6

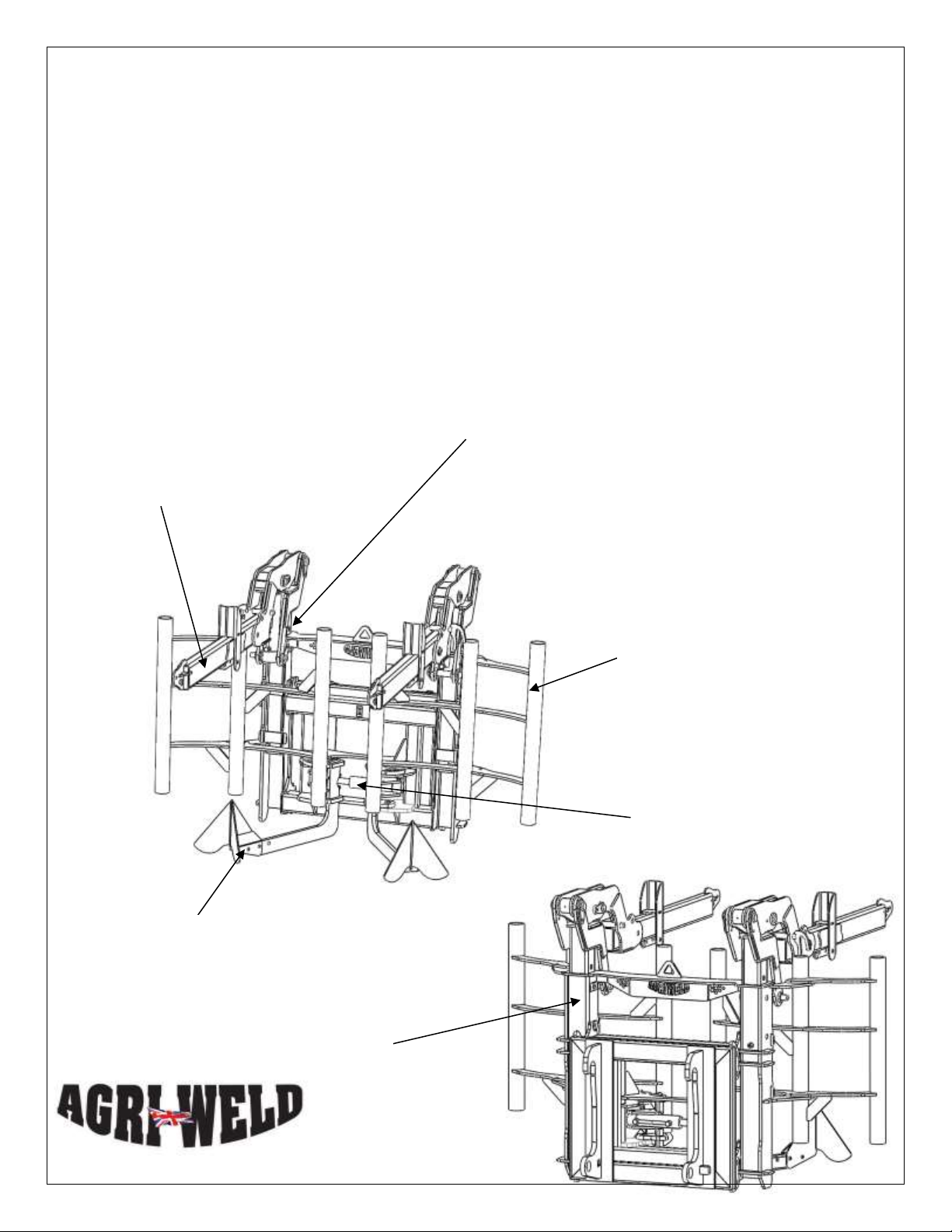

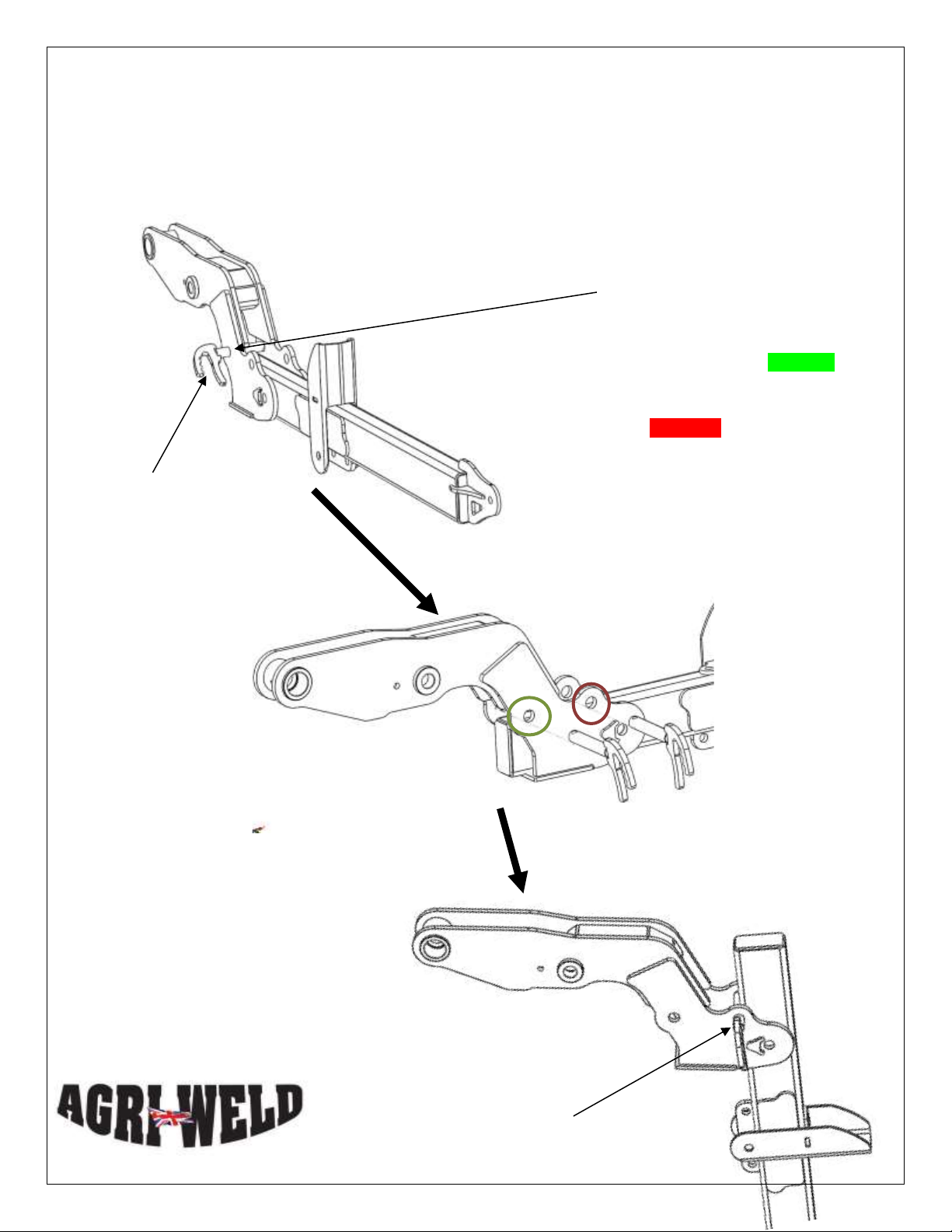

2. Before you attempt to pick up any bags, ensure the ABC bag lift arms are in their

lowest position on the loader hydraulics with the bag cutters in the folded back

position.

3. Carefully locate the bag via the bag loops on to the ABC arms. Ensure the bag

loops are located fully up to the “stop” located on top of the lift arms.

4. Raise the bags off the floor or trailer using the forklift’s boom, tilting the headstock

back slightly to keep the full bag resting against the support cradle. The bag

position is very important to ensure correct ‘cutting’ when ready.

5. Drive to the spreader, drill or other location with the lift arms closed down and NOT

raised at this point. Adjust the height of the implement on the forklift boom to

ensure maximum visibility when performing any manoeuvres. Watch out for

overhead cables and other obstructions such as doorways/overhead cables.

6. When at the desired location, YOU MUST DOUBLE CHECK ABOVE FOR ANY

OVERHEAD CABLES OR OBSTRUCTIONS and move to a safer location if required.

When it is deemed safe to proceed, start the hydraulic oil flow and lift the ABC

arms fully up using the hydraulics on the loader. When raised, the cutters will

automatically swing forward into the cutting position.

