenance ..........................................................................................................27

8.1 Service indication .......................................................................................27

8.2 Maintenance activities................................................................................28

9Troubleshooting.....................................................................................................29

9.1 Evaluation of the pump operating time ......................................................30

10 Shutting down, disposal ........................................................................................31

11 Spare parts and accessories.................................................................................31

Europress 3

12 Warranty ................................................................................................................32

13 Copyright ...............................................................................................................32

14 Customer satisfaction ............................................................................................32

15 Addresses..............................................................................................................32

16 Appendix................................................................................................................33

16.1 Certificate of expert ....................................................................................33

16.2 Approval documents...................................................................................34

This instruction manual

4 Europress

1 This instruction manual

This instruction manual is part of the product.

Read this manual before using the product.

Keep this manual during the entire service life of the product

and always have it readily available for reference.

Always hand this manual over to future owners or users of the

product.

1.1 Precautions

WARNING TERM

Type and source of the danger are shown here.

Precautions to take in order to avoid the danger are shown

here.

There are three different levels of warnings:

Warning Term Meaning

DANGER Immediately imminent danger!

Failure to observe the information will result in

death or severe injuries.

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or severe injuries.

CAUTION Dangerous situation!

Failure to observe the information may result in

minor or severe injuries as well as damage to

property.

1.2 Explanation of symbols and typeface

Symbol Meaning

Prerequisite for an activity

Activity consisting of a single step

1. Activity consisting of a several steps

Result of an activity

• Bulleted list

Text Indication on display

Highlighting Highlighting

Safety

Europress 5

2 Safety

2.1 Intended use

The Europress leak detector for pressurised systems is a class 1

leak detector according to EN 13160-1.

The Europress leak detector may only be used to detect leaks in the

tanks listed below which are not pressurised (i.e. operated under at-

mospheric conditions) and which are used for aboveground or un-

derground storage of the liquids described below.

Tanks

• Double-walled steel or plastic tanks with approval of use of the

German Institute for Building Technology (Deutschen Institut für

Bautechnik) and which are suitable for water-polluting liquids.

The interstitial spaces of the tanks must be resistant to the liquid and

its vapours and must not contain leak detection fluid.

A leak detector may be connected to a single aboveground tank or

to several underground tanks with a total interstitial space volume of

4 m³.

Liquids

• Steel tanks: Water-polluting liquids

• Plastic tanks: Water-polluting liquids with a flash point of more

than 55 °C

• AdBlue® (urea solution 32.5 %) according to DIN 70070

The leak detector must be resistant to the liquid and its vapours. The

materials used are: PVC, silicone, ABS, NBR, PA6, EPP, EPDM.

The permissible density of the liquid depends on the tank height / the

tank diameter.

Tank height/tank Ø Permissible density

≤2.00 m ≤1900 kg/m³

≤2.50 m ≤1740 kg/m³

≤2.60 m ≤1670 kg/m³

≤2.76 m ≤1580 kg/m³

≤2.84 m ≤1530 kg/m³

≤2.90 m ≤1500 kg/m³

Any use other than the application explicitly permitted in this instruc-

tion manual is not permitted.

Safety

6 Europress

2.2 Predictable incorrect application

The Europress leak detector must never be used in the following

cases:

• Hazardous area (Ex)

If the device is operated in hazardous areas, sparks may cause

deflagrations, fires or explosions.

• Mounting in access chambers of underground tanks

• Use with aggressive liquids which attack the connection hoses

and the leak detector.

2.3 Safe handling

This product represents state-of-the-art technology and is made ac-

cording to the pertinent safety regulations. Each device is subjected

to a function and safety test prior to shipping.

Operate the product only when it is in perfect condition. Always

observe the operating instructions, all pertinent local and na-

tional directives and guidelines as well as the applicable safety

regulations and directives concerning the prevention of acci-

dents.

WARNING

Severe burns or death caused by mains voltage in the control

unit.

Do not expose the leak detector to water.

Interrupt the mains voltage supply before opening the leak de-

tector or before performing maintenance and cleaning work and

make sure it cannot be switched on by accident.

Do not tamper with the leak detector in any way whatsoever.

