5

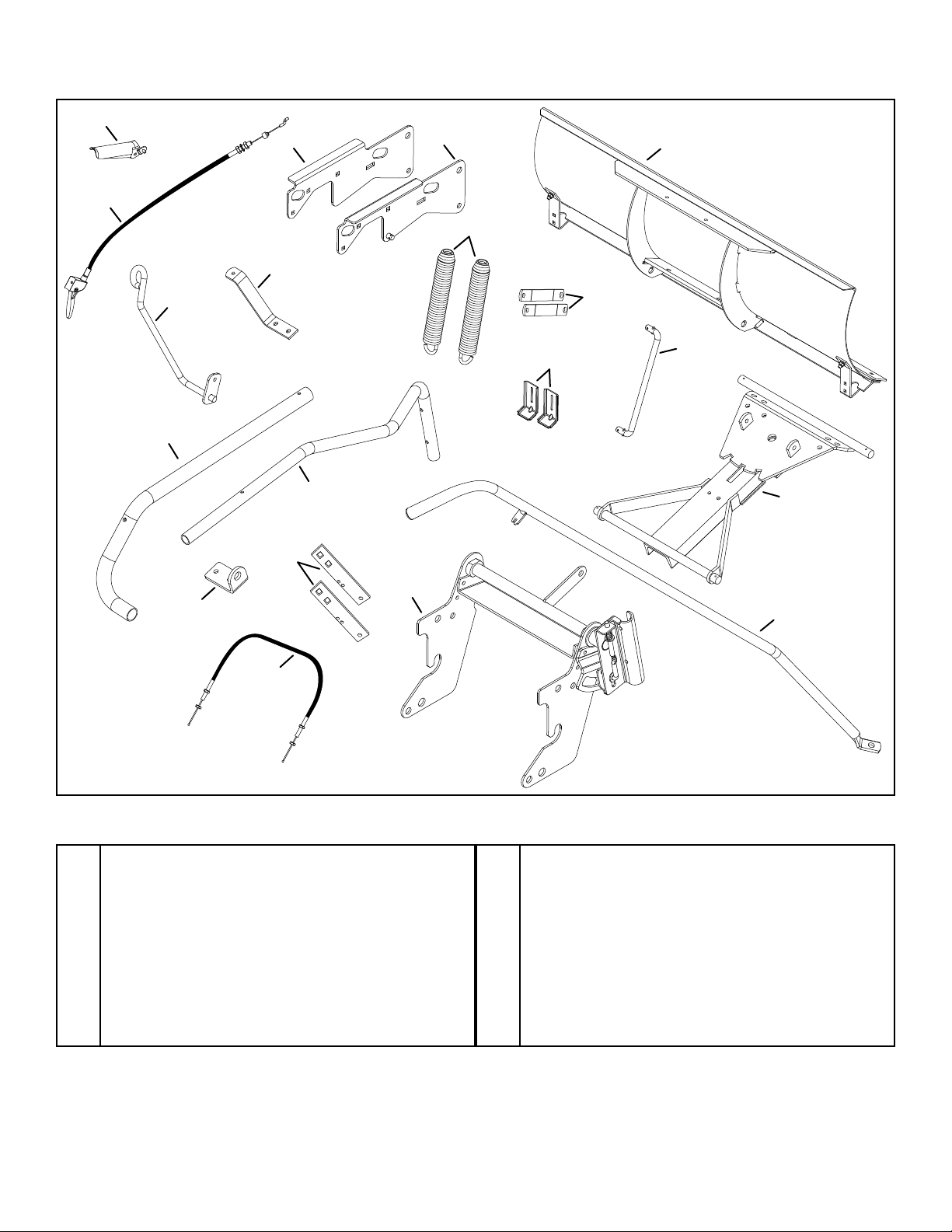

CONTENTS OF PARTS PACKAGE

REF PART NO. QTY. DESCRIPTION

A 43510 2 Hex Bolt, 1/2" x 2-3/4"

B 41596 2 Hex Bolt, 1/2" x 2"

C 43020 2 Hex Bolt, 1/2" x 1-1/2"

D 43084 2 Hex Bolt, 5/16" x 1-3/4"

E 43087 2 Hex Bolt, 3/8" x 1-1/4"

F 43001 4 Hex Bolt, 3/8" x 1"

G 43182 2 Hex Bolt, 5/16" x 3/4"

H 44071 2 Hex Bolt, 3/8" x 3-1/2"

I 48106 1 Shoulder Bolt

J 43350 6 Carriage Bolt, 3/8" x 1"

K 710-0305 2 Carriage Bolt, 3/8" x 1-1/4"

L 44326 6 Carriage Bolt, 5/16-18 x 1"

M 43085 1 Hex Bolt, 5/16" x 1-1/2"

N 43648 2 Hex Bolt, 1/4" x 1-1/2"

O 43010 4 Cotter Pin, 1/8" x 1-1/4"

P 712-3083 4 Nylock Nut, 1/2"

Q HA21362 10 Nylock Nut, 3/8"

R 47189 3 Nylock Nut, 1/4"

S 44072 1 Whizlock Hex Nut, 3/8"

T 712-0256 2 Hex Jam Nut, 5/16"

U 23658 1 Spacer, Long

REF PART NO. QTY. DESCRIPTION

V 47810 11 Nylock Hex Nut, 5/16"

W 712-0206 4 Hex Nut, 1/2"

X 43015 4 Hex Nut, 3/8"

Y 47364 2 Spacer, Short

Z 43003 4 Lock Washer, 3/8"

