SECTION 1

IiiITRODUCTION

PURPOSE OF EQUEIMENT

Aichi Work Platforms are designed to transport and raise

personneland tools to overhead work areas.

USE OF EQUIPMENT

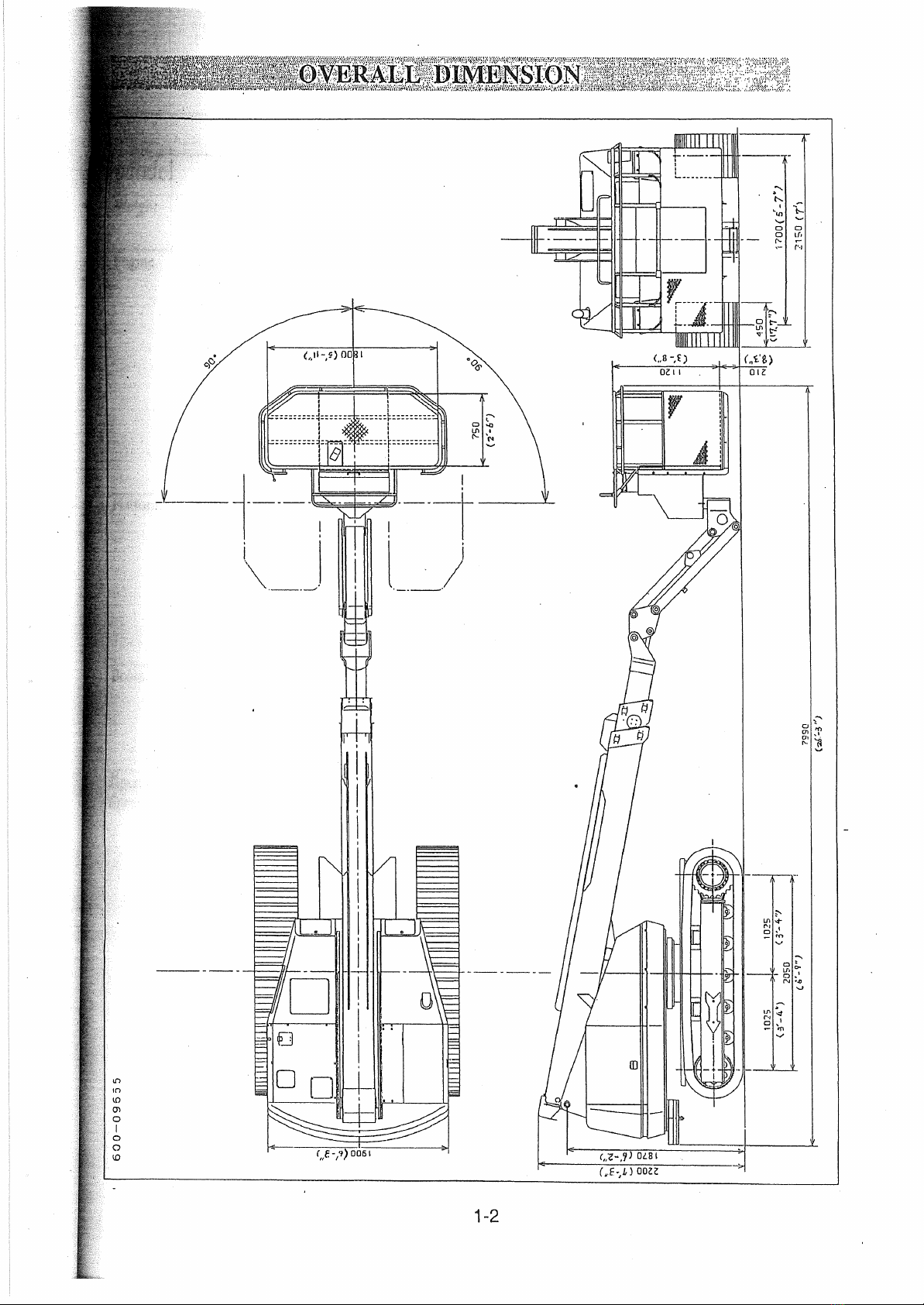

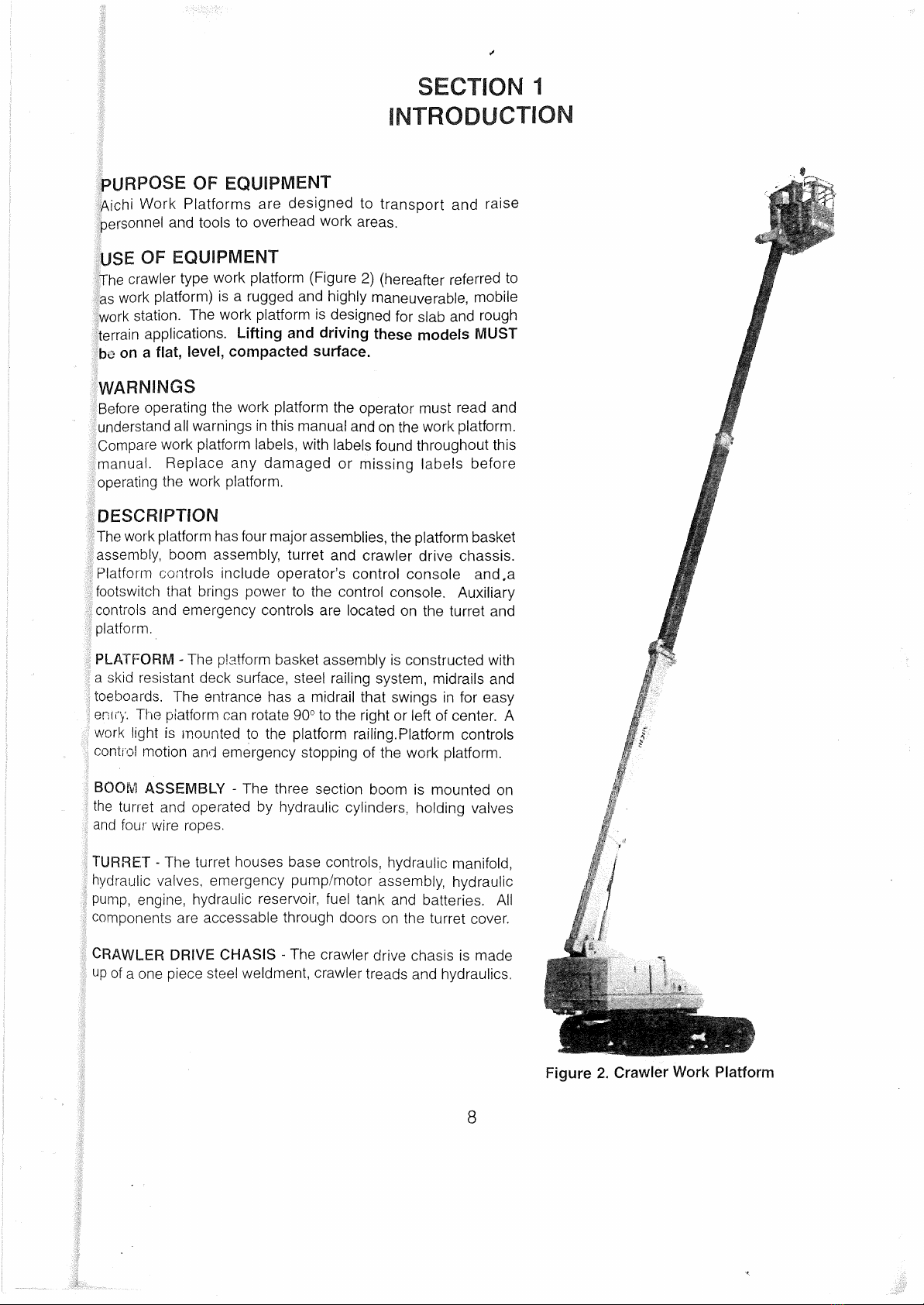

The crawler type work platform (Figure 2) (hereafter referred to

as work platform) is a rugged and highly maneuverable, mobile

work station. The work platform is designed for slab and rough

terrain applications. Lifting and driving these models MUST

1:),: on a flat, level, compacted surface.

