OPERATION MANUAL

Class Degree of Risk

WARNING

A safety hazard could result in bodily injury or damage to the device if the

safety instructions are not properly followed.

CAUTION A hazard that could result in light or moderate bodily injury or damage

to the device if the safety instructions are not followed.

Thank you for purchasing 90°Angle Spindle RAS - 101 / RAS - 151E. This spindle is designed for grinding, small

diameter drilling and milling.

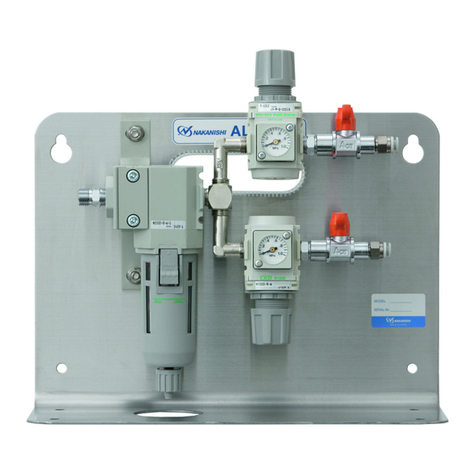

The <E3000 CONTROLLER / E2530 Control Unit>, <Brushless Motor> or <Air Motor> and <Air Line Kit > are

rquired to drive this spindle. Read this Operation Manual carefully before use. Also read <E3000 CONTROLLER /

E2530 Control Unit>, <Brushless Motor> or <Air Motor> and <Air Line Kit> Operation Manuals.

