Section I

1-1 SCOPE

Wherever applicable, the service instructions given in this

manual refer to pertinent information provided in the

Operating Manual. The information in each manual covers

model 6625A, 6626A, 6628A, and 6629A. The main

differences between the models are the number and type of

outputs each model contains. These differences are specified

in each of the manuals.

The following is a listing of the information contained in this

manual with a brief description concerning its scope and

purpose.

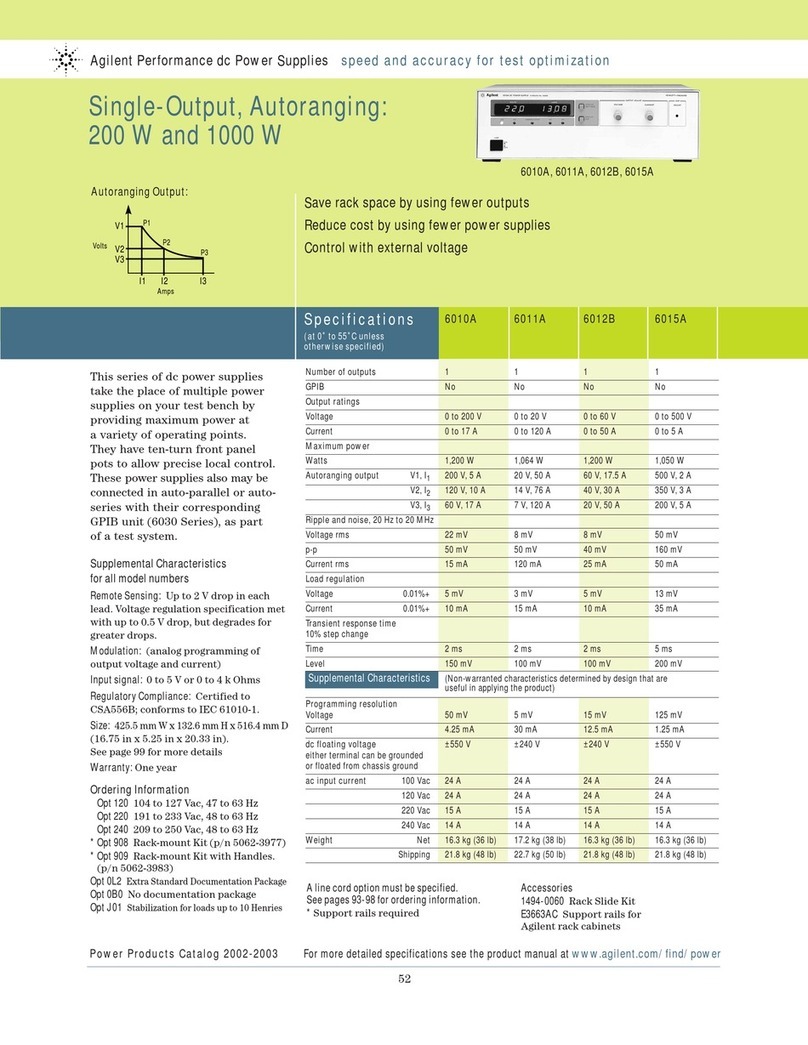

Principles of Operation: Section II provides block diagram

level descriptions of the supply’s circuits. The GPIB

interface (digital circuits), the power control (analog and

digital circuits), and power output (analog circuits) are

described. These descriptions are intended as an aid in

troubleshooting.

Verification: Section III contains test procedures that check

the operation of the supply to ensure that it meets the

specifications given in Section I of the Operating manual.

Troubleshooting: Section IV contains board level

troubleshooting procedures to isolate a malfunction to a

defective board (GPIB or output board) or assembly (front

panel, power transformer, or cable assembly). Additional

troubleshooting procedures are provided to isolate the fault

to a defective component on the board. Board and assembly

level removal and replacement procedures are also given in

this section.

NOTE

Calibration is generally required after a repair is made.

Software calibration procedures are given in Appendix A

of the Operating Manual. After calibration is completed,

perform the applicable test(s) given in Section III of this

manual to ensure that the supply meets all specifications.

Replaceable Parts: Section V provides a listing of

replaceable parts for all electronic components and

mechanical assemblies.

Circuit Diagrams: Section VI contains functional schematics

on the functional schematics also appear on the block

diagrams in Section II. Thus, the descriptions in Section II

can be correlated with both the block diagrams and the

schematics.

Logic Symbology: Appendix A gives a brief description of

the logic symbols used on the functional schematics.

Fault Indicator (FLT) and Remote Inhibit (INH): A fault

indicator and remote inhibit circuit, which provide

additionalshutdownprotection should eitherthe GPIB

and/or controller fail, are available optionally. See a

separate document entitled, "Appendix E Option 750

Operating Instructions" for the Multiple Output Linear

System DC Power Supply Agilent Models 662xA (Agilent

P/N 5957-6372).

1-2 SAFETY CONSIDERATIONS

This product is a Safety Class 1 instrument, which means

that it is provided with a protective earth terminal. The

instrument and this manual should be reviewed for safety

markings and instructions before operation. Refer to the

Safety Summary page at the beginning of this manual for a

summary of general safety information. Safety information

for specific procedures is located at appropriate places in the

manual.

1-3 INSTRUMENT AND MANUAL

IDENTIFICATION

Agilent Techonologies instruments are identified by a two-

part Serial number, i.e. 2601A-00101. The first part of the

serial number (the prefix) is a number/letter combination

that denotes either the date of manufacture or the date of a

significant design change. It also indicates the country of

manufacture. The first two digits indicate the year (25 =

1985, 26 = 1986, etc), the second two digits indicate the week,

and “A” designates the U.S.A. The second part of the serial

number is a different sequential number assigned to each

instrument.

and component location diagrams. The names that appear

INTRODUCTION

1-1

This manual contains principles of operation, verification,

and troubleshooting information for the power supply.

Replaceable parts lists and circuit diagrams are also

provided. Installation, operation, programming, and

calibration procedures as well as detailed specifications are

given in a separate Operating Manual, Agilent Part No.

06626-90001.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com