AGA marvel M18SZ Manual

Installation

Operation

and

Maintenance

Instructions

Built In

Wine Cellars

M18SZ

M24SZ

M24DZ

MPRO24DZ

Note: Wine Cellars are designed exclusively for the storage of

wine. Wine Cellars cannot aain storage temperatures suitable

for fresh food storage.

2

is committed to building a quality product

in an environmentally friendly manner. Our processes are

tightly controlled and closely monitored. We have achieved

certications in ISO 9001 for quality assurance, ISO 14001

for environmental management, and OHSAS 18001 for oc-

cupational health and safety from Lloyd’s Register Quality

Assurance.

NOTE

!CAUTION

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situa-

tions that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operat-

ing this appliance.

Recognize Safety Symbols,

Words, and Labels.

!WARNING

WARNING-Hazards or unsafe practices with

high probability of personal injury or property / prod-

uct damage.

CAUTION-Hazards or unsafe practices which could

result in personal injury or property or product damage.

NOTE-Important information to help assure a problem

free installation and operation.

CONTENTS

Unpacking the wine cellar .....................................................3

Tools required ..................................................................3

Warranty registration ...........................................................4

Dimensions for M(XX)SZ with Glass Door ...........................5

Dimensions for M24DZ with Glass Door ...............................6

Dimensions for M24DZ with Glass Overlay Door...................7

Dimensions for MPRO24DZ with Glass Door .......................8

Pre installation considerations ............................................9

Rough in opening ...........................................................9

Select location ................................................................9

Electrical requirements .................................................10

Corner installation .........................................................10

Installing the cabinet .........................................................11

Anti tip bracket considerations .......................................11

Leveling the unit ................................................................12

Installing the power module ..............................................12

Placing power module on top of cabinet .........................12

Power module electrical connections .............................13

Installing the grille .............................................................14

Custom Grille and Door Overlay Panels ............................17

Mounting Grille Overlay Panel ......................................17

Overlay Door Panel Instructions ....................................18

Hinge and gasket adjustments ..........................................20

Installing side panels .........................................................21

Installing the kickplate .......................................................21

Installation checks ............................................................22

Common installation errors ..............................................22

Use and care guide ...........................................................23

Operation of your wine cellar ...........................................23

Defrosting .......................................................................24

Cleaning .........................................................................24

Condenser cleaning procedure ......................................24

Energy saving tips .............................................................25

Product sounds ................................................................25

Troubleshooting guide ......................................................26

Obtaining service ..............................................................26

Warranty ...........................................................................27

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm..

3

!CAUTION

!WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in back or other injury.

Remove Interior Packaging

Your wine cellar has been packed for shipment with all

parts that could be damaged by movement securely fas-

tened. Remove internal packing materials and any tape

holding internal components in place. The owners manual

is shipped inside the product in a plastic bag along with the

warranty registration card, and other accessory items.

Important

Keep your carton and packaging until your wine cellar has

been thoroughly inspected and found to be in good condi-

tion. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly in particular the plastic bags which can

be a suffocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE RE-

TAILER.

If the power module was shipped or has been laying on

its side for any period of time allow the power module to

sit upright for a period of at least 24 hours before plugging

in. This will assure oil returns to the compressor. Plugging

the power module in immediately may cause damage to

internal parts.

UNPACKING YOUR WINE CELLAR

Tools to have available for installation:

• Phillips screwdriver

• Flat blade screwdriver

• Hex head nut drivers size 1⁄4" and 5⁄16"

• Level

• Drill and drill bit (#6 - .204)

• Open end wrenchs size 1⁄4", 7⁄16" and 1⁄2"

• Slip joint pliers

• Adjustable wrench

• Tape measure

• Hex socket and ratchet size 7⁄16"

• 3/32" Hex key (Allen wrench)

Help Prevent Tragedies

Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous even if they sit out for "just a few days".

If you are getting rid of your old freezer, please follow

the instructions below to help prevent accidents.

Before you throw away your old refrigerator:

•Take off the doors or remove the drawers

•Leave the shelves in place so children may not easily

climb inside.

