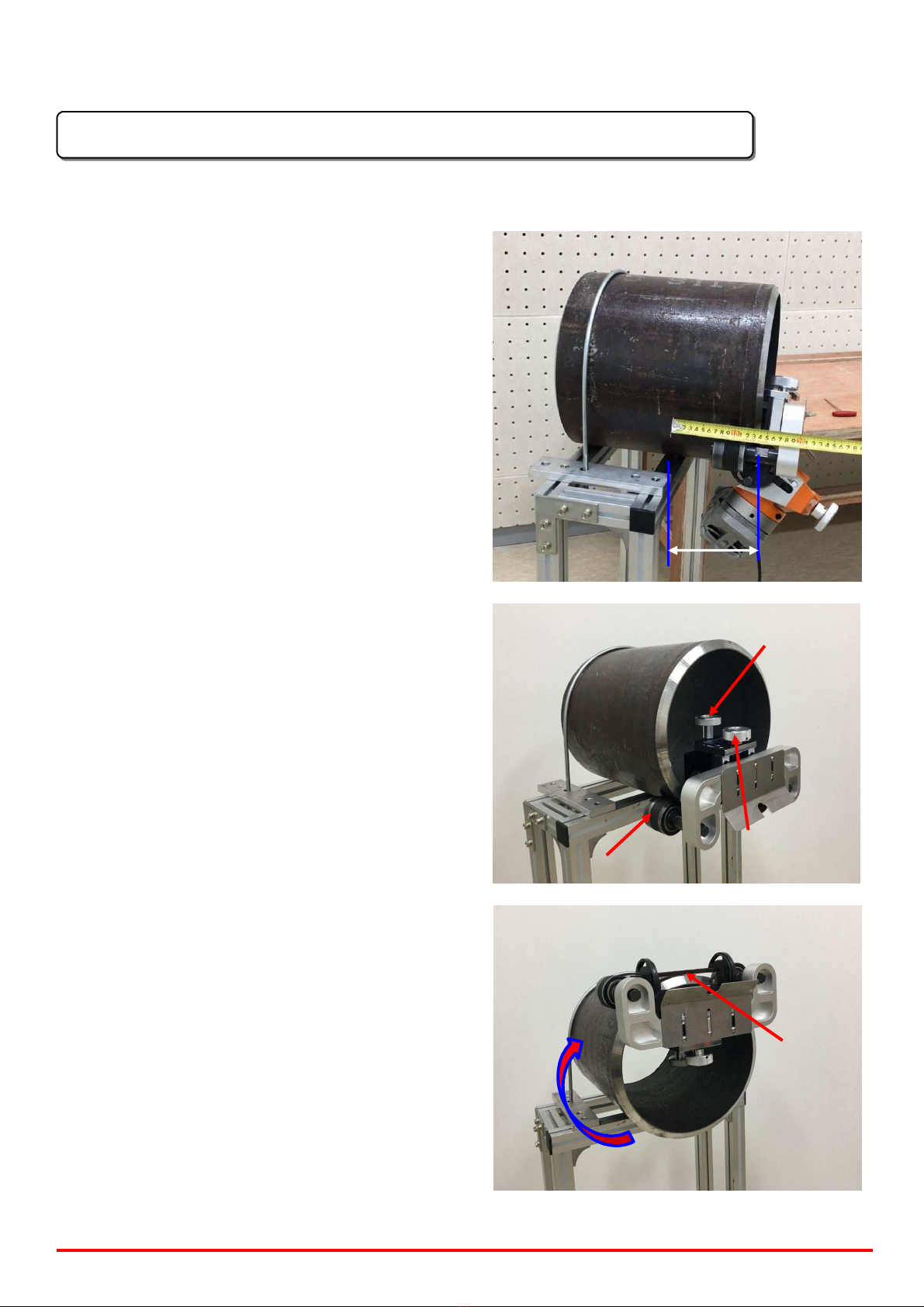

5. Turn the machine installed from the bottom

of the pipe clockwise so that it could be

positioned on the top of the pipe. (This

machine should be turned in clockwise

direction only. Never turn it anticlockwise.)

6. Turn the Chamfering Value Adjustment

Handle (Chamfer-Mill List No. 16) of the

Chamfer-Mill and set the beveling value to

be below zero (0) level. After that, install the

machine between the End Caps (List No. 7)

on both sides and match the angle. Tighten

4 units of M8x20 hexagonal bolts (Chamfer-

Mill List No. 27). (At this time, if the

beveling value is not set at under zero (0)

level, it may cause damages on the machine

and installation could be difficult.)

7. Insert the two Operational Handles (List No.

19) on both sides to the Outer Roller Shaft.