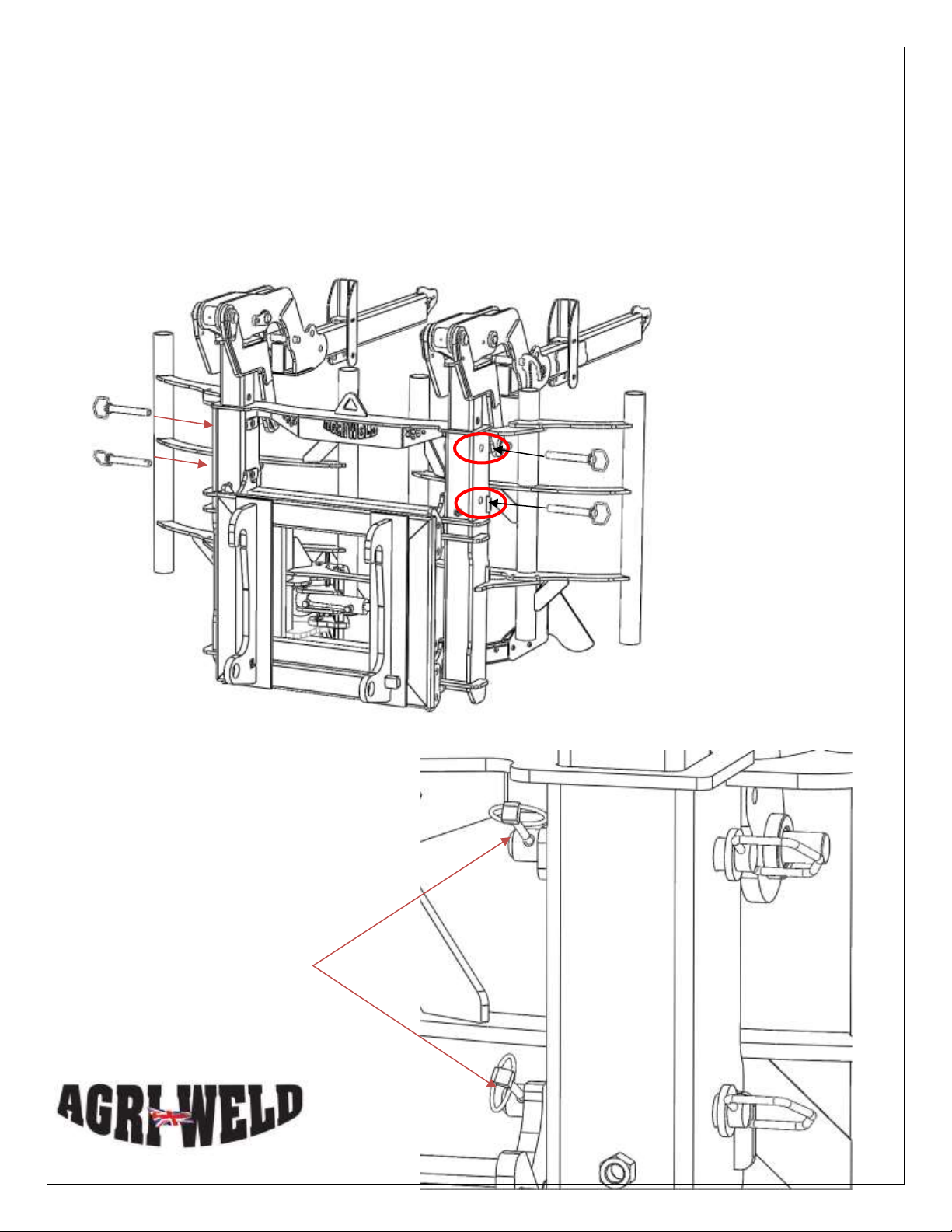

7. Lower the bag lift arms and bags using the loader hydraulics downwards on to the

cutters. There is no need to bury the cutter right up in to the bag. When the bag

is pierced sufficiently for the product to flow quickly, lift the bag/s up off the cutters

using the hydraulics on the loader and let the bag fully empty.

8. If loaded with more than 1 bag, when the first bag is empty, you will need to tilt

fully back again so that the second bag slides down to the “stop” as you did for

the first bag and repeat the operation.

9. When you have emptied the bag/s, keeping the ABC bag lift arms raised, drive to

a safe location to drop off the empty bags. BEWARE OF ANY OVERHEAD CABLES &

OBSTRUCTIONS whilst manoeuvring around.

10. With the cutters still in their working position, tilt the forklift carriage forwards so that

the bags slide off.

11. After you have dropped off the empty bags, tilt the carriage back to return the

ABC to a normal centred position and lower the bag lift arms down to their

lowest position. The cutters will also retract and the cycle of operation is

complete.

12. Repeat the process as required.

13. STORAGE: For storage of the ABC when not in use, the arms must be lowered to

the minimum position achievable BEFORE the cutters retract. The cutters are

need to remain in the cutting position (forwards) to enable to ABC to stand

upright alone.