!WARNING

4

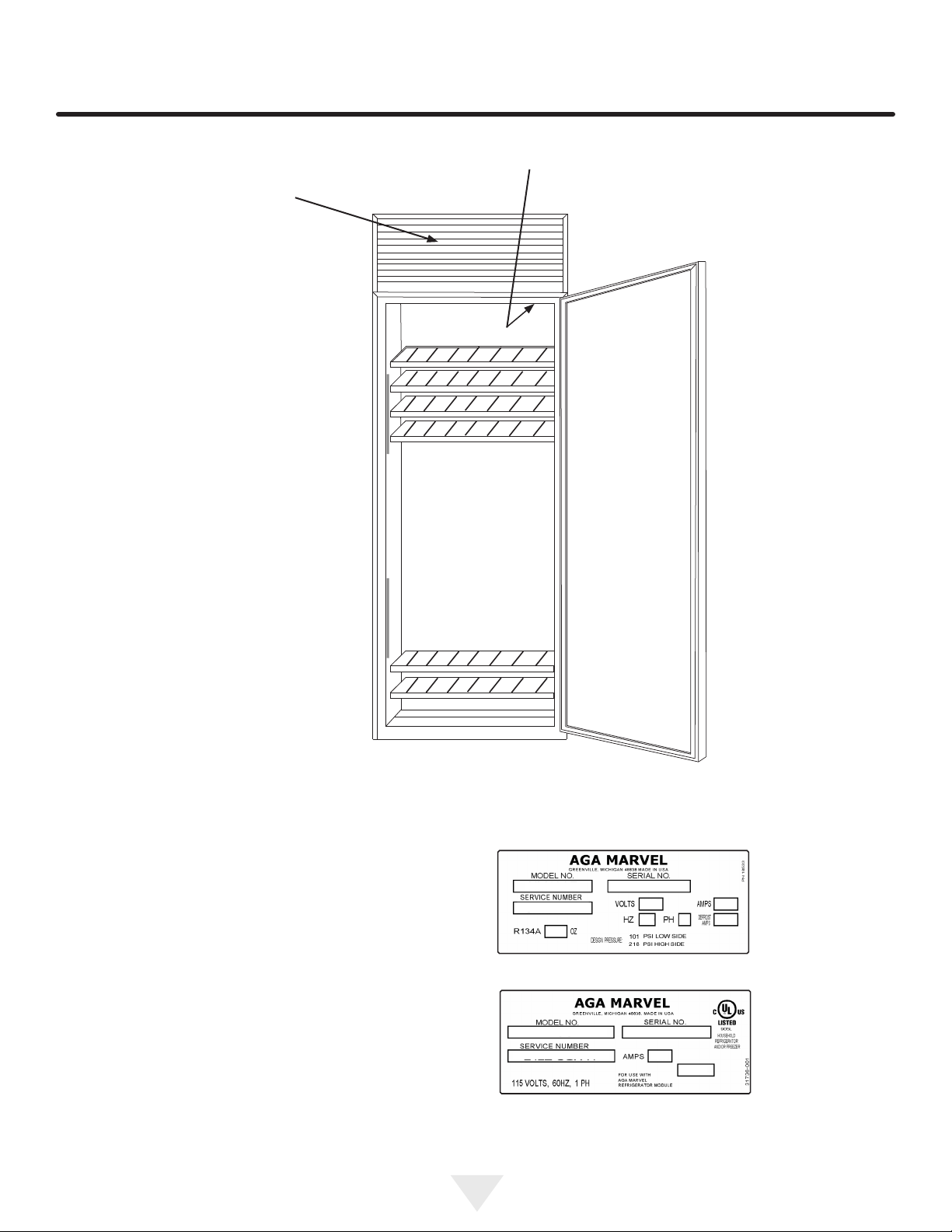

Power module serial

plate is behind the

grille on the front of

the power module-

Cabinet serial plate is on the

inside top liner toward the right

side-

It is important you send in your warranty registration card

immediately after taking delivery of your wine cellar.

The following information will be required when registering

your unit.

Service Number

Serial Number

Date of Purchase

Dealer’s name and address

The service number and serial number can be found on the

serial plates which are located on the power module and

the cabinet. See gure 1 above for locations.

Warranty Registration

Figure 2

Power module

serial plate

Figure 3

Cabinet

serial plate

Figure 1

Serial plate

locations

WARRANTY REGISTRATION

5

PRODUCT DIMENSIONS FOR M(XX)SZ WITH GLASS DOOR

1⁄2"

(12.7mm)

1⁄2"

(12.7mm)

73" to 735⁄8"

(185.4cm to 187cm)

251⁄8"

(63.8cm)

197⁄8"

(50.5cm) To kickplate

To face of door

84" to 845⁄8"

(213.4cm to 214.9cm)

241⁄2"

(62.2cm)

273⁄16"

(69.1cm)

"B"

"C"

"A"

11"

(27.9cm)

29⁄16"

(6.5cm)

Electrical Requirements:

A grounded 115 volt, 60 cycle, single phase, 15 amp

dedicated circuit is required. Follow all local building codes

when installing electrical and unit.

MODEL "A" "B" "C"

M18SZ-BGX 18" (45.7cm) 17" (43.2cm) 4111⁄16" (105.9cm)

M24SZ-BGX 24" (61cm) 23" (58.4cm) 4711⁄16" (121.1cm)

This manual suits for next models

3

Table of contents

Languages:

Other AGA marvel Wine Cooler manuals

AGA marvel

AGA marvel Refrigerated Wine Cellar 3SWCE User manual

AGA marvel

AGA marvel MP15WS Manual

AGA marvel

AGA marvel 3BARM Manual

AGA marvel

AGA marvel ML24WSG0 Series Manual

AGA marvel

AGA marvel 6SDZE Manual

AGA marvel

AGA marvel ML15WS Manual

AGA marvel

AGA marvel MP24WSG0LS Manual

AGA marvel

AGA marvel 30WCM (Marvel) Manual

AGA marvel

AGA marvel MP24WSG0 Manual

AGA marvel

AGA marvel 6BARM Manual