(List No. 16)

8. When inserting the left-hand side

Operational Handle, if it is difficult to insert

the Handle because the position of the

motor is not appropriate, loosen the Locking

Bolt (Chamfer-Mill List No. 13), adjust the

position of the Handle and then tighten the

Locking Bolt again.

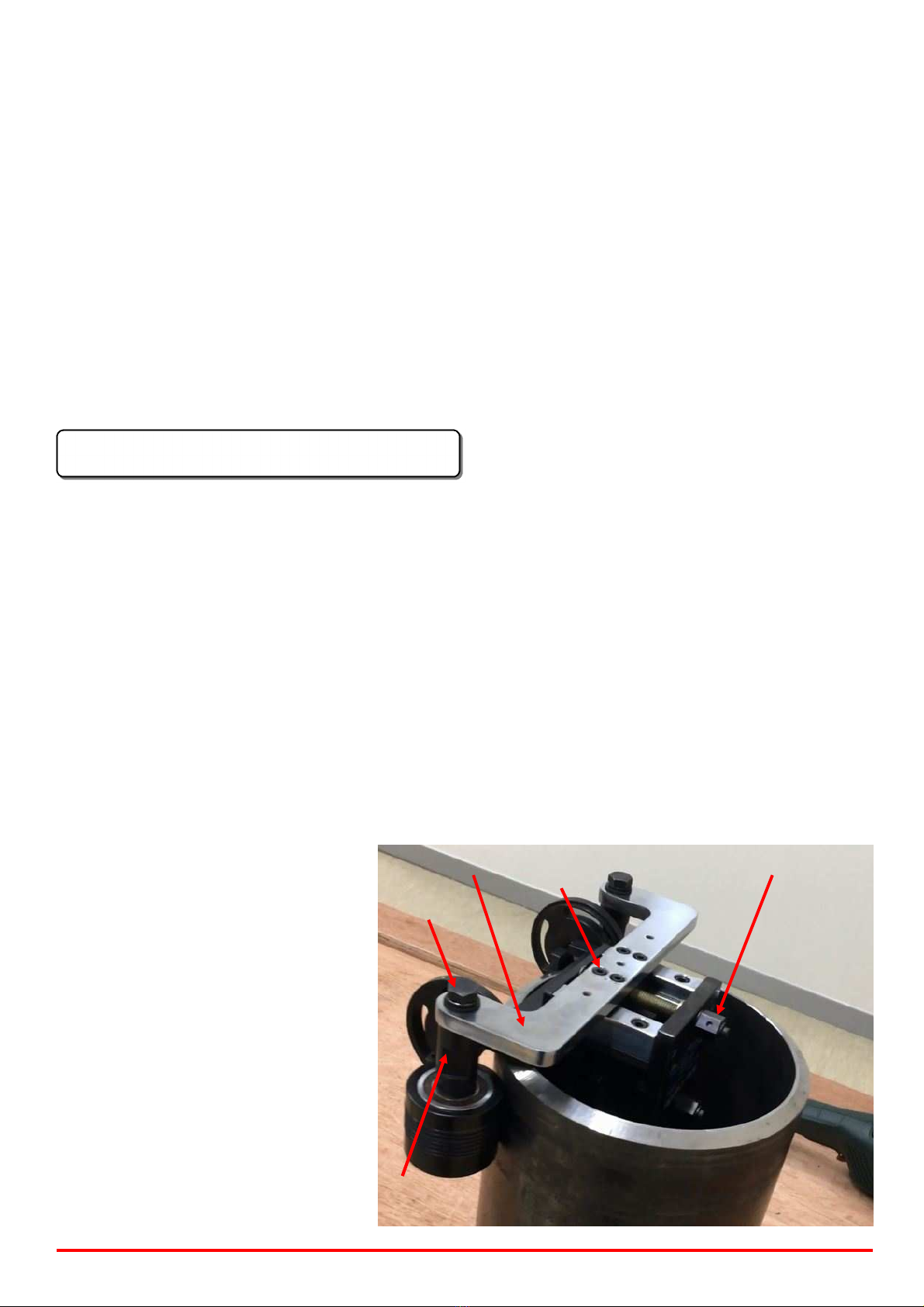

End

cap

No.13 Locking

bolt

Operational Handles

9. After wearing the protective kit, turn on the switch of the motor first and then adjust the

intended beveling value by turning the Beveling Value Adjustment Handle (Chamfer-Mill

List No. 16) (Actual beveling work is started from this point on at a standstill state). Start

the beveling work by turning the Operational Handles clockwise with your hands.

10. The speed of the rotation should be different according to the beveling quantity, materials

and state of the insert tips. Therefore, the workers should adjust the speed of the rotation

appropriately.

11. After the beveling work is finished, turn off the switch of the motor and set the beveling

value at below zero (0) level for safety and beveling work next time.

MP0020-26 User’s Manual - 6 - AHA Industrial Co / www.ahaind.com