OM-K0410E

90°Angle Spindle

RAS-101・RAS-151E

002

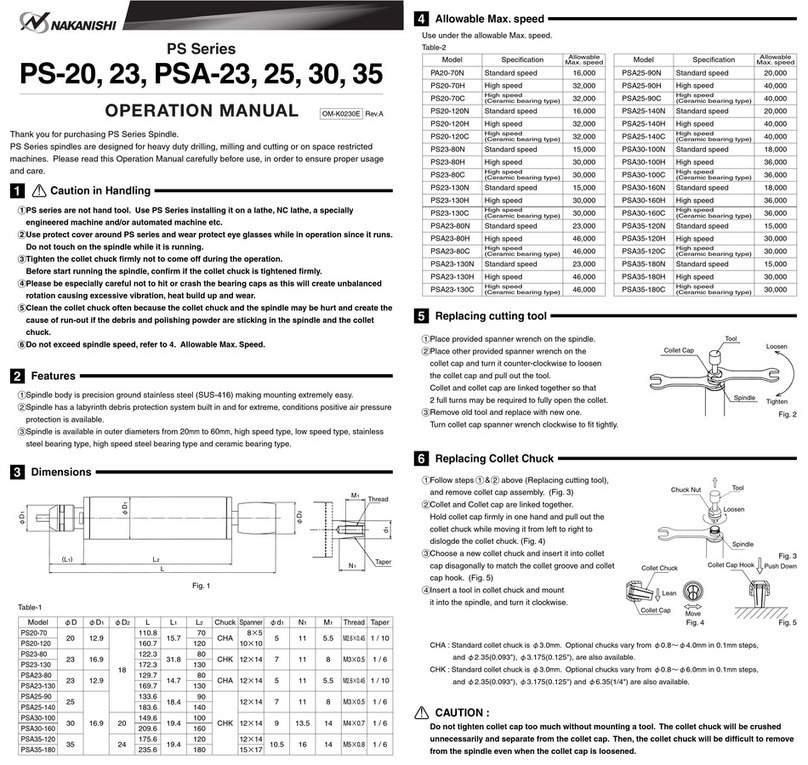

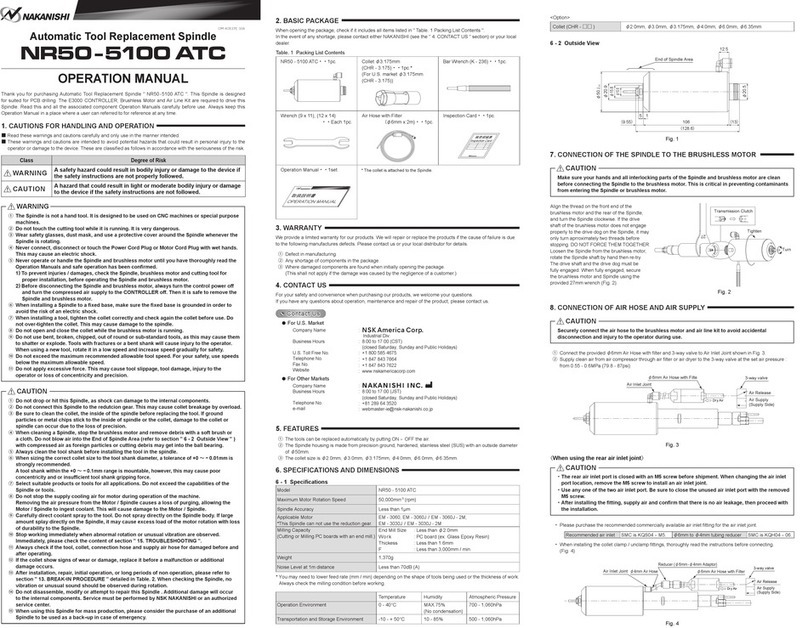

3. SPECIFICATIONS AND DIMENSIONS

3 - 1 Specification

Model RAS - 101 RAS - 151E

Maximum rotating

speed at the tool

For Air Motor 2,870min-1 7,200min-1

For Brushless Motor 7,490min-1 7,490min-1

Maximun Motor

Rotation Speed

For Air Motor 7,650min-1 19,000min-1

For Brushless Motor 20,000min-1 20,000min-1

Applicable Motor

For Air Motor AM - 300R / L, AM - 300RA / LA

AM - 310R / L, AM - 310RA / LA

AM - 3020R / L

AM - 3020RA / LA

For Brushless Motor EM25 - 5000 - 4M / 5M / 8M

EM25 - 5000 - J4 / J5 / J8

EM - 3060, EM - 3060J

EM - 3060J - 2M, EM - 3030J

EM - 3030J - 2M

Applicable Control Unit (For Brushless Motor)

E2530 Control Unit E3000 CONTROLLER

Spindle Accuracy Less than 2μm

Reduction Ratio 1 / 2.67

Weight 325g 413g

Noise Level at 1m distance Less than 70dB (A)

