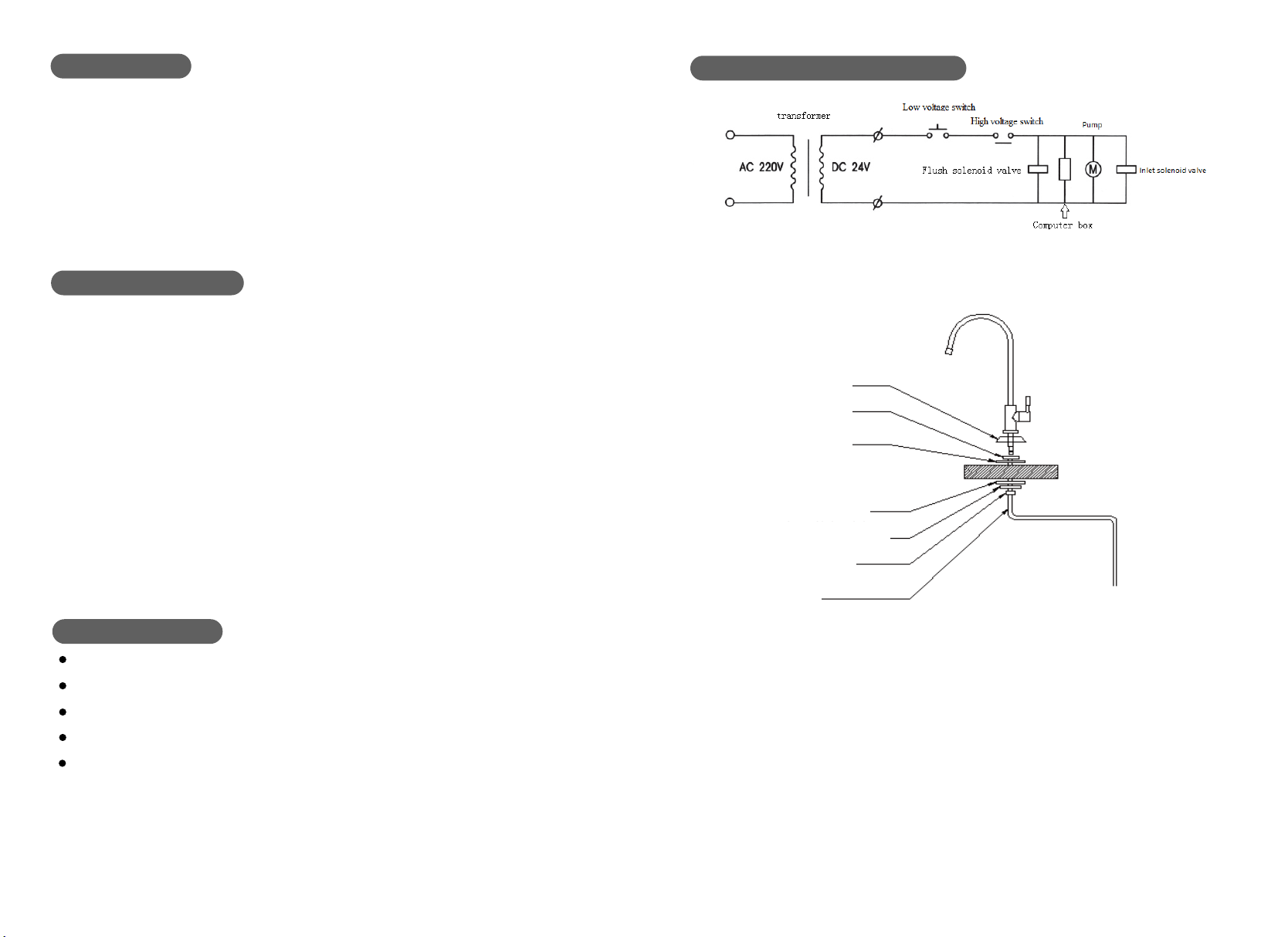

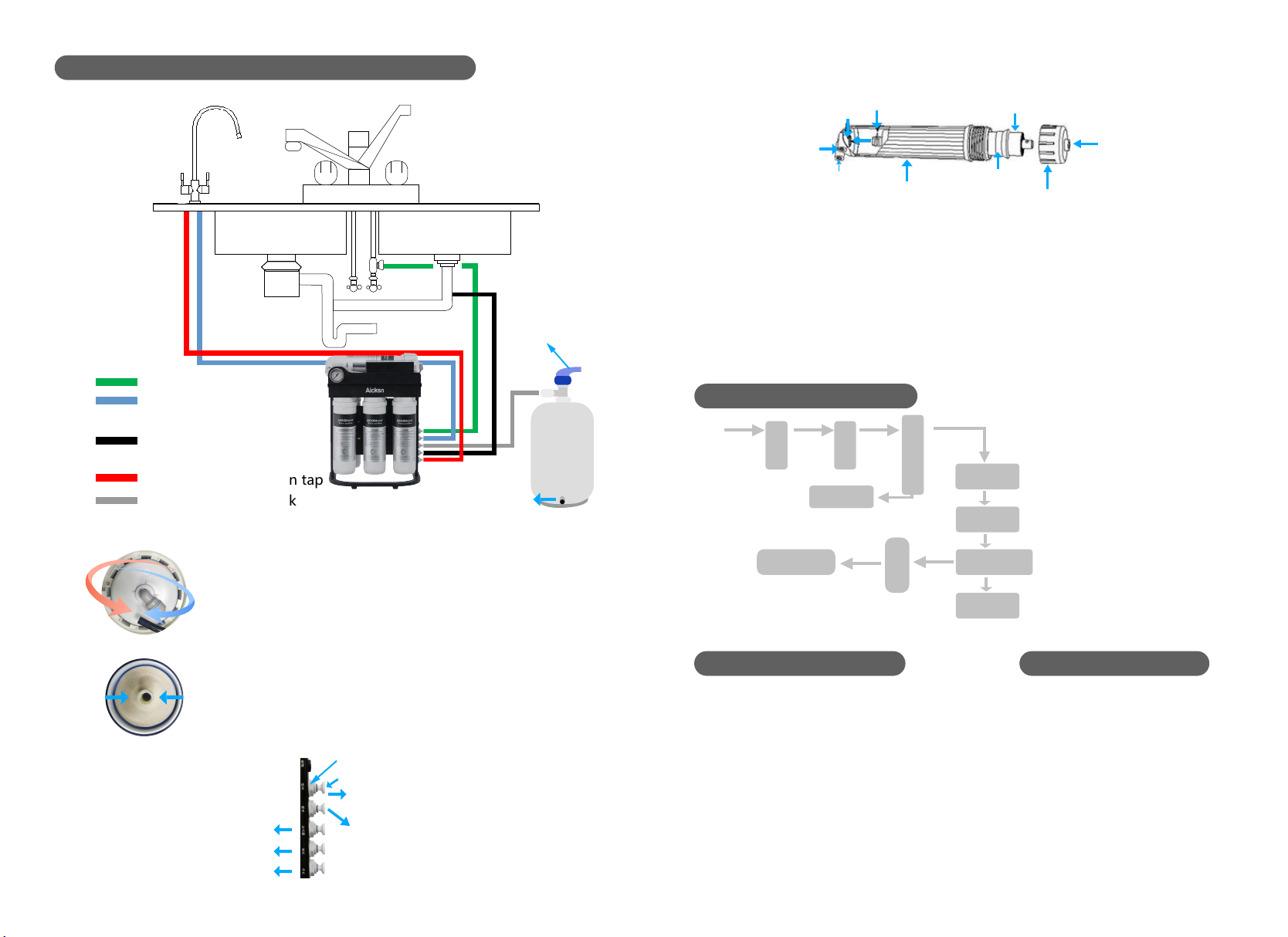

Installation instructions

Set up machine

1.Close the main water inlet valve of the tap water and open the parts package of

this pure water machine. Wrap the external thread of the 1/4" water inlet ball valve

on the raw material tape and connect it to the side hole of the water inlet tee, then

wrap the external thread of the water inlet tee on the raw material tape and

connect to the reserved 1/2" The tap water pipe joint.

2.Because this machine uses membrane separation technology, waste water will

be discharged during the water production process. A small hole (6mm) is

reserved in the sewer to facilitate the insertion of the drainage pipe. After installa-

tion, it needs to be sealed with silicone to prevent water leakage

3.Tap a small 12mm hole in a suitable place on the water bucket, and then install

the goose neck faucet (matched with the pressure storage bucket). The goose

neck faucet can also be fixed on the wall with a plastic hanger.

4.Check the host is installed on the table or under the sink to determine how many

holes to drill for the water pipe (the following is for reference only, and the actual

installation should depend on the actual situation).

(1)The matching model of RO host and pressure storage bucket: If the host and

pressure storage bucket are installed under the cabinet, there is no need to drill

another; if the host is installed on the table and the pressure bucket is installed

under the cabinet, drill 4 6mm holes are connected to the water inlet pipe, the

pressure barrel water pipe, the pure water pipe and the drain pipe respectively.

(2)RO main pipe and pipeline machine supporting models. Both the main machine

and pipeline machine are installed on the platform. At this time,3 6mm holes

should be drilled to pass through the inlet pipe, drain pipe and overflow pipe (line

machine).

(3)under the sink. At this time, 4 6mm holes should be drilled to connect the water

inlet, the pressure bucket water pipe, the drain pipe, and the drain pipe.

(4)After the pipe is connected to the drill hole, silica gel is required to prevent

water seepage.

