2Rockwell Automation Publication 6300-IN001A-EN-P - June 2023

ASEM On-Machine Monitor and On-Machine Panel PC Installation Instructions

Product Overview

Designed for full IP65 protection grade industrial applications, your ASEM

On-Machine product features:

• Powder coated die-cast aluminum alloy chassis with anti-scratch

treatment

• Aluminum or True Flat aluminum front panel

• Fully configurable button area with hard-wired connection mode which

accommodates an SIL-3 emergency stop (E-stop) button

• Light emitting diode (LED) status indicators

• Resolution up to full high-definition (FHD)

• Bottom arm, top arm, or VESA mounting

VESA (Video Electronics Standards Association) mount, also known as Flat Display Mounting

Interface (FDMI), is a standardized mounting format that makes it easier to select the correct

mount for your product and allows you to mount the product on a wall so that it takes up less

space, or on a movable arm for better ergonomics.

• Microsoft® Windows® 10 IoT Enterprise 2016/2019 64-bit Operating System

• Dual core Intel® Celeron® and Intel Core™ of 7th generation 15W Intel Kaby

Lake Unit Level Traceability (ULT) platform

Required Tools and Optional Accessories

You need the following tools to install and connect your On-Machine product.

• DC power supply (see Power Requirements on page 2)

• Torque limiting screwdriver with 2.5 mm hex key bit

• I/O cables, which are shielded and rated for indoor use

• Wire stripper, cutter, and crimper tool

• Clean, microfiber cloth

• For bottom arm, top arm, or VESA mounting:

- Adapter plate (see publication 6300V-PC005 for proper selection)

- Monitor arm or VESA bracket

• Optional accessories:

- CFast card (for panel PC only)

- Connection terminal buttons and E-stop button for select models with

button area

- Side handles or perimeter handle, and keyboard tray (see publication

6300V-PC005 for ordering information)