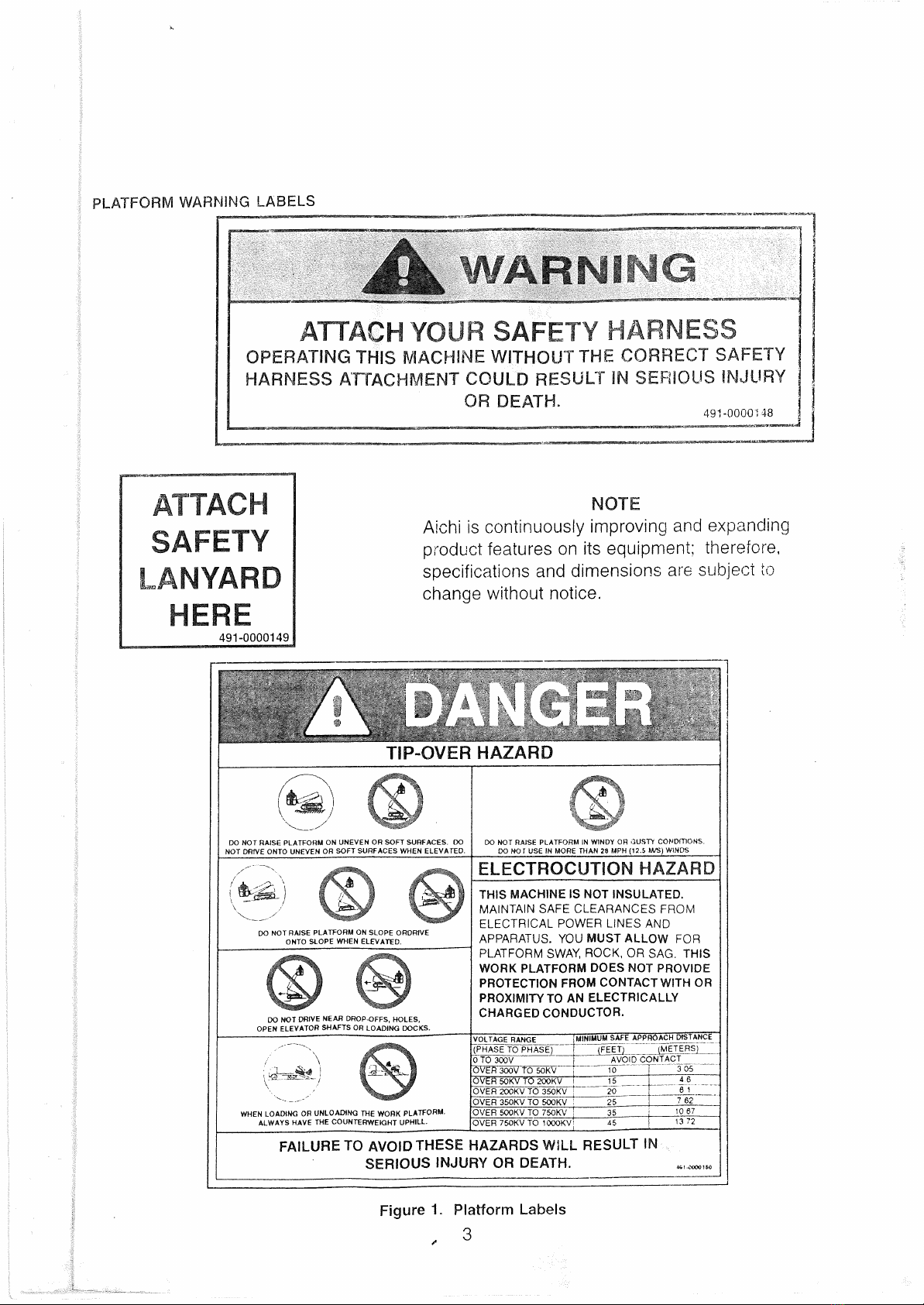

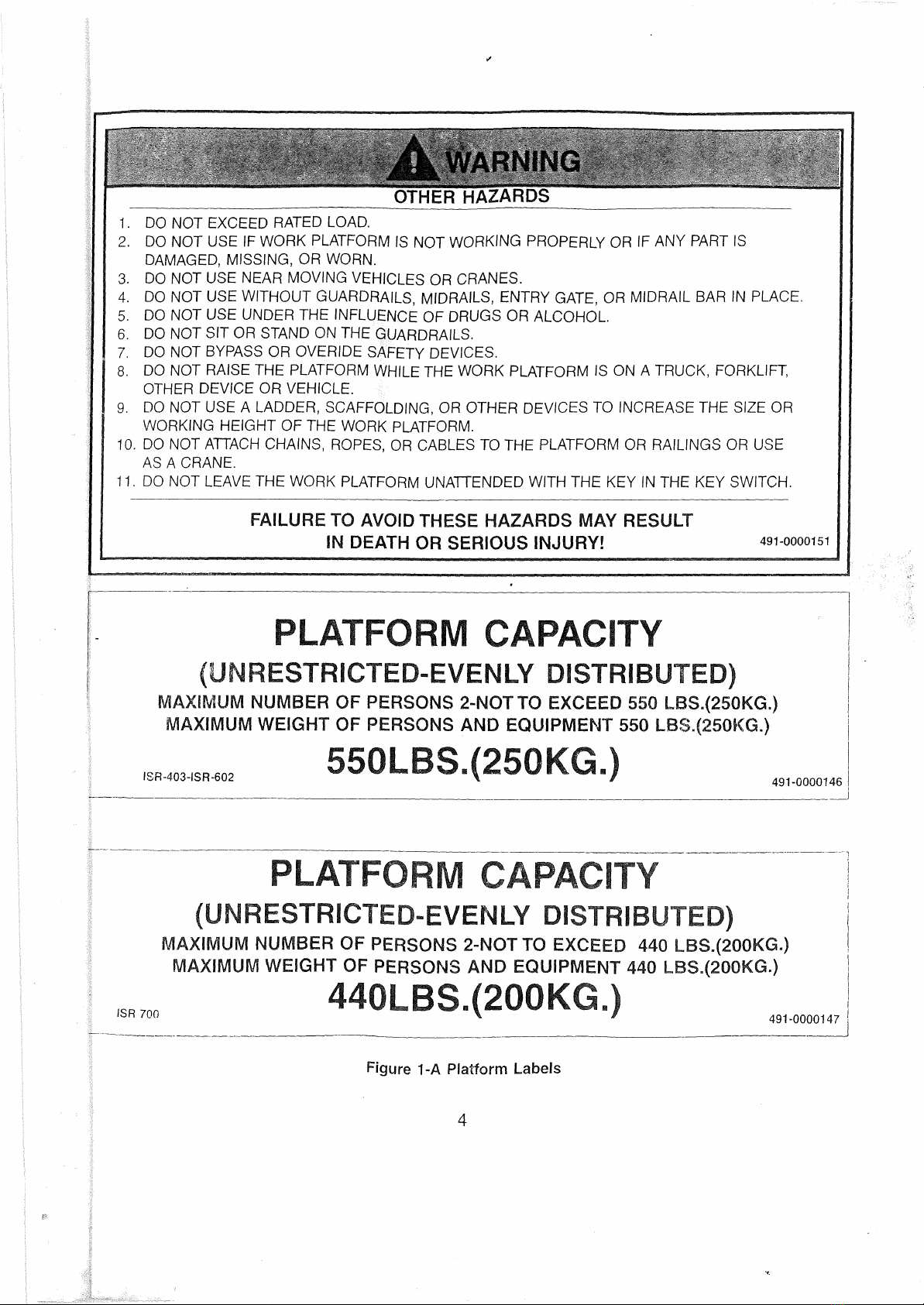

WARNINGS

Before operating the work platform the operator must read and

understand all warnings in this manual and on the work platform.

Compare work platform labels, with labels found throughout this

manual. Replace any damaged or missing labels before

operating the work platform.

DESCRIPTION

The work platform has four major assemblies, the platform basket

assembly, boom assembly, turret and crawler drive chassis.

Platform controls include operator's control console and ,a

footswitch that brings power to the control console. Auxiliary

controls and emergency controls are located on the turret and

platform.

PLATFORM - The platform basket assembly is constructed with

a skid resistant deck surface, steel railing system, midrails and

toeboards. The entrance has a midrail that swings in for easy

entry. The piatform can rotate 90° to the right or left of center. A

work light is mounted to the platform railing.Platform controls

contiol motion and emergency stopping of the work platform.

BOOM ASSEMBLY - The three section boom is mounted on

the turret and operated by hydraulic cylinders, holding valves

and four wire ropes.

TURRET - The turret houses base controls, hydraulic manifold,

hydraulic valves, emergency pump/motor assembly, hydraulic

pump, engine, hydraulic reservoir, fuel tank and batteries. All

components are accessable through doors on the turret cover.

CRAWLER DRIVE CHASIS - The crawler drive chasis is made

up of a one piece steel weldment, crawler treads and hydraulics.

8

Figure 2. Crawler Work Platform