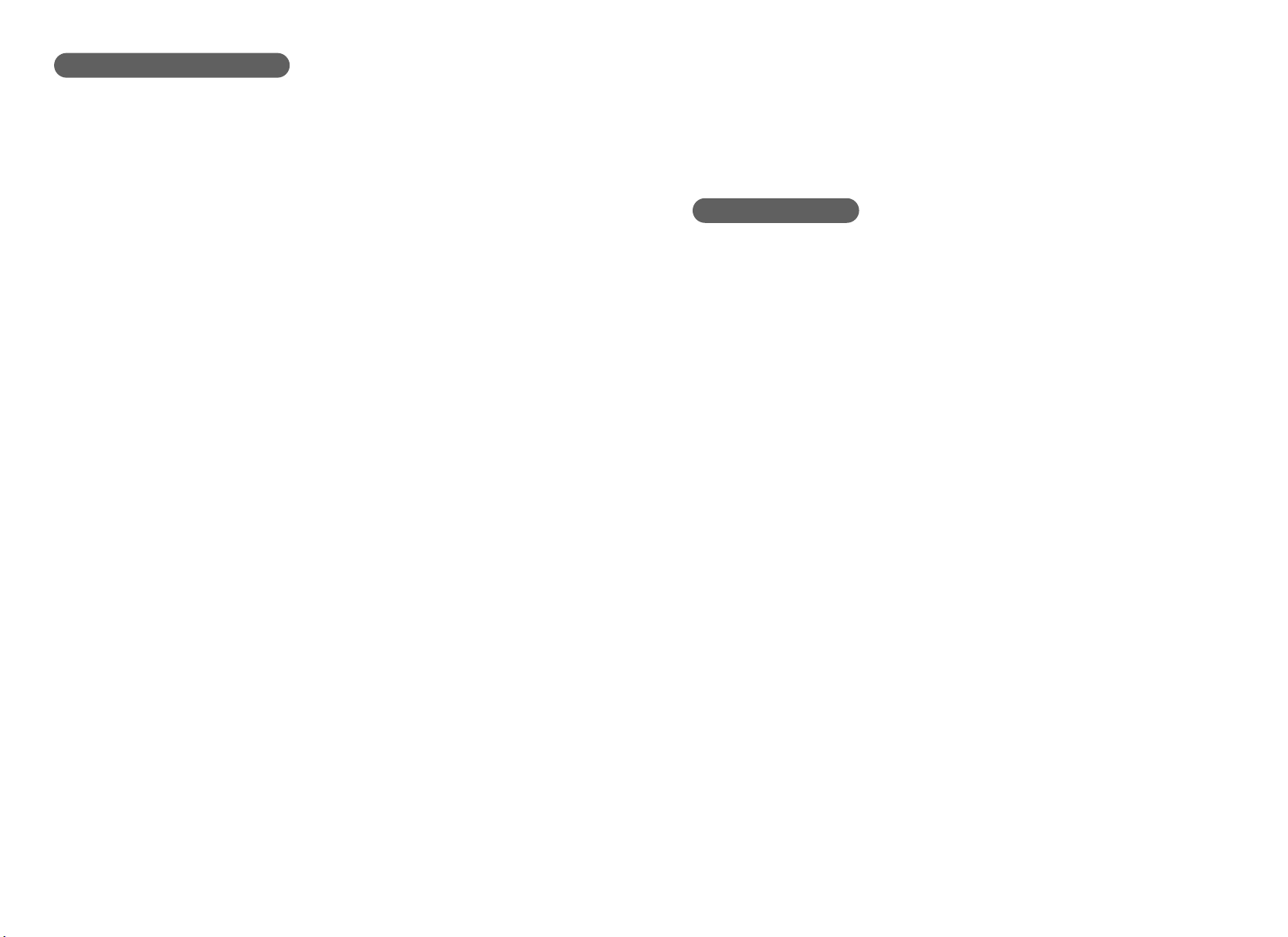

(5)Connect the pressure tank to the pressure tank ball valve, and connect the 1/4"

water pipe joint.

(6)Put a pipe plug on the 1/4" PE water pipe nozzle and connect the water pipe.

Set up machine

After confirming that the waterway connection is correct, you must also confirm:

1.Whether the power socket has electricity

2.Is there a water supply from Then enter the debugging of this machine, the

method is as follows:

1.Open the main tap water inlet valve, and open the water inlet ball valve (the valve

handle is in a line with the valve body), close the pressure bucket ball valve, and

open the goose neck faucet. 2. Insert the power trace head into the power socket.

At this time, the high-pressure pump starts. After a while, it starts to drain from the

waste water outlet, and enters the state of fresh water after 1.5 minutes. Also, after

waiting for a period of time, there is water flowing from the goose neck faucet.

After 10-20 minutes, open the pressure barrel ball and pour water into the

pressure barrel. When using this product for the first time, the pure water that

enters the pressure storage tank must be discharged twice before it can be used

after it is full.

Note:

(1)When using this water purifier for the first time, there may be a small amount of

black water when you turn on the goose neck faucet to drain the water. Please

continue to rinse.

(2)The TDS test data may be slightly higher when the water purifier is used for the

first time, please continue to rinse.

87