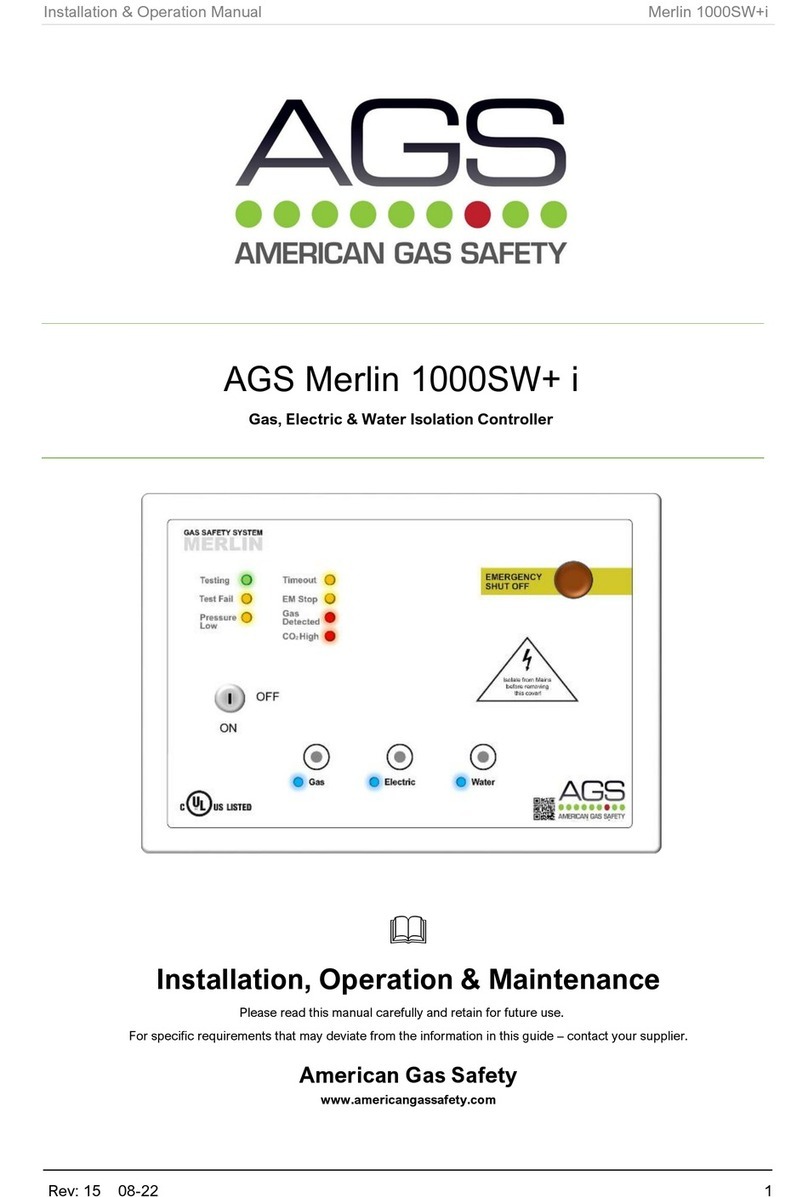

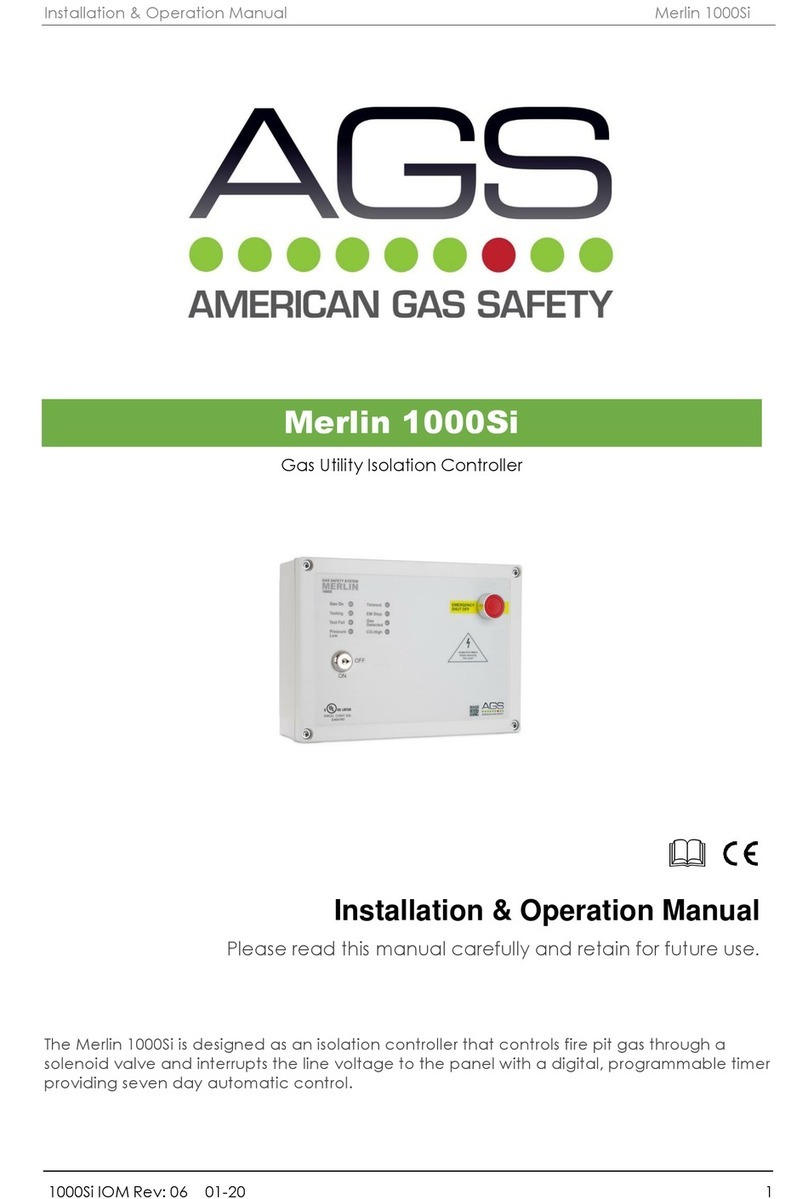

Merlin 1000S Gas Utility Controller User & Installation Manual

Rev: 05 Date: 29-10-18 2

Table of contents

1GENERAL INFORMATION ...................................................................................3

2INSTALLATION & CONNECTION......................................................................3

2.1 Panel Mounting.............................................................................................................3

2.2 1000S Circuit Board Terminals......................................................................................3

2.3 POWER [1]......................................................................................................................4

2.4 GAS VALVE [2]...............................................................................................................4

2.5 BMS OUT [3] ...................................................................................................................4

2.6 PRESSURE SENSOR [4]....................................................................................................4

2.7 EM REMOTE [5] ..............................................................................................................4

2.8 GAS DETECTOR [6] ........................................................................................................4

2.9 FS 1/2/3/4 [7] .................................................................................................................5

2.10 CO2 MONITOR [8].........................................................................................................5

2.11 12VDC [9].......................................................................................................................5

2.12 INTERNAL BUZZER ...........................................................................................................5

2.13 PANEL TIMEOUT FACILITY ..............................................................................................5

3OPERATION ........................................................................................................5

3.1 SYSTEM ON & OFF .........................................................................................................5

3.2 LED STATUS .....................................................................................................................6

POWER ...............................................................................................................................6

GAS ON..............................................................................................................................6

TESTING...............................................................................................................................6

TEST FAIL .............................................................................................................................6

PRESSURE LOW...................................................................................................................6

TIMEOUT..............................................................................................................................6

EM STOP .............................................................................................................................6

GAS DETECTED ..................................................................................................................7

CO2 HIGH ..........................................................................................................................7

3.3 EMERGENCY SHUT OFF .................................................................................................7

3.4 BMS INTERGRATION.......................................................................................................7

3.5 FIRE ALARM INTERGRATION..........................................................................................7

3.6 FAN SWITCH INTERGRATION.........................................................................................8

3.7 GAS FILL & PROVE TIME ................................................................................................8

3.8 AUTO RESET ....................................................................................................................8

1000S WIRING ............................................................................................................................9