AIR CREATION Aérodrome de Lanas - 07200 AUBENAS - France

Tél.: 33 (0) 4 75 93 66 66 - Fax: 33 (0) 4 75 35 04 03 - Internet: www.aircreation.fr

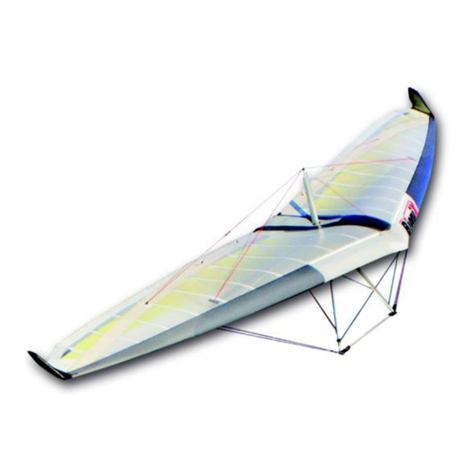

b) Preflight-check

The wing preflight check will be easier if made before lifting the wing above the trike. The

following is a brief summary of the minimum pre-flight inspection, which assumes that the

scheduled maintenance checks outlined in the maintenance manual has been performed. If you are

unsure, it does no harm to increase the number of items in your inspection in accordance with the

recommendations of the maintenance manual.

1. Position the wing horizontally once coupled with the trike.

2. Visually check the symmetry of the two leading edges.

3. Check noses plates assembly, bolts, nuts, thimbles and Nicopress of the front lower longitudinal cables,

swan catch correctly positioned, pushpin and wires attached.

4. Slide your hand along the leading edges to check for possible damage. Make sure the profile of the

upper surface of the leading edge is free of deposits of raindrops, insects, snow or ice. Clean/dry if

necessary.

5. Check the crossbar/leading edges connection, bolts, nuts, by unzipping the lower surface access. Check

for correct fastening of lower flying wires and upper wires, also their condition, swages and thimbles.

Check that the sail is not snagged on a metallic part. Close the lower surface access.

6. Check the fastening of the sail at the wing tips and the position lock of the two pivoting sleeves by

means of the Parker screws.

7. Check the fitting of the upper surface battens and the closure of their tighteners on the trailing edge.

8. Check fitting and condition of the reflex bridles and their attachment to the sail.

9. Check that no upper cables are wrapped around the kingpost and that the luff lines are well positioned in

the grooves of the pulleys at the top of the kingpost.

10. Check the thimbles and swages of the rear lower cables at the keel end.

11. Check the correct routing of the tensioning cables on each side of the kingpost without crossing.

Check the tensioning system at the end of the keel, the nuts and bolts, the correct position and security

of the push pin.

12. Slide your hand along all of the the lower cables to detect signs of wear.

13. Check that the lower cables are attached to the A frame, check the nuts and bolts, check the condition of

the cables and their Nicopress clamps, and the push-pin of the control bar. All the cables should be loose

enough to pivot in the direction of the tension. Close the leather cover webbings.

14. Check the assembly of the central junction of the cross tubes, the nuts and bolts, the cover webbing, the

restraining straps of the keel, and the securing of the tensioning cables.

15. Check the hang bracket, the locking rings and positioning screws for condition (possible twist, cracks)

and free pivoting movement.

16. Check that the safety cable of the hook is correctly positioned and fastened. It must pass under the

tensioning cables. This system secures the fastening of the trike as well as tensioning of the crossbars.

17. Check that all zippers are closed, as well as the fabric closures on the wingtips by means of the velcros.

18. Once the wing is assembled on the trike, check the position of the hang point attachment bolt, its

butterfly nut and security ring.