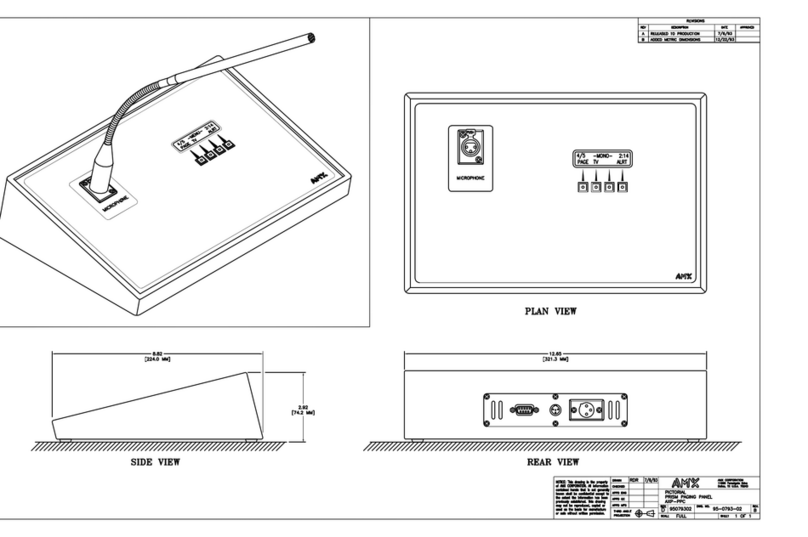

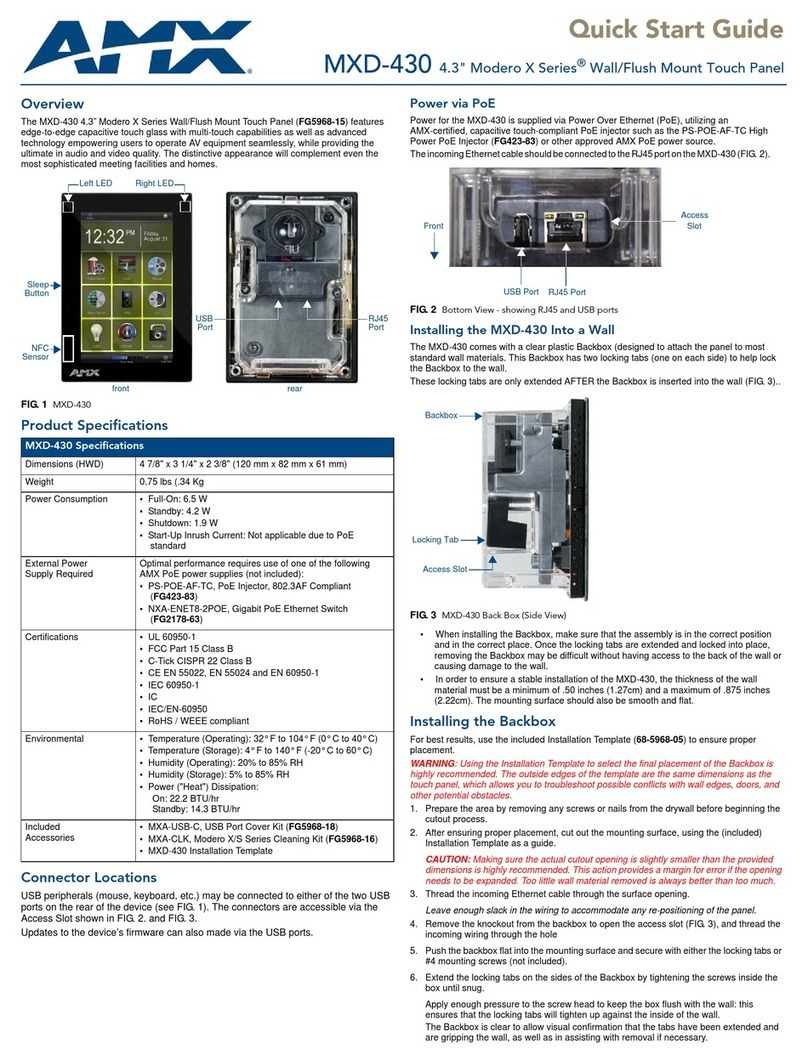

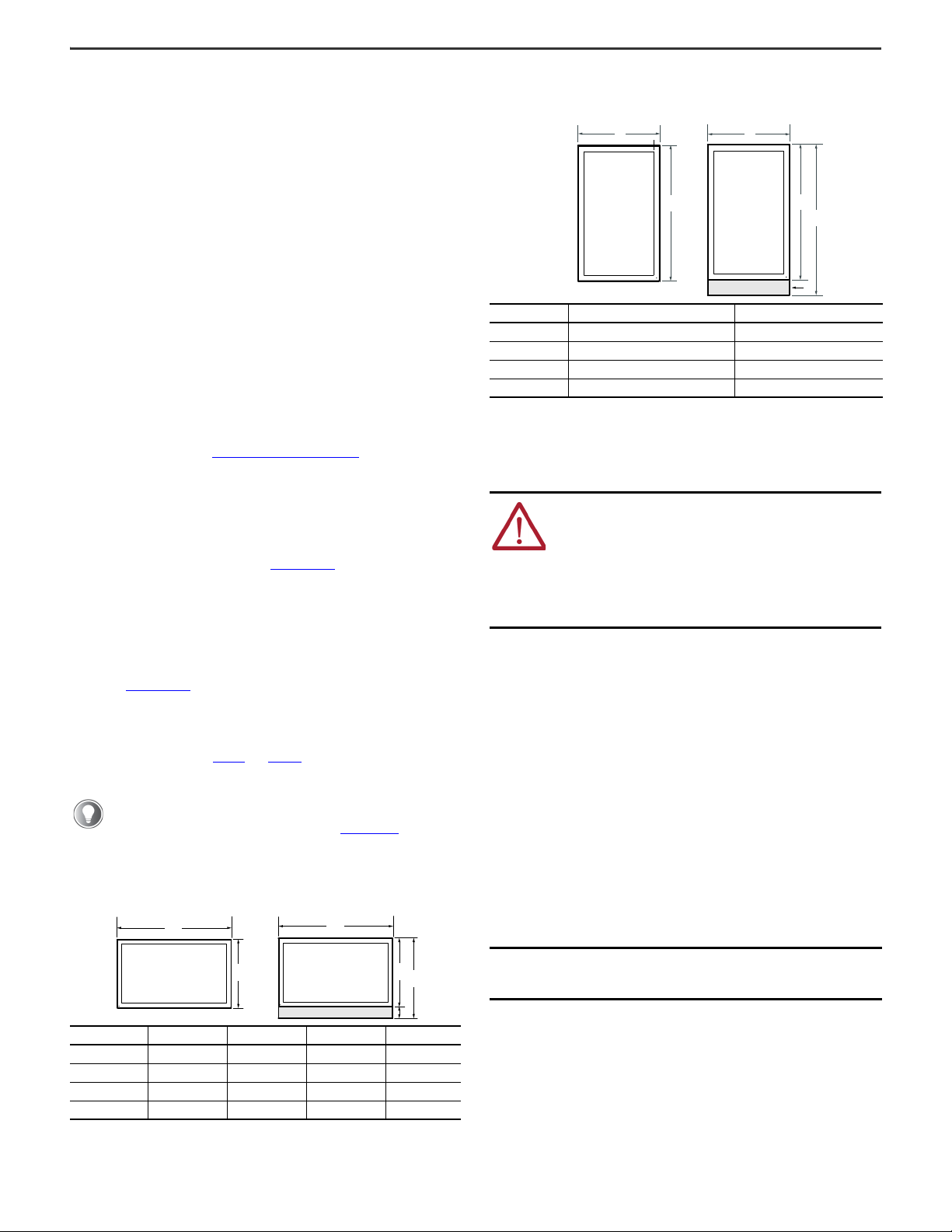

Approximate Dimensions

Dimensions that are shown in Table 1 and Table 2 are shown in millimeters

(inches). Dimensions are not intended to be used for manufacturing purposes.

Environmental Requirements

Follow these environment requirements to make sure that your On-Machine

product provides service with excellent reliability

• Your installation site:

- must have sufficient power,

- must be indoors and non-hazardous,

- must not expose your On-Machine product to direct sunlight, and

- must be placed in an industrial or control room environment that uses

some form of power isolation from the public, low voltage mains.

• The surrounding air temperature must not exceed the maximum

temperature for your On-Machine product.

• The ambient air temperature range is:

0…50 °C (32…122 °F) for all processors.

• The surrounding air temperature range for storage is:

-10…+60 °C (14…140 °F).

• The relative humidity of the ambient air must be:

20…90% noncondensing at 0…40 °C (32…104 °F) and

20…80% noncondensing at 41…50 °C (105…122 °F).

Power Requirements

The nominal output power must be 25% larger than the drained power.

• The output voltage rise time has to be less than 100 ms.

• Consider the working temperature and the thermal derating of the power

supply.

• The inrush current cannot exceed a peak current of 10 A and a pulse width

time of 400 μs.

If you will be adding an accessory (such as side handles, perimeter

handle, or keyboard tray), plan for a wider width at your installation

site. See the applicable section in publication 6300-UM001 for

approximate dimensions of your chosen accessories.

Table 1 - Approximate Dimensions by LCD Size [mm (in.)]: Landscape

Dimension 15.6 in. 18.5 in. 21.5 in. 24 in.

A396.30 (15.60) 461.80 (18.18) 528.80 (20.82) 585.2 (23.04)

B245.80 (9.68) 282.60 (11.13) 320.20 (12.61) 352.8 (13.89)

C304.30 (11.98) 341.10 (13.43) 378.70 (14.91) 411.3 (16.19)

D58.50 (2.30) 58.50 (2.30) 58.50 (2.30) 58.50 (2.30)