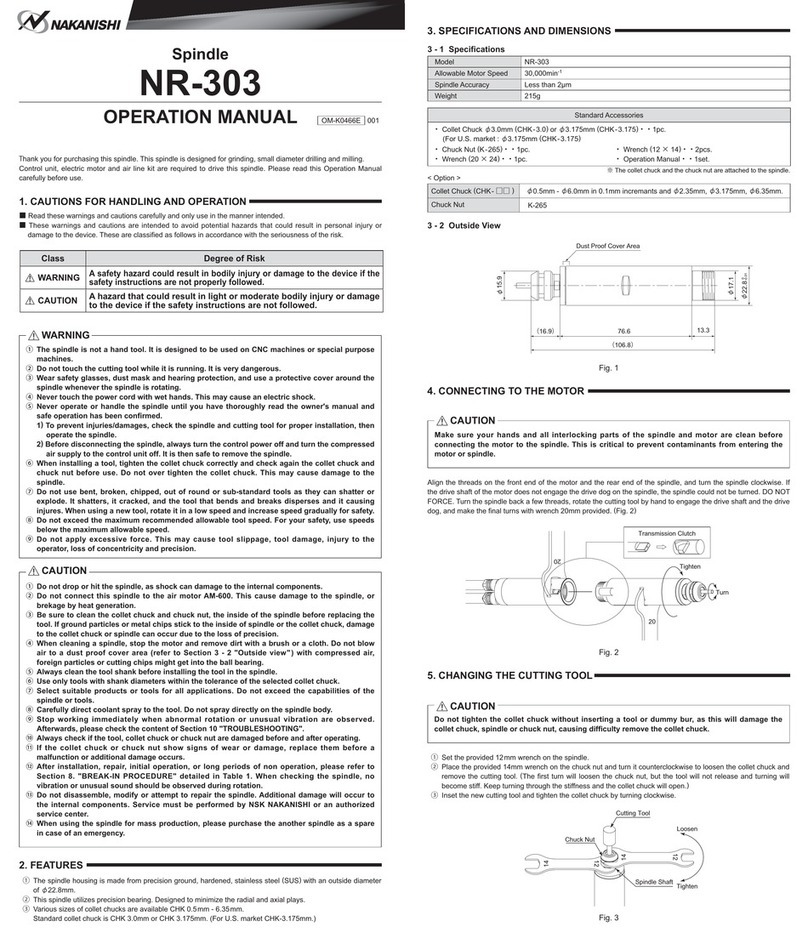

Loosen

14

12

Spindle Shaft

Chuck Nut

Tool

①Remove the tool according to the section

" 5. CHANGING THE TOOL " procedure

above and remove chuck nut assembly

(Fig. 5).

②The collet chuck and chuck nut are secured

by a groove in the collet chuck and a flange

in the chuck nut. To remove the collet chuck

hold the chuck nut in one hand and push

diagonally down on the collet chuck. The

collet chuck should be released (Fig. 6).

③To install the collet chuck, hold the collet

chuck at a slight angle, and insert it into the

chuck nut (Fig. 7).

Press the collet chuck in the chuck nut by

positioning the collet chuck in the chuck nut

and pressing down on flat surface (Fig. 6).

Be sure to fully engage the latch inside

the chuck nut into the groove on the collet

chucks outer circumference area (Fig. 8).

Fig. 5 Fig. 6

Groove

Latch Collet Chuck

Chuck Nut

Latch

Collet Chuck

Wrench Seat

Chuck Nut

Down

Fig. 7 Fig. 8

1. CAUTIONS FOR HANDLING AND OPERATION

■Read these warnings and cautions carefully and only use in the manner intended.

■These warnings and cautions are intended to avoid potential hazards that could result in personal injury or

damage to the device. These are classified as follows in accordance with the seriousness of the risk.

WARNING

①This spindle is not a hand tool. It is designed to be used on CNC machines or special purpose

machines.

②Do not touch the cutting tool while it is running. It is very dangerous.

③Wear safety glasses, dust mask and use a protective cover around the spindle whenever the

spindle is rotating.

④Never connect, disconnect or touch the Power Cord Plug and Motor Cord Connector with wet

hands. This may cause an electric shock.

⑤Never operate or handle the spindle until you have thoroughly read the owner's manual and

safe operation has been confirmed.

1) To prevent injuries / damages, check the spindle and cutting tool for proper installation,

before operating the spindle.

2) Before disconnecting the spindle, always turn the control power off and turn the compressed

air supply to the Control Unit off. Then it is safe to remove the spindle.

⑥When installing a spindle to a fixed base, make sure the fixed base is grounded in order to

avoid the risk of an electric shock.

⑦

When installing a tool, tighten the collet chuck correctly and check again the collet chuck and

chuck nut before use. Do not over-tighten the collet chuck. This may cause damage to the spindle.

⑧Do not use bent, broken, chipped, out of round or sub-standard tools as they may cause

shatter or explode. Tool with fractures or a bent shank will cause injury to the operator. When

using a new tool, rotate it in a low speed and increase speed gradually for safety.

⑨Do not exceed the maximum recommended allowable tool speed. For your safety, use speeds

below the maximum allowable speed.

⑩Do not apply excessive force. This may cause tool slippage, tool damage, injury to the operator

or loss of concentricity and precision.

