GDMUiF13-1G Version 0030 2

1 Table of Contents

1Table of Contents................................................................... 2

2Amendment Record Sheet..................................................... 4

2.1 Table of Amendments.......................................................................... 4

2.2 Amendments........................................................................................ 4

3General ................................................................................... 5

3.1 About this Document............................................................................ 5

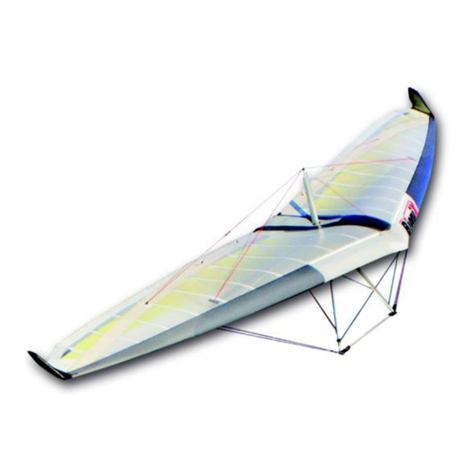

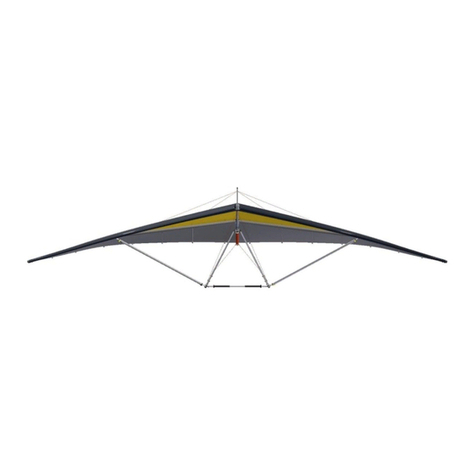

3.2 3-Perspective Diagram......................................................................... 6

Figure 3-1: iFun 13 in 3 Perspectives.......................................................................................6

4Technical Specifications –Performance.............................. 7

4.1 Technical Specifications....................................................................... 7

4.2 Maximum Added Load / Trikes Adjustment ......................................... 7

4.3 Performance (*).................................................................................... 8

5Instructions for Use ............................................................... 9

5.1 Rigging................................................................................................. 9

5.1.1 Assembly................................................................................................................9

Figure 5-1 : EasyFit Tighteners..................................................................................................9

Figure 5-2 : Path of Tensioning Cables .....................................................................................9

5.1.2 Disassembly.........................................................................................................10

5.2 Preflight Check................................................................................... 11

5.3 Flight Specifications........................................................................... 12

5.3.1 Operational Limitations.........................................................................................12

5.3.2 Controls ................................................................................................................12

5.3.3 Flight Techniques .................................................................................................12

6Maintenance ......................................................................... 20

6.1 Assembling from Shipping Crate........................................................ 20

6.1.1 Reassembly Guide .............................................................................................20