2.4 Staff qualification

Mounting, commissioning, maintenance and cleaning may only be

performed by specialised companies as per § 3 of the German Ordi-

nance on Installations for Handling Water-Polluting Substances

(VAwS of March 31, 2010) unless such activities do not have to be

performed by specialised companies according to the applicable lo-

cal directives or unless the manufacturer of the device has such ac-

tivities performed by his own, trained staff.

Electrical work may only be performed by trained electricians and in

compliance with all applicable local and national directives.

Safety

Europress 7

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to malfunctions and are prohibited for safety reasons.

2.6 Usage of spare parts and accessories

Usage of unsuitable spare parts and accessories may cause dam-

age to the product.

Use only genuine spare parts and accessories of the manufac-

turer (refer to chapter 11, page 31).

2.7 Liability information

The manufacturer shall not be liable in any form whatsoever for di-

rect or consequential damage resulting from failure to observe the

technical instructions, guidelines and recommendations.

The manufacturer or the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this device, in particular in case of improper use of the

device, misuse or malfunction of the connection, malfunction of the

device or of connected devices. The manufacturer or the sales com-

pany shall not be liable for damage whatsoever resulting from any

use other than the use explicitly permitted in this instruction manual.

The manufacturer shall not be liable for misprints.

Product description

8 Europress

3 Product description

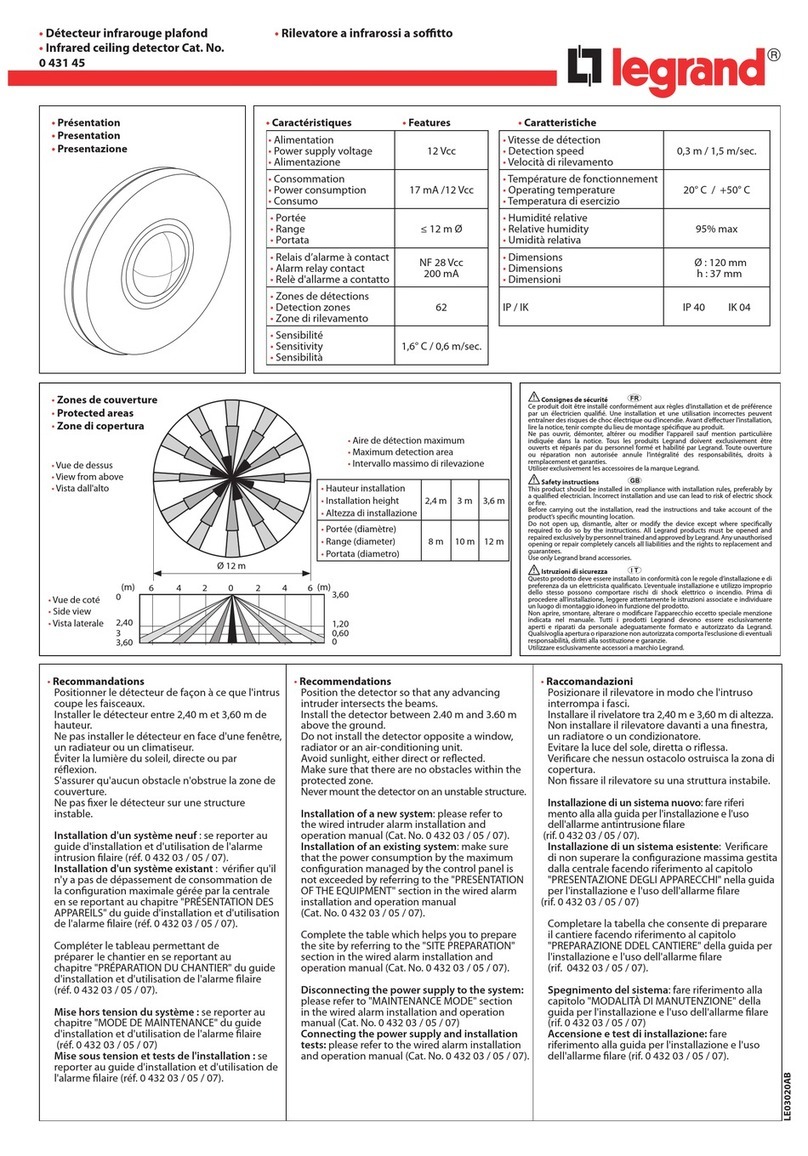

1 Rubber grommet

2 Green LED “Supply

ON”