CAUTION

①Do not ecxeed the maximum allowable motor speed 20,000min-1.

②Do not drop or hit this spindle, as shock can damage to the internal components.

③Be sure to clean the collet chuck and chuck nut, the inside of the spindle before replacing the

tool. If ground particles or metal chips stick to the inside of spindle or the collet chuck, damage

to the collet chuck or spindle can occur due to the loss of precision.

④When cleaning a spindle, stop the motor and remove debris with a soft brush or a cloth. Do not

blow air into the dust proof cover area (refer to section " 3 - 2 Outside view " ) with compressed

air as foreign particles or cutting debris may get into the ball bearing.

⑤Always clean the tool shank before installing the tool in the spindle.

⑥

When sizing the correct collet chuck size to the tool shank diameter, a tolerance of + 0 〜

-

0.01mm

is strongly recommended. A tool shank within the + 0 〜

-

0.1mm range is mountable, however,

this may cause poor concentricity and or insufficient tool shank gripping force.

⑦Select suitable products or tools for all applications. Do not exceed the capabilities of the

spindle or tools.

⑧Carefully direct coolant spray to the tool. Do not spray directly on the spindle body.

⑨Stop working immediately when abnormal rotation or unusual vibration are observed.

Afterwards, please check the content of section " 10 TROUBLESHOOTING ".

⑩Always check if the tool, collet chuck or chuck nut are damaged before and after operating.

⑪

If the collet chuck or chuck nut show signs of wear or damage, replace them before a malfunction

or additional damage occurs.

⑫After installation, repair, initial operation, or long periods of non operation, please refer to

section " 8. BREAK-IN PROCEDURE " detailed in Table 2. When checking the spindle, no

vibration or unusual sound should be observed during rotation.

⑬Do not disassemble, modify or attempt to repair this spindle. Additional damage will occur

to the internal components. Service must be performed by NSK NAKANISHI or an authorized

service center.

⑭When using this spindle for mass production, please purchase the another spindle as a spare

in case of an emergency.

2. FEATURES

①The spindle is capable of working on corners dificult to work or unit for working or unfit for working with straight

type spindle.

②The spindle housing is made from precision ground, hardened, stainless steel (SUS) with an outside diameter

of ȭ22.8mm (RAS-101)or ȭ30mm (RAS-151E).

③Various sizes of collet chucks are available CHK 0.5mm - 6.35mm. Standard collet chuck is CHK - 3.0mm or

CHK - 3.175mm. (For U.S. market CHK - 3.175mm.)

Standard Accessories

・Collet Chuck ȭ3.0mm (CHK-3.0) or ȭ3.175mm (CHK-3.175)・・1pc.

(For U.S. market ȭ3.175mm (CHK-3.175))

・Chuck Nut (K-265) ・・1pc.

・Wrench (12 ×14)・・2pcs.

・

Wrench

(22 ×27 : RAS-151E) or (20 ×24 : RAS-101)・・1pc.

・Operation Manual・・1set.

*The collet chuck and chuck nut are attached to the spindle.

Collet Chuck (CHK- □□ )ȭ0.5mm 〜ȭ6.0mm in 0.1mm increments and ȭ2.35mm, ȭ3.175mm, ȭ6.35mm

Chuck Nut K-265

<Option>

CAUTION

Use less than the maximum allowable motor speed 20,000min-1.

DO NOT exceed the maximum allowable motor speed 20,000min-1 for the spindle.

