2

IMPORTANT SAFEGUARDS

1. Read Instructions - All the safety and operating

instructions should be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions

should be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the

operating instructions should be adhered to.

4. Follow Instructions - All operating and use instructions

should be followed.

5. Cleaning - Unplug the unit from the outlet before

cleaning. Do not use liquid cleaners or aerosol cleaners.

Use a damp cloth for cleaning.

6. Attachments - Do not use attachments not

recommended by the product manufacturer as they may

cause hazards.

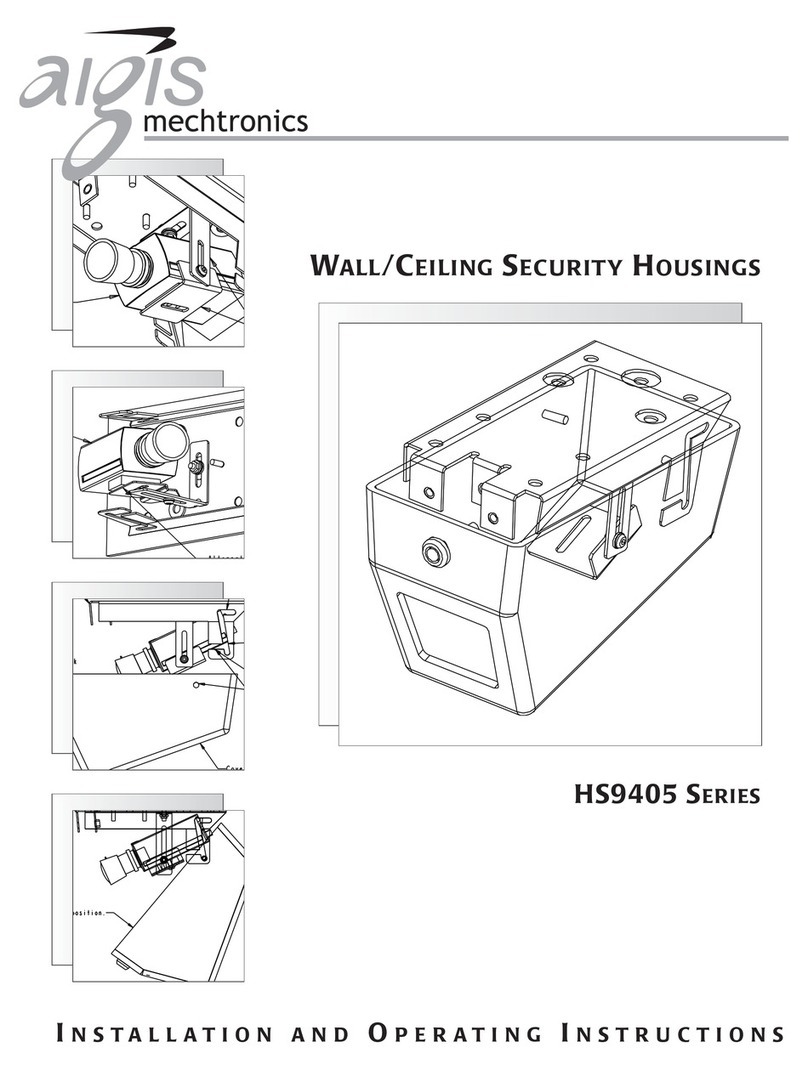

7. Accessories - Do not place this unit on an unstable stand,

tripod, bracket, or mount. The unit may fall, causing

serious injury to a person and serious damage to the unit.

Use only with a stand, tripod, bracket, or mount

recommended by the manufacturer, or sold with the

product. Any mounting of the unit should follow the

manufacturer's instructions, and should use a mounting

accessory recommended by the manufacturer.

An appliance and cart combination should be moved

with care. Quick stops, excessive force, and uneven

surfaces may cause the appliance and cart combination

to overturn.