A

B

A

BC

D

Device Only with Button Area

Button Area

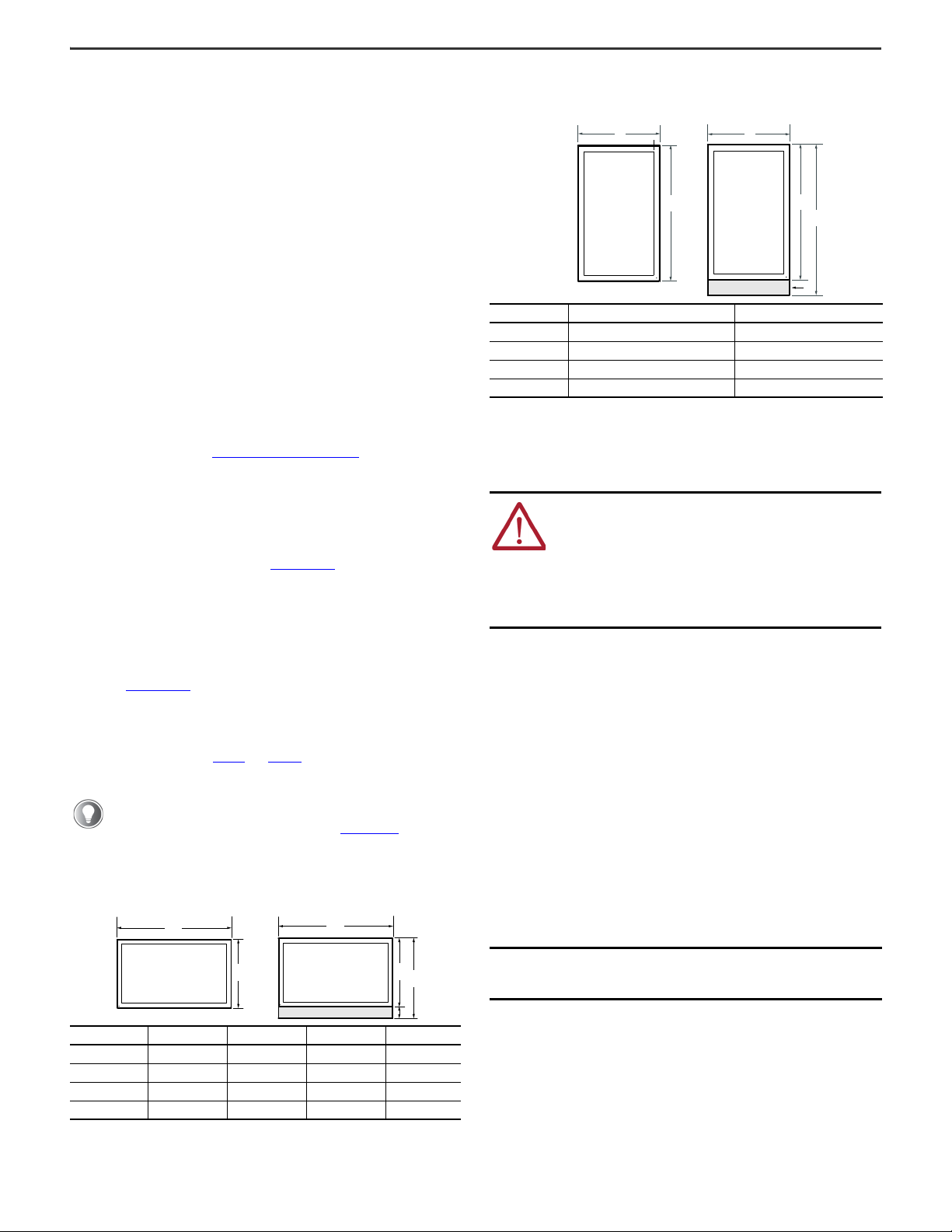

Table 2 - Approximate Dimensions by LCD Size [mm (in.)]: Portrait

Dimension 21.5 in. 24 in.

A320.20 (12.61) 352.80 (13.89)

B528.80 (20.82) 585.20 (23.04)

C587.30 (23.12) 643.90 (25.35)

D58.50 (2.30) 58.70 (2.31)

ATTENTION: This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage Category II

applications (as defined in IEC 60664-1), at altitudes up to

2000 m (6561 ft) without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/EN 61326-1. Without appropriate

precautions, there can be potential difficulties with

electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

IMPORTANT If a non-sufficient power source is used, the initial boot

process can be negatively effected and the operating

system (OS) can cause corruption.

Device Only with Button Area

Button Area