3 - 2 Outside view

Fig. 2 RAS-151E

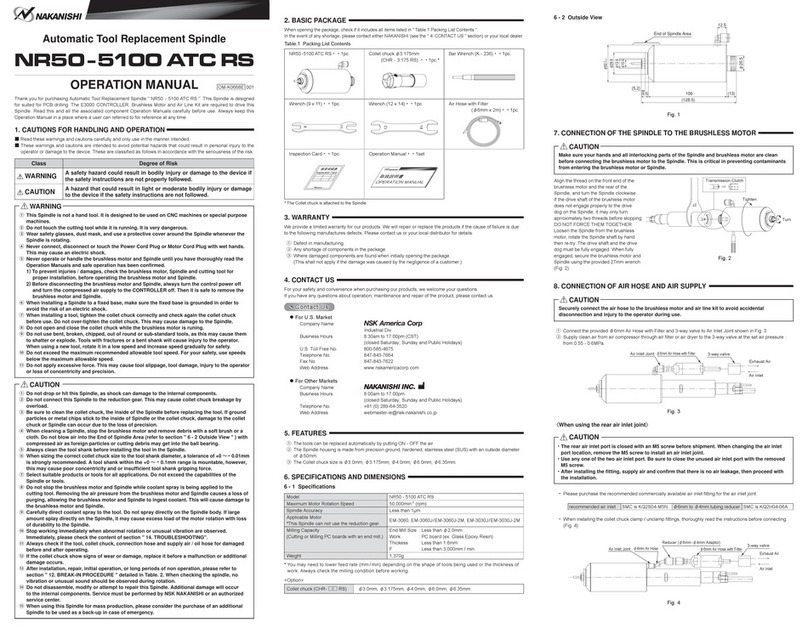

4. CONNECTING THE SPINDLE TO THE MOTOR

Align the threads on the front end of the motor

and the rear end of the spindle, and turn the

spindle clockwise. If the drive shaft of the motor

does not engage the drive dog on the spindle,

the spindle could not be turned. DO NOT

FORCE. Turn the spindle back a few threads,

rotate the tool by hand to engage the drive

shaft and the drive dog, and make the final

turns with provided wrench.

Turn

Tighten

RAS-101

Transmisson Cluch (

-

)

RAS-151E

Transmisson Cluch (+)

Fig. 3

-0.01

0

Ǿ

22.8

-0.01

0

Ǿ

22.8

1475(16.9)1475(16.9)

47

-0.01

0

Ǿ

30

47

Ǿ15.9

Ǿ15.9

-0.01

0

Ǿ

23

Dust Proof Cover Area Dust Proof Cover Area

Fig. 1 RAS-101

5. CHANGING THE TOOL

①Set the provided 12mm wrench on the spindle.

②Place the provided 14mm wrench on the chuck nut and

turn it counterclockwise to loosen the collet chuck and

remove the tool. (The first turn will loosen the chuck nut,

but the tool will not release and turning will become stiff.

Keep turning through the stiffness and the collet chuck

will open.)

③Clean the collet chuck and chuck nut, then insert the new

tool and tighten the collet chuck by turning clockwise. Do

not overtighten.

12

12

14

Tool

Spindle Shaft

Loosen

Tighten

Chuck Nut

14

Fig. 4

CAUTION

・Make sure your hands and all interlocking parts of the spindle and motor are clean before

connecting the motor to the spindle. This is critical to prevent contaminants from entering the

motor or spindle.

・RAS-101 is drive (

-

) configuration clutch. The (

-

)drive spindles were designed to be used with (

-

)

drive motors and speed reducers.

Do not tighten the collet chuck without inserting a tool or dummy bur, as this will damage the collet

chuck, spindle or chuck nut, causing difficulty removing the collet chuck.

CAUTION

6. REPLACING THE COLLET CHUCK

When installing the collet chuck in the chuck nut, make sure to fully engage the latch inside the

chuck nut to the groove on the collet chucks outer circumference area. In addition, remember that

if the collet chuck is attached without being engaged with the latch of the chuck nut, the collet

chuck cannot be removed and this may cause damage to the collet chuck or the spindle.

CAUTION

Temperature Humidity

Atmospheric Pressure

Operation Environment 0 - 40°CMAX.75%

(No condensation) 700 - 1,060hPa

Transportation and Storage Environment -10 - + 50°C 10 - 85% 500 - 1,060hPa