AA 49344 1 Screw, #10 x 1-3/4"

BB 43009 2 Washer, 3/4"

CC R19172410 8 Washer, Large

DD R19212113 6 Washer, 5/8"

EE R19171616 4 Washer, Small

FF 43081 4 Washer, 5/16"

GG 05762 1 Cable Mount Bracket

HH 726-0178 2 Nylon Tie

II 711-0309 4 Clevis Pin, 5/8"

JJ 44074 2 Plastic Cap

KK 43343 8 Hair Cotter Pin

LL 746-0260 2 Cable End Fitting

MM 43348 1 Extension Spring

NN 43349 1 Spring Pin,

OO 48083 1 Plastic Grip

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

(1) 7/16" Wrench

(1) 1/2" Wrench

(1) 9/16" Wrench

(1) 3/4" Wrench

(1) Adjustable Wrench

(1) Phillips Screwdriver

(1) Hammer

• Removeallpartsandhardwarepackagesfromthe

carton. Lay out parts and hardware and identify using

the illustrations on pages 3 and 4.

NOTE: Not all of the supplied parts and hardware will be

needed for one particular tractor. Unneeded items may be

discarded after assembly has been completed.

NOTE: Right hand (RH) and left hand (LH) are

determined from the operator's position while seated on

the tractor.

CAUTION: Do not begin assembling

until the tractor engine, muffler and exhaust

deector have been allowed to cool off.

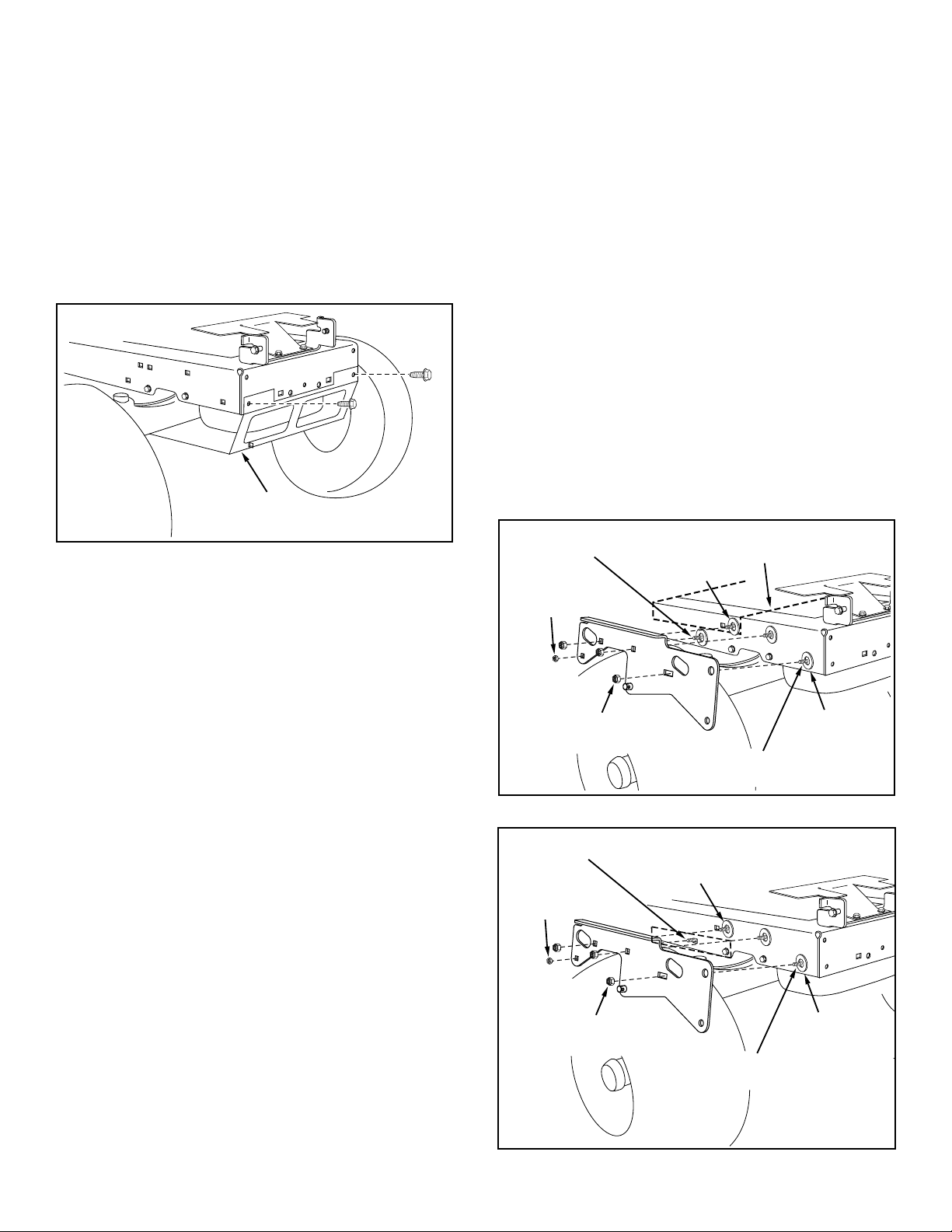

STEP 1: (SEE FIGURE 1)

• Lookunderthefrontofyourtractor.Ifthereisasingle

mower deck suspension bracket located underneath

the middle of the front axle, continue on to step 2. If

your tractor does not have a mower deck suspension

bracket underneath the middle of the front axle, skip

to step 5 on page 7 for tractors with dual suspension

brackets.

MOWER DECK

SUSPENSION

BRACKET

FIGURE 1