3 Button “Test”

4 Red LED “Alarm”

5 Button “Mute”

6 Yellow LED “Service”

7 Button “Set”

8 Measurement valve

9 Measurement line

connection

10 Pressure gauge con-

nection

11 Cover for hose con-

nections

12 Suction line connection

13 Test valve

14 Pressure line connec-

tion

15 Condensate trap with

filter

16 Cable gland

Fig. 1: Exterior view and dimensions

The leak detector Europress generates a constant overpressure in

the interstitial space of the tank and triggers an alarm in the case of a

pressure drop.

Europress contains the following elements in an impact-resistant

plastic housing: display elements and controls, a pressure pump, a

pressure switch, a safety valve, a printed circuit board with the elec-

tronic components for processing the output signal, a filter and three

hose connections for the pneumatic connection to the interstitial

space of the tank.

The green LED “Supply ON” lights up when mains voltage is avail-

able. The alarm is indicated visually and audibly and is made avail-

able via a voltage-free relay contact (1 changeover contact).

Product description

Europress 9

Drying filters (not included) are used to dry the air compressed for

the operating pressure to a residual humidity level of approx. 10 %

and a filter is used to remove the dust particles. The dried and fil-

tered air is pumped into the interstitial space of the tank. Pressure

fluctuations in the interstitial space are compensated for by the pump

and the safety valve.

3.1 Function

The green LED “Supply ON” lights up when mains voltage is avail-

able and the device is ready for operation.. The pump integrated into

the leak detector draws in air via the drying filter and pumps it via the

pressure line to the tank's interstitial space until a constant overpres-

sure has been built up.

The pressure switch measures the pressure in the interstitial space

via the measurement line and keeps it at a constant level together

with the pump. The safety valve at the pump opens if the pressure is

too high in order to prevent the interstitial space test pressure (0.6

bar) from being reached.

If a leak occurs in the tank's inner or outer wall either above or below

the level of the stored liquid or the ground water, and if this leak is

greater than the pump's pumping capacity, the overpressure will

drop. When the alarm threshold is reached, the red LED “Alarm” and

the audible alarm are activated and the relay is energised.

The audible alarm can be muted with the button “Mute”. The switch-

ing point for "Alarm on" is at least 30 mbar higher than the static

pressure of the stored liquid or the ground water.

3.2 Operating modes

Europress is equipped with an output relay to transmit the alarm sig-

nal to additional external devices. If no error condition is present, the

relay is de-energised. In the case of an alarm, the relay is energised.

Europress can be operated with or without additional external de-

vices. The following types of additional devices can be used: visual

and audible alarm units, telecommunication devices, building control

systems, building automation systems, etc.

Product description

10 Europress

3.3 Application examples

1 Red: Measurement

line

2 Drying filter

3 Transparent: Pres-

sure line

4 Green: Suction line

5 Electrical connection

6 Outer wall

7 Interstitial space

8 Inner wall

Fig. 2: Application example

1 Europress

2 AFRISO event

reporting system

3 Internet

4 E-mail

5 Cell phone

6 Fax

7 Phone

Fig. 3: AFRISO event reporting system for remote reporting of leaks

Technical specifications

Europress 11

Fig. 4: Europress in protective housing,

without (A) or with heating (B),

pre-assembled and ready to be connected. The horn is connected to

the output relay. Protection IP 55.

1 Horn HPW 2 5 Red: Measurement line

2 Mute button for horn HPW 2 6 Green: Exhaust line

3 Europress 7 Transparent: Suction line

4 Protective housing 8 Heating controller

9 Heating

4 Technical specifications

Table 1: Technical specifications

Parameter Value

General specifications

Weight 1.2 kg

Emissions The A-evaluated sound level of the

audible alarm is at least 70 dB(A) at a

distance of one metre.

