TOGGLE-AIRE MODEL 2530 & 3530 SERIES PRESSES

INSTALLATION, OPERATION, AND MAINTENANCE

-8-

NOTE: In some cases, with the ram is in

the down position and the air is

on, it may not be possible to

adjust the ram up. To adjust up,

shut off air supply before

adjusting.

2. Final adjustments should always

be made by screwing the ram down

to the desired point.

3. Lock the ram adjusting screw in

place with the lock nut.

NOTE: Once tools have been set, always

replace all press guards before

proceeding.

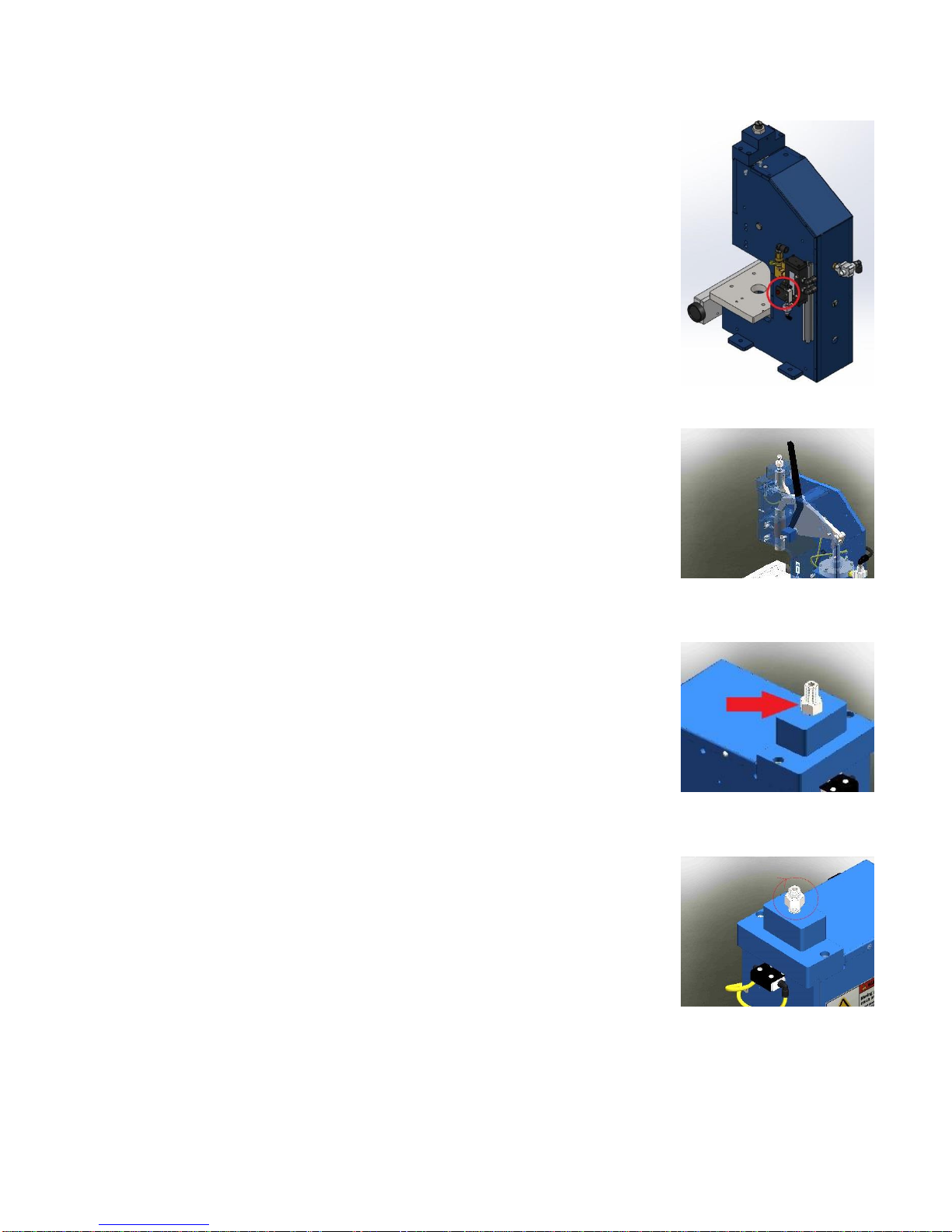

3. Important principles of set up and

operation.

(See photos 2.10, 2.11, 2.12)

When setting up and operating it is

important to keep in mind that the press is

a pneumatically powered TOGGLE press.