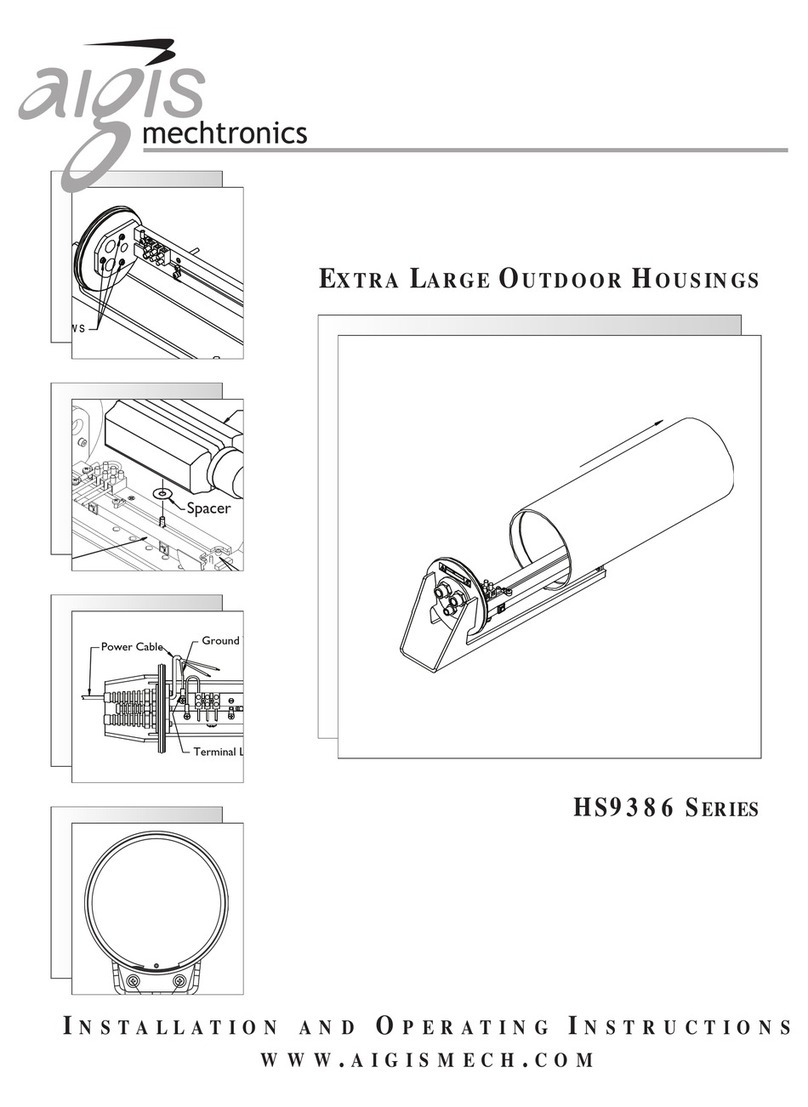

8. Ventilation - Openings in the enclosure, if any, are

provided for ventilation and to ensure reliable operation

of the unit and to protect it from overheating. These

openings must not be blocked or covered. This unit

should not be placed in a built-in installation unless proper

ventilation is provided or the manufacturer's instructions

have been adhered to.

9. Power Sources - This unit should be operated only from

the type of power source indicated on the marking label.

If you are not sure of the type of power supply you plan

to use, consult your appliance dealer or local power

company. For units intended to operate from battery

power, or other sources, refer to the operating

instructions.

10. Grounding or Polarization - This unit may be equipped

with a polarized alternating-current line plug (a plug

having one blade wider than the other). This plug will fit

into the power outlet only one way. This is a safety

feature. If you are unable to insert the plug fully into the

outlet, try reversing the plug. If the plug should still fail to

fit, contact your electrician to replace your obsolete

outlet. Do not defeat the safety purpose of the polarized

plug.

Alternately, this unit may be equipped with a 3-wire

grounding-type plug, a plug having a third (grounding) pin.

This plug will only fit into a grounding-type power outlet.

This is a safety feature. If you are unable to insert the plug

into the outlet, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the

grounding-type plug.

11. Power-Cord Protection - Power-supply cords should be

routed so that they are not likely to be walked on or

pinched by items placed upon or against them, paying

particular attention to cords and plugs, convenience

receptacles, and the point where they exit from the

appliance.

12. Power Lines - An outdoor system should not be located

inthe vicinity of overhead power lines or other electric

light or power circuits, or where it can fall into such

power lines or circuits. When installing an outdoor

system, extreme care should be taken to keep from

touching such power lines or circuits as contact with

them might be fatal. U.S.A. models only - refer to the

National Electrical Code Article 820 regarding installation

of CATV systems.

13. Overloading - Do not overload outlets and extension

cords as this can result in a risk of fire or electric shock.

14. Object and Liquid Entry - Never push objects of any kind

into this unit through openings as they may touch

dangerous voltage points or short-out parts that could

result in a fire or electric shock. Never spill liquid of any

kind on the unit.

15. Servicing - Do not attempt to service this unit yourself as

opening or removing covers may expose you to

dangerous voltage or other hazards. Refer all servicing to

qualified service personnel.

16. Damage Requiring Service - Unplug the unit from the

outlet and refer servicing to qualified service personnel

under the following conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into

the unit.

c. If the unit has been exposed to rain or water.

d. If the unit does not operate normally by following the

operating instructions. Adjust only those controls

that are covered by the operating instructions, as an

improper adjustment of other controls may result in

damage and will often require extensive work by a

qualified technician to restore the unit to its normal

operation.

e. If the unit has been dropped or the cabinet has been

damaged.

f. When the unit exhibits a distinct change in

performance--this indicates a need for service.

17. Replacement Parts - When replacement parts are

required, be sure the service technician has used

replacement parts specified by the manufacturer or have

the same characteristics as the original part.

Unauthorized substitutions may result in fire, electric

shock or other hazards.

18. Safety Check - Upon completion of any service or repairs

to this unit, ask the service technician to perform safety

checks to determine that the unit is in proper operating

condition.

19. Coax Grounding - If an outside cable system is connected

to the unit, be sure the cable system is grounded. U.S.A.

models only--Section 810 of the National Electrical Code,

ANSI/NFPA No.70-1981, provides information with

respect to proper grounding of the mount and supporting

structure, grounding of the coax to a discharge unit, size

of grounding conductors, location of discharge unit,

connection to grounding electrodes, and requirements

for the grounding electrode.

20. Lightning - For added protection of this unit during a

lightning storm, or when it is left unattended and unused

for long periods of time, unplug it from the wall outlet

and disconnect the cable system. This will prevent

damage to the unit due to lightning and power-line

surges.