Output relay 1 changeover contact

Breaking capacity output

relay

max. 250 V, 2A, resistive load

Technical specifications

12 Europress

Parameter Value

Relay fuse T 2 A

Operating pressure in

interstitial space

Approx. 530 mbar

Switch point Alarm On 465 to 485 mbar

Switch point Alarm Off 510 mbar (point of reference, results

from switching hysteresis)

Switch point Pump On 500 mbar (point of reference, results

from switching hysteresis)

Switch point Pump Off 520 to 540 mbar

Safety valve opens ≥570 mbar

Connecting hose PVC hose 6 x 2 mm

Length of connection lines Max. 50 m

Temperature range

Ambient -5 °C to +50 °C

Storage -10 °C to +60 °C

Voltage supply

Nominal voltage AC 100-240 V ± 10 %

Rated power < 10 VA

Electrical safety

Degree of protection II

Protection IP 30

Mode of operation and

additional mode of opera-

tion

Type 1.B

Electromagnetic compatibility (EMC)

Interference According to CISPR 22

Noise immunity According to EN 61000

4.1 Approvals, tests and conformities

Europress HV complies with the EMC Directive (2004/108/EC), the

Low Voltage Directive (2006/95/EC), the Construction Products Di-

Transport and storage

Europress 13

rective (89/106/EEC) and has the Technical Approval of the German

Institute for Building Technology Z-65.23-3.

5 Transport and storage

CAUTION

Damage to the device due to improper transport.

Do not throw or drop the device.

Protect from wetness, humidity, dirt and dust.

CAUTION

Damage to the device due to improper storage.

Protect the device from shock when storing it.

Protect from wetness, humidity, dirt and dust.

Only store the device within the permissible temperature range.

6 Mounting and commissioning

The leak detector may only be installed and commissioned by a spe-

cialised company, see chapter 2.4, page 6.

6.1 Safety information on mounting

In the case of underground tanks, the hydrostatic pressure of the

ground water acting on the tank bottom must not exceed 435 mbar.

The hydrostatic pressure of the stored liquid including any overlay

pressure must not exceed 435 mbar.

Install the leak detector in such a way that it cannot cool down

to temperatures of –5 °C, e.g. Mount the leak detector in a pro-

tective housing with a heating. See chapter 11, page 31 for ac-

cessories.

6.2 Installation site

Choose an installation site that is as close as possible to the

tank to be monitored. The ambient temperature specified must

not be exceeded.

Mount the leak detector to an even, rigid and dry wall at eye

level.

The leak detector must be accessible and easy to oversee at all

times.

The leak detector must not be exposed to water or splash water.

Do not mount the leak detector in damp rooms.

Mounting and commissioning

14 Europress

The leak detector must not be installed in hazardous areas or in

access chambers of underground tanks.

If the case of outdoor applications, the leak detector must be

mounted in a protective housing with IP 55 protection. If the leak

detector is installed in a protective housing, an additional

weather-proof audible alarm must be installed outside of the

protective housing. See chapter 11, page 31 for accessories.

If the leak detector is installed below rooftops or in rooms that

are only partially closed, protect it against direct atmospheric in-

fluences or use a protective housing as mentioned above.

6.3 Installing the leak detector

1. Fasten the leak detector the wall (use Aor B),

a drilling template is included.

2. Open the leak detector.

3. Connect the unit electrically as described in chapter 6.4 on

page 15.

Mounting and commissioning

Europress 15

4. Close the leak detector.

6.4 Electrical connection

Mains voltage is interrupted and cannot be switched on by acci-

dent.

1 Pressure switch

2 Pump

3 Cable routed through

upper cable gland

4 Cable routed through

bottom cable gland

5 Relay fuse

6 Relay connection

7 Mains connection

Fig. 5: Electrical connection

Connect the leak detector directly to the supply network without

a switch and without a plug!

If you want to route the mains or relay cable trough the top of

the housing, replace the rubber grommet at the top of the hous-

ing by the enclosed cable gland.

Close any cable glands at the bottom of the housing that are not

used by means of the enclosed plugs.

Mounting and commissioning

16 Europress

Power supply

Connect the leak detector to mains by means of a permanently in-

stalled cable such as NYM-J 2 x 1.5 mm².

1. Route the mains cable through the upper or bottom cable gland

into the leak detector.

2. The phase must be connected to terminal L1, the neutral con-

ductor to terminal N. The leak detector supply cable must have

a separate fuse (max. 16 A). Do not connect it to the circuit of

other electrical devices.

