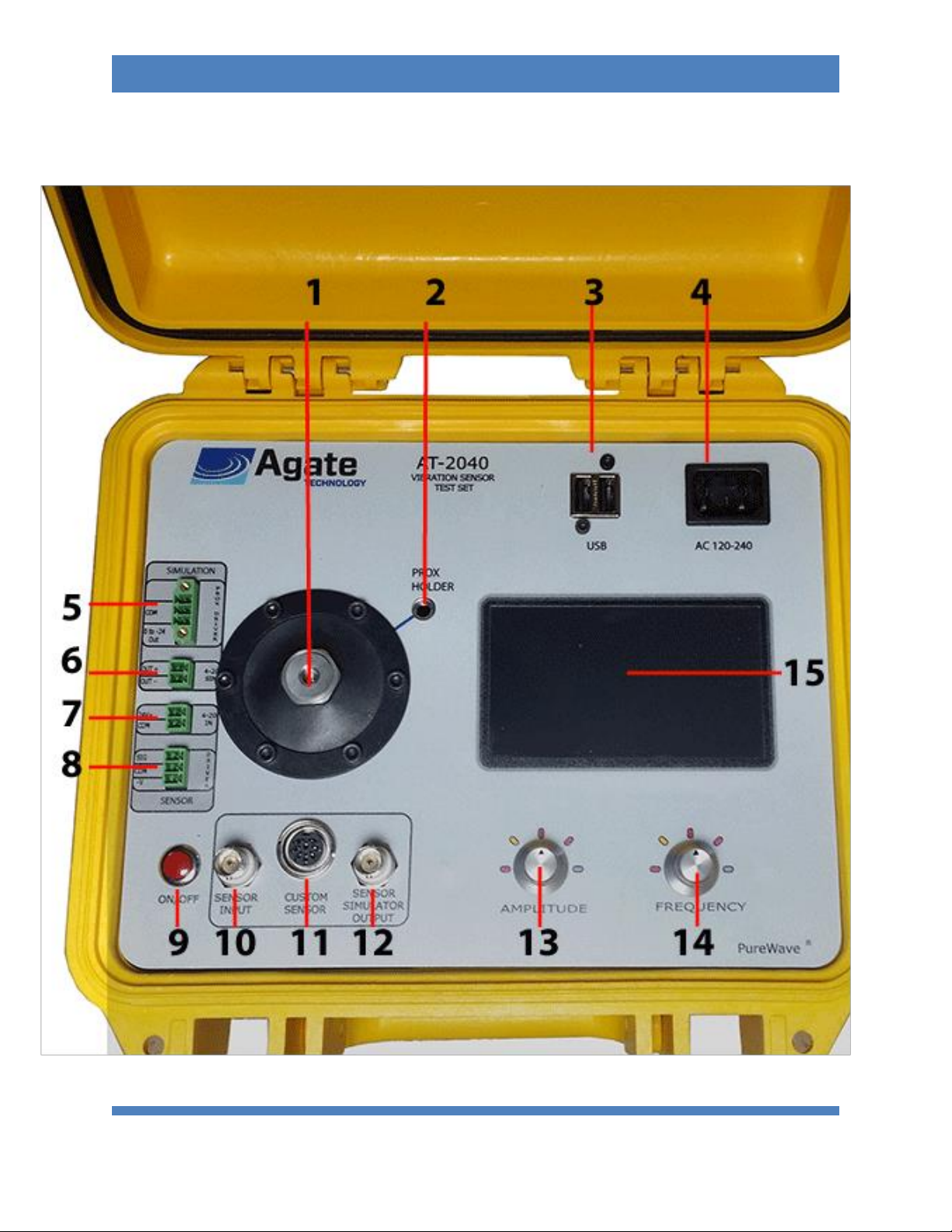

Electrodynamic Shaker: Produces 4.5 lbf pk of sine force and is made with carbon fiber composite and

isolated linear bearings. This provides low distortion when shaking the transducer load.

Reference Accelerometer: NIST traceable calibration standard accelerometer with ¼-28 tapped

mounting hole.

Computer: 1 GHz Cortex-A8 processor, 512 MB DDR3 RAM, 20GB of storage memory included, with USB

and network connectivity.

Charge Converter: For direct input of charge mode accelerometers

Signal Generation Board: Consists of multiple amplifiers and channels selectable by internal relays. This

is categorized into three different applications.

1. The Power Amplifier Output: To control the vibration of the electrodynamic shaker at

the amplitude and frequency set by the user.

2. Input: To read in sensitivity of multiple transducer types.

3. Signal Generator: To output a wide range of simulated voltage and current

measurements.

LCD Screen: Color 4.3 inch LCD 480x272 resolution display with resistive touch screen.

Primary Functions of the AT-2040:

•To shake or excite a transducer under test.

In shake mode, AT-2040 can be used as a variable frequency, variable amplitude shaker.

In this mode, the frequency and amplitude are set manually by the user, while the

computer provides high accuracy measurement signals.

•To calculate transducer sensitivity.

By comparing signals sent to the reference accelerometer by the signal generation

board and the signals returned by the transducer under test, the AT-2040 can

automatically determine test transducers sensitivity to a high level of accuracy.

•To produce a NIST traceable calibration certificate.

Once the sensitivity has been calculated and saved across the test transducer’s

frequency range, the AT-2040 will produce a NIST traceable certificate and graph in PDF

format. This certificate is stored into the computer’s memory, or recalled and exported

anytime to USB.

•To simulate a transducer using a precision signal generator (function generator).