The key element in the machine is the

TOGGLE or KNUCKLE JOINT. A toggle is a

simple machine in and of itself. It is a great

multiplier of force. The press takes the

output of the cylinder, couples it to a lever,

which drives the toggle. As the toggle

straightens it drives the press ram

downward, creating a powerful squeeze at

the end of the stroke. The moment that the

toggle hits end of stroke, the upper toggle

link encounters a stop block. The press is

then reversed when the impulse pin is

driven out through the front plate, which in

turn actuates the return valve (A-2530).

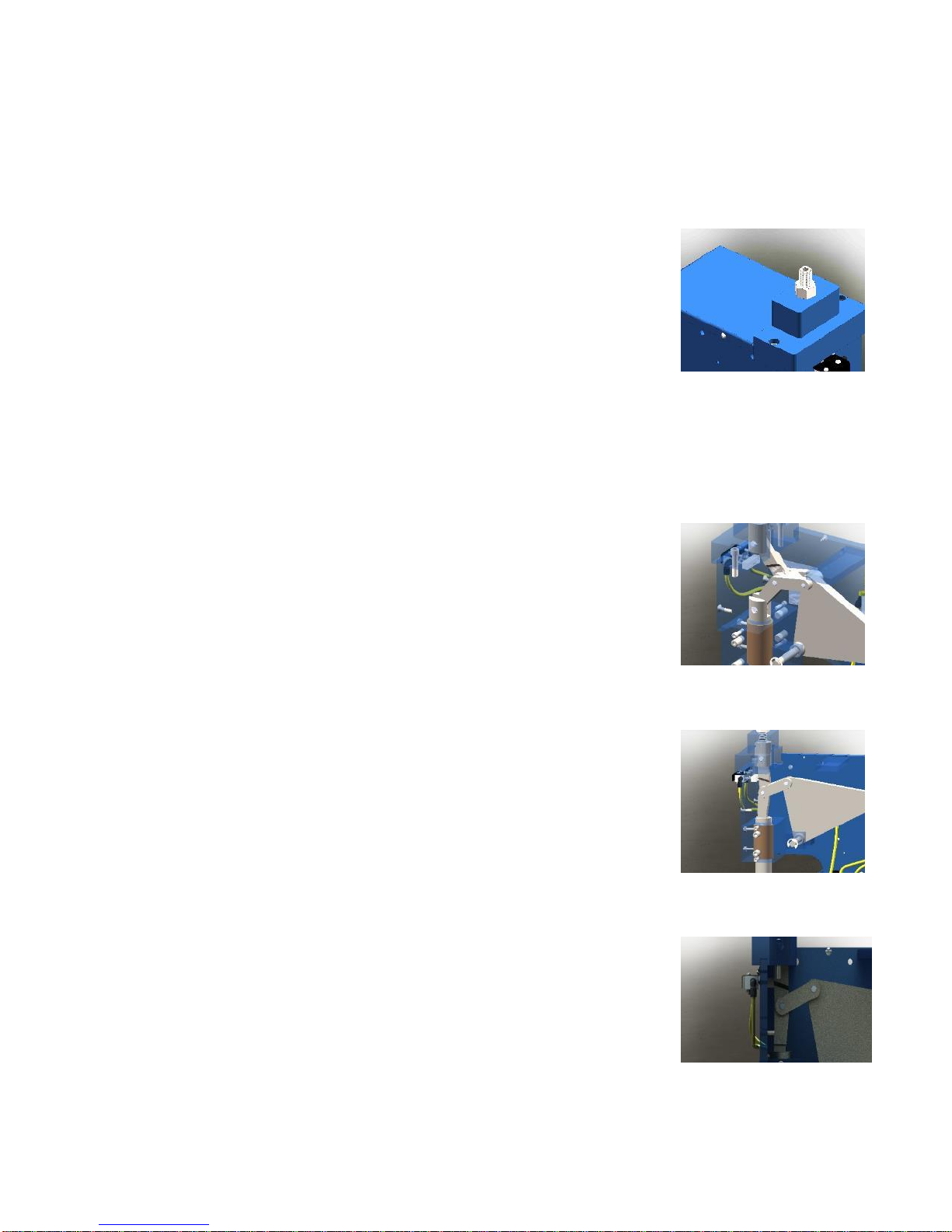

When controlled in this manner the press is

very accurate, with a repeatability of plus

or minus .001". It is crucial that you

recognize this relationship. Your tooling

should be built with a shut height that falls

within the shut height range of the press.

In standard 2530 presses this is approx.

5.375" maximum to 4.625" minimum and

in standard 3530 presses this is approx.

6.375” maximum to 5.625” minimum.

Photo 2.9

Photo 2.10

Photo 2.11

Photo 2.12