GSi PNEG-2314 User manual

Other GSi Farm Equipment manuals

GSi

GSi EVO-50 Instructions for use

GSi

GSi 2000 Series User manual

GSi

GSi PNEG-2113 User manual

GSi

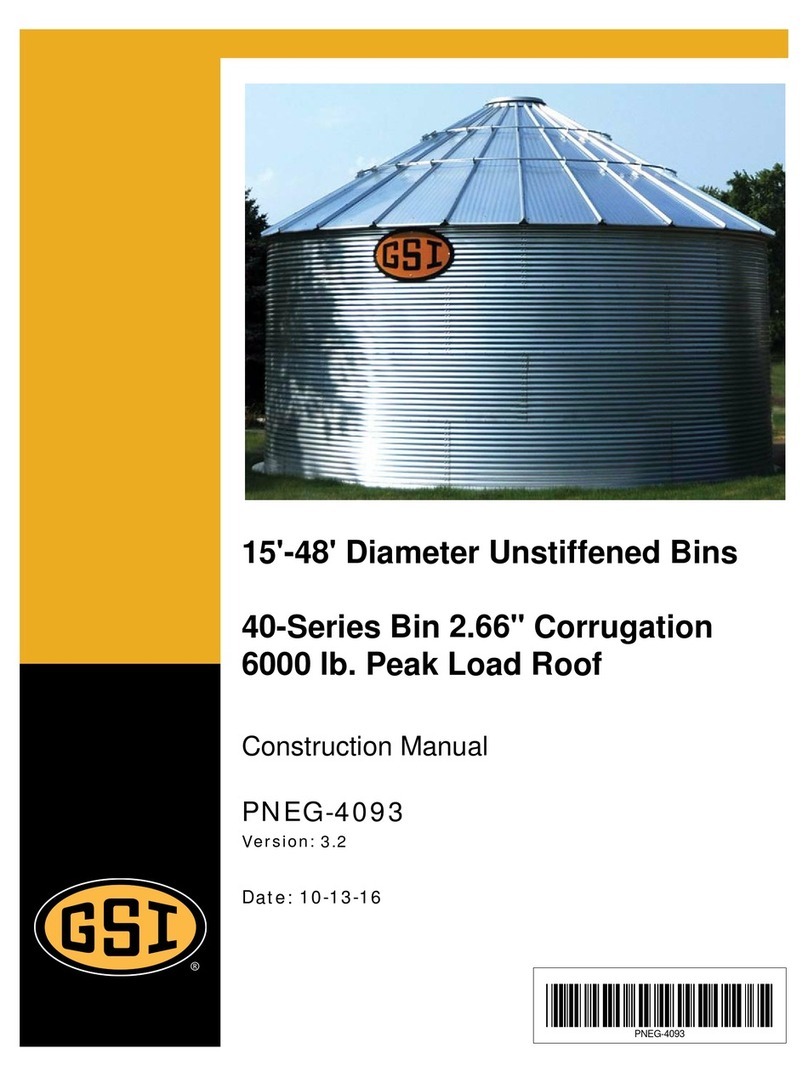

GSi 40 Series Instructions for use

GSi

GSi Vision Watchdog User manual

GSi

GSi COMPETITOR 2000 Series Operation manual

GSi

GSi PNEG-1724 User manual

GSi

GSi PNEG-2105 User manual

GSi

GSi TopDry TD-101164 User manual

GSi

GSi AIRSTREAM User manual

GSi

GSi Design III Series User manual

GSi

GSi BFT Series User manual

GSi

GSi 40 Series Instructions for use

GSi

GSi Sweep II Series User manual

GSi

GSi 40 Series Instructions for use

GSi

GSi GRA User manual

GSi

GSi PNEG-2309 User manual

GSi

GSi TopDry User manual

GSi

GSi TopDry Series User manual

GSi

GSi 40 Series Instructions for use

Popular Farm Equipment manuals by other brands

Checchi & Magli

Checchi & Magli TEXDRIVE owner's manual

Amazone

Amazone Cenius 4003-2TX operating manual

MASSEY FERGUSON

MASSEY FERGUSON MF 9313S Operator's manual

Cima

Cima BLITZ Maintenance Instruction

Amazone

Amazone CombiDisc 3000 Original operating manual

HE-VA

HE-VA Disc-Roller XL Contour Operating instructions/spare parts list