Output

The output signal of the leak detector is made available via a volt-

age-free relay contact (1 changeover contact).

Permanently install the relay cable, route it through the upper or

bottom cable gland into the leak detector and connect it to the

terminals with the corresponding designations.

Safely isolate the relay cable. The isolation characteristics of the

relay cable must at least comply with IEC 60227 or IEC 60245.

If no error condition is present, the relay is de-energised. In the case

of an alarm, the relay is energised.

CAUTION

Destruction of the switching contact and adverse effects on the

function of electrical systems due to voltage peaks when induc-

tive consumers are switched off.

Use commercially available standard RC combinations such as

0.1 µF/100 Ohm for inductive consumers.

Mounting and commissioning

Europress 17

9 V battery for alarm in the case of power failure

If a standard 9 V battery is connected, an alarm sound is activated in

the case of a power failure. The alarm sound cannot be muted; it re-

mains on until mains power is available again. When mains power is

available again, the device immediately resumes operation. If a leak

has occurred in the meantime, this is indicated.

6.5 Connection line

Hoses from the leak detector to the tank to be monitored, see also

fig. 6 and fig. 7, page 19.

1. Use pressure-proof (at least PN10 for tanks containing inflam-

mable liquids), oil- and water-resistant plastic hoses 6 x 2 mm

for the measurement hose (red), the suction hose (green) and

the pressure hose (transparent. The hoses must be resistant to

the stored liquid and its vapours.

2. Protect the plastic hoses by means of rigid, weather-proof pro-

tective pipes. According to the German TRbF 20 No. 4.1.4 sec-

tion 8, the protective pipes must be resistant to the permeation

of inflammable liquids and their vapours.

3. The connection lines must have the full cross section over the

entire length, there must be no bends and indentations.

4. Do not fit any shut-off elements.

5. Hose connections must be secured by means of hose clamps

which fit over the entire circumference.

Under the following conditions, you may also use quick-action cou-

plings (shutting off at one end, nominal diameter 7.2, Rectu Base

Mounting and commissioning

18 Europress

type 26) at the tank side of the pressure line and the measurement

line of the interstitial space:

• The coupling part with the shut-off element is directly and per-

manently mounted to the tank.

• The connection piece for the pressure line and the measure-

ment line is secured by means of one hose clamp for each

hose.

• The pressure line and measurement line must be mounted and

connected in such a way as to prevent twisting.

Quick-action couplings enable factory-filling of the interstitial space

with dried air which considerably reduces the time required on site

for commissioning. The following must ensured:

• There is only dried air (or nitrogen) in the interstitial space.

• The coupling part at the tank end must not get dirty during

mounting in order to prevent damage to the seal.

6. Slide the cover over the connections to protect hose connec-

tions.

Mounting and commissioning

Europress 19

1 Measurement line, red

hose

2 Suction line, green

hose

3 Pressure line, white or

transparent hose

4 Drying filter

5 Interstitial space

Fig. 6: Connecting an aboveground tank

1 Measurement

line, red hose

2 Pressure line,

white or

transparent

hose

3 Distributors

Fig. 7: Connecting several underground tanks

Mounting and commissioning

20 Europress

Leak test

1. Check the connection lines for leaks prior to connection to the

interstitial space. To do so, perform a leak test with 600 mbar.

CAUTION

Damage to or destruction of the measurement system if the test

pressure at the connected Europress exceeds 600 mbar.

Make sure the test pressure does not exceed 600 mbar.

The connection lines can be considered to be tight if the pres-

sure drop within a period of 30 minutes is less than 20 mbar.

2. Connect the connection lines to the interstitial space of the tank

after a successful leak test.

Basic filling

The pump of the leak detector must not exceed the pump capacity of

100 l/h.

1. Fill the interstitial space to obtain a pressure of approx. 500

mbar. Use an installation pump with a greater capacity for this

purpose.

2. The intake air must be dried by means of a sufficiently large dry-

ing filter.

3. Once a pressure of 500 mbar has been built up, disconnect the

installation pump and connect the leak detector.

This manual suits for next models

2

Table of contents

Other Afriso EURO-INDEX Security Sensor manuals