3

AGC Stopray SMART –Processing Guide –Version 4.1 –May 2020

CONTENTS

1.

PRODUCTS ......................................................................................................................................................................4

I.

RECEPTION AND STORAGE ...............................................................................................................................4

1.

Unloading ...................................................................................................................................................................4

2.

Storage of the packs ........................................................................................................................................5

II.

PROCESSING .......................................................................................................................................................6

1.

Safety & General Information .........................................................................................................................6

2.

Cutting ............................................................................................................................................................7

3.

Edge Processing .........................................................................................................................................7

4.

Edge Deletion .................................................................................................................................................8

5.

Washing .....................................................................................................................................................................8

6.

Silk screen printing .........................................................................................................................................9

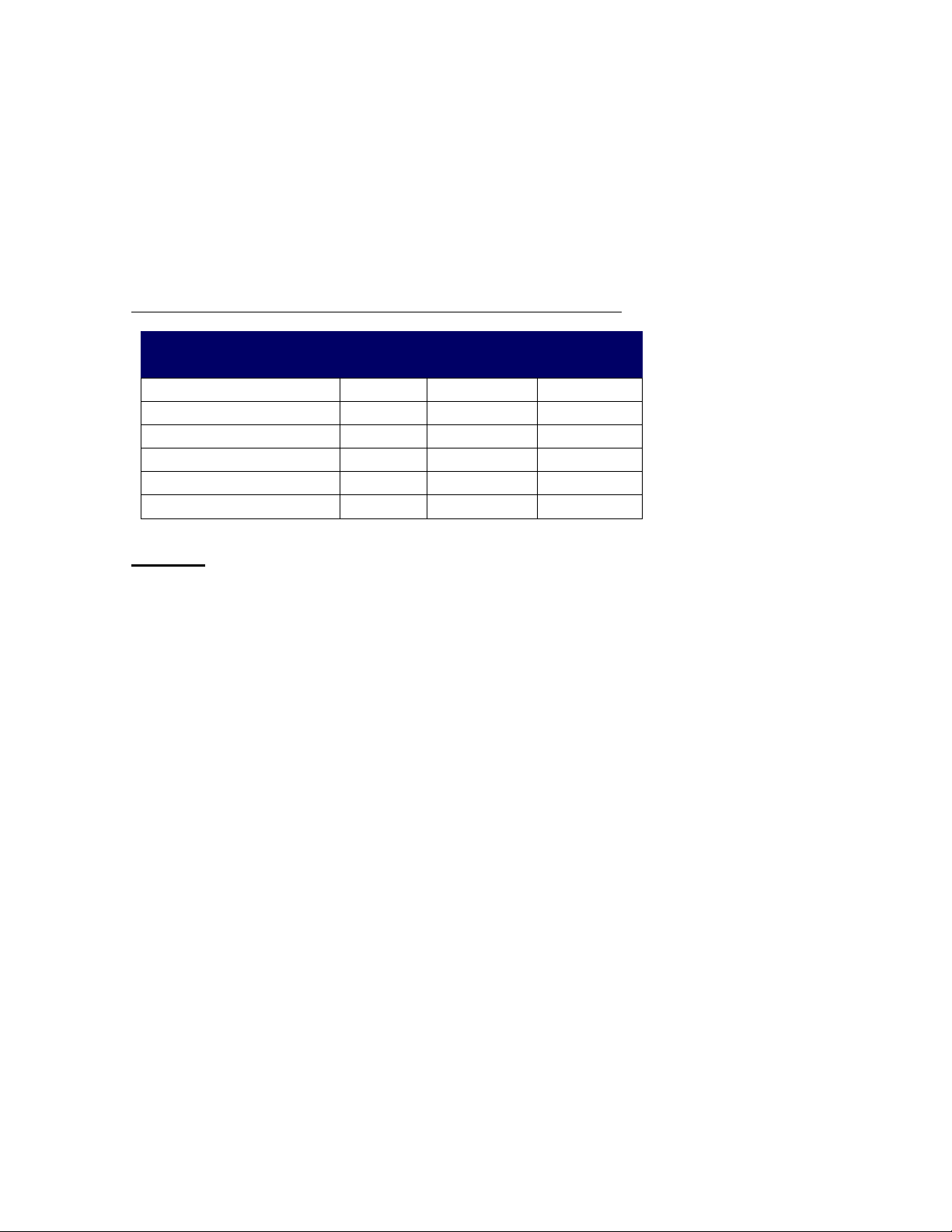

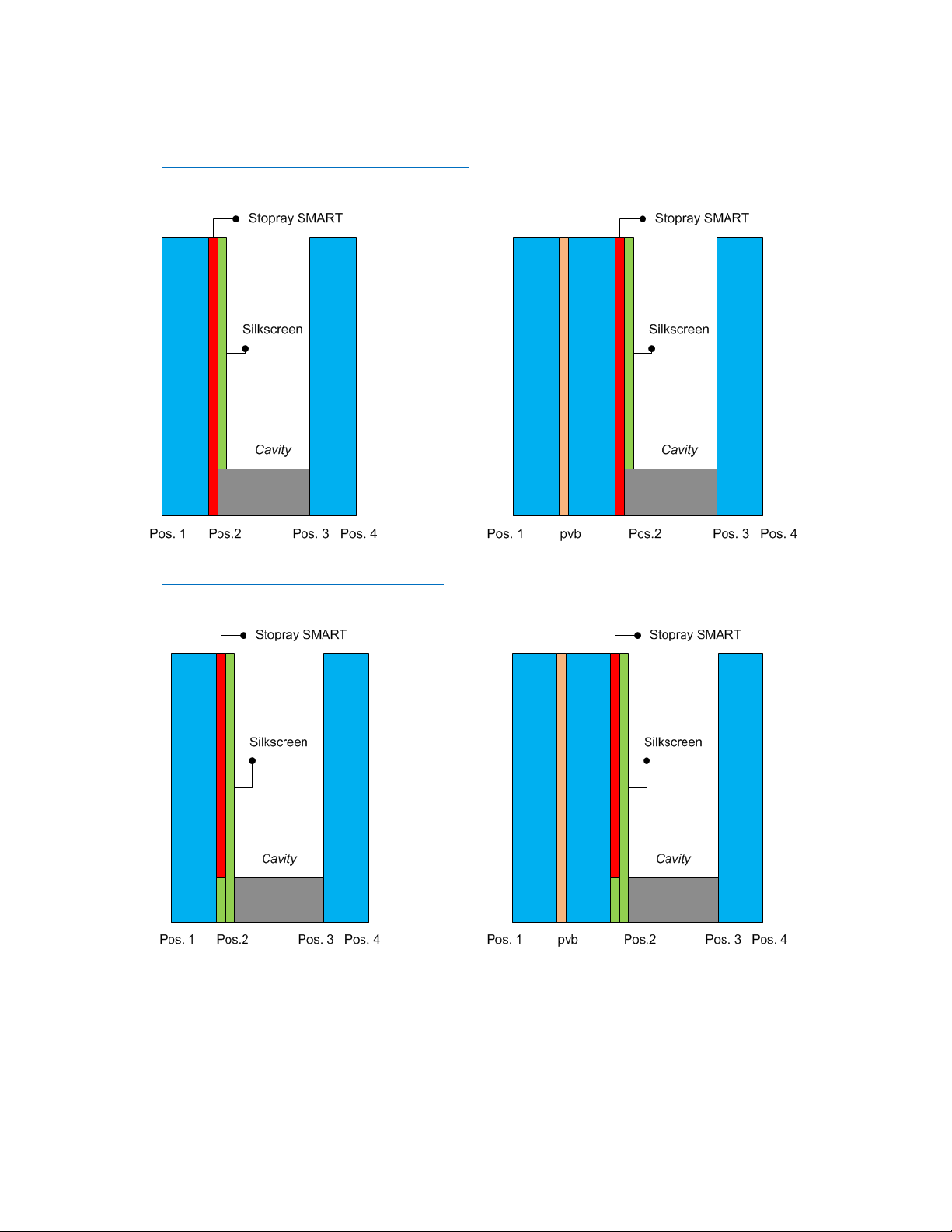

6.1

Stopray SMART with silkscreen................................................................................................................9

6.2

Stopray SMART laminated with silkscreen .............................................................................................11

7.

Thermal Toughening / Heat strengthening .................................................................................................... 11

7.1

Introduction ............................................................................................................................................. 11

7.2

Generalities............................................................................................................................................. 11

7.3

Recommendations ..................................................................................................................................12

7.4

Settings...................................................................................................................................................13

7.5

Unloading................................................................................................................................................14

7.6

Heat Soak test ........................................................................................................................................14

7.7

Quality control.........................................................................................................................................14

7.8

Packaging ...............................................................................................................................................15

8.

Bending ........................................................................................................................................................15

8.1

Curved annealed glass (on a concave mould)........................................................................................15

8.2

Curved toughened glass (on a concave mould)......................................................................................16

9.

Lamination ................................................................................................................................................17

10.

Assembly in Insulating Glass Unit...................................................................................................................19

11.

Use in Structural glazing...............................................................................................................................20

12.

Identifying the coated surface.......................................................................................................................20

13.

Storage of cut sizes / IGU.............................................................................................................................21

13.1

During processing in the same factory .................................................................................................21

13.2

To send cut size to another factory .......................................................................................................21

13.3

On site ..................................................................................................................................................21

III.

CONFORMITY and GUARANTEE ..........................................................................................................................22

1.

Conformity....................................................................................................................................................22

2.

Warranty...................................................................................................................................................22

3.

Local Standards ........................................................................................................................................22

4.

Disclaimer ....................................................................................................................................................22

IV.

GLAZING INSTRUCTIONS.................................................................................................................................22

V.

CLEANING ON FACADE ........................................................................................................................................22